|

By WYEDelta - 3 Years Ago

|

In the spirit of trying to improve the Street performance of the old gal I invested in a 6V Tach (positive ground naturally) and Vacuum Gauge. These instruments provide additional insight beyond the timing light and feeler gauges. A new speedometer cable is on its way to complete the cluster (unless 6V O2 sensors exist?).

I was surprised to learn that the vacuum is 15" at 450 rpm while in neutral. The Lincoln shop manual calls for 18"-21" @450rpm. Anyone have a similar bone-stock Y block achieving at least 18-19" idle vacuum?

My engine also draws 16.5" @ 2100 and 14-15" @2800rpm. Do these numbers sound reasonable?

I gave the engine a once over in search of a vacuum leak with a tightening wrench, screwdriver and starter fluid but found nothing obvious.

![]()

|

|

By KULTULZ - 3 Years Ago

|

See If This Helps -

https://www.onallcylinders.com/2016/03/31/vac-visual-quick-guide-vacuum-gauge-readings/

|

|

By WYEDelta - 3 Years Ago

|

Thanks for posting that article --definitely contains good "rules of thumb."

In my case the engine idles "fairly" steady between 14.5"-15.0" @450 rpm --500 rpm. The engine purportedly was recently rebuilt (not under my ownership) so I sure hope the rings aren't bad.

There are a couple of smoking guns I'm going after next. The first one being the spark plugs ceramics look very old for a recently refreshed engine. I can't imagine someone screwing old spark plugs into a refreshed engine but that's what I see. I'm going to pull a couple of plugs and inspect.

The other problem I have is the engine stumbles as I gently accelerate past 3000 rpm. It dare not push it to 3500 rpm because of how bad it gets. Again, maybe this is related to the spark plugs? Or is the 2140 Teapot acting up?? I'll start with the plugs and see where that leads.

Ideally I'd like to resolve this low vacuum issue and establish a baseline performance understanding BEFORE switching the fuel and ignition system from the current 2140 + Loadmatic Dizzy over to a Edelbrock AVS2 500cfm with '57 Dizzy solution (different thread).

|

|

By Deyomatic - 3 Years Ago

|

Are you sure that your total timing is set correctly? Can you describe this stumble above 3000 RPMs? Does it happen once, or does it keep skipping every second or two until you back off?

I don't think I'd be too worried about 15" of vacuum. I had an engine that couldn't make more than 11 at idle...granted it had a lopey cam...

The idle circuit in the carb is tied to the vacuum- one method of setting idle mixture is to use the vacuum gauge and turn the mixture screws until you get the highest reading. Maybe fiddle with those a bit to see if the reading goes up?

|

|

By WYEDelta - 3 Years Ago

|

The stumble begins at 3000 rpm and progressively becomes more pronounced as I push the pedal more. I back off at about 3300rpm as the engine grows unhappy. Skipping and surging also sounds about right (stumbling). But it cruises OK at 2800 rpm although I do begin to sense "faint hesitations."

I used another vacuum gauge to set the idle screws as you describe above. Both screws are providing best vacuum (14.4-15") when backed out about 7/8 of turn out. BTW, the engine does die (sputters to a stop) if either screw is tightened down to 1/2 turn off stop.

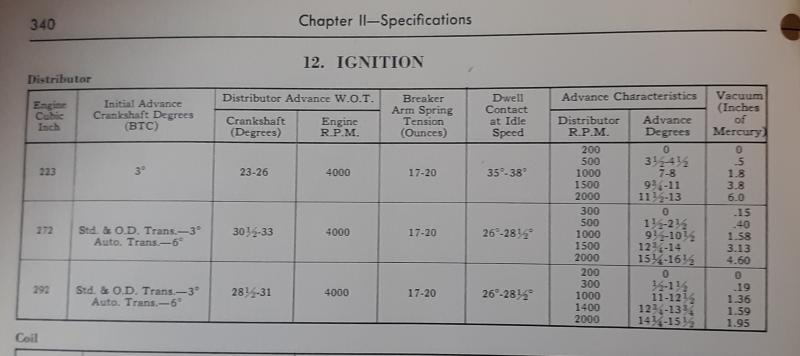

Indeed, the total timing might be off. I set the initial timing back to the book's spec of 3 BDC (I had been running it at 10 BDC) . When rev'ing while in Park (no load), the timing light on the new crank timing tape shows a total of 27 degrees at 2200 rpm. As you guys know the Loadmatic doesn't have centrifugal advance so no additional timing with higher rpms. However, who knows what is happening to the total timing while under load? In this regard the Loadmatic is a black box of sorts.

You're right the 15" idle isn't end of the world territory but I'd sure be happier closer to the 18" minimum the book cites...

|

|

By miker - 3 Years Ago

|

I’m not familiar with the Lincoln, but Fords initial advance on the FYB is really conservative. I wouldn’t be afraid to go back and try it at 10 initial. If it pings, back it down a little and try again.

Old plugs could very well be laying down, or the wires if they’re old. I’ve also had misses develop like that from old fuel. Didn’t look or smell bad, but fresh fuel cured the problem. I blame that on the ethanol. My modern cars (I poured it in since it looked clean) burned it no problem.

Got any idea how many miles it went since the “refresh” and how long it was laid up? If it was re ringed with the old iron rings they might not have even been broken in. Or they could be lightly stuck and some miles will improve that.

|

|

By WYEDelta - 3 Years Ago

|

Plug wires look brand new unlike the discolored porcelain plugs. Getting at the plugs to change them is a real bear. Makes me wonder if a guy, say the builder, used the old plugs to simply protect the heads and keep critters out, and later, a second guy, installed the exhausts before checking the condition of the plugs. Weird things like this can happen especially in a case such as this one, wherein the fellow I bought the car from said the engine had finally been reassembled about a year ago after sitting in a machine shop, post machining, for 8-10 years.

Long story short I'm breaking in the engine and debugging it...I've put about 600 miles on it thus far (changed the original break in oil at 75 miles). All sorts of fun issues have popped up along the way. The low vacuum is the latest. Maybe the rings haven't completely set after 600 miles ---probably stretching wishful thinking? The engine has hydraulic lifters ---maybe they're still a bit lazy?

BTW, the engine slightly ping'd at 10 BTC initial when shifting from 2-3 rd. It wasn't rattling can bad, probably will go back towards 10, but wanted to rule out a wrong initial timing as the cause of low vacuum.

Another note --- the idle set screw is completely backed off in order to acheive the idle 450 rpm. I'm also considering removing the Teapot (again) and checking the secondary throttle plates. The book calls for a 0.004" clearance using a 3/16" wide shim gauge. Maybe the secondaries are open too much and contributing to the low vacuum?

More tuning fun and games. Trying to stick to the, "Make one change at a time, test, think and then adjust," which an old timer finally ingrained my thickness with moons ago.

|

|

By KULTULZ - 3 Years Ago

|

Here is another TECH ARTICLE that may help -

Cranking Vacuum & Speed Tests - https://www.motor.com/magazinepdfs/082001_05.pdf

If there was a vacuum leak, the needle would be bouncing.

I would pull the plugs first and read them. If junk install fresh plugs. The low steady reading to me indicates possibly low compression (how long did the rebuild sit - frozen rings?) (cyls leak-down test), ignition and/or valve timing. It might be a good idea to use a piston stop the verify the balancer index markings are correct (and DIST is installed correctly). If not, have the balancer rebuilt and if still cannot find true TDC check cam timing.

You have tip-in hesitation at mid-range, I would suspect a DIST calibrated incorrectly (does the ADV CANISTER hold vacuum?) or an accelerator pump defect/mis-adjusted (or worse yet if the TV linkage is not adjusted correctly) (does that period HYDRAMATIC use a manual TV?).

I have no idea if there is someone that can go through and calibrate a LOM DIST (DIST MACHINE w/ MANOMETER). Good quality points and are adjusted correctly? The tension on the points has to be correct as this is a part of the LOM advance design.

GEN is charging correctly and have a good BATT? She needs good electric to run correctly.

|

|

By WYEDelta - 3 Years Ago

|

The vacuum is definitely steady but apparently low @ 15" /450rpm. I have no way of telling how long the machined engine sat before complete assembly and fire-up but antidotally it could be up to 7-8 years. Based on the excellent feedback I'm getting here from you guys (TY), it's dawning on me I'd better run compression tests while tackling changing out the spark plugs (kill two birds).

Before installing a new 7" timing tape on the Harmonic Balancer (MSD 1" wide white tape with graduations upto 60 degrees BTD), I turned Cyl #1 to TDC, verified the cam lobes were on TDC, and the pointer aligned perfectly with the HB's 0 degree mark. Several timing light rounds later I'm 99% sure the HB is in good shape.

Funny you included the HydraMatic setup article. This was the very first issue I ran into. While embarking on the maiden voyage around the block, I immediately became aware that the TV lever was maladjusted. The car shifted thru all 1-2, 2-3, 3-4 before 10mph! That setting would have rendered the tranny toast in a hurry. I'm confident this gem is now shifting correctly. I happen to be partial to the early Dual Range HydraMatics, it's one of the main reasons I bought this particular year and model Lincoln the clincher being the 317 "Y" of course!.... ; -)

. .

|

|

By Hoosier Hurricane - 3 Years Ago

|

|

You say that the high speed stumble starts at 3000 and gets worse by 3500. Old Lincolns had relatively soft valve springs, and with age they could be even softer. You may be experiencing valve float or lifter "pump up" . Just another thought to muddy your diagnoses.

|

|

By WYEDelta - 3 Years Ago

|

|

Thanks, keep'em coming!

|

|

By Deyomatic - 3 Years Ago

|

I think I'd start with a tune up. Fresh plugs, cap, condenser, points...sounds like your wires are new...maybe get a cheap replacement set to verify that yours are good.

Then I think I'd chase timing. Are you sure you have the right timing tape? I just picked up one of those timing lights that you set your advance on a dial and then match up the TDC mark...it advances the flash so you don't need timing tape. It worked pretty well.

The other thing that bothers me is that your idle set screw is turned all the way out. I know nothing of those teapots but that idle screw situation doesn't sound like any carburetor I've ever messed with. Maybe try a known good one...or if you don't know anyone WITH a known good Teapot, then maybe even slap an adapter with something else that's known to be good just to see how it runs. Would that even work with your distributor?

|

|

By Lou - 3 Years Ago

|

|

WOW, Nice car.....Lou

|

|

By KULTULZ - 3 Years Ago

|

Stale ethanol gasoline ...

How long did the car sit with fuel in the tank?

BTW - Did you check fuel pressure and delivery volume? Clean filter?

It is a beautiful car. 4DR?

*****

READ THIS - https://www.onallcylinders.com/2021/09/24/what-is-a-leakdown-tester-and-how-do-you-use-it/

If thinking of doing a compression check. Also report or post photos of the plugs when pulled.

|

|

By WYEDelta - 3 Years Ago

|

Fresh 87 octane gas. Figure this 8.0 CR engine doesn't need 89 or 91 (plus it's 0.30 cents/gallon cheaper than 91). The cap and wires sure look very new as did the points and condenser when I inspected them and set the gap.

The 7" timing tape is correct. It's the diameter of the HB and when placed on the only three original markings --0, 10 BDC and 20 BDC ---it aligned perfectly.

I haven't checked and verified the fuel pump pressure (yet...?).

The idle screw being all the way backed off also bothers me bunches. The initial thought is maybe the secondaries are too far open? Searching for vacuum leaks that might explain everything hasn't delivered. I'disconnected all of the vacuum lines (brake booster, fuel pump wiper assist, etc,) and sprayed starter fluid on the typical offenders but thus far have come up empty handed.

Back to firsts ---I'll change the plugs and post pics with 48 hours. Stay tuned,,,

(She appreciates compliments being a whistle straight and pampered black 4-door. Doesn't suit every man's taste but there ain't no denying she's a plus-sized looker! ; - ).

|

|

By Joe-JDC - 3 Years Ago

|

|

I will plead ignorance on the Lincoln Y, but 7* initial timing seems low even for a stock, low compression engine. Have you tried to set the initial timing up to 10*-12* and checked vacuum? I bet the vacuum will come up to 17" or more with more initial timing and not ping while driving. It might actually help your stumble at 3000 rpm. It should not hurt to try more timing as long as the total is not over ~38-40* with no vacuum advance. Joe-JDC

|

|

By WYEDelta - 3 Years Ago

|

I just pulled the plugs on the Passenger side ---Cylinders 1,2,3,4. I found that the plugs on 3 & 4 were barely screwed in! The weight of the wrench turned them off!!

Would this help explain why these cylinder plugs are wet (see pics)? Cylinders 1 & 2 tips are light grey, 3 & 4's dark and wet. The gaps are also all over the place ---rangining from 0.024 to 0.037.

I can't say these issues were the cause of low vacuum problem and stumbles ---but certainly weren't helping....

What say you?

|

|

By KULTULZ - 3 Years Ago

|

BEFORE I FORGET ! (and it is becoming common lately) ...

The DIST CURVE should be shown in your WSM under IGN - SPES for the engine. That may help to verify the correct curve and if anything might be frozen.

The machine shop must have just stuck the old plugs in thinking the owner would take care of that. Loose plug(s) may be your compression loss. One way to find out.

As for the secondaries being adjusted incorrectly, usually that is done to try and hide a big cam. Again, settings and adjustments will be found in the WSM under FUEL - SPECS.

Did the seller start a restore and lost interest?

Keep us posted on this thread as you have an interesting project going (and yes, I am jealous).

|

|

By Ted - 3 Years Ago

|

|

WYEDelta (12/13/2023)

Fresh 87 octane gas. Figure this 8.0 CR engine doesn't need 89 or 91 (plus it's 30 cents/gallon cheaper than 91).

You will want to run 91-93 octane gasoline not so much for the octane but for the reduced amount of ethanol in the premium grade versus what you find in the 87 & 89 grades. If you read the small label on the pumps, it will say ‘Contains up to 10% ethanol’. The increased ethanol content in the 87 and 89 octane grades will many times contribute to off idle and hesitation issues. Even with the reduced ethanol content in the premium grades (3-5% in my part of the country), I find it necessary to jet the primary side carburetor jetting up a couple of numbers in the Teapot carbs in which to compensate for the ethanol content. 10% ethanol in the 87 & 89 grades just complicates the problems even more. In checking the ethanol content here, I have found as much as 30% ethanol coming from pumps labeled as 'Contains up to 10% ethanol'. You really don't know what you have until you do an actual ethanol content check.

Another plus side to any fuel with a reduced ethanol content is the shelf life of the fuel is further extended. This is of benefit to those who do not drive their vehicles enough to turn over the fuel in tank every ninety days.

|

|

By KULTULZ - 3 Years Ago

|

|

10% ethanol in the 87 & 89 grades just complicates the problems even more. In checking the ethanol content here, I have found as much as 30% ethanol coming from pumps labeled as 'Contains up to 10% ethanol'. You really don't know what you have until you do an actual ethanol content check.

Another plus side to any fuel with a reduced ethanol content is the shelf life of the fuel is further extended. This is of benefit to those who do not drive their vehicles enough to turn over the fuel in tank every ninety days.

!!! AMEN !!!

And you are not sure of how much water is in the station fuel tanks or what quality fuel you are buying (some distributors may add more ethanol to the mix to save costs). Without EVAP, it is a losing proposition. TOP TIER FUEL has a meaning.

Also, if the car sat with fuel in it, most likely the system is fouled with varnish and rust (incl mechanical pump and carb). When you do a pump volume delivery check and catch it in a glass jar, you will see any rust/sediment and then let it sit for awhile and you will see the water content as it settles.

|

|

By WYEDelta - 3 Years Ago

|

I completed changing out all (8) spark plugs last night with new Autolite 216s gapped at 0.032". The old plugs had all sorts of issues to include (3) with non-compressed plug rings (finger tight) and (2) with less than 0.24" gaps. I thought I had this whipped, so I immediately took her out for a test drive only to face disappointment ---the performance didn't change much. The idle vacuum @450 rpm is still a mere 15" and the engine still stumbles/misses beginning at 3,000rpm. Keep in mind this stumble/miss occurs as I gradually approach 3,000 rpm (I'm not instantaneously pedaling it to to the metal).

So now I find myself facing that old, "is it the ignition vs. carburation" dilemma. A couple of more observations I'd like to share with you:

1. When in Neutral and idling with no load, the engine's rpms will instantly rev from 450 rpm to 4500 - 4700 rpm each time I wrap the accelerator pedal. I can do this 4- 5 times in quick succession and the engine responds flawlessly. Wouldn't this TEND TO INDICATE the ignition system is PROBABLY not the primary issue? As a minimum I believe this allows me to rule out bad points or a bad condenser. However the dizzy curve still remains in question.

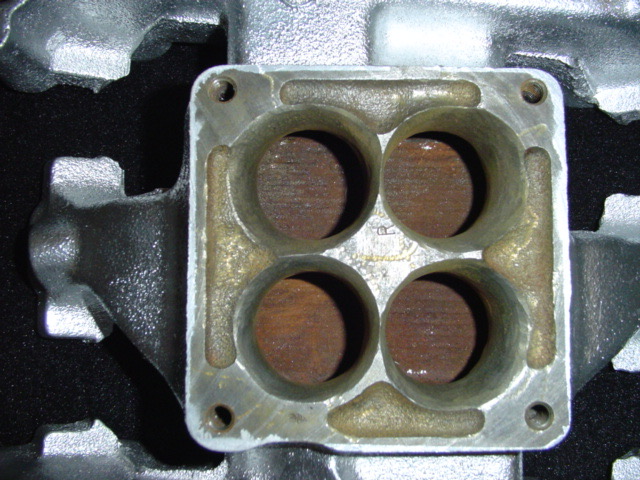

2. Regarding the 2140 Teapot ---I must fess this is my first rodeo with such a carb. It bothers me that the choke tube, which projects up through the base of the carb and into the carb air- cleaner (as a source of clean air), is CONSTANTLY DRAWING VACUUM (to heat the bi-metallic spring in the choke assembly). Is this tube supposed to constantly suck air or should it only draw air during the choke heat-up period? The intake with the Integrated choke housing is also a first for me (see pics below)

Thanks for all of your support on helping me "debug" this engine. The previous owner did his part in getting the engine reassembled and stabbed back into the bay but he unfortunately "ran out of time (88) and funds" to finish sorting her out for reliable performance street use. This has become my job and contribution to our beloved hobby (bedeviled at times too).

|

|

By KULTULZ - 3 Years Ago

|

"Is this tube supposed to constantly suck air or should it only draw air during the choke heat-up period? The intake with the Integrated choke housing is also a first for me (see pics below)."

Yes, continuous draw as it provides fresh inlet air for the choke (stove) operation (vacuum) and as a coolant so as not allow the thermostat coil to over heat). The carb is calibrated to allow for that vacuum draw.

Is this heat related, say does it breakdown at cold operation or when heated (coolant)? The COND may be breaking down with heat. Remember, when you floor it at stand still, there is very little load on the engine.

You're planning on adding an EDEL CARB later? What about the divorced choke style on your present intake. Are you going to use a later intake? You have a DUAL ADV DIST in good health?

You do have TED'S TECH ARTICLE on how to modify that carb to use with a DUAL ADVANCE DIST?

|

|

By WYEDelta - 3 Years Ago

|

Thanks for the explanation on how this style choke mechanism works and confirming the tube continuously draws air.

I’ll try accelerating above 3000 rpm when the engine coolant is “cool” tomorrow morning and report back.

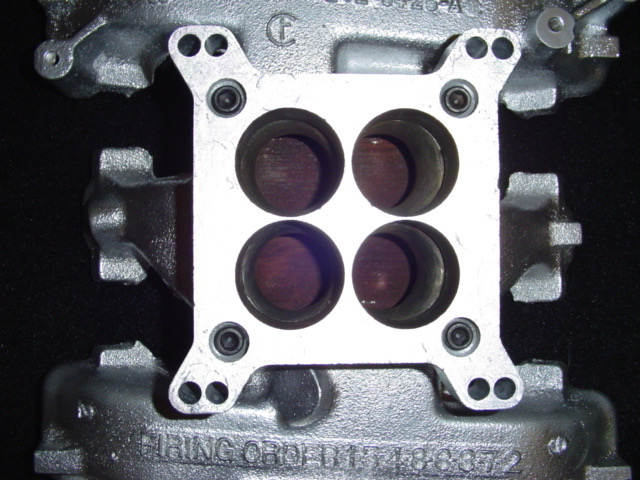

Indeed my plan is to replace the Teapot and existing intake with a 500 cfm Edelbrock AVS2, a ‘57 intake (sans choke tube), and ‘57 dual dizzy. The ‘57 intake has been media blasted, inspected for cracks, painted etc. and the ‘57 dizzy completely rebuilt. I also purchased the correct hex oil pump drive to mate onto the dizzy. I refer to all of these parts as the “‘57 package.”

I’ve read TED’s article and will probably take the intermediate step of modifying the Teapot to enable it to run with the ‘57 intake, dizzy, hex drive BEFORE installing the Edelbrock. If this combo runs good I might even forgo the Teapot/Edelbrock swap to retain the factory look (especially the Factory Air Cleaner). Now that would be neat!

But before embarking on this eventual ‘57 Package swap I think it prudent to first sort out the vacuum and stumble issue and effectively establish the factory engine’s “baseline” performance. Understanding this baseline being necessary to honestly judge the before and after benefits of the swap…

I’m going to stick to this plan for a bit more and continue crossing possible causes off the list. I might find out that this path was a mistake and waste of time e.g. when I finally give up and pull the ‘54 intake off, to swap in the ‘57 intake, I find THE CAUSE —a torn intake gasket!” Nobody ever said the scientific method was painless or cheap. Which reminds me—off I go to pray again that it’s not the rings.

More to come.

|

|

By KULTULZ - 3 Years Ago

|

"I’ve read TED’s article and will probably take the intermediate step of modifying the Teapot to enable it to run with the ‘57 intake, dizzy, hex drive BEFORE installing the Edelbrock. If this combo runs good I might even forgo the Teapot/Edelbrock swap to retain the factory look (especially the Factory Air Cleaner). Now that would be neat"

That to me (personally) would be sweet as it will retain factory install appearance.

You stated previously when first driven, it appeared the TV LINKAGE was not adjusted correctly and then you made some adjustment(s) and she seemed to then shift correctly. The curb idle is dictated by correct throttle linkage adj. as it will allow proper throttle linkage adj. and that is tied directly to TV adj. May be why the curb idle adj. screw won't control curb idle screw to adjust properly. To properly adjust throttle linkage curb idle and TV linkage is a fairly complex adj. that will be found in your LINC WSM. It has to be dead-on as one works off the other.

As for the vacuum reading. It is low (too low) for a stock camshaft (at what altitude do you live?).

1) Need to perform cylinder(s) leak-down test to determine if the rings are good or not. Only GOD knows the quality of the rebuild and what was or not done (and how long it sat before initial fire/break-in).

2) The vacuum gauge also shows possible late valve timing and/or late IGN timing. IMO, the balancer indexing needs to be confirmed with a piston-stop method. If the balancer is indexed correctly, you then proceed further with diagnostics from there.

3) It needs a fuel pressure and delivery volume test performed. Any indication of the carb being gone through? The volume test ( caught in a glass container) will also identify any trash in the fuel system. Again, only GOD knows how long she sat with sour fuel in the tank,

You are aware LINC/MERC used a square bore 4V carb mounting pattern until the LYB was finally replaced? The only true wide mounting pattern carb intake manifold was found on the LYB 332CI HT engine so the EDEL carb will require an adapter.

You say you have a LYB DUAL POINT DIST? Is it FORD or aftermarket? If FORD, can you post the DIST ID NOS.?

|

|

By KULTULZ - 3 Years Ago

|

"I’ll try accelerating above 3000 rpm when the engine coolant is “cool” tomorrow morning and report back."

What you are trying to do here is determine if the tip-in hesitation happens when the engine is cold (choke closed) or warmed (choke open). If no hesitation with the choke closed, it may indicate a lean condition without the choke. If the hesitation happens when the engine is warm, it may indicate a timing problem, bad condenser (when heated) or possible valve float.

Again, the DIST timing curve has to be verified (and this includes the CARB SPARK CONTROL VALVE).

Carry a note pad with you and when it does happen watch the vacuum gauge.

QUESTION - Is Nos. 7 and 8 plugs hard to get to due to the integral PS steering box design and size?

|

|

By WYEDelta - 3 Years Ago

|

"You stated previously when first driven, it appeared the TV LINKAGE was not adjusted correctly and then you made some adjustment(s) and she seemed to then shift correctly. The curb idle is dictated by correct throttle linkage adj. as it will allow proper throttle linkage adj. and that is tied directly to TV adj. May be why the curb idle adj. screw won't control curb idle screw to adjust properly. To properly adjust throttle linkage curb idle and TV linkage is a fairly complex adj. that will be found in your LINC WSM. It has to be dead-on as one works off the other."

Troubleshooting why the curb idle screw has to be completely backed-off the shaft in order to tame the engine down to 450rpm, I completely disconnected the throttle linkage from the Teapot to ensure the TV Linkage assembly wasn't inadvertently pulling on the throttle. No tension, same outcome. Next time I pull the Teapot, which was rebuilt, I'll check the secondary plates aren't open too much ---WSM calls for 0.004" gap using 3/8" shim.

Regarding the Edelbrock carb adapter--Somewhere on this site I read Ted machines the 4V intakes to remove the 4 holes and mills down the carb mounting surface. I might contact him for this service once I've solved some of these other unknowns.

Changing plug 7 was a pain but managed to finally get at it from below the car. Plug 8? There is no Plug 8! Please don't mention Plug 8 again. LOL

(Snaked 8 past the PS box but not before depositing 1.3oz of right hand skin)

|

|

By KULTULZ - 3 Years Ago

|

"Troubleshooting why the curb idle screw has to be completely backed-off the shaft in order to tame the engine down to 450rpm, I completely disconnected the throttle linkage from the Teapot to ensure the TV Linkage assembly wasn't inadvertently pulling on the throttle. No tension, same outcome. Next time I pull the Teapot, which was rebuilt, I'll check the secondary plates aren't open too much ---WSM calls for 0.004" gap using 3/8" shim."

GOOD DIAGNOSIS!

You are ahead of me ...

FORGOT TO MENTION -

Make sure your choke fast idle cam is adjusted correctly and completely falls.

|

|

By KULTULZ - 3 Years Ago

|

"You are aware LINC/MERC used a square bore 4V carb mounting pattern until the LYB was finally replaced? The only true wide mounting pattern carb intake manifold was found on the LYB 332CI HT engine so the EDEL carb will require an adapter."

"Regarding the Edelbrock carb adapter--Somewhere on this site I read Ted machines the 4V intakes to remove the 4 holes and mills down the carb mounting surface. I might contact him for this service once I've solved some of these other unknowns."

I think maybe you are confusing the FYB intake and the LYB intake.

LYB had a very low carb mounting pad on all applications I a$$-u-me for ACL clearance. To mount the EDEL, you will need to use a spacer and an adapter to clear the runner(s). If you do decide to go this route (which is none of my business) make sure to check that the OEM ACL will allow the hood to be shut.

Watch These Two Videos - How to Update the Lincoln 368CI Carburetor 1956 & 1957 Lincoln

https://www.youtube.com/watch?v=N-J4L5K2pF4

https://www.youtube.com/watch?v=pqPqne1Li_c

If I understood you incorrectly, please go easy on me. I am old and very fragile ...

|

|

By Deyomatic - 3 Years Ago

|

I "made" such an adapter for a FYB 9425-A intake a long time ago. I picked up a 1" aluminum carb spacer and gasket matched the mounting holes, drilled and countersunk them so the Allen bolt heads would allow a carburetor to sit flat, and then bolted an Edelbrock 500 on. That woke my 272 up big time from the old 2BBL that was on it.

|

|

By WYEDelta - 3 Years Ago

|

Appreciate the info and videos! on how to properly machining/set-up an '57 intake for a newer pattern 4bbl Edelbrock! Wish I had one of those nifty modern 4BBL 332 Intakes instead. This intake must be a rare duck.

Once ready for the intake swap, I plan on using this adapter:

https://www.speedwaymotors.com/Holley-Edelbrock-to-Carter-WCFB-4-Barrel-Carburetor-Adapter-Plate,5551.html

Speaking of ducks ---rain is finally falling again in Northern CA. Wet conditions forecasted or another 2-3 days. I'll use this downtime to poke around the engine some more in search of the cause of the low vacuum/zero curb idle setting. I'll report out...

|

|

By peeeot - 3 Years Ago

|

I didn’t see any mention of verifying ignition dwell angle in the conversation so far. Dwell is critical to generating spark energy and makes a huge difference in idle quality and spark quality at higher RPMs. If the dwell is too short the spark may be breaking up above 3000rpm, especially if the mixture is on the lean side (harder to ignite). Revving without load wouldn’t necessary show this. Setting dwell is one of the first things I do in a tune-up. If you change it, it will affect your timing as well.

Also, the Loadomatic “black box” can be demystified somewhat if you tee into the distributor vacuum line and bring it into the car with a gauge. Then, you can observe the vacuum reading the distributor “sees” at various speeds and loads. With that data in mind, you can apply vacuum with a hand vacuum pump directly to the distributor and observe the corresponding advance using a timing tape and normal timing light or a dial-back timing light. This way you can get a pretty good picture of what your total advance is on the road.

Regarding the choke stove air intake: how strong does it suck? I agree that it should always be drawing a small amount of air, but usually they draw more air when the engine is cold and less once the choke has fully opened. You can rule out a concern here by temporarily disconnecting the choke, setting it fully open, and plugging the vacuum source to the choke.

Secondary throttle plates that are too far open, or poor alignment/seating of any of the throttle plates in the carburetor could cause some of your idle-related symptoms.

Beautiful car by the way!

|

|

By KULTULZ - 3 Years Ago

|

LOAD-O-MATIC THEORY - http://m571.com/yblock/loadomatic.htm

Back in the day, the procedure was to remove the DIST and set it up on a SUN MACHINE w/ MANOMETER. I would think it was rarely done as if the TECH stuck in a fresh set of points and condenser (flat-rate) and it ran well around the block she was good to go.

If once re-installed and there was a performance problem, you would go to the vacuum supply side diagnostics.

|

|

By KULTULZ - 3 Years Ago

|

"Secondary throttle plates that are too far open, or poor alignment/seating of any of the throttle plates in the carburetor could cause some of your idle-related symptoms."

If the secondaries are indeed adjusted in this manner, it was trying to hide something,

|

|

By WYEDelta - 3 Years Ago

|

Back in the garage tonight after Christmas holidays and finally completed the Cranking Compression test on a warm engine.

Results:

Cyl1---100 psi

Cyl 2 ---105 psi

Cyl 3 ---107 psi

Cyl 4 --102 psi

Cyl 5 ---112 psi

Cyl 6 --106 psi

Cyl 7 --100 psi

Cyl 8 ---104 psi

The good news is a fairly tight range of 100 -112 psi but the Lincoln Shop manual calls for 135psi +- 10. "Y"ikes!

What do you guys think? Are these below spec cranking compression values the cause of the low vacuum at idle (14-15" vs factory spec of 18-21")? The numbers seem to indicate the rings weren't installed correctly or didn't seat well.

Tomorrow I'm going to pull the intake and check/pray for a bad gasket.

One of the other things I noticed while under the car is that the single exhaust muffler (followed by two old resonators) is very old and rusty. So I'm also disconnecting the exhaust tomorrow morning on the Hail Mary chance that the exhaust is restricted.

|

|

By KULTULZ - 3 Years Ago

|

Compression Test

The compression test works by spinning the engine through its cycles with the compression tester in place of the spark plug in the cylinder. As the engine makes pressure, the gauge will move and hold to the highest point read by the gauge. Take measurements for all cylinders and then compare the readings to each other. A healthy engine will have a range of no more than 10 percent variance between the readings.Hot vs. Cold test: An engine that has been brought up to temperature will be better sealed and give a more accurate reading for the normal temperature range of the engine; however, a cold engine will give you the worst-case scenario because the metal has not expanded. Also, engine compression readings can vary depending on altitude and other factors, so it is more important to compare the cylinders to each other rather than the assumed compression number. If you find one or more cylinders are below the 10 percent range of the others, squirt a little oil down the cylinders and try again. If the pressure comes up significantly, the problem may be worn piston rings. If the pressure does not come up on retest, the issue may be with the valves or the head gaskets.

(or late valve and/or ignition timing).

Leak-down Test

The leak-down test measures how well the cylinder is sealing. This is done by inserting compressed air (around 100 psi) into the cylinder at TDC and then measuring how much is lost from the seals (there will always be some). This is done by two gauges on the leak-down tester.

SOURCE - https://www.motortrend.com/how-to/engine-diagnosis-leakdown-compression-test/

A restrictive exhaust should have shown on the vacuum gauge test.

|

|

By WYEDelta - 3 Years Ago

|

Thanks for sharing the MotorTrend article. It states a 9:1 compression engine should develop about 9 x 14.7= 132.3 psi (at seal level). Factory built '54 317ci's had a 8:1 compression ratio therefore using MT's math should develop about 8 x 14.7 = 117.6 psi which is closer to my values (100-112 psi) and lower than the book's 135 +- 10 psi spec. Curious difference.

I do suspect my engine was relatively "cold" when I performed the test. I had warmed it up for about 10 minutes before beginning the chore of extracting the plugs. Pulling all (8) takes 45 minutes thanks to interplay of the frame, cast iron exhausts, inner fenders, oil filter housing, power steering pump, big hands, smallish and stiff uncooperative tools, weak magnetic hanging lights, etc. Felt like hell froze over by the time #8 fell out of the socket hitting my forehead and solidifying an adamant belief that "hot" engines must bump-up cold values by at least 5-10 psi!

So maybe my compression results aren't too bad after all...? Does anyone else have similar "Y" engine cranking compression numbers you can share?

I don't readily have access to a leak-down tester. I'm toying around the idea of buying one but not before removing the exhaust pipe. I awoke this morning to a forehead swelling with the conviction that a restricted exhaust could contribute to low vacuum and lack of engine acceleration beyond 3,000 rpm. Backing off some lash on the valves is second on the list followed by removing the intake manifold. Further down the list is pulling the timing chain cover and inspecting for a worn chain.

More to come....

|

|

By charliemccraney - 3 Years Ago

|

A compression test is performed with the throttle wide open. If the throttle was left closed, the results will be lower than expected.

|

|

By WYEDelta - 3 Years Ago

|

Good catch! I'll stab a long screw driver down the throat of the Teapot and try again. It's raining and 48F outside ---engine is much colder so it won't be an apple to apple comparison.

|

|

By miker - 3 Years Ago

|

Disconnect the return springs and wire the throttle open. Sticking a screwdriver down and wedging a butterfly is not in your best interest.

I wouldn’t get too hung up on the vacuum reading being a bit low if you get everything else solved and it runs well. I’ve had a lot of worn engines that ran ok and went a lot more miles. Including a couple I just kept adding oil to.

|

|

By WYEDelta - 3 Years Ago

|

PROGRESS!

Spent all day on the car.

1. Re-ran the compression tests on a cold engine with throttle wide open ---basically same results as yesterday's warm engine. Pressures ranged from 102--114 psi. Reinstalled the plugs.

2. Temporarily removed the primary muffler. Took car for spin ---the crazy loud engine still sputtered at 2800-3000 rpm and wouldn't rev past 3100 rpm.

3. Next I decided to change out the condenser in the dizzy even though it's brand new as are the points, rotor, cap, wires, etc. The web is full of stories about unreliable modern condensers... Easy change, take her for a spin, and BINGO!!!! On separate accelerations the engine flawlessly rev'd to 3400, 3600, 3800, and finally 4200 rpm! I can't believe it ---a brand new basic, static, round tin foiled $7 part had needlessly awoken gnawing thoughts of engine rebuilding gymnastics. What a major relief!

I'll reinstall the muffler tomorrow and run it again. If it continues to rev OK I'll probably go ahead and begin the '57 Intake and Centrifugal dizzy swap. The low vacuum condition at idle persists---hopefully, in a sense, I'll find problems with the intake gasket(s).

More to come.

|

|

By miker - 3 Years Ago

|

|

Outstanding. Glad the problem finally turned up. Damn parts with no quality controls.

|