|

Group: Forum Members

Last Active: 15 Years Ago

Posts: 193,

Visits: 594

|

Ok, so I know I remember reading some on this, but can someone straighten me out on exactly how to ID Posted heads? Kevin

|

|

Group: Forum Members

Last Active: 14 Years Ago

Posts: 166,

Visits: 1.9K

|

Hi Kevin, John Mummert wrote an excellent article about identifying posted heads for Y-Block magazine. It appeared in issue #32. If you can, you should pick up a copy. Hopefully John won't mind if I repeat some of the high points. If you are lucky, the head number will tell you what you need to know. Also you can see the stiffening post if the head is off the engine and you are looking through a hole, visible on the head gasket side of the head. The following heads are all posted: -471, -113, C0AE, C1AE, C1TE. None of these heads are posted: EBU, ECG, ECL, ECA-A, ECZ-B, ECZ-C, ED-ECZ. Also no heads cast at the Dearborn foundry (DIF) were posted. Some ECZ-G heads were posted. All heads cast after May 1957 at the Cleveland foundry (CF) were posted. Therefore the only heads in question are ECZ-G heads cast at the Cleveland foundry, as there was a running change. Hope I got this correct, and hope it is helpful. Nick Brann

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 721,

Visits: 93.2K

|

The REASON the ECZ_G heads NEEDED to be posted was at the higher compression 9.5 and up the top of the chamber could fail(collapse). That was not the case with the CLOSED CHAMBER ECZ A, B, C, D heads. Even at high compression ratios. For what its worth. Pete

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

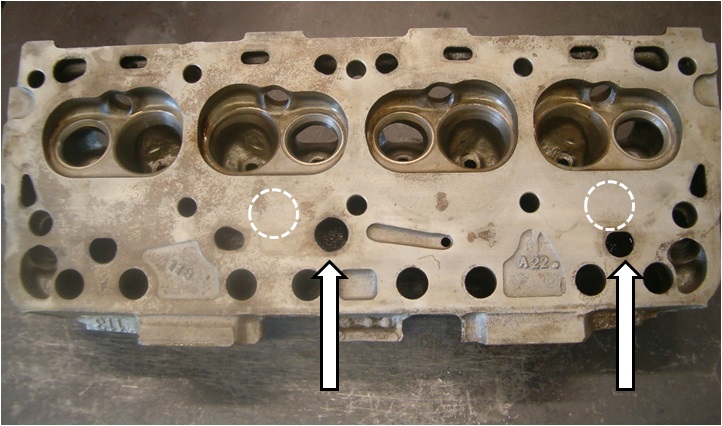

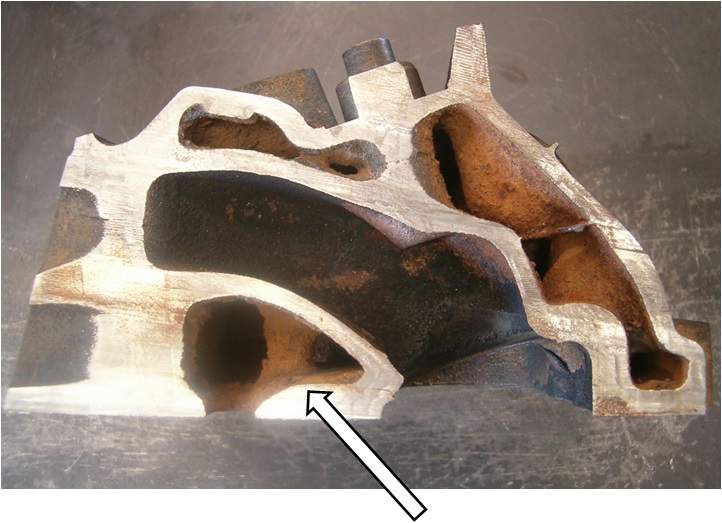

To add to Nick and Petes comments, here are a couple of pictures. The arrows in the top picture simply point to the water ports in which you can use your little finger to reach into and feel for the ‘post’ whose locations are represented by the dotted lines. The second picture simply shows a cutaway of the head in which the post is visible.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 3.3K,

Visits: 238.8K

|

Ted; Seems I read somewhere that the later posted heads were slightly more prone to cracks than unposted heads..Yes / no?. Further, it might be that people who were racing those heads back in the day, like Smokey Yunick, were maybe illegally cutting the heads heavily for stock classes maybe?

N.B.- Sorry, I need to read my posts more carefully. the 2nd line above should have referenced "un posted" heads..

P.S.- Thinking further about it, I might have been mistaken about the posted ECZ-G heads in the 1st line .. It may have been that I read that 1958-9, 5752-113 Heads were somewhat prone to exhaust valve area cracks... Not sure though, ? ? ?.

Paul

|

|

Group: Forum Members

Last Active: 4 days ago

Posts: 347,

Visits: 12.3K

|

FYI, I ran unposted Ecz heads with nitrous and until I increased from a 150 hp to 175 hp shot did I start blowing head gaskets. Basically the unsupported area in the head lifts. Added the bolt fix through the rocker stand to fix it. Just my opinion, I wouldn't be concerned with a low compression street motor but the fix is easy.

Vic Correnti Vic Correnti

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

PF Arcand (3/23/2020)

Ted; Seems I read somewhere that the later posted heads were slightly more prone to cracks than unposted heads..Yes / no?. Further, it might be that people who were racing those heads back in the day, like Smokey Unick, were maybe illegally cutting the heads heavily for stock classes maybe? The majority of cracked ECZ-G heads I come across are of the unposted variety. That’s expected as the majority of ECZ-G heads that were manufactured were unposted. There are less problems with the posted heads overall and much of that has to do with the reinforced decks that are made more stable with the added posts. Adding posts to unposted ECZ-G heads is doable and an accepted fix for the unsupported decks in those particular heads. As mentioned, the ECZ-G heads are in a class all by themselves as the earlier unposted head castings had additional support provided by the intake runners. The ECZ-G heads had reconfigured intake runners that took away a part of the internal casting that helped to support the heads. Also keep in mind that unposted ECZ-G head milling should be limited to 0.025”. The shop manual actually specifies 0.010” as the limit of mill for those heads. I have milled the posted ‘G’ heads as much as 0.065” without any problems with increased compression ratios so the posting definitely fixes the problem. Most Y head problems I’ve come across were the result of the engines overheating and because the two exhaust ports are together at the middle of the head, one or both of those two cylinders will crack first.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|