|

By kari613 - 13 Years Ago

|

|

I here that some one makes 4-5 inch long floor braces for the 56 Ford car. Who might that be? Has any one out there used these and do you have to cut out part of the bad braces. A couple of mine are starting to go bad.Do these new ones slip over the old braces? I'm also looking for a very solid used or maybe a new front cross member out there that a y-blocker isn't using. Thanks

|

|

By lyonroad - 13 Years Ago

|

I've only seen adds for the full length ones and they are not cheap - ($70 - $80) each. My brother in law made his own for a '54 Meteor and said it was easy lol. He owns a machine shop!

Thanks

|

|

By PF Arcand - 13 Years Ago

|

|

For the Floor braces try EMS Automotive, Cleveland, or Concours Parts. Someone recently advertised replacement crossmembers, but I can't recall who. Sorry..

|

|

By rick55 - 13 Years Ago

|

Mac's and Ford Road Parts Store (frps.com) sell the short replacement floor brace ends for $89 or thereabouts. You need to cut out the rusted section. The kit is for all braces, ie 10 pieces from memory and all are different. They make a neat repair when done. If you are replacing floors it may be better to replace the whole brace - Mac's sell these individually, though they are about $80 each.

For the front crossmember you would have to go a long way to get a better replacement than the ones that Goodell Fabrications, Coweta, OK ph.918-486-6498 manufacture and sell direct. Nominate to them what car you have as they have different front mounts. They fit a treat though it is probably easier to take the whole front clip off the car in one piece. They cost something around $300. Similar units without the front mounts attached cost $400+ from Carpenters.

You'll be much happier (and safer) once you have completed the repairs.

Regards

|

|

By Barry L - 13 Years Ago

|

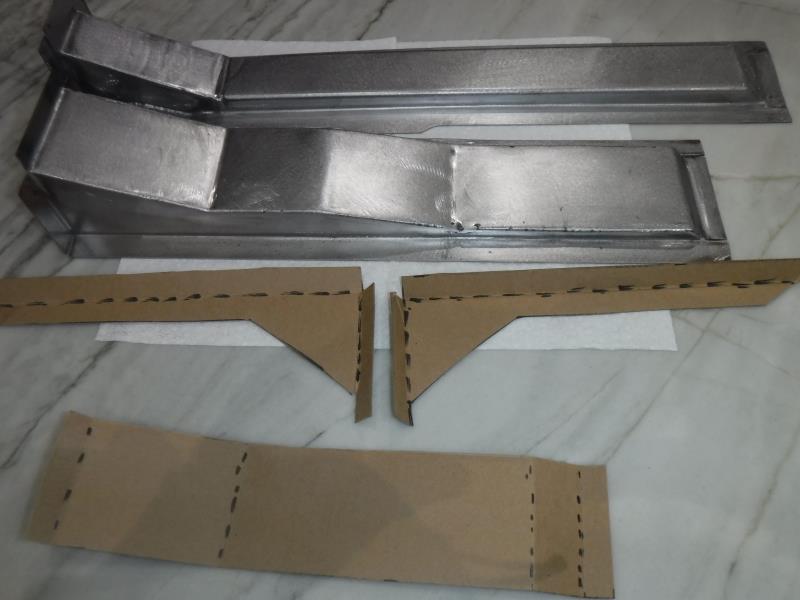

Hi If you can tackle replacing them, you can fairly easily make your own braces. He's what works for me....bend a 5/8ths to 3/4 inch flange on some 18 ga. cold rolled, make a pattern of the side profile of the gusset ( remember a LH & a RH when you cut up the metal) Band saw works well for that. You'll now have two pieces of the gusset, with the third piece being just a flat strip that you weld between the side profiles. Clamp the sides to a flat table, lay the center strip in place , tack it all together,finish weld it all, a little grinding to smooth it off and it should look like this. I can post more pics step by step if you like. Barry

|

|

By wwelch1 - 8 Years Ago

|

|

Can you send me some pics of how you made your braces or post them here.

|

|

By Barry L - 8 Years Ago

|

|

I'll take some new pics and try to make a how-to...give me a few days. Barry

|

|

By wwelch1 - 8 Years Ago

|

|

Thank you

|

|

By Barry L - 8 Years Ago

|

Hi I took a few more pics of the two ways I make floor braces. The first is the type mentioned in my previous post, a profile template of each side of the brace; some are symmetrical , but others have different forward and rear sides. Then a flat strip is welded between them.

The lower brace is of this type.

|

|

By Barry L - 8 Years Ago

|

Hi the second method is to make the part that attaches to the inner rocker and weld that to a preformed hat section. The upper brace in the last pic was made that way, less welding. Hope these pics help. B

|

|

By wwelch1 - 8 Years Ago

|

|

Thank you those picks will help going to try and make mine

|

|

By NoShortcuts - 8 Years Ago

|

rick55 (3/2/2012)

For the front crossmember you would have to go a long way to get a better replacement than the ones that Goodell Fabrications, Coweta, OK ph.918-486-6498 manufacture and sell direct. Nominate to them what car you have as they have different front mounts. They fit a treat though it is probably easier to take the whole front clip off the car in one piece. They cost something around $300. Similar units without the front mounts attached cost $400+ from Carpenters. You'll be much happier (and safer) once you have completed the repairs. Regards

In addition to Rick's comments above regarding Goodell Fabrications' cross member, I believe Rono on our Forum wrote at some length regarding the Goodell unit he installed on his '56 wagon within the last year. I could be incorrect on the time frame . . .

Going at this another way, I saw a current listing on eBay for a rust-free '56 cross member that has apparently been in storage for a l-o-n-g time. Click the link below to see the eBay listing. Note: this is not my listing or the listing of anyone I know.

https://www.ebay.com/itm/1955-1956-Ford-GENUINE-FOMOCO-Original-FRONT-FRAME-CROSSMEMBER-Engine-SteadyRest/122768146003?hash=item1c958d3e53:g:tRwAAOSwDEtZ7LmB

Hope this helps!

|

|

By Rono - 8 Years Ago

|

wwelch1;

Here is the link to the topic I posted in the "This and That" section a while back on replacing the front cross member in our 56 Ranch Wagon; http://forums.y-blocksforever.com/Topic112196.aspx

The Goodall Fabrications front cross member is a very nice piece and more stout than the original. To replace it, removing the front clip is one approach, but I did it by making a fixture of 1" square tubing and angle iron to hold the front fenders in place while removing the radiator core support. In addition to the radiator core support, you will also need to remove the upper radiator valance, lower stone guard, bumper, the radiator (of course) and the headlight bulbs from the pigtails. This way you don't have to cut and or remove your engine bay wiring. I just had to cut the parking light wires but made bullet connectors for them to re-attach. If your front cross member is as badly rusted out as mine was, chances are that your front bolts that hold the lower control arms are rusted in place and may be really tough to get out. Be prepared!

Take your time with this project, it's not that easy. There are quite a few weld points on the old cross member that have to be cut. I used an air chisel on most of them and my plasma cutter on only a couple of places.

Good Luck!

|