|

Author

|

Message

|

|

OlWeldinrig

|

|

|

Group: Forum Members

Last Active: 8 Years Ago

Posts: 78,

Visits: 2.5K

|

Thanks Ted,

We will check it out.And the same time Wow only an 8th of an inch.Thought you needed more meat than that.

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 5 hours ago

Posts: 7.5K,

Visits: 205.9K

|

56F250 (12/21/2015)

How thin is too thin? I have 312 block I want to use which has a rough measurement of about .055 over. How much more can a guy Bore these blocks too safely? Thanks Dave Most 292/312 Y blocks will safely bore to 0.060” over their stock sizes; there are exceptions to this in that extreme core shift will limit even this amount. If core shift is present and not compensated for up front, then the possibility is much higher for a cracked cylinder or cylinder wall distortion early on. Upon sonic checking the cylinders and documenting the direction or location of core shift, then the cylinders can be offset bored so that the cylinder wall thicknesses around its perimeter will be more uniform. My own preference is at least 0.125” for cylinder wall thicknesses on the thrust sides and a minimum of 0.095” between the cylinders (non-thrust sides). The anticipated performance level will dictate to a large degree the minimum cylinder wall thickness amounts.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

PF Arcand

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 3.3K,

Visits: 238.8K

|

Sounds like your 312" block is close to 0.060" over. That seems to be about the practicle limit. To go bigger the block should be sonic tested. Some builders have gone to 3.9"+ but that leaves thin walls & no room for a cleanup rebore. Factory available pistons only went to 0.040" over.

Paul

|

|

|

|

|

OlWeldinrig

|

|

|

Group: Forum Members

Last Active: 8 Years Ago

Posts: 78,

Visits: 2.5K

|

How thin is too thin?I have 312 block I want to use which has a rough measurement of about .055 over.How much more can a guy Bore these blocks too safely?

Thanks Dave

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 881,

Visits: 13.5K

|

Hi, no boost, 3.810 Bore, 3.60 Stroke, 6.370 rod, 13.48 comp, 280Deg @50, trend lifters in a 1500lb car (approx)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 5 hours ago

Posts: 7.5K,

Visits: 205.9K

|

Cliff. That block looks to be a good starting point. Are you looking at using boost?

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 881,

Visits: 13.5K

|

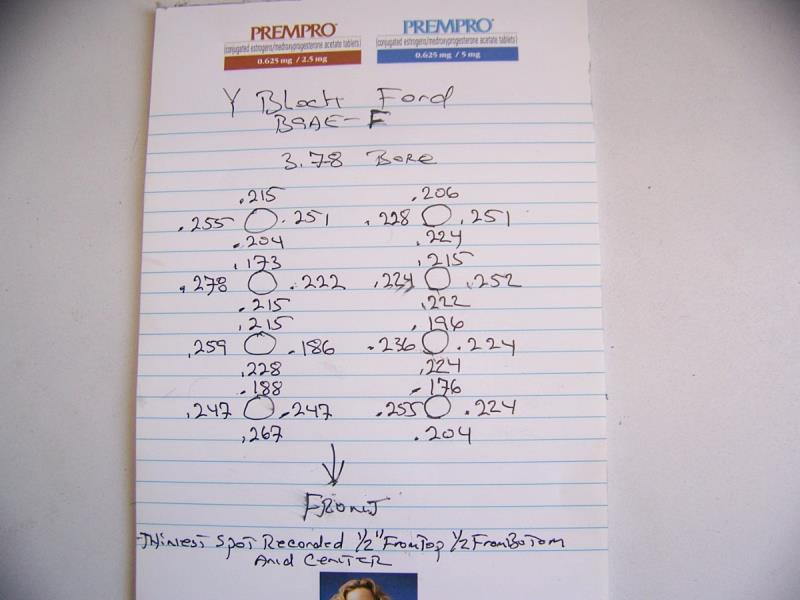

New Test, this is going to 3.810

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 881,

Visits: 13.5K

|

Ted your 100% correct, Measured a .330 piece from a block and my sonic checker showed .411 even after calibrating, so more work to do, thank you for correcting me.

Cliff

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 881,

Visits: 13.5K

|

Hi Ted, I did calibrate the tester before testing, however I can insert a 7/32 drill between cylinders, tight on the left side loose on the right side I have a broken block here and will take and cut out a piece and check to see what's up, this block came out of a truck, also it has been acid dipped to clean out the rust, this is a B9AE-F Block

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 5 hours ago

Posts: 7.5K,

Visits: 205.9K

|

|

|

|

|