|

Author

|

Message

|

|

MoonShadow

|

|

|

Group: Forum Members

Last Active: 3 hours ago

Posts: 4.6K,

Visits: 38.7K

|

There are several different sizes of water pump pulleys. They vary in diameter and depth. If you have any Y-block friends see if they have a stash of pulleys. You should be able to find something to work. Chuck

Y's guys rule!

Looking for McCullouch VS57 brackets and parts. Also looking for 28 Chrysler series 72 parts. And early Hemi parts.

MoonShadow, 292 w/McCulloch, 28 Chrysler Roadster, 354 Hemi)

Manchester, New Hampshire

|

|

|

|

|

slumlord444

|

|

|

Group: Forum Members

Last Active: Last Week

Posts: 1.2K,

Visits: 137.8K

|

You can also put washers behind the crankshaft pulley, Ended up doing that on my Bird. Pressing the hub back on the water pump may be a better idea. There is a spec for the distance form the front of the water pump shaft to the front of the hub and mine was actually off. Did not have a press so shimmed the crank pulley. Finally got it all lined up right or very close. .

|

|

|

|

|

HT32BSX115

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 452,

Visits: 24.4K

|

2721955meteor (3/17/2015)

i would remove the pulley as preveously sujested but remove the pump and put apease of rod on the shaft its self so you dont move the impellor, i use alittle heat on the pulley hub as well. Howdy, I think I would go in a different direction. Find yourself another pump and sell that "High-Mount" pump. They're getting getting somewhat scarce (and valuable) as of late. OTOH, it would be fairly easy to just press the flange a little further onto the shaft if it will go any further...... I was able to press mine all the way off easily when I was using a different water pump pulley that I wanted to align with the outer pulley...  -------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1955 F-600/272/E4OD// Disclaimer: No animals were injured while test driving my F-600 except the ones I ran over intentionally!

---------------------

This post was created using OpenSuSE Linux x64 and Firefox

|

|

|

|

|

Steve

|

|

|

Group: Forum Members

Last Active: 9 Years Ago

Posts: 41,

Visits: 568

|

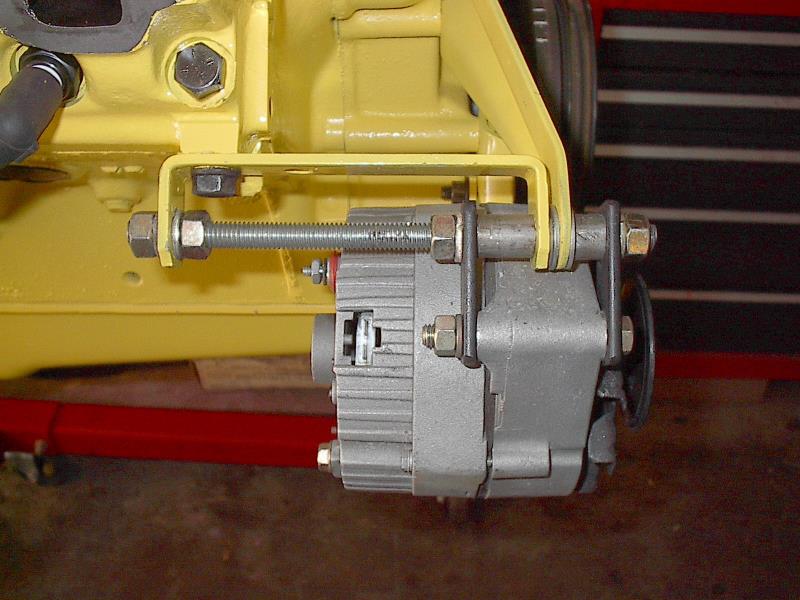

R This is my home-made alternator mount. Crude I realize. Mine is a three wire, and I need to blip the throttle to get the BATT light to go out so it can charge. Once it starts charging it behaves normally. Something about the impedance of the BATT lamp ? Great headers by the way. Mufflers?

|

|

|

|

|

jeves

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 8,

Visits: 354

|

Thanks guys. If I don't find a pulley that fits better I will try pushing the flange back with a press. Steve, just got the headers today.  ~ JE

~ JE

'56 F-250 with 292

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Last Year

Posts: 6.1K,

Visits: 443.0K

|

The water pump alignment baffles me, if that is a stock pulley. There are water pump pulley spacers. Make sure you don't have a spacer behind it and if not, do what the others say. The alternator lines up perfectly with my stock single groove damper. No spacers required. If it turns out that you do need spacers, add them between the block and bracket and remove the one you installed from behind the pulley. That way, if you ever need to replace the alternator, you can get a replacement off-the-shelf and use it as is..

Lawrenceville, GA

|

|

|

|

|

2721955meteor

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 927,

Visits: 190.0K

|

i would remove the pulley as preveously sujested but remove the pump and put apease of rod on the shaft its self so you dont move the impellor, i use alittle heat on the pulley hub as well.

|

|

|

|

|

pegleg

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 3.0K,

Visits: 8.7K

|

If you have access to a press, the flange on that pump can be moved to whatever dimension you wish. Don't need to buy another pump

Frank/RebopBristol, In ( by Elkhart)

|

|

|

|

|

Steve

|

|

|

Group: Forum Members

Last Active: 9 Years Ago

Posts: 41,

Visits: 568

|

I welded a little shield on the underside of the valve cover to keep the oil out of the PCV.

I had to experiment with different valves to achieve a balance between what is a controlled vacuum leak and idle speed.

It idles down to about 600 RPM now which is fine for me.

I have since acquired a later valley cover with the PCV hole in the back, but never installed it.

I like your alternator bracket. I cobbled mine together, but it works fine, and I'd not go back to a generator.

The voltage regulator on the fender is gutted since the alternator is internally regulated; I wired in a fuseable link in there instead.

The Edelbrock 500 carb has been very trouble free, and after I got the calibration kit, was able to dial it in the way I like it.

I'd be interested to see the headers installed too, and must say I think your color choices are superb!

And by the way, I do think there is more than one choice with regard to the water pump shaft length...

|

|

|

|

|

jeves

|

|

|

Group: Forum Members

Last Active: 6 Years Ago

Posts: 8,

Visits: 354

|

Thanks for sharing Steve! I'm debating the same move away from the downdraft tube. Did you use a baffled grommet to keep oil out out of the PCV valve? Mine will have ceramic headers in a couple days but I really like those horns now too. - J

~ JE

'56 F-250 with 292

|

|

|

|