|

Author

|

Message

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 1.7K,

Visits: 102.7K

|

Ball stud link I got from Speedway in Nebraska - then bent / threaded to match the Ford link. I also re-drilled the Holley throttle link to put the ball stud exactly where I wanted it.

Steve Metzger Tucson, Arizona

|

|

|

|

|

RJ Palmer

|

|

|

Group: Forum Members

Last Active: 2 Months Ago

Posts: 17,

Visits: 727

|

Thanks Steve, I'm curious,,,,is that throttle rod which goes from point C to point A on your diagram a purchase or did you fabricate that rod? Dick Palmer

|

|

|

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 1.7K,

Visits: 102.7K

|

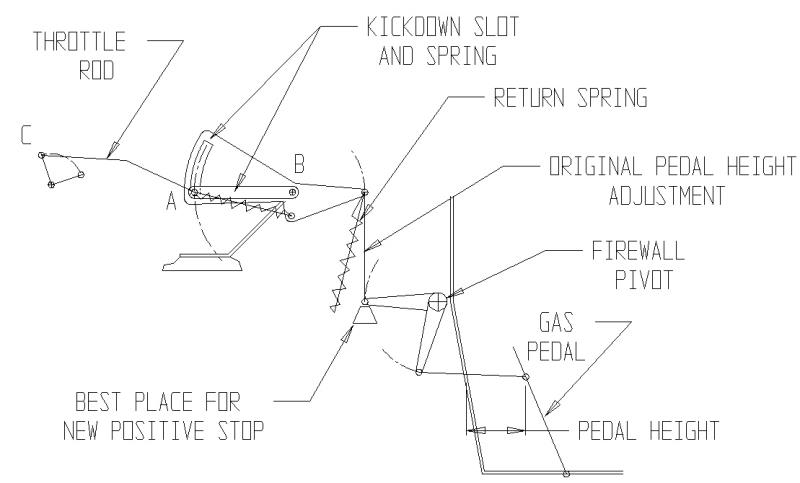

This linkage is sometimes a lot of trouble to sort out. Mostly due to the differing arcs of motion of the various linkage parts - and the "lost motion" slot for the kickdown function. I made this diagram to understand how it worked on my Thunderbird - the sedans and other vehicles vary a bit:  The lost motion slot in the Ford kickdown is "timed" to the position of the throttle with the carb at idle - by use of a 1/4" shank Phillips screwdriver inserted as shown below:  The springs for the kickdown feature must be stiffer than the carb throttle return. This makes the engine go to full throttle before travel starts in the slot. It makes things sequence as the floor pedal is depressed - so there must be enough room under it to reach full throttle before it reaches the floor. Then the overtravel in the kickdown keeps moving the trans lever to the point of initiating the downshift. So..... in the Ford books there is a recommended space under the pedal when it is fully released to idle. When you change carbs - and put a sensible throttle return spring on it - the result is often an imbalance with the kickdown slot spring. It takes some fooling around with the spring ratios to get this to work out. On my outfit - I ended up needing a "stop" for the bellcrank to get a consistent pedal position.

Steve Metzger Tucson, Arizona

|

|

|

|

|

paul2748

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 3.6K,

Visits: 497.7K

|

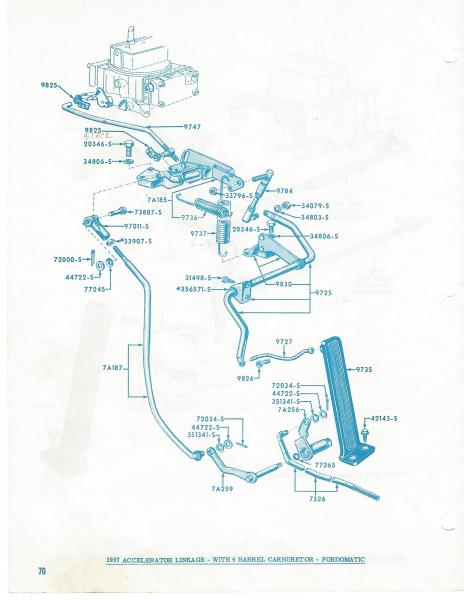

Here is waht the whole thing looks like

54 Victoria 312; 48 Ford Conv 302, 56 Bird 312

Forever Ford

Midland Park, NJ

|

|

|

|

|

oldcarmark

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 3.7K,

Visits: 32.6K

|

Hope its enough Info to get You going. If anyone is looking for an original Fordomatic Service Manual I have several 56-57 available to Purchase. I accept Paypal..

|

|

|

|

|

RJ Palmer

|

|

|

Group: Forum Members

Last Active: 2 Months Ago

Posts: 17,

Visits: 727

|

Got it! Thanks very much for your good advice. I see what you are saying about the throttle rod adjustment. Hope to put everything back together this weekend and then time for road test and fine tune. Again thanks very much...Dick Palmer

|

|

|

|

|

oldcarmark

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 3.7K,

Visits: 32.6K

|

|

|

|

|

|

RJ Palmer

|

|

|

Group: Forum Members

Last Active: 2 Months Ago

Posts: 17,

Visits: 727

|

Thanks very much...do appreciate your help/advice..I'll keep you posted as I progress..

|

|

|

|

|

oldcarmark

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 3.7K,

Visits: 32.6K

|

I think the Holley Rep gave You incorrect information. If You already have the correct Bellcrank and the Link to the Transmission pressure control Lever all You need to do is fabricate a Link from Bellcrank to Carburetor. The Parts He recommended are used on later Model Fords. The Dashpot was installed originally to slow the Throttle return to prevent Stalling. You don't need it with the new 390 CFM Carb, I have the same Carb on my 56 and don't have any problems. Also an Automatic.. I have a Fordomatic Manual which explains how to properly setup and adjust the throttle Linkage and Pressure control rod to Transmission. I will post Pics in AM.

|

|

|

|

|

Talkwrench

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 898,

Visits: 23.2K

|

|

|

|

|