|

Author

|

Message

|

|

NoShortcuts

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 1.4K,

Visits: 179.6K

|

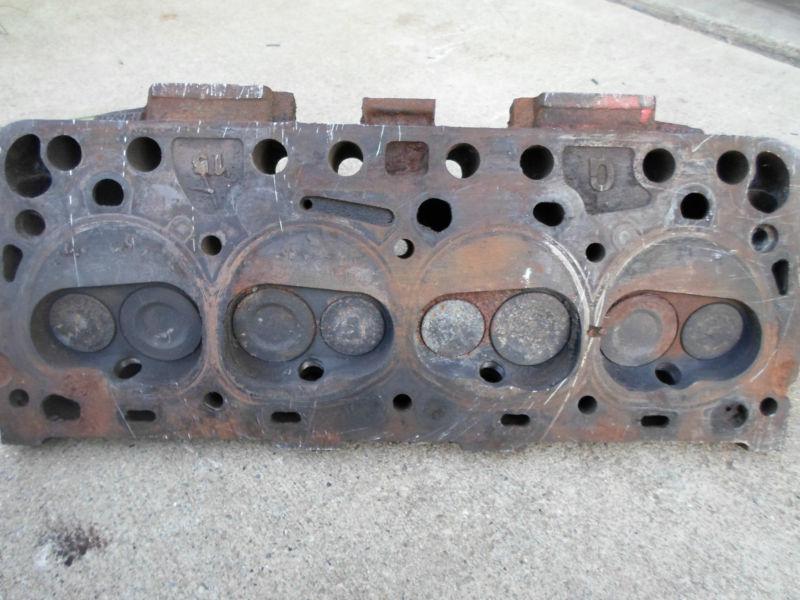

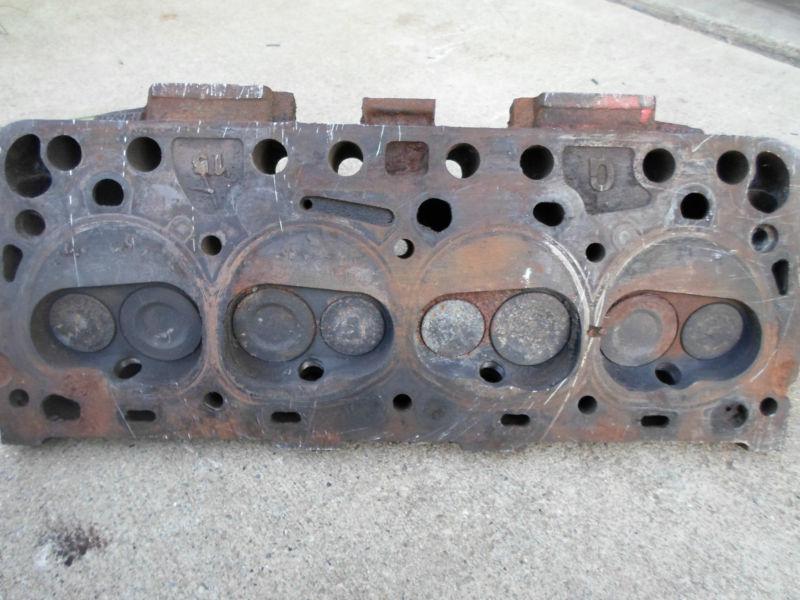

Lord Gaga. Earlier in this link about the heads he purchased, Cliff indicated that one large letter 'G' cylinder head was posted and one was not.

Regarding these heads that Cliff purchased, I was surprised that where the intake valve guide protruded into the intake port bowl on these heads, the protruding guide material was totally removed as opposed to the cylindrical valve guide body being shaped to direct the air flow in the bowl area under the intake valve head.

NOTE: I'm not a flow-bench supported cylinder head porter. I have observed other individual's porting work where the intake valve protruding guide material has been retained, BUT shaped in a wedge, tear-like shape to direct air flow under the intake valve head.

Cliff. My recollection is that you indicated you had worked with John Mummert in modifying the cylinder heads you have installed on your dragster motor. QUESTION: Is it your understanding that the shaping of the intake and exhaust porting immediately below where it enter the valve seats and also above where the valve seats enter the combustion chamber is critical to optimum port air flow numbers.

Thanks for all that you have shared in assembling your motor for the dragster and installing the motor in the dragster body. Much appreciated! .

NoShortcuts

a.k.a. Charlie Brown

near Syracuse, New York

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 881,

Visits: 13.6K

|

Well, I don't know, I cut and try, I do find that there is no profit in following the crowd, I will try anything I can think of, I do think the longer valve guide is best for the street, for race engines who knows,

The heads on my dragster were ported by John with no input from me, I did the valve job and the shorted the guides (for seals).

|

|

|

|

|

Joe-JDC

|

|

|

Group: Forum Members

Last Active: 5 hours ago

Posts: 773,

Visits: 22.6K

|

As someone who has ported cylinder heads for 47 years, it has been my experience that taking the guide out flat like that actually hurts flow, causes turbulence, and a very noisy port because of the turbulence. It also removes some of the stabilizing of the valve, and cooling area for the stems, especially in the exhaust. Another thing that will cause to happen is a siphoning of the oil from the guides. If the exhaust is cut a little wrong, it will actually pressurize the crankcase some and coke up the valve stem into the guide and wear much faster. A simple fix would be to install tapered iron guides, or bronze guides. Problem solved. Joe-JDC

JDC

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 881,

Visits: 13.6K

|

Hi Joe, I think you are right, for the amount of work someone put into these heads I would expect better numbers, they look like bigger is better, however they were cheap, I will do more work on them and see what I can do, I also did a fast check on the bench, so these numbers may not be correct, I ran them with a 3.860 bore, I only checked at .550, it was 65 deg. in the shop, I did no error correcting.

PS my bench is so noisy I don't think I can hear a noisy port (JKM 600)

|

|

|

|

|

NoShortcuts

|

|

|

Group: Forum Members

Last Active: 3 Years Ago

Posts: 1.4K,

Visits: 179.6K

|

Cliff & Joe-JDC. Thanks for your replies to my question about cylinder head porting.

Joe-JDC. Kudos to you and Ted on what you accomplished at the 2019 EMC event in September/October.with the 303 y-block entry. Well done!

NoShortcuts

a.k.a. Charlie Brown

near Syracuse, New York

|

|

|

|

|

Ted

|

|

|

Group: Administrators

Last Active: 8 hours ago

Posts: 7.5K,

Visits: 205.9K

|

|

|

|

|

|

Joe-JDC

|

|

|

Group: Forum Members

Last Active: 5 hours ago

Posts: 773,

Visits: 22.6K

|

Ted is right, the combustion chambers were relieved around both valves thinking it would increase flow, but not true. Some folks think lowering the compression by unshrouding the valves that way is best for supercharging applications. I have seen many changes over the years in thinking, and that is very "old school" way of finishing the combustion chambers. It will work, but not the absolute best. The heads will probably work just fine, and make good power with slightly larger valves in both positions. The issue will be cylinder head gasket sealing if the chambers are too big to be used on a smaller bore block. Joe-JDC

JDC

|

|

|

|

|

Lord Gaga

|

|

|

Group: Forum Members

Last Active: Last Week

Posts: 470,

Visits: 183.3K

|

Here's what I'm talking about. I've never seen G heads with that odd flat sided protrusion opposite the spark plug! The G heads I know and love have combustion chambers like this; :  the Lord Gaga (12/9/2019)

What's with the shape of those combustion chambers? And are they posted?

"FREE SAMPLE"

|

|

|

|

|

Cliff

|

|

|

Group: Forum Members

Last Active: Yesterday

Posts: 881,

Visits: 13.6K

|

I don't know, the work on these is nice, I just think it's old thinking, i'm going to spend some time on them and see where I end up, I would have never done this kind of work however we'll see, maybe it is the way to go, who ever did this was no dope, the work is to nice, the chambers look perfect, the exhaust still has a small amount of guide showing, I'm surprised they have stock valves, the brass tubes are flat sheet stock rolled to fit (you can see the seams), so far the flow is poor for all the work done.

|

|

|

|

|

Joe-JDC

|

|

|

Group: Forum Members

Last Active: 5 hours ago

Posts: 773,

Visits: 22.6K

|

Lord Gaga (12/10/2019)

Here's what I'm talking about. I've never seen G heads with that odd flat sided protrusion opposite the spark plug! The G heads I know and love have combustion chambers like this;  Lord Gaga (12/9/2019)

What's with the shape of those combustion chambers? And are they posted? The simple answer is that all you have to do is grind the metal around the whole circumference of the valve to get the flat indention left. It is called total unshrouding of the valves, and is not necessary, but once the metal is removed, it can't be put back cheaply or effectively. Joe-JDC

JDC

|

|

|

|