|

Group: Forum Members

Last Active: 10 days ago

Posts: 1.8K,

Visits: 306.4K

|

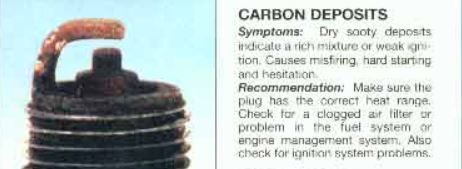

You said the plugs were wet, with fuel I am guessing? Any carbon on the plugs? That and with the fumes, it sounds like the fuel curve is not correct and/or the IGN is not hot enough to fire properly. Just thinking here ...  When running there is a small amount of water coming out that heat tube hole in the intake manifold. If you rev the engine it blows a little more water out of that hole. The water does not smell like antifreeze, actually it has no smell to it that I can tell. The amount is small but I think it is more than just condensation build-up.

As previously stated, water is a by-product of combustion. Is there any exhaust leak noise @ the cross-over tube? Do you live in a humid area?

You stated that she runs better when cold with choke. That indicates a lean mixture (to me) and the smell afterwards (not a heavy fuel smell) also indicates lean. As for the wet plugs, are they the correct heat range and is the IGN SYS actually producing enough volt to fire them? All quality new wires, etc?

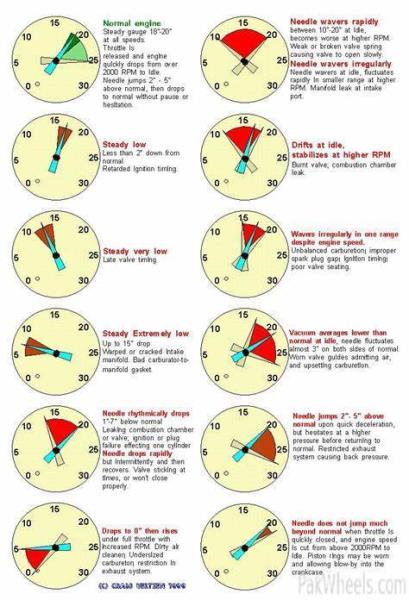

That small movement of the gauge hand may indicate (to me) an IGN misfire or a lean misfire.

____________________________

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 892,

Visits: 13.6K

|

May have an internal crack or rust hole (small) in the intake manifold.

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 43,

Visits: 152

|

Absolutely not! The entire car has been restored including a new tank, new lines, new fuel pump, new fuel filter and new carb!

John

|

|

Group: Moderators

Last Active: 1 hour ago

Posts: 3.7K,

Visits: 323.4K

|

Do you still have that 50 year old gas in the tank, or even a part of that old gas in it? If so, you need to get rid of that stuff before you can effectively diagnose the engine's running behaviour.

John - "The Hoosier Hurricane"

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 43,

Visits: 152

|

I spent some more time with it today. The miss is much worse when it is cold (even with choke engaged and fast idle) but seemed better today then ever after fully warmed up.

I have more vacuum info. It was sitting pretty stead at 19 at idle with a bounce once in a while between 18 3/4 to 19.

Opening throttle to about 2000rpm and the vacuum drops to about 15 but will come back up to 19 pretty quickly. Drop back to idle and it jumps to 24ish and then returns quickly to about 19.

I adjusted the carb a bit and I was able to get 20Hg at idle. Still pretty steady with an occasional bump of 1/4.

It maybe has a total of 4-5 hours of run time since the rebuild (and about 40 miles). I'm wondering if I just need to run it more and let it break in.

One other thing. It does not smoke or have any visible exhaust coming out of it but it makes me smell like exhaust fumes anytime I run it. And if I run it in my large barn with the big door open it will set off the carbon monoxide alarm in a short period (1 minute?). Just seems smellier than I remember older engines.

John

|

|

Group: Forum Members

Last Active: 10 days ago

Posts: 1.8K,

Visits: 306.4K

|

It runs pretty good at idle (450rpm in gear) but as you increase engine speed there is a miss that gets more noticeable as speed increases. Manifold vacuum is about 19 at idle but there is a slight bounce on the needle.

I put on an electric choke cap and removed the heat riser tube that was connected for the old cap.[/quote]

____________________________

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 43,

Visits: 152

|

Quick background:

This engine is in a 1959 Edsel Ranger. The car was running and being used when the previous owner passed away in 1970. The car sat in a shed for 40+ years, then outside for a couple (shed fell down) and then I got it with the engine stuck.

I have the stock 2 barrel intake on it.

I'm currently running a new 2150 Chinese knockoff carb but I've had the same miss with the original carb, just called a Ford 2 Barrel in the shop manual but it's a 2100 (rebuilt but couldn't get it to idle well) and a swap meet Autolite 2100 again rebuilt. The miss is present with any of the carbs and with all of them if I pull the plugs after running they are all fuel wet except #8.

I'm running the original distributor set at 8 degree BTC at idle, vacuum advance disconnected. With it disconnected the timing will increase to about 20 on the mechanical and with it connected to 30ish. It's hard to tell exactly as my crank pulley only has 0, 10, and 20 marks but it's not past 35 degrees.

I've tried two different sets of new points, condensors, coils and plugs. The plug wires are new and test ok for resistance and continuity. I've tried an internal resistor coil (bypassing the external) and one that requires the external resistor. I've tried the original resistor (tested good) and a new one. I also replaced the wire from the coil to the the points. The miss is present in all cases.

It seems to be an ignition problem to me as the compression is good. Just looking for anything here - I put a new timing gear set in and I followed the shop manual for correct indexing and I counted the chain pins several times but suppose I was off one tooth, would the engine still start quickly and run good at an idle? Is there a way to verify the valve timing is correct using the crank pulley and looking at valve positions? Anyway to check without pulling the timing chain cover?

I did what I would call a red neck valve job. I hand lapped the valves, cleaned everything really well and put it back together with new seals, springs, keepers, and rocker shafts. The valve guides all felt good to me, no play, smooth movement of the valves in the guides and again the compression test is good - 140-145 on every cylinder.

I'm surprised by this miss and a bit stumped.

John

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.9K

|

You don’t mention which intake, carburetor, or distributor you have. Those details would be helpful. The higher rpm miss you mention could be as simple as too much ignition advance when there is no load on the engine. The vacuum portion of the distributor would be contributing heavily towards that. Disconnecting the vacuum advance line and bringing the rpm up while in neutral would help to confirm this. If that’s the case, then that would be normal.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 236,

Visits: 237.6K

|

oldcarmark (3/25/2021)

Have You looked at that Tube as a possible Vacuum Leak? Normally that Tube passes through the Intake Manifold from side to side. If its rusted out inside the Manifold it will give You a Vacuum Leak. I sealed the Passage on mine by tapping for 5/16 Bolts. The Water is probably Condensation. The tube runs thru the exhaust cross over, it will not cause a vacuum leak, it would be an exhaust leak It's likely the water coming out of the tube is condensation from the cracked tube causing an exhaust leak, ever watch how much water comes out the tail pipes

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 3.7K,

Visits: 32.7K

|

Have You looked at that Tube as a possible Vacuum Leak? Normally that Tube passes through the Intake Manifold from side to side. If its rusted out inside the Manifold it will give You a Vacuum Leak. I sealed the Passage on mine by tapping for 5/16 Bolts. The Water is probably Condensation.

|