Hi guys,

I might have messed up here...

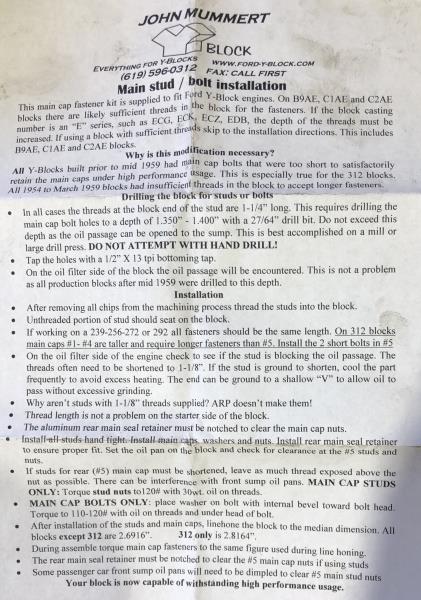

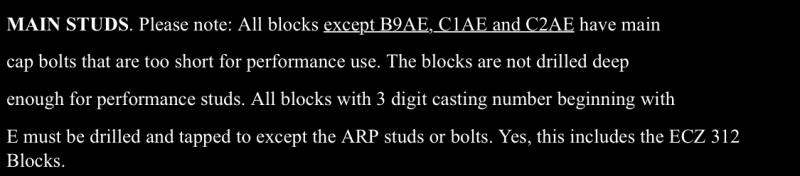

I have some ARP main cap studs for the 272 y block (1956 ECG from truck) and I’m wondering if I can install these in in my engine? Or do I have to drill the block holes deeper to use these studs as the instruction say. My y block isn’t high performance and I was hoping to be able to install them straight out of the pack. I opted for these rather then bolts because I thought they would be better, but if I have to drill the block holes deeper then it’s too far out of my league.

I measured the stud in the main cap compared to the factory bolt and the studs should work, the thread on the nut side is getting close to bottoming out on the thread but with the washers it’s looks like it will be ok. I understand by not drilling the block that the studs won’t have their full clamping potential.

Anyway, are they stillI usable on the 272?

Instructions

I Missed this from Mummert’s website🤦♂️

Thanks, Dennis.

56 F100 - 272 Y Block

NSW, Australia.