|

Author

|

Message

|

|

Florida_Phil

|

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.2K,

Visits: 285.6K

|

I ran into this issue when I installed the Casco PVC kit on my Tbird. The PVC valve must fit all the way into the valley pan or you will have a vacumn leak. As mentioned by others, the pan has a threaded piece welded in where the road draft tube screws down. In time, this threaded piece gets pulled up by the tightening of the screw so that the valve will not seat all the way. As Casco suggests you use a socket and a hammer (small) to drive the threaded piece back down. It did bother me at first to beat on the pan in this way. With a little nudging, I was able to fully seat the valve.

|

|

|

|

|

DANIEL TINDER

|

|

|

Group: Forum Members

Last Active: 11 hours ago

Posts: 1.7K,

Visits: 154.2K

|

charliemccraney (11/2/2021)

Here is a pic of the underside of a valley pan with the baffle. The circular bit with the 3 dimples toward the bottom left is that threaded fitting.  OK, now I remember. Forget the ‘threaded rod’ idea, since if the fitting ever comes loose, it couldn’t be retrieved without removing the pan.

6 VOLTS/POS. GRD. NW INDIANA

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: 8 hours ago

Posts: 6.1K,

Visits: 442.8K

|

You can try a baffled grommet. I use those for the breather and PCV Valve in my valve covers. They work. Take a look at the bottom of the grommet to make sure it has an opening. I've had one or two that had a thin bit of rubber where it should have been open and had to trim that with an xacto knife. It's just a minor defect from manufacture.. https://www.summitracing.com/search/part-type/valve-cover-grommets/universal/yes/baffled-grommet/yes?PageSize=100&SortBy=Default&SortOrder=Ascending

Lawrenceville, GA

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.2K,

Visits: 1.8K

|

I slightly bent my OEM valley pan while removing it/w both heads in place. Although I'm sure it can be straightened, I bought an Aftermarket Ace polished, cast-aluminum pan. It has recesses to allow for installation/removal without removing a head. Although it has the hole for pcv valve, there is no baffle. Ace leaves it up to owner/builder to make and install a baffle that works with whatever pcv valve is used. I'm happy with its quality and price. I think I first read about Ace products on this site.

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: 8 hours ago

Posts: 6.1K,

Visits: 442.8K

|

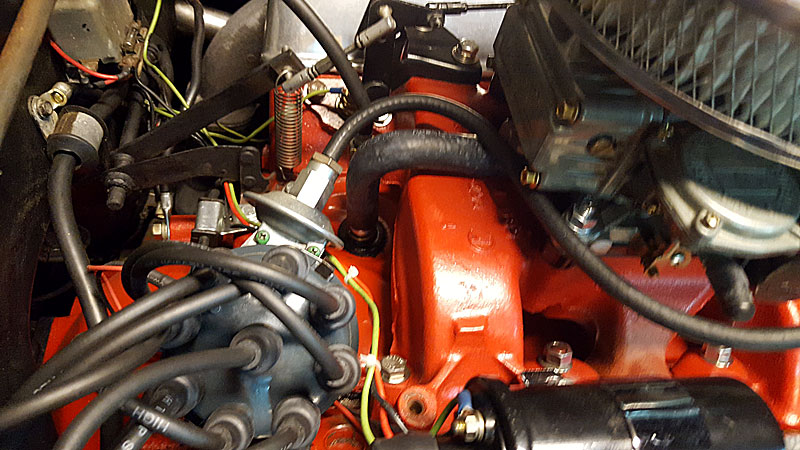

Here is a pic of the underside of a valley pan with the baffle. The circular bit with the 3 dimples toward the bottom left is that threaded fitting.

Lawrenceville, GA

|

|

|

|

|

DANIEL TINDER

|

|

|

Group: Forum Members

Last Active: 11 hours ago

Posts: 1.7K,

Visits: 154.2K

|

Obviously, CASCO’s instructions suggest the mentioned ‘socket’ should somehow surround (?) the threaded fitting, so only the baffle is depressed. But, if you want to be certain nothing amiss should occur while pounding (sloppy/partial spot weld?) and thus totally avoid the grief of removing & replacing the pan should the fitting come loose and drop, you could always buy a long threaded rod at the hardware store, screw it into the fitting, use a thin hollow pipe to to surround it, and then bang on that.

I suppose viewing a clear photo of an OEM valley pan’s underside structure before the attempt would help though, since I seem to remember the baffle has a hole in it, but not specifically where/how the fitting is attached.

6 VOLTS/POS. GRD. NW INDIANA

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.2K,

Visits: 1.8K

|

Thanks for jarring my memory DLK. Yes, the road draft tube cap (if you will) that attaches to the VP, has a long screw that goes into the deflection plate/baffle. Assuming he doesn't put the RDT back into service, the threads in the deflection plate shouldn't be an issue. I'll pass on the 1-3" vacuum at the dip stick.

|

|

|

|

|

DryLakesRacer

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.7K,

Visits: 340.1K

|

My experience there are threads but they are on the bottom of the lower deflection plate and the PCV doesn’t hit it. I would test fit the valve into the grommet before putting it in the valley cover and use some lube on it. I believe there are offset grommets for the aluminum valley covers. I also seen the draft tube cut off just behind the mount, a washer welded on and a PCV installed in the washer with a smaller grommet. When installed there should be 1-3” of vacuum at idle in the crankcase. I tested mine at the dip stick and sealed the oil fill tube.

|

|

|

|

|

charliemccraney

|

|

|

Group: Moderators

Last Active: 8 hours ago

Posts: 6.1K,

Visits: 442.8K

|

For the valley pan with the baffle, there is a thread fitting spot welded to the baffle, for mounting the road draft tube (or in the case of later engines, a PCV hose fitting). That threaded fitting is probably the part getting in the way of the push in style PCV valve. The options are: Remove the pan in order to remove that threaded fitting. If that is the only issue, I suggest welding it back in place but upside down so that factory parts could be reinstalled, only requiring a longer screw. Take a chance and hammer the clearance needed. Make an adapter fitting which will allow installation of the PCV valve and avoid altering original parts..

Lawrenceville, GA

|

|

|

|

|

55blacktie

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 1.2K,

Visits: 1.8K

|

DT, was your conversion on a 55-57 Tbird? I don't recall any part of the road draft tube remaining on the valley pan. A Rubber seal is inserted into the hole, and the pcv valve is inserted into the seal. There are no female threads that I'm aware of, unless the hole, itself, is threaded. I'm speaking from memory, but it's a member of another forum who is actually doing the conversion; I'm just trying to help. Considering what's involved in registering on this site, I didn't suggest he post here himself.

|

|

|

|