|

Author

|

Message

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 1.7K,

Visits: 102.7K

|

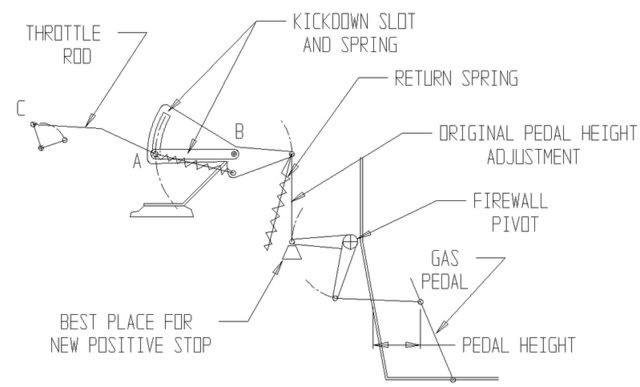

Aw...come'on -you didn't put that scoop on there to help the mileage did ya? Can you make an extension for the transmission lever so as to alter the rate of change as the throttle advances? (Or vice versa - a different hole on the carb lever) I don't have a p[icture that shows me how yours works exactly - but the '56 throttle opens the carb up all of the way - and when it hits the carb stops - there is a spring loaded "overtravel slot" that lets the trans linkage continue on. This means the angular rotation of the throttle is "quicker" than the angular rotation of the kickdown for any amount of pedal.

Steve Metzger Tucson, Arizona

|

|

|

|

|

Hoosier Hurricane

|

|

|

Group: Moderators

Last Active: 9 hours ago

Posts: 3.7K,

Visits: 323.2K

|

John: I helped a friend sort his throttle/transmission problems on his '56. He had such a strong return spring on the carburetor that when he pushed the pedal, the bellcrank on the back of the manifold went into "kickdown" position as AZ28 mentioned, which caused early kickdown and lack of full throttle at the carburetor. John

John - "The Hoosier Hurricane"

|

|

|

|

|

2DRHRDTP57

|

|

|

Group: Forum Members

Last Active: 9 Years Ago

Posts: 207,

Visits: 1.8K

|

Hey John, You and I have experienced a lot of similar problems. I read every page of my 57 Ford manual only not to find anything regarding this kickdown linkage adjustment. In the end I struck gold by purchasing a 1956 1957 Fordamatic Shop Manual from e bay. The adjustment method that I have attached will sure fix your problem if you follow it to a t. You may have to adjust your carb link and pedal to bellcrank link as well, to get everything sweet. the throttle control rod they refer to is your kickdown rod. Only Fig 6 and Fig 8 apply to your 8 cylinder passenger car vehicle. Be sure not to use the 6 cylinder method or truck. I hope you can save to file and resize so you can read this as it has compressed on the forum site, If not you may be able to get a copy locally, or if you PM me your email address I will forward direct, Hope this helps John

1957 ________________ Ford

\___((_______________))___/

(@)________V__________(@)

[________I_____I_________]

__[__]__ o_______o___[__]___

Y Blocks, The New Flathead!

|

|

|

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 1.7K,

Visits: 102.7K

|

The "missing link" that I've had to find in the old Fordo manual before - is the recommended distance between the pedal and floorboard at neutral. There has to be enough bellcrank rotation (out on the firewall) to (1) fully open the carb throttle and then (2) continue to move the trans "kick-down" rod with rotation within the "overtravel" slot. This additional travel is commanding the transmission control pressure to rise. If you don't have enough space to "floor it" and get the full range of motion (command full pressure as well as full throttle) - the kickdown is defeated. You can get wide open throttle but not enough movement in the trans control to get the matching internal pressure. What I found was that technicians (that don't know about the floorboard space requirement) often adjust the kickdown rod to get a raised control pressure at a reduced carb throttle position. This is a simple approach but it may make the tranny kickdown too early, at part throttle. The Fordo manual recommends using a pressure gauge off a specific test port to detect control pressure under various operating conditions - it would catch the problem but.....you have to be deeper into this than most want to go. Also creeping in here - on my outfit and maybe this one - the Holley 600 cfm 4160 throttle had a selection of several different lever ratios (holes) - the teapot carb that came off had one. The distance from the throttle blade shaft center to the attachment point of the linkage arm is important to the total picture. John's comments about the mismatched springs could be tricky to catch - and would explain some variations of bad behavior. Often, the replacement springs sold by the aftermarket are not an exact match for the Ford parts - and if you have a competition rules regulation for instance, that governs throttle return springs - this mismatch could get a lot harder to deal with.

Steve Metzger Tucson, Arizona

|

|

|

|

|

MoonShadow

|

|

|

Group: Forum Members

Last Active: 9 hours ago

Posts: 4.6K,

Visits: 38.5K

|

How do you adjust the height of the pedal from the floor? My setup doesn't have an adjuster from the firewall to the bellcrank. Chuck

Y's guys rule!

Looking for McCullouch VS57 brackets and parts. Also looking for 28 Chrysler series 72 parts. And early Hemi parts.

MoonShadow, 292 w/McCulloch, 28 Chrysler Roadster, 354 Hemi)

Manchester, New Hampshire

|

|

|

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 1.7K,

Visits: 102.7K

|

Good morning Chuck! - On my '56 Bird, its the two joined 90° ball joints that jump the foot feed motion from the firewall bellcrank to the linkage on the engine itself. As usual it is completely covered in this photo - Sorry. According to the "directions" for the '56 - you set-up your idle, with the tension spring holding the overtravel slot closed (with a 1/4 rod - Phillips screwdriver - in the linkage lock holes) - then adjust this length to lift the pedal up off the floor a specific amount.

On mine you have to take the link loose, release the locknut, spin it a few threads and then try it. I never found the "required dimension" of the pedal off the floor 'till I bought the blue Fordo manual. I have a spring tension problem in mine - which John pointed out this morning - so more work is going to be required to make it behave just right. When all is well with the throttle - then you start on syncronizing the tranny control pressure to the linkage position. The control pressure will be low at idle, steadily increasing to full throttle - then after you enter the "overtravel" slot - pressure must reach the point of operating the "kickdown". I think you should be able to "just" reach full throttle and not cause a kickdown - but I will need to get a pressure gauge set-up to do it. Part of the problem (as I see it) is the way the Fordo transmission is rigged to start in 2nd gear. The tranny control pressure is initially "soft" to facilitate a smooth acceleration from stop - unless you completely floor it into the overtravel slot. Builds heat like crazy in normal driving.

Steve Metzger Tucson, Arizona

|

|

|

|

|

Hoosier Hurricane

|

|

|

Group: Moderators

Last Active: 9 hours ago

Posts: 3.7K,

Visits: 323.2K

|

Steve: I don't believe you have the return spring problem. Yours appears correct. The throttle return spring is the vertical one in your picture. It returns the bellcrank, which in turn pushes the carb closed. The '56 I referred to earlier also had a return spring on the throttle lever to pull the carb closed, and that was the one that caused the bellcrank to go into "kickdown" position as soon as you pushed on the accelerator. John

John - "The Hoosier Hurricane"

|

|

|

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 1.7K,

Visits: 102.7K

|

John - The return spring shown in the photo is indeed the original I found on the car when I bought it. It has had a few turns in the caustic to get the gunk and old paint off - then a little acid, gun blue and WD40 to finish. Its in good shape and hasn't been deformed. I have a replacement spring I got from NPD and it was too stiff - way more tension (coils painted together too) than this one. The linkage assembly on the intake hasn't been altered - just mounted flat on the '57 manifold base pads. Need to check the elevation of this point versus the old 9425-A manifold don't I...could add preload to the spring.... The trouble is, even assembled with this original spring - it is not stable at the point shown in the photo. And if you abruptly remove your foot from the foot pedal (as in - slip your foot off sideways) or simply pull out the screwdriver - the linkage doesn't want to return to the neutral point where it is locked in the photo. Instead, it over-travels in the close direction and moves the rear carb link attachment point too far upward. It then "toggles over" and latches against the carb lever (which is tight against its own stop screw). This is bad news...... The upper attachment of the return spring is plainly built to be adjusted by (gentle) bending (I think). How tight should the spring tension be? Does the tab need bent down to relax the situation a bit? Should it just have enough tension to hold things at neutral? I've got a lot more questions than answers. It doesn't seem too stable to me to be balancing everything on springs. I'm pretty sure that using this linkage - intended for the teapot - with this style of carb and spacer has resulted in some differences in the elevation and arc travel of the linkage points. This then contributes to the "toggle" situation. I've got the forward pivot of the carb link rod in the best match of holes in the throttle lever of the 4160 - to try to match the travel of the teapot lever. This may not be the optimum spot to hang it - the bigger carb and other tuning changes is liable to make the road speed considerably different for a given throttle position. The best arrangement I can come up with, is to build a hidden mechanical stop screw and locknut that causes the linkage to absolutely stop at the proper neutral point. I was also thinking it might be a good idea to figure out a way to change the arc of motion to the tranny pressure control rod (kick down). If the throttle position for a given road speed is reduced by the bigger carb - won't the transmission control end up in the wrong pressure range for "cruise"?

Steve Metzger Tucson, Arizona

|

|

|

|

|

Hoosier Hurricane

|

|

|

Group: Moderators

Last Active: 9 hours ago

Posts: 3.7K,

Visits: 323.2K

|

Steve: Is the pivot of the bellcrank worn to the point to allow the carb lever to toggle over? If not, the positive stop looks like the safest solution. Lengthening the carb rod would stop the toggling over, but full throttle would probably not happen. I don't think the change in throttle pressure would be enough to matter at cruise, as long as it doesn't downshift too easily. John

John - "The Hoosier Hurricane"

|

|

|

|

|

GREENBIRD56

|

|

|

Group: Forum Members

Last Active: Last Year

Posts: 1.7K,

Visits: 102.7K

|

This is where my problem lies - points C-A-B fall too close to a straight line - and the return spring is forcing A to go up above C.

I'm thinking that I can get a little mechanical stop to fit on the back of the block. It will then be the adjustment that sets the pedal height and the return spring can be fairly stiff. Extending the throttle rod and the original pedal adjustment link will move A down out of line. But yes, I see - it may be that the pressure control rod set-up will be too close to kickdown for comfort.

Steve Metzger Tucson, Arizona

|

|

|

|