So - you still don't have a target number for the initial advance setting. A stock engine will like about 10º BTDC. Sometimes - you have to strip the paint off the dampener - and carefully scrub the wheel to get a mark to show. These engines will idle really slow - adding timing will add speed and torque and make it hold idle in gear.

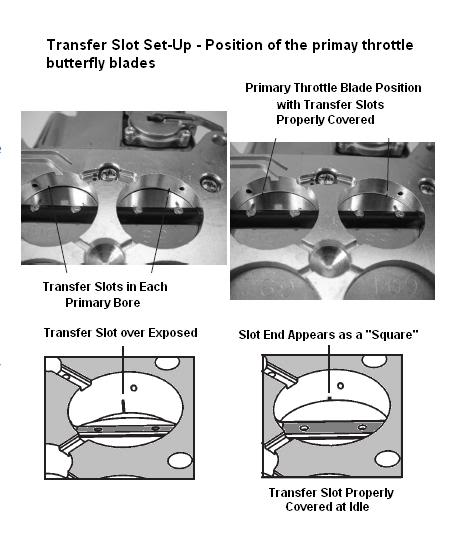

The comments above about the Holley carb - need some illustration. The primary blade has to be properly positioned on the "transfer slot" down inside the carb throat. Without this precaution, the engine will stumble badly and have a very poor transfer from idle to "run". You can best see that blade position - when the carb is off the engine and inverted.

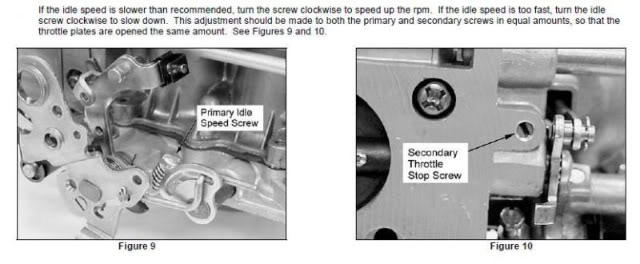

It takes tremendous will power but - once it is set-up - it shouldn't be moved while trying to adjust the idle.......only the mixture screws. The amount of additional throttle to keep the engine running should come - as mentioned above - from the secondary side of the carb. Each of the secondary bores has a "dribble port" for lack of a better name, where fuel constantly bleeds out of the secondary bowl through a small orifice. There is a small screw on the bottom of the carb - just below the secondary pot - that will hold the secondary blades open a bit - add air - and provide idle air to the engine. It can only be seen when the carb is off the engine - and most 4 barrel manifolds have a clearance below it.

Personally, I often replace the screw with a slightly longer bit of thread (cut off a longer screw) so something will protrude below - that I can grab with a needlenose plier to fine adjust. Otherwise, you are stuck with the previous advice - bending the throttle tab. I have seen some tuners replace the screw with a socket type set screw - and use an Allen wrench on it - but I don't have that kind of patience.

After setting the primary throttle to its initial position, turn the mixture screws to their starting spot. Install the carb, , fill the bowls with fuel, start the engine, and successively adjust the secondary blade with the stop screw to make it stay running. The choke needs to be "off" - so it is the first order of business after the engine runs a bit.

Steve Metzger Tucson, Arizona