|

Author

|

Message

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.8K

|

To reiterate what Charlie mentions, changes to the head gasket thickness and any milling of the decks and/or heads will not have a bearing on the valve train rocker arm geometry on engines that use shaft mounted rockers. You can install 1” thick head gaskets and the valve train geometry will basically go unchanged. Granted the pushrod length will be affected but the actual geometry will not. Valve lift and the valve stem lengths, if changed, will affect the geometry though as the rocker arm pivot point in relation to the valve stem tip and rocker sweep is then being altered. I have found that biassing the rocker arm geometry to the high side is advantageous to low lift air flow but that will be at some expense to valve guide wear and/or longevity.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

DANIEL TINDER

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 1.7K,

Visits: 154.2K

|

“The High Side” (?). Does that that mean longer valve stems, or longer pushrods? (sorry if I’m a bit slow on the uptake).

6 VOLTS/POS. GRD. NW INDIANA

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 1.2K,

Visits: 1.8K

|

Shimming stands?

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: 2 days ago

Posts: 6.1K,

Visits: 443.0K

|

DANIEL TINDER (11/20/2023)

“The High Side” (?). Does that that mean longer valve stems, or longer pushrods? (sorry if I’m a bit slow on the uptake). That means to err on the side of having the stand positioned slightly higher than ideal.

Lawrenceville, GA

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: 2 days ago

Posts: 6.1K,

Visits: 443.0K

|

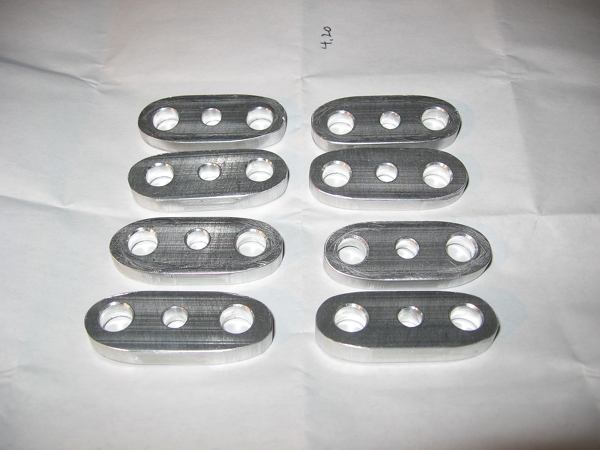

If the stands need to be higher, you need to shim them. Here is an example of shins i have made.

Lawrenceville, GA

|

|

|

|

|

KULTULZ

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 1.8K,

Visits: 306.3K

|

... i wish i would learn to keep my big mouth shut ... Either TED or JOHN should have a TECH ARTICLE written on PROPER VALVE-TRAIN GEOMETRY and how to get there. You would start (IMO) with adj. checking push-rod(s) to find proper rocker arm/valve stem contact/sweep and go from there wouldn't you? I have always wondered why FYB push-rod length(s) differences (between model years) was never really discussed, especially between differing rocker arm ratios.

____________________________

|

|

|

|

|

paul2748

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 3.7K,

Visits: 497.8K

|

Ted did an article on this subject some time ago. I do not have a reference to it.

54 Victoria 312; 48 Ford Conv 302, 56 Bird 312

Forever Ford

Midland Park, NJ

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: 2 days ago

Posts: 1.2K,

Visits: 1.8K

|

Nice job on the shims, Charlie, but they look a bit thick. Have you made others?

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: 2 days ago

Posts: 6.1K,

Visits: 443.0K

|

Here's a link to Ted's article https://www.eatonbalancing.com/2007/12/10/rocker-arm-geometry/When I did mine, I also came across a technique that I think is called mid-lift. I can't find the article now. That method states that at mid lift, if you drew an imaginary line from the valve tip (or roller axis for roller tipped rocker arms) to the center of the shaft, that line should form a 90° angle with the valve centerline. It makes sense as that would ensure that rocker tip travel across the valve tip is minimal. As such, I set the valve at mid lift (cam lift x rocker ratio - lash) / 2 and was able to make a rough measurement of how much the stand height would have to change in order to achieve that 90° angle. If you took very careful measurements, you can probably calculate it exactly. That gave me a god starting point. A checking pushrod is advised for this simply because the required pushrod length will change with a change in stand height and the rocker ratio changes as the depth of the lash adjusting screw is changed. The checking pushrod allows you to keep the adjuster screw locked down so that the variables can be kept to a minimum. It also helps you figure out the length of pushrod you need to order once the geometry is where you want it.

Lawrenceville, GA

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: 2 days ago

Posts: 6.1K,

Visits: 443.0K

|

55blacktie (11/20/2023)

Nice job on the shims, Charlie, but they look a bit thick. Have you made others? They are as thick as necessary. Required thickness will vary from one build to another. I have made others. Here's the easiest way I've found to make them without a machine shop. 3/4" wide strip and a lot of care a patience with a belt sander although if the required dimension is significantly different than standard metal thicknesses, i suggest a machine shop.

Lawrenceville, GA

|

|

|

|