|

Group: Forum Members

Last Active: 2 hours ago

Posts: 157,

Visits: 6.8K

|

In an effort to adjust the transfer slots on my holley 4581 4 barrel to make them square shaped , I think I have totally goofed everything up. On examination, the slots appeared to be elongated to about an eighth inch and the only way I could see to shorten the slots to a square was to wind out the fast idle cam screw (manual choke) which I did until the screw and spring backed out all the way and fell out on the floor. I still needed more adjustment so I picked a long flat screwdriver and loosened the brass screws on the round primary throttle plates and was surprised at how much the plates would slide out of adjustment with me not knowing how to readjust them properly I am hoping someone can refer me to a source that illustrates how to seat and adjust the throttle plates properly and also what setting the fast idle cam should be set to. And finally if I can get everything back to where it was, How DO you adjust the transfer slot? Edelbrock is starting to sound pretty good. Funny with several well meaning people advising me and having sorted through numerous holley videos on line , I could find nothing telling me how to adjust the slot, only that it needed to be square shaped. Thanks George

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 3.7K,

Visits: 32.7K

|

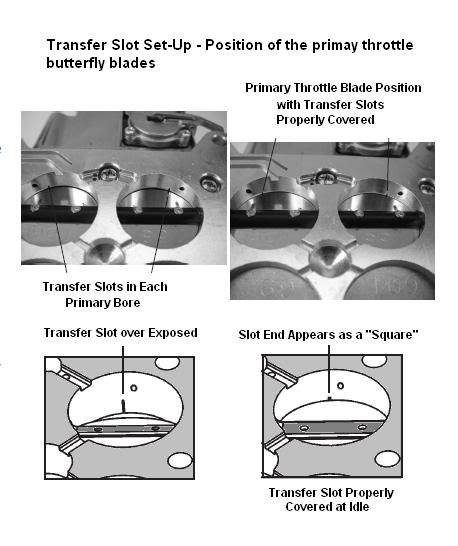

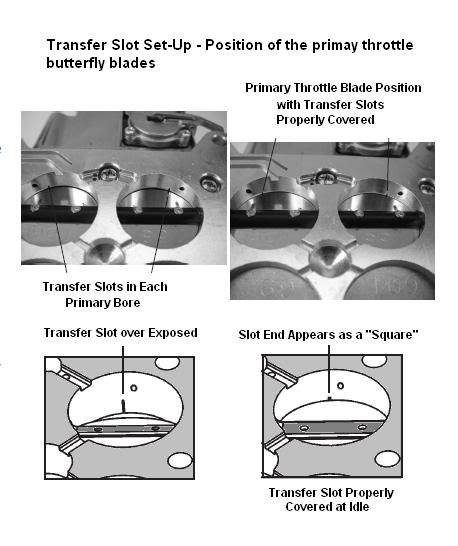

The adjustment is made using the Idle speed Screw on the side where the Throttle linkage hooks up. Turn the Carb over and slowly back off the Idle screw until the Transfer slot BELOW the Throttle Plate looks like a Square. You do need to be sure the Choke fast Idle screw is off and not holding the Throttle plate open.

|

|

Group: Forum Members

Last Active: 6 hours ago

Posts: 774,

Visits: 22.7K

|

On Holleys, if you have loosened the throttle blades, then you need to turn the carb upside down, remove the linkage to the secondary arm(both vacuum diaphragm arm and secondary linkage), back off the primary blades to fully close them, back off the secondary blades to fully close them, and then loosen all eight throttle screws slightly so that the butterflies will move to center themselves in the venturi with the shafts fully closed. Now tighten gently the eight brass screws and open the butterflies by hand to see if they will open to a full 90* wide open throttle, and then close them again. Do they fully close? If so then tighten them as much as you can by hand, and check again for WOT, and if they open and close smoothly, you can start your adjustments. With the vacuum linkage installed again, the secondary throttle blades should be open enough to see .020" of the idle transfer slot showing. You can adjust this by bending the linkage arm, or a set screw if the baseplate has that option. Next install the secondary linkage arm to the throttle arm and you will probably only open the primary just enough to keep the butterflies from sticking(a very tiny amount). Adjust the idle quality screws, and set the idle speed now with the vacuum disconnected and plugged to the distributor. IF the idle speed is too high, close the secondary plate a tiny bit(.018") slot showing, and try again. Idle speed is/should be controlled by the secondary blade position, not the primary as is commonly thought. Hopefully this will get you back to a good idle quality. Joe-JDC

JDC

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.7K,

Visits: 102.7K

|

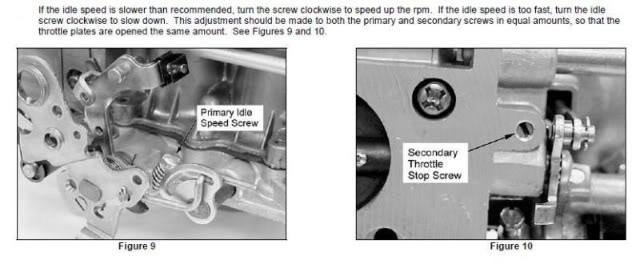

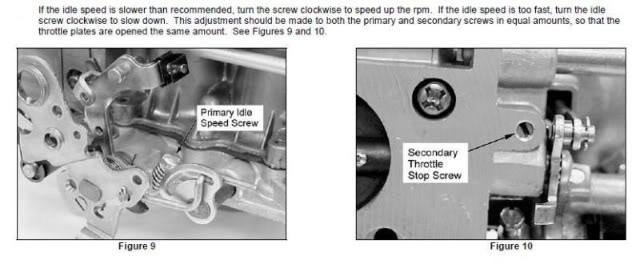

This illustration is lifted from old Demon and /or Holley literature....... Shows the approximately "square" opening seen at the transfer slot when the carb is inverted and the throttle is stopped on its "primary idle speed screw". No fast idle engaged - wound out of the way.  If you can't get the engine to idle with the blade in this position (don't move it) - then you open the secondary a bit to add some intake air.  The secondary throttle stop screw is also only seen with the carb off the engine and inverted. In the base plate directly under the vacuum secondary operating pot. Some have refitted this screw with a socket style set screw - I usually put a cut off section of screw in there that protrudes below the base - and adjust it by grabbing with needle nose pliers. Several avenues are available - whatever works is the rule. On all of my manifolds - this area is open, the casting stops short of interfering with the protruding screw.

Steve Metzger Tucson, Arizona

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 884,

Visits: 14.3K

|

Does opening the secondary introduce air only or will fuel be in the mix also? The reason I'm asking is my car is a little rich at idle. I set the idle mixture for max vacuum as recommended but it's still a tad rich.

Durham Missouri

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.7K,

Visits: 102.7K

|

If you have a "spare" carb to examine (I have several junkers laying around myself) - the two secondary bores have a hole in them that functions as a fixed orifice "fuel leak". When you open the rear blades - it adds some air to go with that fuel. That "leak" keeps replenishing fresh fuel into the secondary bowl if nothing else.

The plan is to put the idle in balance - using small tweaks of the mixture screws - and setting the hot idle speed with the secondary blades. You do this while leaving the primary at the "sweet spot" on the transfer slot.

Doing these initial (and final) tune tweaks requires that you have the engine warm - and the ignition timing on its marks. Having an engine set on the factory initial timing - then moving it up to 10º will require some tuning - so get things where you want them - and go from there.

Steve Metzger Tucson, Arizona

|

|

Group: Forum Members

Last Active: 2 hours ago

Posts: 157,

Visits: 6.8K

|

Thanks Joe. Please keep in mind that I'm just a parts changer and an Autolite 2100 is what I'm used to. I think the mistake I made on the Holley was that I focused only on the primary (front bores ) when I tried to adjust the slot and paid no attention to the secondary . From what I have heard and read, Holly strongly advises not to mess with the setting underneath for the secondary throttle. I only want a smooth idling stock running 292 . I'm going to remove the carb and loosed all 8 shaft screws and try to reseat all 4 blade as you said, then with the throttle held closed, I'll check the slot. Hopefully, I can do this without splitting the baseplate from the main body. Do you the default setting for the fast idle cam screw? manual choke

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 1.7K,

Visits: 102.7K

|

I can't believe Holley would try to dissuade you from using the secondary stop screw - their rep showed me the trick in '69....... Beats the alternative - drilling holes in the primary blades!!!!!!!!!! That's a Holley bulletin picture I posted above.

Steve Metzger Tucson, Arizona

|

|

Group: Forum Members

Last Active: 2 Years Ago

Posts: 927,

Visits: 190.0K

|

GREENBIRD56 (7/26/2017)

This illustration is lifted from old Demon and /or Holley literature....... Shows the approximately "square" opening seen at the transfer slot when the carb is inverted and the throttle is stopped on its "primary idle speed screw". No fast idle engaged - wound out of the way.  If you can't get the engine to idle with the blade in this position (don't move it) - then you open the secondary a bit to add some intake air.  The secondary throttle stop screw is also only seen with the carb off the engine and inverted. In the base plate directly under the vacuum secondary operating pot. Some have refitted this screw with a socket style set screw - I usually put a cut off section of screw in there that protrudes below the base - and adjust it by grabbing with needle nose pliers. Several avenues are available - whatever works is the rule. On all of my manifolds - this area is open, the casting stops short of interfering with the protruding screw.

|

|

Group: Forum Members

Last Active: 2 hours ago

Posts: 157,

Visits: 6.8K

|

Thanks for the illustration. After looking at it I went outside and pulled my carb off, turned it upside down, set the manual choke wide open, backed off the fast idle screw and observed that the primary idle slots were square shaped with the idle screw against the stop. Question: I then examined the secondary butterflies and could not even see the tops of the slots. I did press down gently on the secondary butterflies and felt a little slack and could barely see the tops of the slots when i pushed down. I did also notice the tiny recessed flat head screw that is the adjustor. Know, while I have the carb upside down , do I need to adjust the secondary butterflies to reveal a small square in the slots to match what I did to the primaries? Hope this makes sense.

|