|

Group: Forum Members

Last Active: 3 Months Ago

Posts: 94,

Visits: 422

|

Not yet. We just got home and recovering from the build/trip. I'll get it in the next few weeks.

|

|

Group: Forum Members

Last Active: 2 Months Ago

Posts: 452,

Visits: 24.4K

|

Do you already have the new impeller?

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1955 F-600/272/E4OD// Disclaimer: No animals were injured while test driving my F-600 except the ones I ran over intentionally!

---------------------

This post was created using OpenSuSE Linux x64 and Firefox

|

|

Group: Forum Members

Last Active: 3 Months Ago

Posts: 94,

Visits: 422

|

Summer Ditch! I wish I would have seen that a week ago! I'll probably address that when I pull the pump to install the Flow Kooler impeller.

|

|

Group: Forum Members

Last Active: Today @ 12:34:28 AM

Posts: 1.8K,

Visits: 306.3K

|

Your discussions are similar to the overheating problem(s) in the 55/57 BIRD. The higher rated cap pressure will raise the coolant boiling point also if the system can handle the increased pressure. Another problem you may encounter when pulling the pump is the irregular casting finish of the front cover water volute. HERE - https://img1.wsimg.com/blobby/go/38978bd3-5ae7-4960-b749-ae5d7a9bfeb1/downloads/Potential%20obstruction%20to%20coolant%20flow%20-%20TCC%20-%20.pdf?ver=1704422486572Any reference to a spacer in the above article is to be ignored as that refers to BIRD only.

____________________________

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.7K,

Visits: 340.1K

|

I think I used a Mr Gasket single and needed the shim kit to line it up. My 2018 F150 5.0 will drop 20* when on a down grade. I usually start dropping gears depending on the grade to stay off the brakes. Last News Day I went on a 200 mile rod run with our 56 and it will climb to 190* on a hill but going down it will get to 160*. Normal for mine in town is 170*.

56 Vic, B'Ville 200 MPH Club Member, So Cal.

|

|

Group: Forum Members

Last Active: 3 Months Ago

Posts: 94,

Visits: 422

|

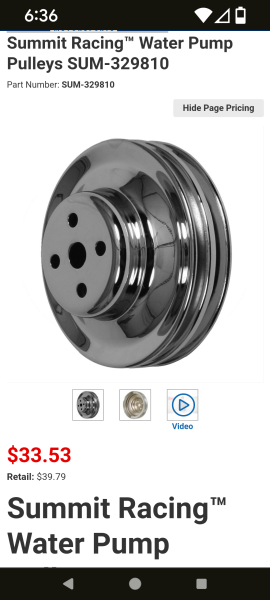

I think the pulley and high flow stat were the most effective things we did on our trip. We are still seeing a temp creep vs RPM. Our super scientific test was down hill runs. Kicking into neutral and coasting would see a temp creep immediately that would eventually reverse. Leaving it in gear and using engine decel hold the RPM about 1700rpm would see the cool down start immediately. To me this is a sign we're still not flowing enough at idle and probably not enough at RPM either. But it's much improved over the stock truck pulley and small thermostat. We can cold start and let it idle for 30 minutes and it's below 160° still. This pulley is what we used and it required no shims with a car pump. Lined up perfectly.

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.7K,

Visits: 340.1K

|

Thru much anguish and hair removal I “fixed” the cooling problem in 1956 292 with addition of a 289/302 water pump pulley which sped up the water pump so coolant was circulating at idle which it was not with the stock 7+” pulley. The problem was discussed at length on this site and a member wrote that doing it would remedy the overheating. I was also able to remove all the bandaid fixes that may have worked to some extent. The high flow MOPAR thermostat does remain along with the fan shroud. I see the use of an impeller with more blades definitely helping as long as there is movement of coolant that you can see at idle by looking in the radiator. When I replaced the original heater with an AC/Heater combo I went to a 13/14 psi cap. At 180* 8oz will add to the overflow tank and will suck back in when cool.

56 Vic, B'Ville 200 MPH Club Member, So Cal.

|

|

Group: Forum Members

Last Active: 3 Months Ago

Posts: 94,

Visits: 422

|

The more pressure you can run, the better. The only down side would be to old/worn out components that need replaced anyway.

We ran a 19lb cap on the F600 from sea level to 12,000ft. The lower rated caps were an issue, the 19lb wasn't.

|

|

Group: Forum Members

Last Active: 2 Months Ago

Posts: 452,

Visits: 24.4K

|

That link didn't seem to work.....

Ok, found it! Your link had a period at the end of it!

Thanks! I did read through that info before.

I see how the circulating pump can absolutely increase flow though the engine. I don't see how it can increase flow through the radiator when the thermostat does that job. (unless the stat is a lower temp unit and is fully open.....or the T-stat "weep" hole is larger)

Total system pressure is pretty dependent on the block temp, T-stat cap relief pressure and the vapor pressure of the water/glycol mix ratio. You can look it up on a coolant mix chart

I.E. 13lb cap, engine/rad pressure will build to 13lb at a very specific temp..... The guy that re-cored my original radiator from 3-4 rows told me I could put up to a 13lb cap on mine.

Anyone here have an opinion on max pressure caps? I don't think a 7psi cap will cut it unless I use a very low temp stat.

I do see how a pump *could" build pressure against a "closed or semi-closed " T-stat, But once the stat is fully open, the pump pressure would be relieved.

AND admittedly, If the pump is capable of REALLY HIGH flow rates, even an open stat might not relieve all the additional pressure produced by the pump!

A pressure gage on the engine side of the (closed or semi-closed) stat will show if that's true and it would vary with RPM! (sounds like a fun test...anyone done that?)

I do not think there's a downside to a better performing pump. I an eager to rebuild my spare pump with one of those impellers!

Thanks for posting that companies stuff!!

Cheers,

Rick

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1955 F-600/272/E4OD// Disclaimer: No animals were injured while test driving my F-600 except the ones I ran over intentionally!

---------------------

This post was created using OpenSuSE Linux x64 and Firefox

|

|

Group: Forum Members

Last Active: Today @ 12:34:28 AM

Posts: 1.8K,

Visits: 306.3K

|

Read this page. It explains the HI-FLOW WP concept - https://flowkoolerwaterpumps.com/pages/why-flowkooler-hi-flow-pumps-end-overheatingI am detailed orientated and believe in NUMBERS MATCH. You can buy a complete/rebuilt or just impeller to retain the original WP HSG casting. The most important thing to remember is not to use as a core return or throw away the original WP. Either sale or keep.

____________________________

|