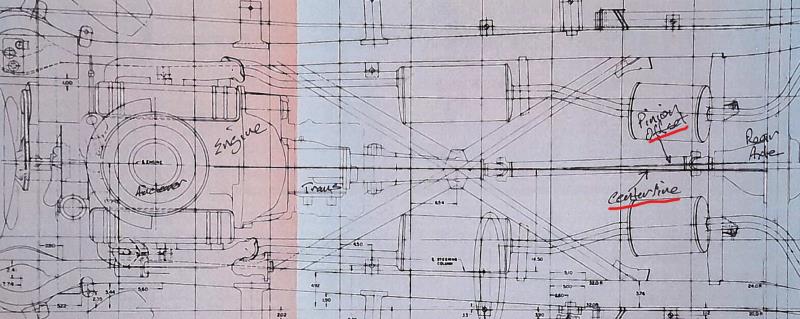

I am planning to purchase a Currie or Quick Performance rear axle. I have attached a Ford Engineering drawing of the '55 Thunderbird chassis which shows the pinion offset which moves it from being aligned with the crank and trans, everything that I have read indicates offset is used when engines are mounted off center to keep the drivetrain in a straight line. Apparently the 1955 Thunderbird was built with the drive shaft out of alignment. Currie suggests building with zero offset.

Anyone have these numbers documented?

1. Wheel mount surface, outside of brake face to outside of brake face:

(I have come with 57.5”)

2. Pinon offset, typically to passenger side:

(I get approx1.75” to passenger side. Have any of you had an axle built with no offset? I want to be sure I am not overlooking some need for the offset.)

3. Center of perch to center of perch, also note if it is above or below the tube center line:

(Drawing indicates 42.187) (I get 1 3/16” down)

4. Pinion angle:

(I have come up with 5 deg down)

.150 Stroked Y-Block:327.25 ci @ >1hp per ci