|

Author

|

Message

|

|

MoonShadow

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 4.6K,

Visits: 38.7K

|

Does the timing jump up when you rev the engine? If not then the vacuum advance is probably all in. Easy to check.

Y's guys rule!

Looking for McCullouch VS57 brackets and parts. Also looking for 28 Chrysler series 72 parts. And early Hemi parts.

MoonShadow, 292 w/McCulloch, 28 Chrysler Roadster, 354 Hemi)

Manchester, New Hampshire

|

|

|

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 513,

Visits: 153.3K

|

It may not idle well but at least for test purposes I'd want the idle RPM lower than say, 650 - otherwise the centrifugal advance probably starts to tip in. Light springs?

Even so that seems like an awful lot of timing advance! If I didn't know better it sounds like vacuum advance connected to a manifold port. Nothing wrong with that but, what you are describing is something different.

|

|

|

|

|

62bigwindow

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 884,

Visits: 14.3K

|

Thought I post a follow up on this. The machine shop had to open it up .001. I also cheated a little and set it on top of wood stove for a bit to warm it up some. Now I have a secondary question. After I got it all back together I checked the timing and it was at 38° at idle. I find this a little odd as the car starts fine and seems to run decent. I knew it was off some but I would think that far advanced it wouldn't even start. I haven't had a chance to look into it yet. Was hoping to get a couple suggestions. The vac advance was unhooked and idle was at 850. Idle is that high due to cam size any lower and it won't idle well.

Durham Missouri

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 3 days ago

Posts: 7.5K,

Visits: 205.9K

|

62bigwindow (12/17/2017)

I had to buy a new damper for my car. For some reason the replacements ID is smaller than the original Ford damper. So I'm going to have to have it honed out . How much press should it have? I was thinking maybe less than .001 Would be sufficient. ....My preference for the interference fit for the damper to the crankshaft is 0.0005"-0.0010”. If honing, then it’s desirable to use a hone that’s specific to honing holes with a key slot in them. This requires a hone with wide shoes and stones.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

62bigwindow

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 884,

Visits: 14.3K

|

Thanks Ted. That is what I was looking for. I dropped off the damper at the machine shop with the old one. Guy said he's seen the same problem often. I figured if he honed it to the same size as the original I couldn't go wrong.

Durham Missouri

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 3 days ago

Posts: 7.5K,

Visits: 205.9K

|

62bigwindow (12/17/2017)

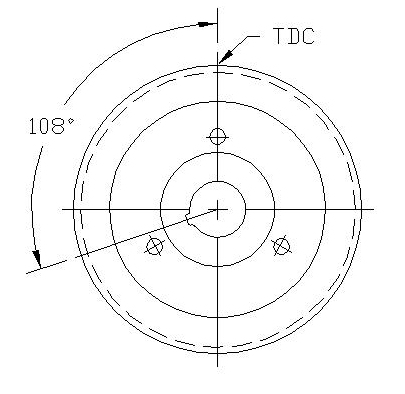

........Also I read somewhere once where the key slot is in relation to the TDC mark but I can't seem to find that info. Can anyone help me out with either. Thanks.See if this picture helps in regards to the TDC placement on the damper.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Last Year

Posts: 6.1K,

Visits: 443.0K

|

If the id of the damper really is too small, send an email to Powerbond about it so that they are aware and can make a change, if they choose. Having it honed a couple thousandths should not be a problem. A caliper is not the best tool for measuring diameter, particularly smaller ones like the damper bore. It will indicate a slightly smaller diameter because of the way the jaws are offset. So the actual measurement may be slightly larger than you see indicated. Within reason, the tighter the fit the better, for keeping everything concentric. If it is at a point where it is difficult to install or remove, at room temperature, with the proper tools, then it is too tight.

Lawrenceville, GA

|

|

|

|

|

Tedster

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 513,

Visits: 153.3K

|

"My thinking is if you have to freeze one and heat another to get it together then something's off. If there is that much interference fit then there is no way it'll come back off without alot of effort."

No, they are made to fit extremely close by design. A puller is the only practical way to remove them. It is kind of a pain. If they just slipped on and off though, they wouldn't be able to perform their function. The crankshaft itself twists as much as 2° at times, the heavy outer steel inertia ring is bonded to the basket by rubber and absorbs torsional vibration by leading and lagging somewhat. Remember that crank is turning 3000, 4000, 5000 RPM at times. Pretty cool, huh?

What would happen otherwise is a crankshaft at a certain RPM would reach a point of resonance. This is a Bad Thing, cracks might develop or the crankshaft can even break. I'd talk to the folks at Powerbond, maybe it's defective. Or have the original rebuilt, the cost is a little better than buying new. Maybe a little quality time polishing the snout, removing any burrs, etc.

|

|

|

|

|

MoonShadow

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 4.6K,

Visits: 38.7K

|

It does sound like you have a clearance problem. Did you contact Powerbond? Sometimes quality control slips. When I got my AOD adapter everything was find except the crank adapter wouldn't fit over the flange and had to be remachined. It happens.

Y's guys rule!

Looking for McCullouch VS57 brackets and parts. Also looking for 28 Chrysler series 72 parts. And early Hemi parts.

MoonShadow, 292 w/McCulloch, 28 Chrysler Roadster, 354 Hemi)

Manchester, New Hampshire

|

|

|

|

|

62bigwindow

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 884,

Visits: 14.3K

|

I've had the stock one off and on a couple times with no problems. The replacement is just too tight. My thinking is if you have to freeze one and heat another to get it together then something's off. If there is that much interference fit then there is no way it'll come back off without alot of effort. I work with stuff everyday that has that much interference and I can say from experience it's no fun to take apart. I was thinking maybe .0005-.001 would be plenty.

Durham Missouri

|

|

|

|