|

Author

|

Message

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.8K

|

Sanddoc (9/18/2016)

Ted, Isky cams is right around the corner from me, once in awhile a bunch of us would be lucky and have lunch with "Isky" been many years

since those days. Gardena Ca, was and is still a hot bed for performance parts.

In your article on the two engines, the hopped up one, does the cam have a part number, or was this something you and Isky cams worked

out? If it's a stock number could you post it.

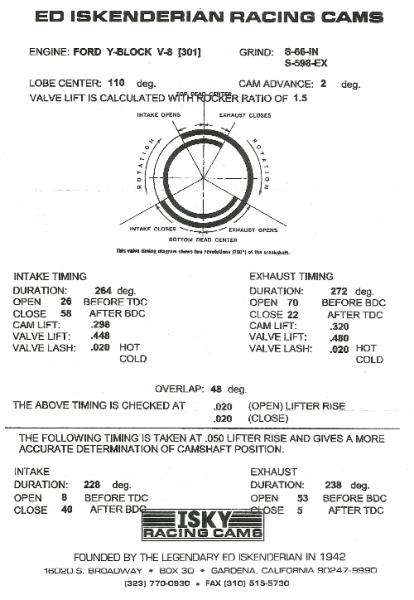

Could you have gone with a higher lift?The 228/238 @ 0.050” camshaft that’s in the ‘two engine’ article is a custom ground camshaft. If ordering it, then simply specify a Y-Block camshaft (301 grind) with S-66-IN and S-598-EX lobe profiles. The cam in the article was ground on 112° lobe centers with 2° of cam advance built in; 2° cam advance will equate to 4° at the crankshaft. The camshaft described in the article was being used with a Ford-O-Matic tranny with a tight converter but either a standard transmission or an auto tranny with a looser converter will be happy with the camshaft being ground on 110° lobe centers. A tighter lobe center in this case will make the engine more responsive on the low end of the rpm scale while also having just a bit more lumpiness to the idle. If taken to the next level, that same camshaft can be ground on 108° lobe centers for even more lumpiness (small lope) in the idle but will be at the expense of some drop in manifold vacuum at idle. Here’s the Isky spec sheet for the same camshaft that’s ground on 110° lobe centers.

As a general rule, the Y with iron heads can handle up to about 0.535” lift at the valve without valve/piston/cylinder wall clearance issues. After that point, intake valve clearance to the edge of the cylinder can be a problem but is resolved by grinding some concave notches in the cylinder walls at the point of intake valve interference. As a general rule, the Y with iron heads can handle up to about 0.535” lift at the valve without valve/piston/cylinder wall clearance issues. After that point, intake valve clearance to the edge of the cylinder can be a problem but is resolved by grinding some concave notches in the cylinder walls at the point of intake valve interference.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

'60 Fairlane

|

|

|

Group: Forum Members

Last Active: 9 Years Ago

Posts: 71,

Visits: 539

|

Ted thank you for posting the grind number information on the custom Isky camshaft you used in the 1.04 HP/CI build. I've been wanting to ask about that cam since you first put up a link to that build a while back. How important to the success of that engine were the metric rings?

I've always thought split duration cams were a good idea when running cast exhaust manifolds and I'm thinking about trying to duplicate your efforts for my 1960 Fairlane with a few small differences. 1) will use a 312 crankshaft and 2) use enough compression to take full benefit of our locally available alcohol free fuel, which typically runs at 91 octane.

Now that Mr. Miller has had some time to live with this engine has he reported back to you his impressions, or if he has made any changes to the axle gearing, etcetera?

Again thank you for your willingness to share with all us "little guys".

-Dave

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.8K

|

'60 Fairlane (9/22/2016)

.....Now that Mr. Miller has had some time to live with this engine, has he reported back to you his impressions, or if he has made any changes to the axle gearing, etcetera?.... Karol has been quite happy with the engine combination as it is. Being the old school top end guy that he is, he has been comfortable with the 3.22 gears and is pleased with the low end performance as it is. He did ask me after driving the car a bit what the rpm limit should be and I told him 6000 rpms. He confessed that he had already been 6000 rpms in 2nd and overdrive. He really likes the automatic choke on the carb and likes the fact that it starts right up after sitting awhile (2 weeks) by simply giving it a couple of pumps of fuel before attempting to start the engine. He was up for lunch this week and he mentioned he would like to put the dual quads back on the car. With that in mind, he’ll work up the dual quad setup with a pair of Teapots and bring it up to my place for a general run in and testing on the dyno mule before actually installing it on his engine. It looks like I’ll be in charge of linkages and fuel lines at this point.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 2 days ago

Posts: 7.5K,

Visits: 205.8K

|

47 ford w/y-block (9/18/2016)

I am wondering if the 292 has any proformance parts to get a higher rpm looking to get 5000-6000 rpm if at all possible and what parts would I need to replace.John Mummert (9/21/2016)

Well prepped C2ae rods or Aftermarket replacement rods. Good valve springs, tubular pushrods and a good balance job would be your basics to make the engine reliable. To make power at 6000 rpm or so you would need some head porting or alum. heads , 228-234 @.050 duration. .500 lift is nice. 600-650 cfm carburetor. Highly modded stock "B" manifold or aftermarket alum., and set of good headers and exhaust. A well built 6000 rpm 292 should make 310-370hp depending on part choice at a streetable compression. We just built a .060" over 292 matching these specs with aluminum heads and manifold, 1" dual oval spacer and our 55' F100 EMC tri y headers made 365hp and 370lbs tq. This response from John was moved from another thread that ends up being a duplicate not getting much traffic. Ted.

Lorena, Texas (South of Waco) Lorena, Texas (South of Waco)

|

|

|

|

|

Shaggy

|

|

|

Group: Forum Members

Last Active: 7 Years Ago

Posts: 123,

Visits: 609

|

Slightly off topic but for maximum revs, destroking wouldnt be a bad thing. I would love to see what a 239 crank in a 312 bored block would do. At that point you are almost a GM 283 in bore/stroke/valve ratio and we know the r's those like in stock classes of racing.

|

|

|

|

|

'60 Fairlane

|

|

|

Group: Forum Members

Last Active: 9 Years Ago

Posts: 71,

Visits: 539

|

^^^^ Land speed racing? ^^^^ Could be fun with a set of John's heads and his new tunnel ram intake, hummmmm

-Dave

|

|

|

|

|

LordMrFord

|

|

|

Group: Forum Members

Last Active: 4 Years Ago

Posts: 687,

Visits: 9.3K

|

Shaggy (9/22/2016)

Slightly off topic but for maximum revs, destroking wouldnt be a bad thing. I would love to see what a 239 crank in a 312 bored block would do. At that point you are almost a GM 283 in bore/stroke/valve ratio and we know the r's those like in stock classes of racing. Callies compstar rods and SRP lightweight pistons can hold well over 8000 rpm's on stock stroke 292. Lighness and balancing is everything.

Hyvinkää, FI

|

|

|

|

|

CK

|

|

|

Group: Forum Members

Last Active: 9 Years Ago

Posts: 152,

Visits: 1.1K

|

What should I expect from a std bottom end if balanced?

I've revved mine to 7000 often

|

|

|

|

|

Lord Gaga

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 464,

Visits: 183.3K

|

CK (10/5/2016)

What should I expect from a std bottom end if balanced? I've revved mine to 7000 often A hole in the block or oil pan?

"FREE SAMPLE"

|

|

|

|

|

PF Arcand

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 3.3K,

Visits: 238.8K

|

CK: You didn't describe your engine, but if the cam is stock or a mild grind, there is no point in running it up to 7000 RPM. And as has been pointed out, if the components are stock, you're courting big trouble...

Paul

|

|

|

|