|

By mgcookwv - 9 Years Ago

|

The throttle linkage doesn't match up from the holley 4000 to the holley 0-8007, I need some kind of bushing to go to the bigger hole on the carb so it will clear all other parts when the gas pedal is depressed and is properly aligned plus part of the linkage body from the car linkage is hitting the manifold itself, I can fix that but my main problem is the car starts and runs fine until the car is place in gear and it acts like bad gas, crossed plug wires or timing is off but after it gets going it runs like a top, keep in mind I was only able to drive it about a half mile total due to the rigged up gas linkage.

My friend that did the work said it is timed correctly from #1 plug which was tdc but he had to time it by sound because there aren't any timing markers or marks on the harmonic balancer.

Now my friend is a total scrubrolet guy, he was doing this fro me as a favor because physically I'm unable to do the work so he isn't familiar with yblocks or fords in general so there is definitely room for error.

your help would be most appreciated from people who made the same modifications.

I am unable to type scrubrolet , it turns it into scrubjet. Don't know what is up with that.

|

|

By miker - 9 Years Ago

|

Ok, I'm guessing here what your looking for. But there have been a variety of bushings for the larger hole (I just looked up the Holley number and looked at the picture). This is one example. Google "Holley throttle rod bushing", there's several that come up.

http://www.jegs.com/i/Longacre+Racing/441/32707/10002/-1?CAWELAID=230006180000856737&CAGPSPN=pla&CAAGID=15769068431&CATCI=aud-67754331191:pla-177199793351&catargetid=230006180003463481&cadevice=t&gclid=CLHeis7stMwCFU1bfgodKY8Irw

I've seen them over the years that are also a rubber/metal combination.

On the idle problem a couple other things come to mind. One is the advance, and the lack of markings. A picture here would really help.

The second is that some manifold/carb combinations are a little tricky to get the gaskets right-it's real easy to get a leak there. Again, a picture would help, and the casting number off the manifold. Someone here will be able to be of more help with more info.

Bad gas has always been a won't idle or miss under load for me, more load than just putting it in gear.

|

|

By Rowen - 9 Years Ago

|

>Now my friend is a total scrubrolet guy,

I am unable to type scrubrolet , it turns it into scrubjet. Don't know what is up with that .

Hahahahaha...... Freaked me out to the first time I saw it to. :0) sorry, just found that funny........

|

|

By charliemccraney - 9 Years Ago

|

Bad gas is easy to test. Disconnect the fuel line from the carb, install a hose nipple, run a length of hose to a funnel and use that, carefully, as a temporary fuel supply, with fresh gas. If the problem is fixed, it was the gas. If it is not fixed, it's not the gas.

Which distributor are you using on your '55 which now has a modern carb?

The timing pointer mounts via the bottom water pump bolts. Install a pointer and turn the crank so #1 is at tdc on compression. Now, assuming that the damper has not slipped, the pointer will be pointing at the general area where the timing marks should be. Get a magnifying glass, a light, a teenager with good eyes and find those marks. When you find them, mark them with some paint that is easy to see. A sewing needle dipped into paint works perfectly for that.

|

|

By paul2748 - 9 Years Ago

|

You said it runs ok when warmed up so I assume it's timed correctly - but keep in mind #1 cylinder on a YBlock is the front cylinder on the passenger side while a scrub has # 1 on the drivers side. Make sure that this was kept in mind when it was timed.

|

|

By Joe-JDC - 9 Years Ago

|

|

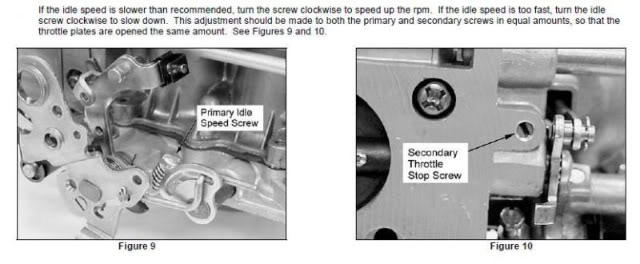

It sounds like you need to check a couple of things on that Holley. It will require you to remove the carb and drain the fuel, and turn it over to check to see if the secondary throttle blades are open .020" showing on the idle circuit slot. The idle on all Holleys except the four corner idle carbs should be controlled by the idle slot in the SECONDARY throttle bores. Adjust them by the little screw on the secondary linkage to show .020", or by bending the linkage tab on the right rear corner of the base plate. Then adjust the idle screws in until they gently bottom out, and back them out approximately 1 complete turn. This should get the idle to settle down so you can fine tune it and set the idle speed with the accelerator arm adjusting screw. Also, you should check the blades at wide open throttle (WOT) to see that they are 90* to the base plate, and adjust the linkage to accomplish. Then lastly you need to check the accelerator pump for .015" clearance between the lever and linkage at WOT. Should now idle in gear correctly. Joe-JDC

|

|

By dbird - 9 Years Ago

|

The timing marks can be difficult to find. A search of how to time using a vacuum gauge would give you an alternate method. I hadn't used it before I read about it on this site and it worked fine for me. Basically as I recall, adjust the distributor timing for max vacuum and back off a little.

Don

|

|

By mgcookwv - 9 Years Ago

|

|

wont type c h e v r o l e t g u y.lol

|

|

By mgcookwv - 9 Years Ago

|

He used a vacuum gauge , got the piston positioned right so I feel it is timed right but we will see.

|

|

By GREENBIRD56 - 9 Years Ago

|

So - you still don't have a target number for the initial advance setting. A stock engine will like about 10º BTDC. Sometimes - you have to strip the paint off the dampener - and carefully scrub the wheel to get a mark to show. These engines will idle really slow - adding timing will add speed and torque and make it hold idle in gear.

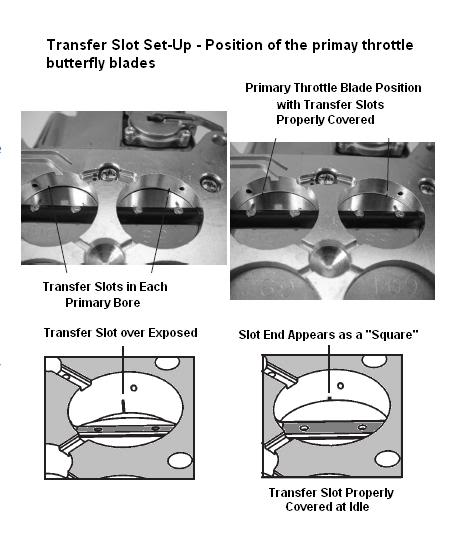

The comments above about the Holley carb - need some illustration. The primary blade has to be properly positioned on the "transfer slot" down inside the carb throat. Without this precaution, the engine will stumble badly and have a very poor transfer from idle to "run". You can best see that blade position - when the carb is off the engine and inverted.

It takes tremendous will power but - once it is set-up - it shouldn't be moved while trying to adjust the idle.......only the mixture screws. The amount of additional throttle to keep the engine running should come - as mentioned above - from the secondary side of the carb. Each of the secondary bores has a "dribble port" for lack of a better name, where fuel constantly bleeds out of the secondary bowl through a small orifice. There is a small screw on the bottom of the carb - just below the secondary pot - that will hold the secondary blades open a bit - add air - and provide idle air to the engine. It can only be seen when the carb is off the engine - and most 4 barrel manifolds have a clearance below it.

Personally, I often replace the screw with a slightly longer bit of thread (cut off a longer screw) so something will protrude below - that I can grab with a needlenose plier to fine adjust. Otherwise, you are stuck with the previous advice - bending the throttle tab. I have seen some tuners replace the screw with a socket type set screw - and use an Allen wrench on it - but I don't have that kind of patience.

After setting the primary throttle to its initial position, turn the mixture screws to their starting spot. Install the carb, , fill the bowls with fuel, start the engine, and successively adjust the secondary blade with the stop screw to make it stay running. The choke needs to be "off" - so it is the first order of business after the engine runs a bit.

|

|

By Riz - 9 Years Ago

|

My timing marks were covered in 30 years of rattle can paint.

One hack I came up with was to get a sheet of the timing tapes I can't remember the diameter right now, but easy to figure out by math or a measuring tape--and mounted it semi permanently with some 3M 2 sided body tape once I found TDC. The tape as a temp fix is still going strong after 4 years. Wasn't planning on the fix lasting this long, but not complaining.

|

|

By mgcookwv - 9 Years Ago

|

|

Yes, that's one of the items I need, thank you.

|

|

By mgcookwv - 9 Years Ago

|

|

MSD 8383

|

|

By GREENBIRD56 - 9 Years Ago

|

I hope you still have the MSD8383 instruction manual. According to the installation instructions, the MSD 8383 distributor comes with the "BLUE" advance stop bushing installed - that is 21º at the crankshaft. The stock engine will operate well with a total of 35º of mechanical advance. So - as delivered it would tolerate an initial crank setting of 14º. It also comes with a factory set of advance springs - (2) HEAVY SILVER springs - and per the included chart, they would reach full travel at about 4000 rpm together with the BLUE bushing. The default RPM limit is 10,000 RPM - don't go there OK?.

Myself, I would suggest the following set-up for a stock engine:

Initial advance at idle 10º

Use the SILVER advance stop bushing (replace the BLUE bushing) to get a 25º limit ,the sum of these being the 35º total

Change out the HEAVY SILVER springs with two of the LIGHT BLUE (for poor gas) as the advance would be all in at 3500 rpm. Using one of the LIGHT SILVER and one of the LIGHT BLUE (better gas) springs would net full advance at about 2800 rpm.

There are no instructions included for the vacuum pot - only a ramp. Many of the vacuum pots have an internal screw that will adjust the "FULL" advance of the unit - but this one is an unknown. Given that these engines in good tune with a factory cam will easily deliver 15 inches of vacuum - it could be adding as much as 16º of additional advance at high vacuum - and that might be a bit too much.

|

|

By miker - 9 Years Ago

|

Based on stock engines, and it's been a while, I'm going to go with Steve on this. I ran a timing computer and a Delco vacuum unit for quite a while. It let me keep the tach drive dizzy in my 55 bird, without spending $700 on a 57 tach drive in need of a rebuild.

The motor will probably take the full vacumn advance at cruise, but you may find a part throttle (60-90% throttle) ping. That's going to be the time to limit the vacuum advance adjustment if it has one.

I had a vacumn gauge in the car, and a hand held vacumn pump, so I could get a second set of hands and look at the advance curve at different vacumn and rpm levels. Bunch of work, and not really needed.

|