|

Group: Administrators

Last Active: 4 days ago

Posts: 7.5K,

Visits: 205.9K

|

PF Arcand (3/26/2021)

Ted: Thanks for the clarification, interesting. However, isn't it somewhat unusual for a factory to use the same Cam timing for a high performance naturally aspirated engine & again for a supercharged engine?Not unusual considering the rush to put the supercharger program into production. From what I can discern from the Ford memos, Ford was using what it currently had on hand to speed up putting the supercharger program in place before the Daytona Beach Speed Trials beginning February 3, 1957.Based on the Ford memo dated November 26, 1956, the proposal was for the supercharged engines to use the standard ‘D’ code camshaft. This is reconfirmed in the Ford memo dated November 28, 1956 where there is no mention of a different camshaft being required in the engine assembly. The memo dated December 6, 1956 does however mention that the first 100 engines would have a ‘race type’ camshaft but those engines would also incorporate the ‘A’ type blower. No mention as to what camshaft would be provided with the engines using the ‘B’ type blower. Another memo also dated December 6, 1956 restates that a production camshaft would be used in both the racing and passenger car kits due to making those engines more drivable or customer acceptable while also stating that maximum racing performance with the supercharger would not be available with that particular camshaft.The factory ‘D’ code camshaft with its 113° lobe centers was an all around good camshaft suitable for use in 4V, 8V, and supercharger applications. As stated above, Ford was aware of the ‘racing’ performance being diminished with the use of the production camshaft. While it’s known that having a wider lobe centerline does increase the potential power output for a boosted application by reducing the amount of blow through during the overlap cycle, a reduced lobe centerline does help an engines low end torque attributes in those instances where they are being used for normal driving and boost is not being generated. In the case of the supercharger application using the 110° lobe centerline camshaft, the increase in duration still offsets any performance deficiency created by the reduced camshaft lobe centerlines. From an engineering perspective and attempting to maintain good idle characteristics but wanting an increase in overall performance, then the lobe centerline can decreased to make for a longer duration camshaft under the same exhaust opening, intake closing curve.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 3.3K,

Visits: 238.8K

|

Ted: Thanks for the clarification, interesting. However, isn't it somewhat unusual for a factory to use the same Cam timing for a high performance naturally aspirated engine & again for a supercharged engine?

Paul

|

|

Group: Administrators

Last Active: 4 days ago

Posts: 7.5K,

Visits: 205.9K

|

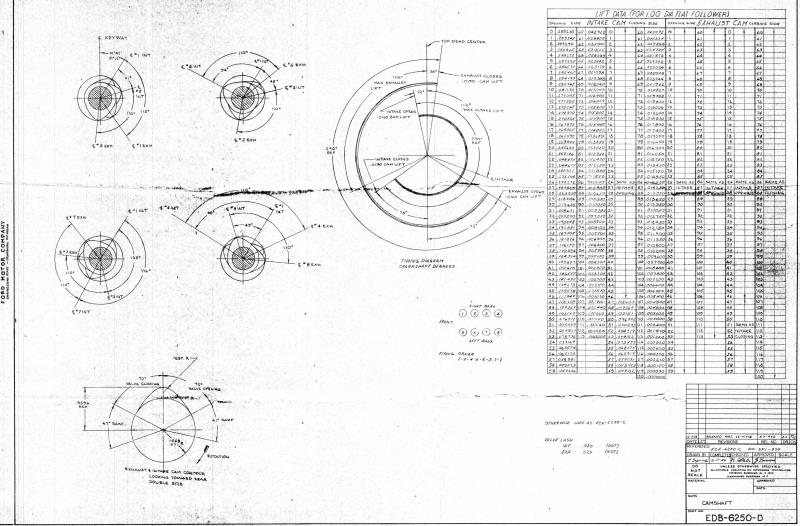

What Cliff has posted is the FoMoCo engineering drawing for the EDB-6250-D camshaft. This is supposedly the camshaft used in the 285HP and 340HP engines. The original drawing is dated 8-11-1956 while there is also a revision on it dated 12-5-1956. Some deciphering of the specs shows it being ground on 110° lobe centers, 0.290” lobe lift, and having ~232° at 0.050” lifter rise. The intake and exhaust lobes are symmetrical (the same). The tappet clearance is shown to be 0.020” hot for the intakes and 0.025” hot for the exhausts.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 3.3K,

Visits: 238.8K

|

Cliff: I also saw it in the previous posting, unfortunately even when enlarged I can't really read it.. So.. ?

Paul

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 890,

Visits: 13.6K

|

Look at this

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 3.3K,

Visits: 238.8K

|

I've started a new post, because the current one on this site re the illusive Camshaft spec's goes back "11 years" now & also deals with the "F" code shaft.. In issue # 122, Jan-Feb. 2021, of Y-Block magazine, was a copy of a letter to a Mr. John Wilson, originally dated Dec. 11 1957. It was from Iskendarian Racing Cams & signed by their then Shop Foreman Sig Erson. The original inquiry was not included, but Sig recommended that Wilson upgrade beyond his initial enquiry to the "E-2 Revmaster Track", which had intake specs of 17/59 & exhaust of 13/63. However, I suspect there was a mistake here on his part, as he listed the valve lift as .410" on both intake & exhaust. (that was less than the std. "D" code cam) But, more importantly, he listed the Cam as having a "stock Ford" part number. That # was ECZ 6250-C.. I've long suspected that the upgraded E code cam was the E-2 & I believe this confirms it..

Paul

|