For those who may be new or just starting with-AN fittings, some recommendations.

For hard tubing, get a good flare tool. For a long time, I used a cheap 37 degree tool. If you've seen or used the typical cheap 45 degree tool, then you'll know what I'm talking about. It does the job, sometimes, if you're careful and is a pita to use and requires extra work to make a serviceable flare. I finally got something better, Allstar Performance ALL11016. It's about $100 now and there are others which look very similar but are closer to $200 with the only difference appearing to be a more comfortable handle for the yoke. It's also made in USA. This produces a much nicer looking flare and requires no extra tools to use. If you are doing more than a few flares, a tool like this is what you want, at the very least.

For comparison, this is what I had been using. I had to use channel locks or an adjustable wrench to get the wing nuts tight enough that there is no gap between the bars. The flares produced were not so great, with the od of the tubing needing to be filed to remove burs created by the clamping of the bars and the id of the tube at the flare being not quite round and reduced diameter. What it boils down to is more work for less quality. You really don't want this tube unless you just don't have the budget, but let's be real, if you're using -AN fittings, you're not on such a tight budget.

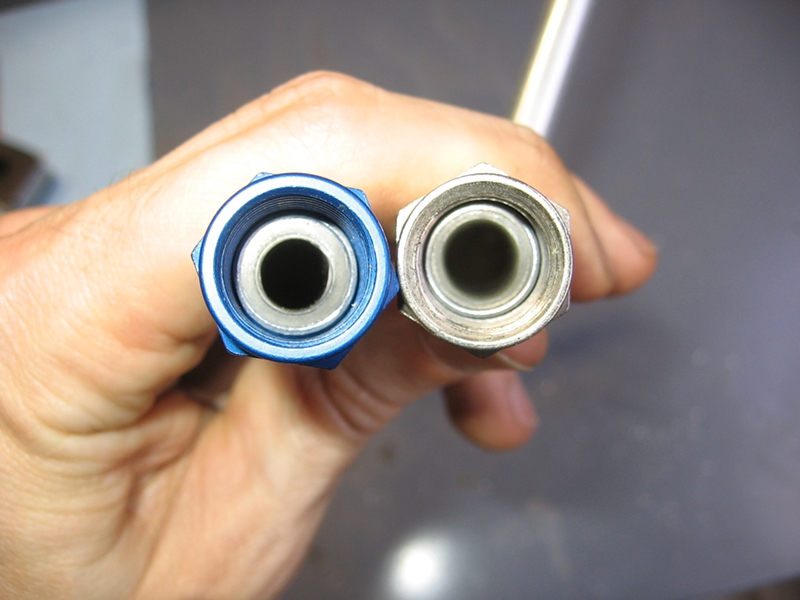

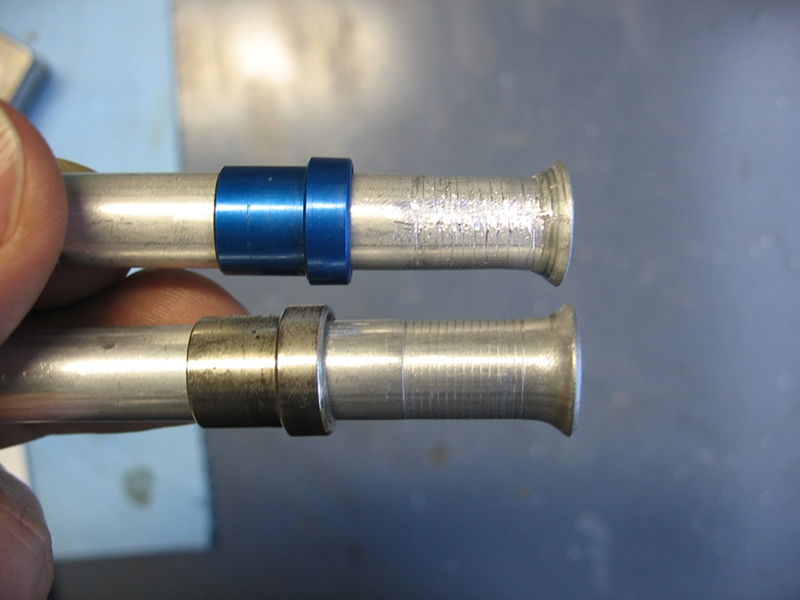

Flare comparison:

The next tools are not a requirement, but nice to have, -AN Wrenches. Regular wrenches work fine. Benefits of -AN wrenches include:

-They are also aluminum so they do not mark aluminum fittings as easily.

-They are marked according to tubing size, not the actual measurement between flats, like standard wrenches. This makes it easier for a novice to pick the right wrench but it only works on for the -AN end of a fitting. For instance a pipe adapter fitting might use a wrench size on the pipe end that falls between the -AN wrenches or the flats to take an inline filter apart may be somewhere between -AN sizes. This is where an adjustable wrench is useful, actually two adjustable wrenches would be good in some instances.

I find that they grip the fitting better and have a better feel than normal wrenches in my opinion and may only be a matter of opinion.

The adjustable wrench is Jegs brand. The set is Summit brand. Both advertised to be made in USA. Summit also offer the adjustable wrench in two sizes.

Next is a tool for general tubing fabrication, a deburr tool. This one is sold by Eastwood and deburrs the inner and outer diameters of the tubing. Very handy but again, not necessary as most tubing cutters have a tool built in to deburr the id and the od can be handled with sand paper or a file.

Lawrenceville, GA