|

Group: Forum Members

Last Active: Last Month

Posts: 785,

Visits: 113.4K

|

Your observation is correct. However, I did NOT drill and tap the hole. It's been a few years ago but I recall not having the proper size bolt for that application and had to select a bolt from the hardware store. It was probably metric. In any case, the hole and thread is stock from Holley. This 5.0 Ford installation allowed for a long bolt but the possibilities are many. Hope this helps, JEFF...............

64F100 57FAIRLANE500

|

|

Group: Forum Members

Last Active: Last Year

Posts: 1.7K,

Visits: 102.7K

|

Personally - I use the "Ozark sidehill" method - a replacement length of screw long enuff to stick out the bottom of the base plate - and be turned with needle nose pliers! Most four barrel manifolds have clearance at that particular spot under the mounting flange (funny thing). At first I tried the proper method, replacing with a bit longer socket head set screw - but fitting the tiny wrench on a hot shaking engine was often painful.

Steve Metzger Tucson, Arizona

|

|

Group: Forum Members

Last Active: Last Month

Posts: 3.7K,

Visits: 32.6K

|

That's something Holley and others could do from the Factory. Would make the Carbs much easier to fine Tune.. That looks like a Spring with 2 Washers and a Locknut under the Base? What size did U tap it for?

|

|

Group: Forum Members

Last Active: Last Month

Posts: 785,

Visits: 113.4K

|

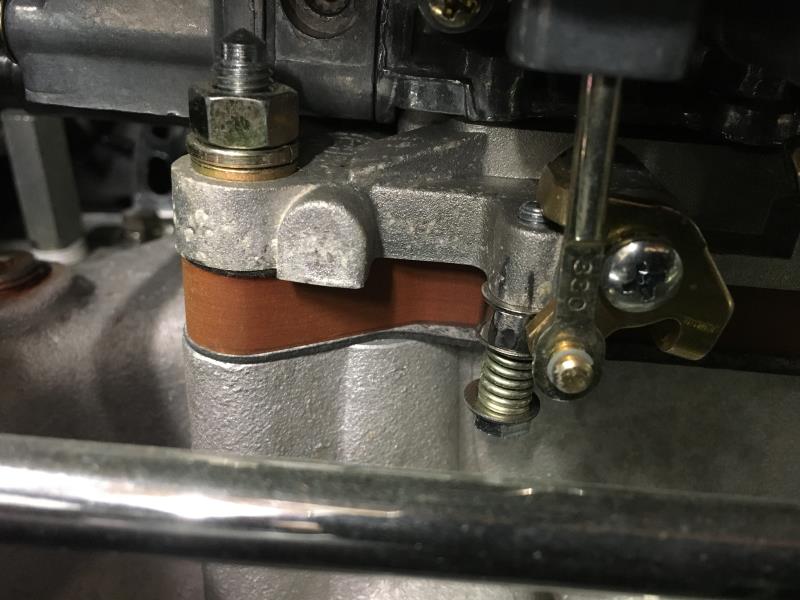

This is the pic of the modified secondary throttle shaft stop on a 302 build. Simple and worked well.  64F100 57FAIRLANE500

64F100 57FAIRLANE500

|

|

Group: Forum Members

Last Active: Last Month

Posts: 785,

Visits: 113.4K

|

Carbs are getting more expensive but it appears the throttle body EFI units are coming down in price and getting better/more user friendly. Everyone I met who went that route claims they will never go back to a carb again. If my carb wasn't working so well I think I would consider the EFI route. So as not to steer this thread off track, good luck with finding the problem and please keep us unformed, JEFF.................

64F100 57FAIRLANE500

|

|

Group: Forum Members

Last Active: Last Month

Posts: 3.7K,

Visits: 32.6K

|

Thanks for the suggestions Jeff. I had similar thoughts regarding the Air Bleeds after doing some reading online. I am no Expert either so any Suggestions are appreciated. I will have another look at it. Maybe something is plugged. If these Carbs weren't so Expensive new I would have gone that Route .Everytime I look at new Ones the Price has gone up. Popular Carbs these 390's.

|

|

Group: Forum Members

Last Active: Last Month

Posts: 785,

Visits: 113.4K

|

I posted that pic thinking you probably would end up drilling and taping. The pic I really wanted to post I couldn't. It was simply a screw with a spring and a jamb nut which made it very easy to adjust on the fly. As far as dying when in drive, it may be a lean-out condition. OK when no load but when some load is applied, the mixture may be too lean to support it. I'm going to make a couple guesses here and please keep in mind I'm not a carburetor expert by any means. If it is a lean-out condition, it could be caused by a missing idle air bleed. May run at idle but with the added load in drive there would be too much air at that point possibly causing a lean-out. Or, a partially plugged idle feed restrictor may possibly have a similar affect. That is, can pass enough fuel at idle but not enough when in drive? It's unlikely both of the above mentioned jets would be missing/plugged at the same time but it may just take one to do this. I believe you did state the idle mixture adjustments were responding properly. It was mentioned in a previous post that a used/hand-me-down carb is of unknown pedigree so if, for example, any one of the numerous gaskets is not registering with ALL the ports, trouble will follow. I believe you mentioned main jets but they should have no affect on idle. At idle, it would be the idle feed restrictors controling fuel flow which you won't be able to change, only verify they are open, in your case. Hope this will help and sorry for my lack of computer skills regarding not being able to post that other picture, JEFF.....................................

64F100 57FAIRLANE500

|

|

Group: Forum Members

Last Active: Last Month

Posts: 3.7K,

Visits: 32.6K

|

Thanks for the Picture Jeff. Most Holleys have that also. Problem with the One I have is the Screw does not go through. The Hole is capped with a little Bump which I assume is the setting Holley has decided should work. The Screw won't back out so my other option is to drill it out and retap. I am going to try bending the Tab slightly and see if that works. I had the same problem with my Car initially as far as stalling in Drive. I never had to use the Secondary adjustment but I think the One I am working on may have to. Runs nice in park and then hardly at all in Drive.

|

|

Group: Forum Members

Last Active: Last Year

Posts: 1.7K,

Visits: 102.7K

|

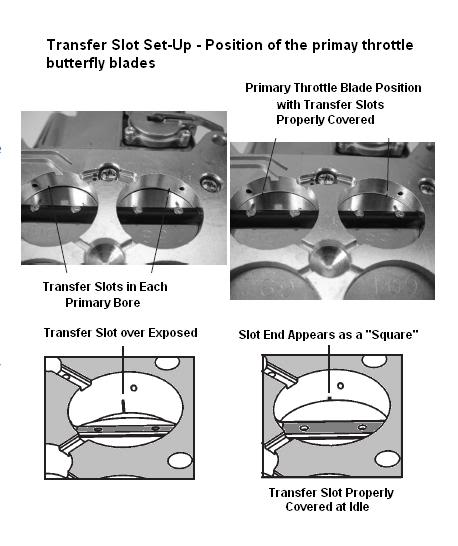

Mark, this is the illustration I referred to earlier - out of the old Street Demon instructions. Shows the carb inverted and setting the primary throttle position (with choke off) so that the transfer slot is appearing as a "square". The suggestion has always worked well so long as the rest of the Holley design carb is in good working condition. I believe you are already aware of this - but there are many that are not.  For "noobies": The adjustment discussed above a couple of notes (opening the secondary blades a bit) is required when placing the primary blade in this position - and then maintaining that position - won't deliver sufficient air to keep the engine at idle. We are talking about a warm engine with the choke "OFF".

Steve Metzger Tucson, Arizona

|

|

Group: Forum Members

Last Active: Last Month

Posts: 785,

Visits: 113.4K

|

The site would not allow me to post the secondary adjuster with the spring and lock nut due to improper format? Sorry, I'll try again later.

64F100 57FAIRLANE500

|