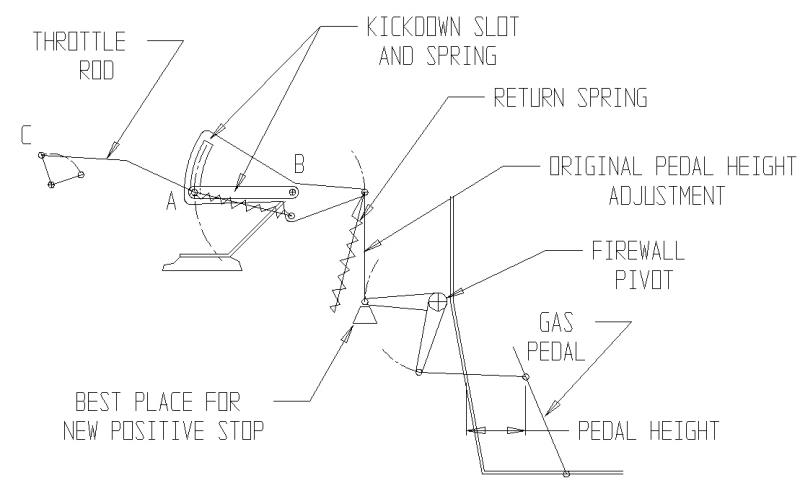

I made this drawing years ago for YBF - and it looks like it has made the rounds......it is specific to the Fordo linkage on the T-bird - but it does show the nuances of trying to make this stuff work. You need both the car manual - and the manual for the Ford-O-Matic to get all of the instructions - they don't appear together for some reason (in the FACTORY literature).

The pedal height off the floor must have sufficient travel to (1) pull the carb primary to the full open throttle position and then (2) continue on to pull the kick-down lever to its full travel position in the slot. Due to the use of aftermarket carbs (I've used both the Holley 4160 and the Road Demon Jr. four barrel) both of them have had a very strong internal throttle return springs - the kick-down spring gets overpowered and moves too early. Try the T-return spring in a teapot and you will see what I mean - very light spring - carb goes wide open before the kick-down moves. Some have told me they simply use two kick-down springs to balance out the newer carbs.

There is a lot of monkey motion in the linkage, so I decided that to get the foot pedal to always start from the same position, the outfit needed a positive stop. I use a stack of washers under a bolt at the back of the intake manifold to stop the bellcrank when the pedal height is correct. That makes everything return to a known point when you release the pedal.

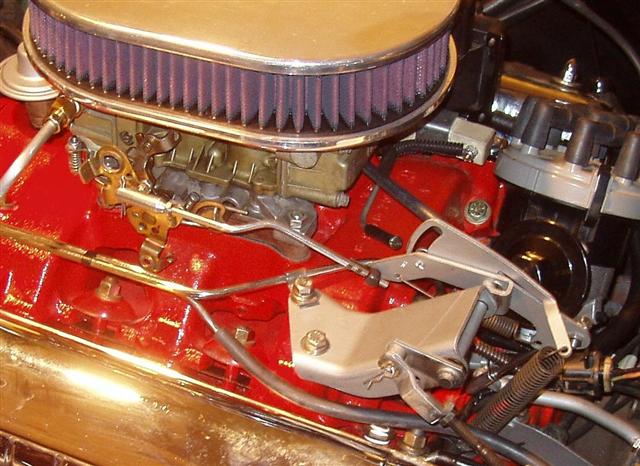

This photo shows the use of a Philips screwdriver as an alignment tool - as explained in the factory manual - to get the linkage adjusted at idle. The throttle pedal is released, a foot solid on the brake - and the carb at hot idle with the trans in gear (my wife usually does the brake holding). With the screwdriver in place, the threaded carb linkages get adjusted to fit into this position. Remove the screwdriver - and nothing should change.

On the near side of the photo - just above the screwdriver handle - you can see the pin that drives the kick-down rod (which is missing in the picture)

.

I don't have a way to show this, but the kick-down rod drops down to a lever on the transmission - where it operates a pressure valve internal to the transmission. As the kick-down rod is actuated, the pressure rises and eventually - it raises the control pressure sufficiently to cause the downshift. The Fordo manual actually has a pressure reading - and a point to check it - when actuation takes place.

Steve Metzger Tucson, Arizona