|

By jrappl - 5 Years Ago

|

I’ve got a freshly rebuilt 292, 0.030 over, new crank, rod and cam bearings (original cam), new pistons and rings, new timing gear set, new oil, fuel and water pumps, valves hand lapped with new springs, rocker arm shafts, and valve stem seals. It runs with compression of 140-145 at each cylinder.

It runs pretty good at idle (450rpm in gear) but as you increase engine speed there is a miss that gets more noticeable as speed increases. Manifold vacuum is about 19 at idle but there is a slight bounce on the needle.

I put on an electric choke cap and removed the heat riser tube that was connected for the old cap.

When running there is a small amount of water coming out that heat tube hole in the intake manifold. If you rev the engine it blows a little more water out of that hole. The water does not smell like antifreeze, actually it has no smell to it that I can tell. The amount is small but I think it is more than just condensation build-up.

The intake seemed to fit nicely and I used new gaskets and torqued to specs.

What can be causing this water leak? Is it common to y-block and is there a fix? Is there something in the exhaust crossover I need to check, intake gasket or something else?

|

|

By oldcarmark - 5 Years Ago

|

|

Have You looked at that Tube as a possible Vacuum Leak? Normally that Tube passes through the Intake Manifold from side to side. If its rusted out inside the Manifold it will give You a Vacuum Leak. I sealed the Passage on mine by tapping for 5/16 Bolts. The Water is probably Condensation.

|

|

By kevink1955 - 5 Years Ago

|

oldcarmark (3/25/2021)

Have You looked at that Tube as a possible Vacuum Leak? Normally that Tube passes through the Intake Manifold from side to side. If its rusted out inside the Manifold it will give You a Vacuum Leak. I sealed the Passage on mine by tapping for 5/16 Bolts. The Water is probably Condensation.

The tube runs thru the exhaust cross over, it will not cause a vacuum leak, it would be an exhaust leak

It's likely the water coming out of the tube is condensation from the cracked tube causing an exhaust leak, ever watch how much water comes out the tail pipes

|

|

By Ted - 5 Years Ago

|

You don’t mention which intake, carburetor, or distributor you have. Those details would be helpful. The higher rpm miss you mention could be as simple as too much ignition advance when there is no load on the engine. The vacuum portion of the distributor would be contributing heavily towards that. Disconnecting the vacuum advance line and bringing the rpm up while in neutral would help to confirm this. If that’s the case, then that would be normal.

|

|

By jrappl - 5 Years Ago

|

Quick background:

This engine is in a 1959 Edsel Ranger. The car was running and being used when the previous owner passed away in 1970. The car sat in a shed for 40+ years, then outside for a couple (shed fell down) and then I got it with the engine stuck.

I have the stock 2 barrel intake on it.

I'm currently running a new 2150 Chinese knockoff carb but I've had the same miss with the original carb, just called a Ford 2 Barrel in the shop manual but it's a 2100 (rebuilt but couldn't get it to idle well) and a swap meet Autolite 2100 again rebuilt. The miss is present with any of the carbs and with all of them if I pull the plugs after running they are all fuel wet except #8.

I'm running the original distributor set at 8 degree BTC at idle, vacuum advance disconnected. With it disconnected the timing will increase to about 20 on the mechanical and with it connected to 30ish. It's hard to tell exactly as my crank pulley only has 0, 10, and 20 marks but it's not past 35 degrees.

I've tried two different sets of new points, condensors, coils and plugs. The plug wires are new and test ok for resistance and continuity. I've tried an internal resistor coil (bypassing the external) and one that requires the external resistor. I've tried the original resistor (tested good) and a new one. I also replaced the wire from the coil to the the points. The miss is present in all cases.

It seems to be an ignition problem to me as the compression is good. Just looking for anything here - I put a new timing gear set in and I followed the shop manual for correct indexing and I counted the chain pins several times but suppose I was off one tooth, would the engine still start quickly and run good at an idle? Is there a way to verify the valve timing is correct using the crank pulley and looking at valve positions? Anyway to check without pulling the timing chain cover?

I did what I would call a red neck valve job. I hand lapped the valves, cleaned everything really well and put it back together with new seals, springs, keepers, and rocker shafts. The valve guides all felt good to me, no play, smooth movement of the valves in the guides and again the compression test is good - 140-145 on every cylinder.

I'm surprised by this miss and a bit stumped.

|

|

By KULTULZ - 5 Years Ago

|

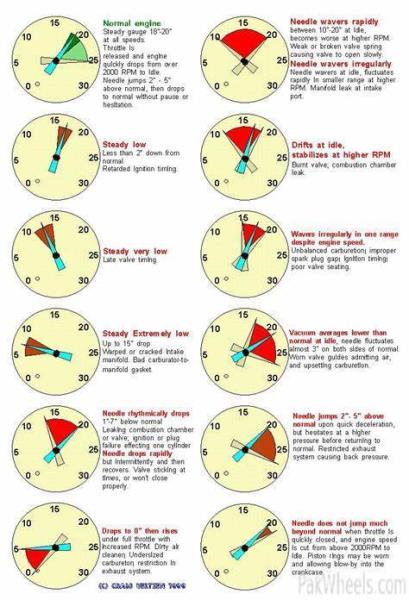

It runs pretty good at idle (450rpm in gear) but as you increase engine speed there is a miss that gets more noticeable as speed increases. Manifold vacuum is about 19 at idle but there is a slight bounce on the needle.

I put on an electric choke cap and removed the heat riser tube that was connected for the old cap.[/quote]

|

|

By jrappl - 5 Years Ago

|

I spent some more time with it today. The miss is much worse when it is cold (even with choke engaged and fast idle) but seemed better today then ever after fully warmed up.

I have more vacuum info. It was sitting pretty stead at 19 at idle with a bounce once in a while between 18 3/4 to 19.

Opening throttle to about 2000rpm and the vacuum drops to about 15 but will come back up to 19 pretty quickly. Drop back to idle and it jumps to 24ish and then returns quickly to about 19.

I adjusted the carb a bit and I was able to get 20Hg at idle. Still pretty steady with an occasional bump of 1/4.

It maybe has a total of 4-5 hours of run time since the rebuild (and about 40 miles). I'm wondering if I just need to run it more and let it break in.

One other thing. It does not smoke or have any visible exhaust coming out of it but it makes me smell like exhaust fumes anytime I run it. And if I run it in my large barn with the big door open it will set off the carbon monoxide alarm in a short period (1 minute?). Just seems smellier than I remember older engines.

|

|

By Hoosier Hurricane - 5 Years Ago

|

|

Do you still have that 50 year old gas in the tank, or even a part of that old gas in it? If so, you need to get rid of that stuff before you can effectively diagnose the engine's running behaviour.

|

|

By jrappl - 5 Years Ago

|

Absolutely not! The entire car has been restored including a new tank, new lines, new fuel pump, new fuel filter and new carb!

|

|

By Cliff - 5 Years Ago

|

|

May have an internal crack or rust hole (small) in the intake manifold.

|

|

By KULTULZ - 5 Years Ago

|

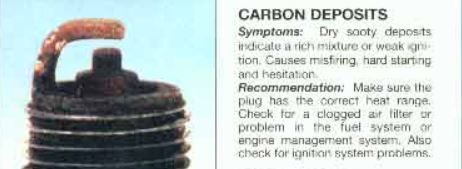

You said the plugs were wet, with fuel I am guessing? Any carbon on the plugs? That and with the fumes, it sounds like the fuel curve is not correct and/or the IGN is not hot enough to fire properly. Just thinking here ...

When running there is a small amount of water coming out that heat tube hole in the intake manifold. If you rev the engine it blows a little more water out of that hole. The water does not smell like antifreeze, actually it has no smell to it that I can tell. The amount is small but I think it is more than just condensation build-up.

As previously stated, water is a by-product of combustion. Is there any exhaust leak noise @ the cross-over tube? Do you live in a humid area?

You stated that she runs better when cold with choke. That indicates a lean mixture (to me) and the smell afterwards (not a heavy fuel smell) also indicates lean. As for the wet plugs, are they the correct heat range and is the IGN SYS actually producing enough volt to fire them? All quality new wires, etc?

That small movement of the gauge hand may indicate (to me) an IGN misfire or a lean misfire.

|

|

By Ted - 5 Years Ago

|

In addition to the other suggestions, I'll recommend putting the distributor in a distributor machine and insure all is well within that. Bent shaft, worn points lobe, excessive end play, or worn bushings are just some of the things to look for.

|

|

By Tedster - 5 Years Ago

|

jrappl (3/26/2021)

Quick background: This engine is in a 1959 Edsel Ranger. Is there a way to verify the valve timing is correct using the crank pulley and looking at valve positions? Anyway to check without pulling the timing chain cover?

Yes.

|

|

By KULTULZ - 5 Years Ago

|

|

Is there a way to verify the valve timing is correct using the crank pulley and looking at valve positions? Anyway to check without pulling the timing chain cover?

The easiest and most accurate for a runner engine (IMO) is a piston stop - https://www.wikihow.com/Find-Your-Engine%27s-Top-Dead-Center-(TDC)

What year is the intake (CASTING ID NOS)? FORD began going to the exhaust manifold style choke stove in 59.

And like Ted mentioned, have the DIST checked. Do you know what type breaker plate(s) it has, one or two piece pivot?

|

|

By Ted - 5 Years Ago

|

|

jrappl (3/26/2021)

...It seems to be an ignition problem to me as the compression is good. Just looking for anything here - I put a new timing gear set in and I followed the shop manual for correct indexing and I counted the chain pins several times but suppose I was off one tooth, would the engine still start quickly and run good at an idle? Is there a way to verify the valve timing is correct using the crank pulley and looking at valve positions? Anyway to check without pulling the timing chain cover?

If your engine is running smoothly at 450 rpm, it’s doubtful that the camshaft timing is a problem.

Here’s a quick way to double check the cam timing without any tools other than a wrench or breaker bar in which to turn over the engine using the damper bolt..

- Remove a valve cover.

- The spark plugs being removed will allow the engine to be turned over more easily.

- With a straight edge on the #1 or #6 intake and exhaust valve retainers and the valves being closed, insure that the valves are level with each other when they are both closed. #1 and #6 share the same TDC on the damper so it does not matter which cylinder is used for the following check.

- Rotate the engine so that the #1 or #6 cylinder has both the valves at overlap. The exhaust valve will be closing and the intake valve will be opening. With that same straight edge that was used earlier, position the opening and closing of the valves so that the retainers are level once again but this time with both valves open.

- Assuming the damper has not slipped, the TDC mark on the damper should be aligned closely to the pointer. In a perfect world and on an engine that just had the camshaft degreed in, the damper should be showing 4-6° advanced. But at this point you’ll be happy with anything close to the TDC mark.

- If you find that the damper is 20+° off from where it should be, then double check that the damper ring has not slipped. While this holds true for the standard car and pickup/truck dampers, the Thunderbird damper timing marks are on the pulley and cannot slip.

|

|

By DryLakesRacer - 5 Years Ago

|

|

At the end of the above post by Ted is why when I had my damper rebuilt from Damper Dude I filed a TDC notch on the pulley. An easy way to see if it has moved.

|

|

By KULTULZ - 5 Years Ago

|

It used to be ... in a GALAXIE far, far away...

There was a HP damper re-builder years ago that after rebuilding the damper would fully index the outer ring to allow easier timing and/or valve adjustments. He would also pin the outer ring to the hub to prevent any future ring movement. But that would reduce some of the balancers purpose I would suppose for a driver.

|

|

By jrappl - 5 Years Ago

|

Thanks for the info.

First, I'll say that currently, after running the car some more and doing some carb adjustments using a vacuum gauge it is running ok. Still has a slight miss especially when cold but it seems better when warmed up. Still there but much less noticeable. It starts well, runs pretty good at low idle (450-475) in gear, accelerates without any hesitation and has good power - maybe I'm just being really picky now or it needs more break-in time.

I believe the distributor is original (59 Edsel) single plate and it feels tight. With the current point settings the dwell is pretty steady (26-27) through all engine speeds. Ignition timing seems to be working correctly also.

I started with Standard Motor ignition stuff - points, condenser, cap, rotor, Autolite 45 plugs, name brand plug wires and a generic 12v internal resistor coil (bypassed external).

After seeing the wet plugs I changed to Blue Streak points (all copper), condenser and coil (external resistor with a new resistor) and Autolite 46 plugs.

Right after the new ignition parts I thought the miss was just as bad but it is much better now.

I'll just run it a bit and see how it goes.

|

|

By KULTULZ - 5 Years Ago

|

|

After seeing the wet plugs I changed to Blue Streak points (all copper), condenser and coil (external resistor with a new resistor) and Autolite 46 plugs.

AUTOLITE 46 (BF-82) is the correct heat range for that engine. 45 is too cold (BF-42)

|

|

By blocky - 5 Years Ago

|

|

hi all just a quick question about noisey tappets! history first,new motor with all new USA valve train.new cam bearings and cam, new tappets and push rods, and new rocker arms and shafts and new valves and springs and of course full reco heads, you get the picture.can not get no. 6 to be quiet for very long before adjusting yet again, all the others are behaving themselves.i have had some horrible thoughts about what i may be in for very soon.the engine runs fine on 8 pots under revs and also at idle, it just will not shut up (noisey tappets) any thoughts may help thank you

|

|

By Ted - 5 Years Ago

|

blocky (3/31/2021)

hi all just a quick question about noisey tappets! history first,new motor with all new USA valve train.new cam bearings and cam, new tappets and push rods, and new rocker arms and shafts and new valves and springs and of course full reco heads, you get the picture.can not get no. 6 to be quiet for very long before adjusting yet again, all the others are behaving themselves.i have had some horrible thoughts about what i may be in for very soon.the engine runs fine on 8 pots under revs and also at idle, it just will not shut up (noisey tappets) any thoughts may help thank you

Blocky. Your question will be better answered if started as a new thread or posting. Being asked at the end of another unrelated thread will not get as many responses.

|