I had been skeptical of that slot because I know when you do stuff like that, you make a dual plane manifold less of a dual plane manifold. Then several years ago, Ted did some testing suggesting a pretty decent gain between 2500 and 3500 rpm, right where a street engine will be able to make use of it, without affecting any other aspect of the output significantly.

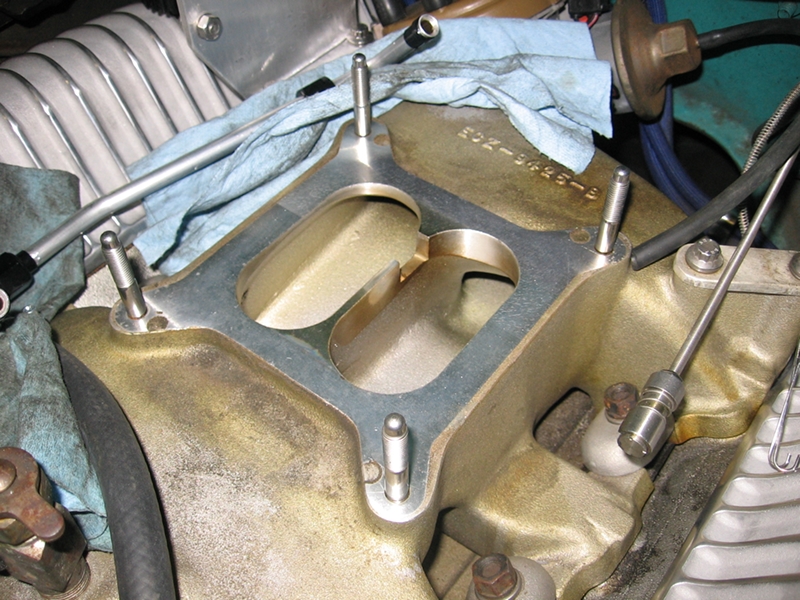

http://www.eatonbalancing.com/2014/11/23/intake-manifold-plenum-slots/So I had it filled. I also took some time to smooth the transition from the carb to the ports and plenum and make the ports a closer match to the heads and smooth some bumps that I could feel in a couple ports. I didn't get too aggressive with this because the intake flows better than I currently need it to out of the box. So just smoothing and port matching, trying to err on having the intake ports a little smaller than the heads - don't know that that is the best choice, it just seems that tumbling over a ledge will be better than hitting a wall. I'm sure a lot can still be improved there, if need be and hopefully I didn't remove too much to ruin anything.

I also cut a 4-hole gasket into a 2-oval gasket to properly isolate each plane as much as possible. There is still some crossover going on with the carburetor, but you can't do much about that.

After all this, there is a subtle yet noticeable improvement starting at about 2000 rpm and I gained 1" hg, for 17" which is great considering that the cam is the repop of a blower cam that Mummert produced a decade ago.

It cost me $50 to have that slot welded. If you have one of these and it is in a street vehicle, it's a good $50 to spend.

Lawrenceville, GA