This is probably a question that only Ted can answer

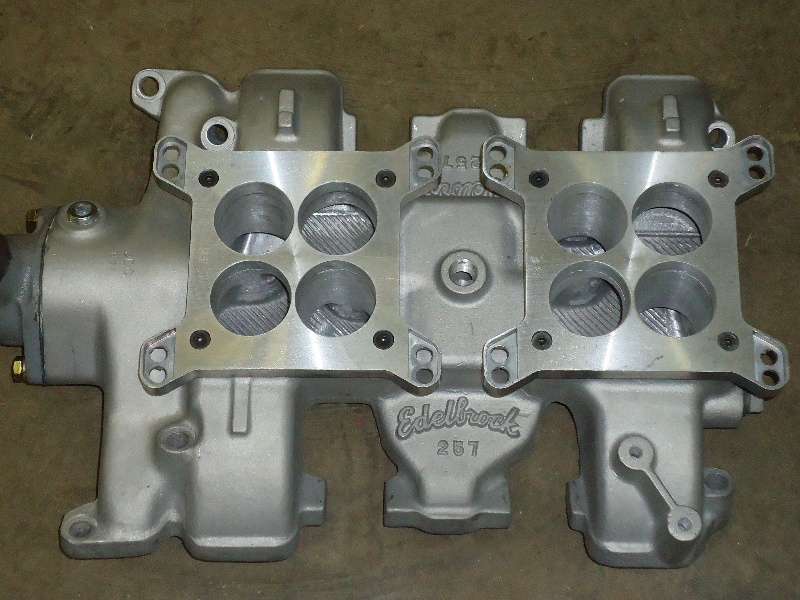

I am modifying my edelbrock 257 for my project 292 and using adapters for the holley flange style carbs like this one from Joe Craine . I plan on going with a FITECH or holley dual injection setup.

My question is if the manifold was opened up straight down from the adapters into the manifold or if the holes were tapered? from the pic it looks to be machined from the holley adapter opening of 1 3/4" straight down? cant tell for sure?