|

Author

|

Message

|

|

82warren

|

|

|

Group: Forum Members

Last Active: 7 Years Ago

Posts: 51,

Visits: 84

|

On a trip to PA from MN to a wedding in our '54, a rear wheel bearing puked it's guts, we were lucky to find an axle, replaced it and came on home.

I got busy last week, bought two complete bearings on eBay, pulled my axles out, cut the retainer rings off then pulled the bearings off with a big puller I made, this worked really good, takes a lot of pressure to remove these things.

Then using my 12 ton press, carefully pressed each one on, I would estimate it took 5 tons to push them on. The retainer rings took even more pressure, probably 8 tons or so but we got them into place against the bearings tight. This friction is all that holds the bearings in place

and the only thing that keeps your axles in the car.

I used gasket maker on the plates that hold the bearings & axle in, also made sure the drain holes in the backing plates were open.

So, now we have all new rear wheel bearings, our long trip out west in

August should go a lot better, at least we hope so.

A big THANKS to all the guys that gave help with parts and advice, us Y-blockheads have to stick together.

Thanks again,

Warren, in MN

|

|

|

|

|

MoonShadow

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 4.6K,

Visits: 38.5K

|

Back in the day  we used a torch to heat up the retainer ring red hot then dropped it over the end of the axle. It would drop straight on tight and level. Of course a press works too.

Y's guys rule!

Looking for McCullouch VS57 brackets and parts. Also looking for 28 Chrysler series 72 parts. And early Hemi parts.

MoonShadow, 292 w/McCulloch, 28 Chrysler Roadster, 354 Hemi)

Manchester, New Hampshire

|

|

|

|

|

snowcone

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 169,

Visits: 5.9K

|

I have never pressed them on and was taught to heat them and then drop them on when they expanded.

I replaced mine just a couple of months ago

I would be concerned about pressed ones coming off.

Gary - 1958 Star Customline and 1940 Ford Deluxe Hotrod

|

|

|

|

|

2721955meteor

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 927,

Visits: 190.0K

|

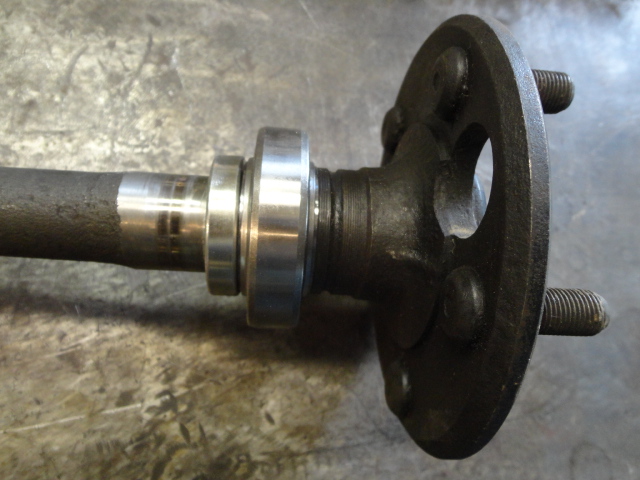

Where is the retainer in the picture of the installed new bearing.

I put the axle in the freezer over night, then warm the bearing inner race (put the retainer on first) use the old ring to tape the new bearing in to place. then heat the new retainer to install.

On removing the old bearing, heat the retaining ring, or cut with a grinder. with the bearing wrap alight rag around the bearing put on your safety glases,block of wood under the bearing or steel and take a 5 pound hamer and back the outr portion. it will split then heat the iner race, or cut it with a grinder being careful not to nick the axel. Only cut it 2/3 the way.then with a mild steal drift tapit off.

No special pullers needed

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.8K

|

Warren. I’m guessing that the axle retaining plates are slotted so that they slip over the axle with the bearings already in place? I’m like Cliff in that I don’t see them on your axles with the freshly installed bearings.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

82warren

|

|

|

Group: Forum Members

Last Active: 7 Years Ago

Posts: 51,

Visits: 84

|

Guys ... It takes plenty of pressure to push those bearings on, you cannot heat them.

The retainer ring is shown there, it's the smaller thing next to the bearing. These bearings have no 'shoulder', that is the ring, up tight against the bearing.

Heating the rings is fine but no worries about using a good press, they go on tough, they aren't going anywhere. They were pressed on in the Ford plants, not heated. In fact, the rings and bearings could have been pushed on together in one quick operation, I'd bet the farm on it.

My cousin came out of WW2 in '46, worked for Ford as production engineer all his working life, he said everything was pressed together cold in specialized machines, things we guys can't duplicate in our shops, at least not real easy.

Hope this helps ...

warren

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.8K

|

|

|

|

|

|

2721955meteor

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 927,

Visits: 190.0K

|

82warren (7/15/2016)

Guys ... It takes plenty of pressure to push those bearings on, you cannot heat them.

The retainer ring is shown there, it's the smaller thing next to the bearing. These bearings have no 'shoulder', that is the ring, up tight against the bearing.

Heating the rings is fine but no worries about using a good press, they go on tough, they aren't going anywhere. They were pressed on in the Ford plants, not heated. In fact, the rings and bearings could have been pushed on together in one quick operation, I'd bet the farm on it.

My cousin came out of WW2 in '46, worked for Ford as production engineer all his working life, he said everything was pressed together cold in specialized machines, things we guys can't duplicate in our shops, at least not real easy.

Hope this helps ...

warren

a bit of heat on the iner race and axel in the freezer works great,we are not all in front of a big press

|

|

|

|

|

carl

|

|

|

Group: Forum Members

Last Active: Last Month

Posts: 1.2K,

Visits: 20.6K

|

Warren if you are missing the retainer plates I probably have some stashed away that I will send you,just let me know Carl

|

|

|

|

|

aussiebill

|

|

|

Group: Forum Members

Last Active: 5 Years Ago

Posts: 1.8K,

Visits: 11.4K

|

did you forget the retainer plate ?

AussieBill YYYY Forever Y Block YYYY AussieBill YYYY Forever Y Block YYYY Down Under, Australia

|

|

|

|