|

Author

|

Message

|

|

unibody madness

|

|

|

Group: Forum Members

Last Active: 7 Years Ago

Posts: 53,

Visits: 1.7K

|

Merry Christmas to you as well.

Mine should be out of the body shop after the new yea,r and I too will be posting picks after all these years.

|

|

|

|

|

Bill Childs

|

|

|

Group: Forum Members

Last Active: 9 Years Ago

Posts: 67,

Visits: 472

|

Nice work and great share uni-mad. My front end too was installed with the Gibbons Cordoba kit. Figured the car exhaust would be tight but didn't work it out when all was in one place... so I went ahead and bought a set of the Spotlite stainless log headers just in case. They look good and will be easy to modify if need be. I suppose it all comes down to exactly where the engine rests. My project began with custom motor mounts for a 351 installed. I cut those away and did my best to fab some new mounts for the 292 using stock dimensions for engine to body/frame. We'll see how it works out when the 292 comes back from the machine shop. Can't wait! I'll start a project post soon when I have something juicy to show. Warm and merry Festivus to yawl!

Bill C

Drag it home, figure it out.

|

|

|

|

|

unibody madness

|

|

|

Group: Forum Members

Last Active: 7 Years Ago

Posts: 53,

Visits: 1.7K

|

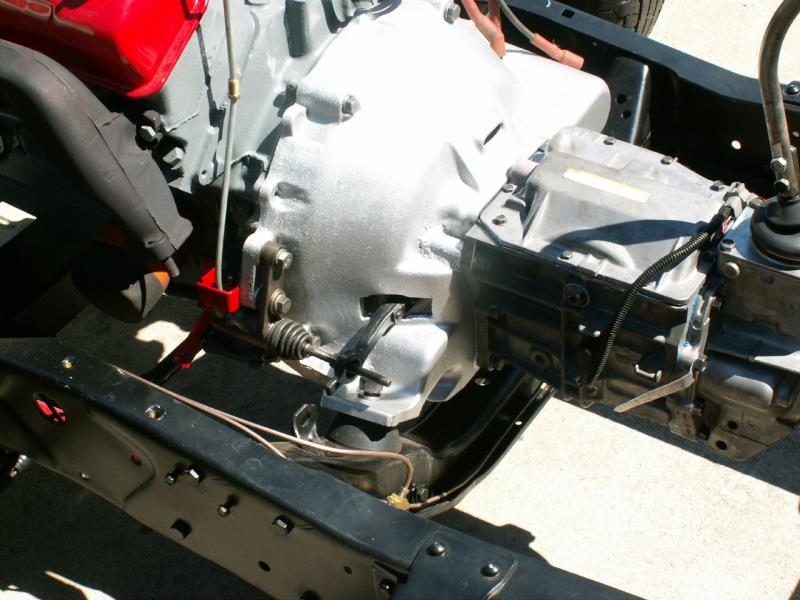

I have the Gibbons 79 Cordoba set up in my 61 unibody. I have a set of exhaust manifolds facing rearward .I replaced the manual steering box with a power box, there is enough room to run the manifolds down and out the back. Clearances are tight, however the only mods I had to make were dumping the z bar for a hydraulic clutch set up, and I built a bracket with a wheel that attaches to the top of the truck frame, that keeps the e brake cable off the exhaust on the drivers side

|

|

|

|

|

Bill Childs

|

|

|

Group: Forum Members

Last Active: 9 Years Ago

Posts: 67,

Visits: 472

|

Wow boys, gobs of great info from all. Time to get busy and make some calls. Problem I'm facing now is everything is apart, so relying on photos and rough dimensions I took earlier. You know how it goes. Thanks a bunch guys!

Bill C

Drag it home, figure it out.

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.8K

|

Here is a link to the past thread on header and/or exhaust testing. This link takes you straight to page 10 of the thread giving a summary of all the different headers tested up to that point but there’s a bunch of good information including graphs on the previous pages. Going back to the start of the thread will get you some pictures of the various headers that were tested. http://forums.y-blocksforever.com/FindPost99070.aspx Here’s the part of that same thread that goes into detail on the round ports at the headers mating to a rectangular port at the head. http://forums.y-blocksforever.com/FindPost57787.aspx And here’s another thread that discusses the different ports at the heads. http://forums.y-blocksforever.com/FindPost46291.aspx

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Bob Gardner

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 118,

Visits: 2.0K

|

I have Sanderson Headers on my '56 F100. I have a Toyota power steering box on the driver's side. Which is pretty big and the headers clear the box but required some careful routing of the hoses to clear the last tube on that side.

|

|

|

|

|

dbird

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 279,

Visits: 4.0K

|

Along with miker's thoughts about Thunderbird headers, Sanderson headers for the bird move the collectors to the far side of the steering column. I get a measurement of about 5.5 inches from inside of flange to inside of collector flange. I don't know how much this would help with the Chisler suspension as I get roughly 30 inches from collector to collector, maybe 31 if I don't include the flange and my 56 f100 frame width is 34 inches outside. If it sounds close, Sanderson might be willing to send you their dimensions. Best of luck.

Dbird

55 Thunderbird, 56 F100 in the works

Modesto, CA

|

|

|

|

|

miker

|

|

|

Group: Forum Members

Last Active: 2 Weeks Ago

Posts: 1.9K,

Visits: 194.9K

|

Just a couple thoughts. Maybe spotlight would send the headers just tack welded, so you can easily modify them, and just finish weld the the rest. Second, Stan's Muffler in Auburn WA makes the flanges that FPA uses for the Tbird headers that he and Mummert sell. I used those flanges for the custom headers on the roadster. And they're on the FPA headers on my 'bird. Local to me, I drove down and picked them up. Flat, thick, no problems.

This assumes you've got access to at least tack welding everything together.

miker

55 bird, 32 cabrio F code

Kent, WA

Tucson, AZ

|

|

|

|

|

MoonShadow

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 4.6K,

Visits: 38.4K

|

Welding stainless is not as uncommon as it once was. Looking at those headers I've always thought they followed the same exit path ad the stock exhaust. They may be closer. Also the people that are offering them may be willing to change that path for you. Any local shop with a bender should be able to bend them but mandrel bending will keep the curves better. It's not that serious but a regular pipe bender will stretch or crush a bit of the pipe while bending. Mandrel benders don't affect the tubing shape. I would be tempted to buy a set of them and have them bent to fit. I would suggest getting in touch with Spotlight Kustoms and see if they can help you out. The stainless exhaust look good and last long. Let us know how you handle there may be other Y-Blockers out there with similar problems.

Y's guys rule!

Looking for McCullouch VS57 brackets and parts. Also looking for 28 Chrysler series 72 parts. And early Hemi parts.

MoonShadow, 292 w/McCulloch, 28 Chrysler Roadster, 354 Hemi)

Manchester, New Hampshire

|

|

|

|

|

Bill Childs

|

|

|

Group: Forum Members

Last Active: 9 Years Ago

Posts: 67,

Visits: 472

|

I was wondering just how critical that port mismatch would be. This is not a high performance build but is warmed up a bit - expecting maybe 240 hp or so max. A good header fit without a lot of fabrication and hassle is more important than squeezing a few extra ponies out. I believe that Spotlite drivers side stainless log header tucks in closer to the engine than the stockers with the indentation cast into them. Looks like it from top view at least. But like you say, that stainless tube wouldn't be too tough to modify to fit if need be. Hmm...

Bill C

Drag it home, figure it out.

|

|

|

|