|

Author

|

Message

|

|

peeeot

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 357,

Visits: 25.5K

|

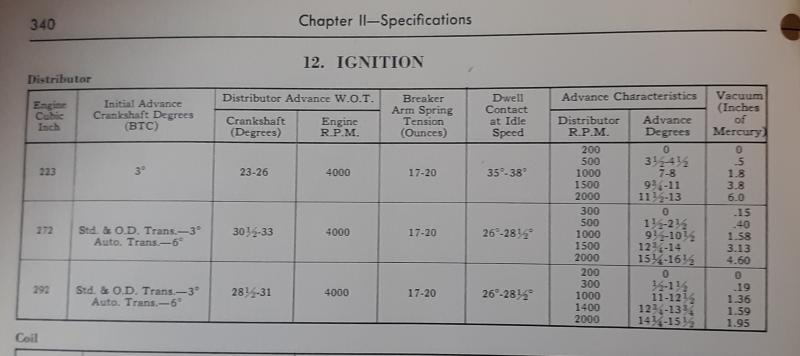

I didn’t see any mention of verifying ignition dwell angle in the conversation so far. Dwell is critical to generating spark energy and makes a huge difference in idle quality and spark quality at higher RPMs. If the dwell is too short the spark may be breaking up above 3000rpm, especially if the mixture is on the lean side (harder to ignite). Revving without load wouldn’t necessary show this. Setting dwell is one of the first things I do in a tune-up. If you change it, it will affect your timing as well.

Also, the Loadomatic “black box” can be demystified somewhat if you tee into the distributor vacuum line and bring it into the car with a gauge. Then, you can observe the vacuum reading the distributor “sees” at various speeds and loads. With that data in mind, you can apply vacuum with a hand vacuum pump directly to the distributor and observe the corresponding advance using a timing tape and normal timing light or a dial-back timing light. This way you can get a pretty good picture of what your total advance is on the road.

Regarding the choke stove air intake: how strong does it suck? I agree that it should always be drawing a small amount of air, but usually they draw more air when the engine is cold and less once the choke has fully opened. You can rule out a concern here by temporarily disconnecting the choke, setting it fully open, and plugging the vacuum source to the choke.

Secondary throttle plates that are too far open, or poor alignment/seating of any of the throttle plates in the carburetor could cause some of your idle-related symptoms.

Beautiful car by the way!

1954 Crestline Victoria 312 4-bbl, 3-speed overdrive

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 1.8K,

Visits: 306.3K

|

LOAD-O-MATIC THEORY - http://m571.com/yblock/loadomatic.htmBack in the day, the procedure was to remove the DIST and set it up on a SUN MACHINE w/ MANOMETER. I would think it was rarely done as if the TECH stuck in a fresh set of points and condenser (flat-rate) and it ran well around the block she was good to go. If once re-installed and there was a performance problem, you would go to the vacuum supply side diagnostics.

____________________________

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 1.8K,

Visits: 306.3K

|

"Secondary throttle plates that are too far open, or poor alignment/seating of any of the throttle plates in the carburetor could cause some of your idle-related symptoms." If the secondaries are indeed adjusted in this manner, it was trying to hide something,

____________________________

|

|

|

|

|

WYEDelta

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 31,

Visits: 15.3K

|

Back in the garage tonight after Christmas holidays and finally completed the Cranking Compression test on a warm engine.

Results:

Cyl1---100 psi

Cyl 2 ---105 psi

Cyl 3 ---107 psi

Cyl 4 --102 psi

Cyl 5 ---112 psi

Cyl 6 --106 psi

Cyl 7 --100 psi

Cyl 8 ---104 psi

The good news is a fairly tight range of 100 -112 psi but the Lincoln Shop manual calls for 135psi +- 10. "Y"ikes!

What do you guys think? Are these below spec cranking compression values the cause of the low vacuum at idle (14-15" vs factory spec of 18-21")? The numbers seem to indicate the rings weren't installed correctly or didn't seat well.

Tomorrow I'm going to pull the intake and check/pray for a bad gasket.

One of the other things I noticed while under the car is that the single exhaust muffler (followed by two old resonators) is very old and rusty. So I'm also disconnecting the exhaust tomorrow morning on the Hail Mary chance that the exhaust is restricted.

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 1.8K,

Visits: 306.3K

|

Compression Test

The compression test works by spinning the engine through its cycles with the compression tester in place of the spark plug in the cylinder. As the engine makes pressure, the gauge will move and hold to the highest point read by the gauge. Take measurements for all cylinders and then compare the readings to each other. A healthy engine will have a range of no more than 10 percent variance between the readings.Hot vs. Cold test: An engine that has been brought up to temperature will be better sealed and give a more accurate reading for the normal temperature range of the engine; however, a cold engine will give you the worst-case scenario because the metal has not expanded. Also, engine compression readings can vary depending on altitude and other factors, so it is more important to compare the cylinders to each other rather than the assumed compression number. If you find one or more cylinders are below the 10 percent range of the others, squirt a little oil down the cylinders and try again. If the pressure comes up significantly, the problem may be worn piston rings. If the pressure does not come up on retest, the issue may be with the valves or the head gaskets. ( or late valve and/or ignition timing). Leak-down TestThe leak-down test measures how well the cylinder is sealing. This is done by inserting compressed air (around 100 psi) into the cylinder at TDC and then measuring how much is lost from the seals (there will always be some). This is done by two gauges on the leak-down tester.

SOURCE - https://www.motortrend.com/how-to/engine-diagnosis-leakdown-compression-test/A restrictive exhaust should have shown on the vacuum gauge test.

____________________________

|

|

|

|

|

WYEDelta

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 31,

Visits: 15.3K

|

Thanks for sharing the MotorTrend article. It states a 9:1 compression engine should develop about 9 x 14.7= 132.3 psi (at seal level). Factory built '54 317ci's had a 8:1 compression ratio therefore using MT's math should develop about 8 x 14.7 = 117.6 psi which is closer to my values (100-112 psi) and lower than the book's 135 +- 10 psi spec. Curious difference.

I do suspect my engine was relatively "cold" when I performed the test. I had warmed it up for about 10 minutes before beginning the chore of extracting the plugs. Pulling all (8) takes 45 minutes thanks to interplay of the frame, cast iron exhausts, inner fenders, oil filter housing, power steering pump, big hands, smallish and stiff uncooperative tools, weak magnetic hanging lights, etc. Felt like hell froze over by the time #8 fell out of the socket hitting my forehead and solidifying an adamant belief that "hot" engines must bump-up cold values by at least 5-10 psi!

So maybe my compression results aren't too bad after all...? Does anyone else have similar "Y" engine cranking compression numbers you can share?

I don't readily have access to a leak-down tester. I'm toying around the idea of buying one but not before removing the exhaust pipe. I awoke this morning to a forehead swelling with the conviction that a restricted exhaust could contribute to low vacuum and lack of engine acceleration beyond 3,000 rpm. Backing off some lash on the valves is second on the list followed by removing the intake manifold. Further down the list is pulling the timing chain cover and inspecting for a worn chain.

More to come....

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: Last Year

Posts: 6.1K,

Visits: 443.0K

|

A compression test is performed with the throttle wide open. If the throttle was left closed, the results will be lower than expected.

Lawrenceville, GA

|

|

|

|

|

WYEDelta

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 31,

Visits: 15.3K

|

Good catch! I'll stab a long screw driver down the throat of the Teapot and try again. It's raining and 48F outside ---engine is much colder so it won't be an apple to apple comparison.

|

|

|

|

|

miker

|

|

|

Group: Forum Members

Last Active: 2 Weeks Ago

Posts: 1.9K,

Visits: 194.9K

|

Disconnect the return springs and wire the throttle open. Sticking a screwdriver down and wedging a butterfly is not in your best interest.

I wouldn’t get too hung up on the vacuum reading being a bit low if you get everything else solved and it runs well. I’ve had a lot of worn engines that ran ok and went a lot more miles. Including a couple I just kept adding oil to.

miker

55 bird, 32 cabrio F code

Kent, WA

Tucson, AZ

|

|

|

|

|

WYEDelta

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 31,

Visits: 15.3K

|

PROGRESS!

Spent all day on the car.

1. Re-ran the compression tests on a cold engine with throttle wide open ---basically same results as yesterday's warm engine. Pressures ranged from 102--114 psi. Reinstalled the plugs.

2. Temporarily removed the primary muffler. Took car for spin ---the crazy loud engine still sputtered at 2800-3000 rpm and wouldn't rev past 3100 rpm.

3. Next I decided to change out the condenser in the dizzy even though it's brand new as are the points, rotor, cap, wires, etc. The web is full of stories about unreliable modern condensers... Easy change, take her for a spin, and BINGO!!!! On separate accelerations the engine flawlessly rev'd to 3400, 3600, 3800, and finally 4200 rpm! I can't believe it ---a brand new basic, static, round tin foiled $7 part had needlessly awoken gnawing thoughts of engine rebuilding gymnastics. What a major relief!

I'll reinstall the muffler tomorrow and run it again. If it continues to rev OK I'll probably go ahead and begin the '57 Intake and Centrifugal dizzy swap. The low vacuum condition at idle persists---hopefully, in a sense, I'll find problems with the intake gasket(s).

More to come.

|

|

|

|