|

By 57FordPU - 16 Years Ago

|

|

The new race truck will surely be controversial. I will show the progress on the roll cage, chassis and the Y-Block engine. The 57 Ford pickup is now officially retired, due to budget restraints it will be a donor for some race and safety parts. I hope to put it back on the street in the future. The roll cage main hoop is the first fabrication project.

|

|

By BIGREDTODD - 16 Years Ago

|

Hopefully everyone will look past certain characteristics, and just enjoy another kick-ass truck Charlie...and, it looks as if we are going to have to start a thread on the Unibody here, too

|

|

By Ted - 15 Years Ago

|

|

Charlie. By all means keep up the posts. Certain deviations will be obviously be overlooked.

|

|

By 57FordPU - 15 Years Ago

|

|

Thanks Todd and Ted, I will continue to post as long as there is an interest. I like to start with a clean frame.

|

|

By Glen Henderson - 15 Years Ago

|

|

By all means keep us updated Charlie, I have always wanted to put a Ford in a scrub, just never got around to it!

|

|

By 569104 - 15 Years Ago

|

|

Charlie, Sound like good clean fun to me. I have no doubt you will reach your goal. Thanks for sharing. I too have always wanted to put a Ford in a scrub... A nice Ford blue big block in one of their flagship cars (camaro or a vette) and enter it in all the car shows. My way of getting back for all the classic Fords defaced with a scrub engine!

|

|

By BFOOTER03 - 15 Years Ago

|

|

Charlie, are you going to name it the Flying Scrub??

|

|

By 57FordPU - 15 Years Ago

|

|

Bing, I like your idea..............

|

|

By BIGREDTODD - 15 Years Ago

|

|

You sure make quick work of a cleaned frame Charlie... I've been considering sneaking a gantry lift into my garage for pulling bodies, but I think Corinne might not see the practicality.

|

|

By pegleg - 15 Years Ago

|

|

I had a chance to stop by Charlies last weekend. They invited me to stay over New Years Eve for dinner and a Movie. I had a fantastic time, the hospitality and the dinner was outstanding. The new Truck is going to raise some eyebrows at the Lakes and the Salt Flats. Very professional, and slick. Nothing , and I mean absolutely nothing, in the world is going to be more fun than the look of horror on the faces of the Generals Brainwashed minions when they see the Y-Block FORD in that truck.  If you get a chance to take a camera when he opens the hood, aim it at the Scrub lovers when they first see it. The photos will be priceless. For years we've had to endure Scrub powered Fords, charlies gonna turn the tables on them. It'll be GREAT!! With one of Tim's engines in it it's going to fly. If you get a chance to take a camera when he opens the hood, aim it at the Scrub lovers when they first see it. The photos will be priceless. For years we've had to endure Scrub powered Fords, charlies gonna turn the tables on them. It'll be GREAT!! With one of Tim's engines in it it's going to fly.

|

|

By MoonShadow - 15 Years Ago

|

|

We need some really BIG Y-block decals! Chuck in NH

|

|

By 57FordPU - 15 Years Ago

|

|

Frank, We had a great time with your visit. You are welcome here anytime. You helped me better understand the blower referencing for the fuel pump or regulator if we use a blow through carb setup. Chuck, There will be plenty of Y-Block information on the car. Here is a mockup of the roll cage.

|

|

By 57FordPU - 15 Years Ago

|

|

Its possible, but not likely that I will use this setup. It just gives me inspiration while I'm building the truck.

|

|

By glrbird - 15 Years Ago

|

|

charlie, There are lots of people making gobs of horsepower with twin turbos on GM engines, if the head gaskets will hold 30 psi of boot 200 should be a breeze!!!!!!! And then there is Nitrous to cool the intake charge. Truck is looking fast already.

|

|

By 57FordPU - 15 Years Ago

|

|

Gary, We think a lot alike, it would be great to run 30 psi and nitrous. If the engine would stay together, all you would have to do is point it down the track and hold on. Unfortunately, no fuels are allowed in any pickup classes and you are right to address the sealing of the head gasket with that kind of boost. After talking to Jerry C and Cliff Williamson (you can see his ad on the inside cover of Y-Block Magazine, issue #101) sealing the combustion area is a major problem that can be resolved to some degree. By silver soldering wire in the groves of the steel head gasket you might get away with a boost of 10 to 12 psi. To get it up to 15 or more you would probably have to machine rings in the block to accept a Loc-Wire seal and that would be very expensive due to the irregular shape of the circle. Here are the arm and leg restraints.

|

|

By glrbird - 15 Years Ago

|

|

charlie, you need to make friends with an owner of a CNC 3 axes mill to do your blocks. Great looking truck so far. Keep us posted. I have enjoyed the postings of your exploits.

|

|

By 57FordPU - 15 Years Ago

|

|

Up till now it has been mostly tearing down, collecting parts, and trial fitting. Now the building actually starts. Here are a few shots of the roll cage outriggers. Driver's side front

Driver's side front finished. You can't see the bottom plate closing the outrigger.

Driver's side rear

Yes, it went right through the middle body mounts. I left them for added strength. Not to worry, there are still four body mounts left. Again, you can't see the bottom enclosing plate.

Next, it will be interesting trying to stay within the rules and set the engine back as far as possible, a new firewall will have to be built.

|

|

By grovedawg - 15 Years Ago

|

|

I'm sad to see the brick retired. But also very excited to watch this build. Good luck Charlie!

|

|

By 57FordPU - 15 Years Ago

|

|

Thanks grovedawg. Now that the outriggers are done, I needed to get some paint on the rolling chassis.

With 123" wheel base, I hope to get a stable ride.

9" rear axle in the background is off to be narrowed and have some alloy 31 spline axles installed.

Not sure yet if I will need dropped spindles.

|

|

By Glen Henderson - 15 Years Ago

|

|

Good looking welds Charlie. I have promised a buddy that I would go with him next week and dig an old S10 drag truck out of the back side of a junk yard. The truck was wrecked a couple years ago and the owner striped it and hauled the chassis to the junk yard. I looked it over and it was a well built rig with a 12 point cage. The cab, front sheet metal and bed are toast, but the frame and cage survived and appear to be undamaged. He does not have any concrete plans for it at this time but for $75, I told him if he didn't want it I did. I think that you could cut the floor and firewall from it and graft it to another cab.

|

|

By 57FordPU - 15 Years Ago

|

|

Thanks Glen. Wow, you could never start a race car any cheaper than that. The cab is wider in the shoulder area than at the floor and most cages I have seen follow that contour. However, for that price I would cut the replacement cab right down the middle and put it back together again over the cage. Should be easier than a chop top on a 50 Merc!

|

|

By 57FordPU - 15 Years Ago

|

|

Engine and trans mounts are not quite finished yet, but I thought I'd show some progress pictures. I still have to fab up a bellhousing mount. It will be a quazi motor plate. With three sets of mounts, I didn't think it needed to be a full plate.

|

|

By charliemccraney - 15 Years Ago

|

|

That poor hunchback.

|

|

By yehaabill - 15 Years Ago

|

|

Y-Guy Charlie: I want to see the 'chute mounts, when you get to the rear!!! Bill

|

|

By 57FordPU - 15 Years Ago

|

|

Nice Charlie, it took me a couple of hours to figure out your comment. I guess I just forgot the "moto". Bill, you and me both. That will be at least another $1500 expense when added to the new requirement of a Hans device.

|

|

By Hollow Head - 15 Years Ago

|

|

Charlie, not only the HANS but also a helmet with suitable klips. Though, to some helmets you can get them installed afterwards by the manufacturer. Both thumbs up for your project, keep pushing

|

|

By BIGREDTODD - 15 Years Ago

|

|

Looking great Charlie!

|

|

By 57FordPU - 15 Years Ago

|

|

Thanks Todd, hope you are feeling better. Seppo, yes, most suppliers will attach the clips to my helmet. Lots of racers are upset about the rule because there is no wall to hit and feel like it is just another unnecessary expense. Quite a few have spun, but very few have had a catastrophic accident. However, I bet someone who survives a horrible crash in the future will swear by them.

|

|

By charliemccraney - 15 Years Ago

|

|

The hans device is just one of those things where it will be fine until someone does die and it very likely could have been prevented if such a device was used. Sure, the odds are that it won't happen, but it is a small price to pay when the odds are against you and it does happen.

|

|

By mctim64 - 15 Years Ago

|

The new helmet that Kathy got me for Christmas has the place for attachment already there, the prices are coming down too.  No big deal, it just looks a little uncomfortable. No big deal, it just looks a little uncomfortable.

|

|

By Grizzly - 15 Years Ago

|

|

Guy's, It's not just racing that is seeing the introduction of Hans devices look at page 70-71 in the BMW motorcycle riders accessories http://www.motorcycles.bmw.com.au/common_content/motorcycles/assorted_content/accessories/new/AU/rider_equipment_2010_EAL_AU.PDF. Mind you I think you can even get BMW undies  BMW have every conceivable accessory. BMW have every conceivable accessory. That may give you an option of not attaching your helmet. I'm guessing that there may be some room for interpretation until compulsory racing recognized hans devices are required?? How long until this sort of device is mandatory for road going vehicles? Cheers Warren Adams

|

|

By Hollow Head - 15 Years Ago

|

Well, I quess it's about how flexible you are, but watch how this guy hits his head to the steering wheel. He has the visor closed, it opens at the crash and then closes by hitting the wheel...  HANS for you Charlie, please. Old people are not flexible! HANS for you Charlie, please. Old people are not flexible!http://www.youtube.com/watch?v=TTzbBRyOO0o

|

|

By 57FordPU - 15 Years Ago

|

|

Engine setback allowance makes a huge hole in the firewall.

Once I started on the floor, I just couldn't seem to stop!

|

|

By pegleg - 15 Years Ago

|

|

Charlie, Where's the radio gonna go?

|

|

By glrbird - 15 Years Ago

|

|

Charlie They say anyone can restore a car, but it takes a real man to cut one up! GOOD JOB!

|

|

By 57FordPU - 15 Years Ago

|

|

More cutting................

Here is your radio Frank..........

|

|

By pegleg - 15 Years Ago

|

Phew! I was worried there for a moment!

|

|

By yalincoln - 15 Years Ago

|

|

it's a good thing that it's a extended cab, at least he won't have to sit in the bed. nice job charlie, good luck.

|

|

By 57FordPU - 15 Years Ago

|

|

Time to start filling in the big holes..........

Floor should go fast.

|

|

By BIGREDTODD - 15 Years Ago

|

|

I like the floor bracing that ties to the transmission X-member. Firewall is going to look great with the tunnel finished off...that's a very impressive undertaking that's unfolding beautifully.

|

|

By 57FordPU - 15 Years Ago

|

|

Thanks Todd, a little break from the floor to set up the rear axle. The driveline angles will help determine the tunnel dimensions. UPS brought a nice surprise. The alloy axles, studs and bearing retainers are from Strange. The narrowed 9" housing and pumpkin setup are performed by Speed Frame Engineering in Farmersville, CA who sponsor me (thanks Al).

|

|

By 57FordPU - 15 Years Ago

|

|

More new parts to finish the rear axle installation. Pinion mount panhard bar bracket, new U-bolts. Also a firewall mount heim for the steering.

|

|

By Y block Billy - 15 Years Ago

|

|

I was hoping to see the brick run at Loring before you retired it? The reveiws of the place have been great from what I read, the people like it a lot.

|

|

By 57FordPU - 15 Years Ago

|

|

Thanks Billy, I would have liked to run there too. I have talked to a few fellow racers that ran there and they said it was the smoothest track they have ever been on. It also would have been fun to set a record there with a Y-Block for others to shoot at. Their meets are in July and another big swing back east like we did in 2008 would be great. We could do Maxton in June, Loring in July, Columbus in early September and make the October Bonneville meet. Corene and I spent 70 days in that 8' camper on the first trip. We stayed with friends and relatives from time to time, but 58 nights were spent in the camper and we did quite well. Do I think she would put up with 140 days on the road? We would have to hit up every friend, acquaintance and relative for lodging to survive that.

|

|

By pintoplumber - 15 Years Ago

|

|

You're welcome here again.

|

|

By 57FordPU - 15 Years Ago

|

|

Thanks Dennis, you guys are automatics, as long as you will have us.

|

|

By Y block Billy - 15 Years Ago

|

|

I have plenty of room in Maine. However, Loring is another 350 miles north of me so I would probably have to camp with you up there.

|

|

By 57FordPU - 15 Years Ago

|

|

Billy, if it comes to pass and you are not off some place saving the world, we would have a great time. I just read where Maxton will probably not get it's lease renewed. That would be a shame, it was developing it's own reputation in the East and was showing increased participation and speeds. More work on the floor and a drive shaft loop.

|

|

By 57FordPU - 15 Years Ago

|

|

Flooring work is new to me. Progress is slow and time is precious, I work on the new race truck as much as possible, but more important priorities take precedent (darn all nine grand kids, my wife, myself, our parents, friends, the garden, etc.)

|

|

By BIGREDTODD - 15 Years Ago

|

|

I'd say you're showing it who's boss, Charlie... Nice work transitioning the factory floor contours to the flat floor skeleton...and I love how you re-purpose things to achieve the shapes you need, very clever.

|

|

By 57FordPU - 15 Years Ago

|

|

Back on the rear axle with the new alloy axles, long wheel studs and brakes installed.

|

|

By nonne_56 - 15 Years Ago

|

|

Charlie Thank's for your great hospitality from me and my family. It's really nice to follow your project when we have seen it in live. Good luck and hope to see you again and best regards to your wife. Tomorrow i leave for Australia for 2 weeks of work, hope to find something y-block related " down under" to help me survive.

|

|

By dullchrome - 15 Years Ago

|

|

Nice work Charlie..as always. Cant wait to see it our at the track. Chris

|

|

By nonne_56 - 15 Years Ago

|

|

Next week i will be in Melbourne and the week after in the Sidney area. Is there any place to visit when it comes to our cars

|

|

By 57FordPU - 15 Years Ago

|

|

Thanks Chris, you know I will be there eventually. Bernt, you are welcome here anytime. It was a pleasure to meet you and your family. I enjoyed talking to your son and finding out he was a gear head, even if he has a rice rocket. We especially enjoyed finding out about Sweden's politics, weather, and day to day life. When you said you had to chuckle when you only had to pay $4 per gallon for gas for that big LTD rental car, remember that if you took a trip at home like you did here in California, you would have had to show your passport at least 4 times!!! It might not be to bad to pay close to $8 when you don't have far to drive.

|

|

By 57FordPU - 15 Years Ago

|

|

Adapting the GMC Sonoma shock mounts to the Ford 9" u-bolt brackets.

|

|

By texasmark1 - 15 Years Ago

|

|

why the long wheel studs? noticed them on the front of "Jake" as well... just wondering... thanks,Mark

|

|

By Hollow Head - 15 Years Ago

|

As in Drag Racing, long bolts prevent wheels to come off of the hubs even if the bolts are loose? Ok, it does wobble a lot before it comes off and gives a signal to the driver... With short bolts it just comes off... and then crash and learn thing  . .

|

|

By aussiebill - 15 Years Ago

|

nonne_56 (5/19/2011)

Next week i will be in Melbourne and the week after in the Sidney area. Is there any place to visit when it comes to our cars Berndt, google " pinkys car events" and click on Victoria ( melb) and NSW (Sydney) for events that may tie in with your visit. Where in Sydney will you be working etc and when. Best regards bill

|

|

By 57FordPU - 15 Years Ago

|

|

Seppo, I like your explanation as a reason for the long wheel studs. I learn something new everyday. Hey Mark, my reason for using them (and Tim as well), is that 1" lug nuts fully engaged on the studs (with threads left over) are required for classes over 200 mph (and I plan to go there).

|

|

By nonne_56 - 15 Years Ago

|

|

Thank's Bill and sorry Charlie for hijacking your thread a little bit but i am sure you understand and forgive. I dont know where i will be in Sidney, i will visit a lot of dairies around there. Thanks for the tip, i will google and see what i can find.

|

|

By 57FordPU - 15 Years Ago

|

|

No problem Bernt. Here are the clamped leaf springs that really stiffened up the rear suspension.

|

|

By 57FordPU - 15 Years Ago

|

|

No "C" notches required, just fabricated axle bumpers from the stock units.

|

|

By nonne_56 - 15 Years Ago

|

aussiebill (5/20/2011)

nonne_56 (5/19/2011)

Next week i will be in Melbourne and the week after in the Sidney area. Is there any place to visit when it comes to our cars Berndt, google " pinkys car events" and click on Victoria ( melb) and NSW (Sydney) for events that may tie in with your visit. Where in Sydney will you be working etc and when. Best regards bill Bill There is something on Liverpool Catholic Club on Sunday, do you know if it worth a visit. Funny, my Aussie colleque knows Pinky, it,a small world..

|

|

By aussiebill - 15 Years Ago

|

nonne_56 (5/24/2011)

aussiebill (5/20/2011)

nonne_56 (5/19/2011)

Next week i will be in Melbourne and the week after in the Sidney area. Is there any place to visit when it comes to our cars Berndt, google " pinkys car events" and click on Victoria ( melb) and NSW (Sydney) for events that may tie in with your visit. Where in Sydney will you be working etc and when. Best regards bill Bill There is something on Liverpool Catholic Club on Sunday, do you know if it worth a visit. Funny, my Aussie colleque knows Pinky, it,a small world.. Berndt, generally street machine show but everything will be there, bit modern for me, dont forget SYDNEY DRAGWAY has 2 day meet and is not far.

|

|

By texasmark1 - 15 Years Ago

|

|

longer wheel studs = ok to do over 200 mpg, huh? guess I'm safe with my stock ones! thanks for the edge-u-mo-cation! Mark

|

|

By 57FordPU - 15 Years Ago

|

|

Mark, Thanks for the comment, I welcome them all. I'm just trying to share what's needed to be able to compete and go straight. The long studs are but one of a "long as your arm" list of safety requirements. Pinion mount panhard bar.

|

|

By glrbird - 15 Years Ago

|

|

charlie What is the reason for the panhard bar on a leaf spring car, do you think there is enough lateral movement at high speed to need this, or is the other thinking?

|

|

By 57FordPU - 15 Years Ago

|

|

Gary, That's a good question, it wouldn't seem like one would be needed to go in a straight line. Drag racers use them all the time because of rear axle "walk" during launches and shifts and road racers need them for cornering. I've done my best with the rear springs to maintain stability by making them stiffer and installing new bushings. Even with that there is some side play and just a little creates some "rear steer" that increases with speed. The main problem would be in a spin. You want that chassis to be stable and stay as flat as possible.

|

|

By aussiebill - 15 Years Ago

|

57FordPU (5/26/2011)

Gary, I've done my best with the rear springs to maintain stability by making them stiffer and installing new bushings. Even with that there is some side play and just a little creates some "rear steer" that increases with speed. The main problem would be in a spin. You want that chassis to be stable and stay as flat as possible. Charlie, while you,re thinking of spinouts you may want a compass on the dash to get back on course. lol.

|

|

By texasmark1 - 15 Years Ago

|

|

so that's why we used to see a lot of cars with a compass on the dash!! now that's what I call "recalculating"!!

|

|

By 57FordPU - 15 Years Ago

|

|

Although I have never actually spun, I did do a bit of driving while looking out the driver side window at El Mirage in 2009. While I don't talk about spins much, I think about them quite often and how to deal with it. A compass to get back on course wouldn't be necessary because immediately after straightening up I would head straight back to the pits to change my cloths.

|

|

By 57FordPU - 15 Years Ago

|

|

The floor and driveshaft tunnel are finally finished.

Same with the transmission cover and recessed firewall.

|

|

By charliemccraney - 15 Years Ago

|

|

Looks good. Is that sections of bed floor?

|

|

By 57FordPU - 15 Years Ago

|

|

Thanks Charlie, you nailed it, when you live on the farm, you use what you got. Here are the donors.

|

|

By Doug T - 15 Years Ago

|

|

Hi Charlie Great progress on the truck, you guys rock out there! I was a little surprised by the location of the axle joint for the Panhard rod. I thought as a general rule Panhard rods should be as long as possible, the ends on the axle and frame should be at the same elevation, that is, the 'rod' should be horiizontal and the height of the rod determines the rear roll center. I am not sayin' what you have wont do what you need, just wondering if that is accepted practice for LSR vehicles.

|

|

By 57FordPU - 15 Years Ago

|

|

Doug, thanks for the comment. Panhard technology is very comprehensive and specific to dirt or asphalt. I lay no claim to knowledge of circle track suspension setups, but I've tried to follow the dirt track applications. First off, utilizing a panhard bar with leaf springs is very uncommon in closed course race cars. But, here I am trying to fuse everything together for a system that suites me. Dirt cars usually have center mounted panhard bars with a 20" minimum length (mine is 21") to affect the roll equally left and right. Attaching the panhard bar to either end of the axle affects the roll mostly in the direction of attachment. Next the axle mount being lower than the frame mount lowers the roll center keeping it to a 2" maximum difference (mine is 1 1/2"). The effects of all this is minimized due to the fact that I will only have about 1" of suspension travel. Having said all that, most people say that it takes lots of trial and error to fine tune the panhard bar setup, and that's too bad because all I can do is hope that the first trial is not an error. (Now I need to get up to speed with anti-sway bar setups)

|

|

By 57FordPU - 15 Years Ago

|

|

With the firewall finished, it is off to the paint shop with the cab. All other parts to the truck are painted.

|

|

By Hollow Head - 15 Years Ago

|

Good progress Charlie! Is that "round one" your new helmet at the door opening?  Is air suspension allowed at Bonneville? That would make the ride smooth and you could choose the ground clearance at seconds. Juha Kankkkunen went over 300 km/h on the ice this spring and he drove a Bentley with stock air suspension.

|

|

By GREENBIRD56 - 15 Years Ago

|

|

Hi Charlie - nice looking truck. I was thinking about those leaf springs too......In a recent article I saw a "replacement" for a rear leaf spring, a composite. Where the forward portion of the spring was made rigid (a bar from pivot to axle) and only the rear half was a clamped on flexible spring bar attached to the rear shackle. Quarter elliptic spring? It created a (very) short version of the "truck arm" arrangement used on the NASCAR speedway cars.

|

|

By yehaabill - 15 Years Ago

|

|

Y-Guy Charlie: I think, with the clamped leaf set-up, you can custom "Tune" by removing or adding clamps. Can't wait to see it finished and the "LOOKS" it's going to get when you lift the hood!!!! Keep it up, Bill

|

|

By 57FordPU - 15 Years Ago

|

The composite leaf would be great, but if I had the time and funds I would use a 4 link with air bags.

Bill, I have a smile on my face right now just thinking about it.

|

|

By 57FordPU - 15 Years Ago

|

Seppo, sometimes it takes me a while for concepts to sink in. It finally dawned on me that your comment about the "helmet" was the hanging light fixture . . I had great plans to use the Y-Block Quick Time bell, but have decided to abandon it for now. I have a good idea of how to modify it to use a Y-Block flywheel and starter, perhaps next year. Tim set me up with a T-5 adaption to a stock truck bell. He also modified the throwout bearing to match up the truck clutch arm with a diaphragm clutch type bearing. I am using the metal on top of the scatter shield to double the width. Tech has passed me with the 3" band, but with greater speeds expected, they will want more. It is such a blessing to have a friend like Tim. If it wasn't for him I would just be a spectator.

|

|

By Hollow Head - 15 Years Ago

|

Helmet or hair dryer  . Anyway, waiting to see that all come together and to be raced. I know, that time will come. Should we start betting you against Tim? . Anyway, waiting to see that all come together and to be raced. I know, that time will come. Should we start betting you against Tim?

|

|

By 57 ranchwagon - 15 Years Ago

|

|

Hi Charlie the truck is looking good. I have been fighting with the install of a quicktime bellhousing on my car finally got it sorted this week. I had to rebuy a new flywheel and there were pretty extensive mods to the block and starter definetly not a bolt on kit as it was sold to me. Quicktime was really helpful prompt with advise and tech support, unfortunately the people who sold it to me use a in house flywheel manufacture and they leave a lot to be desired. I ordered the new wheel from the people quicktime recommend and it looks like its going to work.

|

|

By mctim64 - 15 Years Ago

|

|

57FordPU (7/7/2011)

It is such a blessing to have a friend like Tim. If it wasn't for him I would just be a spectator.Likewise Charlie! I never would be doing this if it hadn't been for you. You can ask Kathy if that is a blessing or not.  (you know Kathy enjoys this almost as much as I do.  ) )

|

|

By grovedawg - 15 Years Ago

|

|

Hey Charlie. Just wanted to pop over and say how nice it was to finally meet you in Bonneville this year. Any progress on you truck?

|

|

By 57FordPU - 15 Years Ago

|

|

Thanks Grovedawg, it was great meeting you too. It is always nice to put a face together with people on the forum. Not as much progress on the race truck as I would like, but a little. Check fitting the cab with the 6" wide scatter shield.

|

|

By 57FordPU - 15 Years Ago

|

|

finishing up the new crossmember to mount the ears of the stock truck bell. I wished there was a part available for things like this, but it's all made from scratch. I try to make things removable to give more clearance while removing the engine and trans in one piece. Driver side

Passenger side

|

|

By mctim64 - 15 Years Ago

|

Looks good Charlie! Glad to see you getting back to work, there is some racing to do next summer.

|

|

By 57FordPU - 15 Years Ago

|

|

Changing to a stock pickup bell for the T-5 means creating a new clutch release bearing.

|

|

By mctim64 - 15 Years Ago

|

|

So that's how you are gonna do it. Looks good.

|

|

By 57FordPU - 15 Years Ago

|

|

Scatter shield now doubled, finished welding and trimmed to clear the firewall.

|

|

By glrbird - 15 Years Ago

|

|

Nothing like creating something totaly illogical to sharpen you fab skills. great Job.

|

|

By Fordy Guy - 15 Years Ago

|

|

Just call it good old American ingenuity!

|

|

By 57FordPU - 15 Years Ago

|

|

Thanks Gary and Bud. I keep trying to remind myself that it's the journey, but I still long for the destination. Putting sheet metal around the Y-Block.

|

|

By Hollow Head - 15 Years Ago

|

Charlie... more close up pics about the engine! Who cares about GMC grille  ? Even that the truck looks very good and yellow as usual... ? Even that the truck looks very good and yellow as usual...

|

|

By glrbird - 15 Years Ago

|

|

My Dad use to say GMC stood for Grand Ma's Crap, but now it means Great Motor Change. Is there a reason you like yellow, Looks good to me.

|

|

By ecode ragtop - 15 Years Ago

|

|

since the great bail out, it stands for Goverment Motors Company !!!!

|

|

By Grizzly - 15 Years Ago

|

|

Charlie, With some work you could change the "G" or the "C" to an "F". That'd get some looks. Cheers Warren

|

|

By MoonShadow - 15 Years Ago

|

|

Got My Cash!

|

|

By grovedawg - 15 Years Ago

|

It's too bad you have to cover such a gorgeous motor with that crapy GMC sheetmetal...   Looking good! Looking good!

|

|

By Fordy Guy - 15 Years Ago

|

|

Gotta Mechanic Comin' !!!!!!!!!!!!!!

|

|

By 57FordPU - 15 Years Ago

|

|

Is that all you guys got? I need help developing a thicker skin to face the jaw dropping GM lovers at the track. Besides, I like Go Mr. Charlie.

|

|

By GREENBIRD56 - 15 Years Ago

|

|

Could you just dump the letters in favor of a Blue Oval? Just the letters "FORD" would cause some interesting side effects......

|

|

By Hollow Head - 15 Years Ago

|

That letter idea is great! Big white letters over black background. And also same treatment to tail gate  ! !

|

|

By 57FordPU - 15 Years Ago

|

Now you're talkin'.........That gives me something to work with.

|

|

By LordMrFord - 15 Years Ago

|

I spotted this bumper sticker on internet surfing tour and your project came up to my mind.

|

|

By 57FordPU - 14 Years Ago

|

|

Converting the stock gas tank into a water reservoir for engine cooling.

|

|

By glrbird - 14 Years Ago

|

|

Charlie, is this instead of a radiator or added colling? Where is it mounted?

|

|

By 57FordPU - 14 Years Ago

|

|

All pickup classes require a radiator in their original location, but not required to be used. The gas tank will be mounted in it's original location and be the only source of water for engine cooling.

|

|

By charliemccraney - 14 Years Ago

|

|

It only needs a radiator, or it needs an original radiator? Maybe you can find some aerodynamic advantage by finding a small radiator to mount with a sheet of aluminum to help seal off the grill?

|

|

By 57FordPU - 14 Years Ago

|

|

Good thoughts Charlie. The rule book says that the radiator must be the same size as the original (or larger). Also there is to be no blocking of air flow allowed before or after the radiator. Guys used to try to get by the blocked radiator rule by blocking behind the radiator, but no longer.

|

|

By glrbird - 14 Years Ago

|

|

Is the reason for the tank, putting that weight further back and lower, or is their something else you are thinking of. Can you duct or direct the air coming threw the radiator say for the intake air?

|

|

By 57FordPU - 14 Years Ago

|

|

Gary, you are exactly right about putting the weight lower and back farther. Consensus is equal side to side of course and 52% front axle and 48% back. However, a current record holder at over 200 mph with one of these bodies actually likes more weight on the rear axle? I'll get it figured out. As you can imagine, with the driver and the tank on the same side, it will take considerable ballast on the passenger side and strategically located. Yes you can and I like the reasoning of directing the air from the grille and radiator area to the air intake, but I haven't completely decided on the type or location of the induction system and it may be best to take air from a forward facing scoop or the base of the windshield. By the way, I just got turned down by the tech committee to substitute the intercooler for the stock radiator. Sounded reasonable to me, but nope.

|

|

By glrbird - 14 Years Ago

|

|

Charlie Can you turn the stock radiator into a functioning intercooler, and still look like a radiator?

|

|

By charliemccraney - 14 Years Ago

|

Since a stock sized radiator has to be in the stock location, why not use a radiator for it's designed purpose? Install a smaller fuel tank in the driver side rear. Mount some steel plates to the passenger side rear. I understand the lower center of gravity but there will always be coolant in the engine. You can't do anything about that. The extra in the radiator won't amount to much and it will make it easier to get the weight distribution of the truck correct. And I imagine that you would have to carry less coolant which might end up reducing the overall weight of the truck.

Does the water tank method keep the engine at a consistent temperature?

Are there any restrictions on the installation of the turbos? You could try installing them remotely, like just ahead of the rear axle. Try to Run all of the tubing down the passenger side. The intake air will be cooler. The length of aluminum tubing for the pressurized air should keep it cool particularly since under hood temps won't influence it throughout most of the length, possibly eliminating the need for an intercooler which could cancel out the added weight of the coolant in the radiator. There can be fewer bends to reduce the pressure drop. The exhaust gas temperature will be cooler at the turbos and so the turbos will probably have to be built to account for that.

You'll be using a bed cover, right? I'll bet there is a high pressure area you could exploit for the intake air but it might either take some trial and error or some test runs with sensors in place to find the right spot.

|

|

By Hollow Head - 14 Years Ago

|

Jep, and why not to use additional intercooler in some other place. In front of windshield under the grille or why not even instead of the tailgate. Atleast airflow would be great behind the cabin  http://www.7tune.com/intercooler-placement-of-the-week/ http://ststurbo.com/

|

|

By 57FordPU - 14 Years Ago

|

|

Gary, My original thought was to cut the heart out of the original radiator core and place the intercooler in it. They said no. The stock radiator is very wide and will have difficulty getting charge and cooling lines around it. Then I wanted to put holes in the radiator core just large enough to run the lines through and they said no. Pickup classes have no altered or competition coupe type rules that allow such modifications, they want most of the pickup to look original.

|

|

By 57FordPU - 14 Years Ago

|

|

Charlie, I do like the alternative turbo location idea. When I ran the exhaust up out of the bed behind the cab in the brick, I had visions of running a turbo there. And like Seppo said, there are lots of locations to put an intercooler. I have seen street Corvettes with turbos at the rear of the car and the claim is there is little loss of performance due to the remote location. With the engine set back that is allowed, I believe I have plenty of room in front of the motor. The constant temp issue is important. I believe I will have to run a remote reservoir with a thermostat in line. The remote tank will help fill the block due to the low water tank and the thermostat will help to heat up the engine. Hopefully it will also restrict the flow enough to keep it hot during the runs.

|

|

By Hollow Head - 14 Years Ago

|

|

I think that remote location is no problem in bonneville. Turbos can be built to spool so quickly that you can't even feel the lag. It's different world in drag racing where you have to take off the line as soon as possible. In bonneville it is important to leave the line without spinning the wheels and build up the speed constantly? Right? Water cooled intercooler must be out of the question because it would need so much water to work efficiently that it increases weight too much? In drag racing they change the water after each 1/4 mile run and if there is about 10 lites of water inside of it, it's boiling hot after each run when charges and temperatures are high.

|

|

By MoonShadow - 14 Years Ago

|

Since this is in the desert and dry air is common how about a spray bar, something like the swamp coolers, help to cool the intercoolers? There would be more water on board at the start up but it would be used up during the pass? Of course they may not like the idea of water on the salt. I think I just talked me out of that Idea but I'll post it anyway. You never know where the next big thought will come from.  Chuck Chuck

|

|

By 57FordPU - 14 Years Ago

|

|

Nothing exciting, just a little more progress. Bed cover frame.

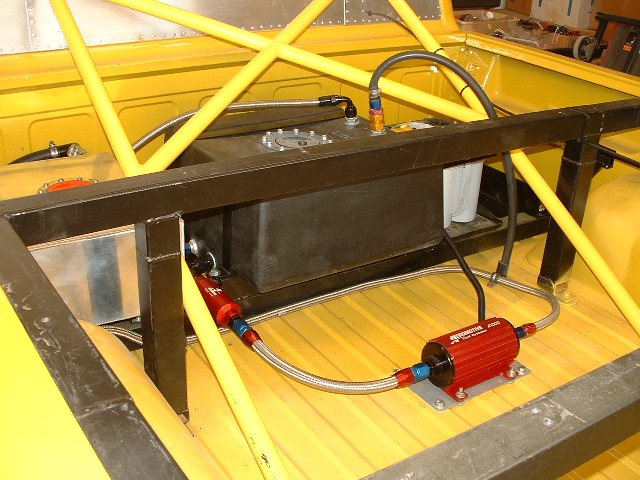

Fuel cell and battery mounted.

|

|

By 57FordPU - 14 Years Ago

|

|

Rear braces for the roll cage main hoop.

|

|

By speedpro56 - 14 Years Ago

|

|

LOOKS GREAT!!

|

|

By Hollow Head - 14 Years Ago

|

Looks nice indeed. Charlie, give us one photo of the whole truck, please.

|

|

By 57FordPU - 14 Years Ago

|

|

Seppo, I don't want to drag a GM product under everyone's nose, so I will wait until the body is finished and I will give you at least one look. I needed to double the firewall thickness. The rules say it needs to be at least .060" thick and I only made it .045". Somehow I thought it didn't make any difference since the stock firewall was only .030" thick, but I just didn't want to run a chance in having tech reject it.

|

|

By Hollow Head - 14 Years Ago

|

Safety first, even if it costs you a couple of gray hairs  . .

|

|

By 57FordPU - 14 Years Ago

|

|

I wish I had grey hair, heck, I wish I had any hair!

|

|

By 57FordPU - 14 Years Ago

|

|

Start roll cage installation.

|

|

By MoonShadow - 14 Years Ago

|

|

Its a bit sad after your clever use of a wheel barrow. Now you not only need a new one but a firewall too! Chuck

|

|

By bird55 - 14 Years Ago

|

This is probably not the first time a GM product has been improved with the technology of a wheelbarrow

It looks great Charlie, fun watching all the progress.

|

|

By 57FordPU - 14 Years Ago

|

|

If you look closely, the new firewall is another wheelbarrow. I found a new one at Lowe's with a broken handle and made the manager an offer he couldn't refuse.

|

|

By DryLakesRacer - 14 Years Ago

|

|

Charlie everything you've done looks great. I constructed a scattershield like yours in 1975 for my GMC over the stock bellhousing in in the 2nd year of running I had to add down panels to the back of it. I don't know if any inspector will need to have you do that. Their fear at that time was the clutch coming back thru the bell housing and thru my metal floor. I used 3 pieces of 1/4" plate; rectangle in the middle and a triangular piece on each side. It was long before I became a SCTA inspector. Check the rule book again on the metal thickness of the firewall. My recollection was .060" for aluminum and steel was not mentioned. I could be wrong on that as I don't have a rule book with me. My original race car had a .050" and I added a second one directly behind it because it was aluminum...Good luck PS: I think showing your build here shows how much goes into a LSR vehicle. It's not for the feint-of-heart or those who need to pay for everything to be done..........JD

|

|

By DryLakesRacer - 14 Years Ago

|

|

Looked at my book .060" is required. Guess I just live in the past............Good Luck

|

|

By 57FordPU - 14 Years Ago

|

|

Thanks for the input JD. Can you tell us a little about the car that put you in the "2 club"? Are you still an active tech inspector? Progress continues with new master cylinders, swing pedals, and steering. The Coleman swing pedals were donated by a former student of mine who now does round track racing (thanks Alan).

More steering. I had to watch for header clearance and access to changing the #8 spark plug.

Seat mounted.

|

|

By yehaabill - 14 Years Ago

|

|

Y-Guy Charlie: I just noticed the "Blower" on the mock-up engine...tell us more...lol

|

|

By mctim64 - 14 Years Ago

|

Charlie is always playing with new ideas. I just sent off my Bonneville Reg. fee!

|

|

By DryLakesRacer - 14 Years Ago

|

|

Charlie. I'll try to do a condensed version. I started at El Mirage in 1975 with a 40 Chevy coupe I ran with a 270 GMC. It quickly became a 302 in 1976 and set a record at Bonneville at 144.1 on gas. Stock head carbureted. (still have the car) In 1981 I bought a 32 Austin American Roadster and after rebuilding set a record of 162.9 in 1985 with the same engine. It was a VERY controversial roadster in a tough crowd. After many years my son wanted to drive 200. I remembered Joe Fontana had gone over 200 in a 53 Studebaker in 1985 with a 12 port GMC on fuel. We teamed up in 1997 and after 5 years my son reach the goal and set a record of 202+ in 2002. He was 34 years old. It was not easy. Every year on the salt we fixed something, many would have given up. In 2003 I got back in the car and bumped his record to 210.9. I had broken the trans in 1st gear as I left the trailer. We removed the broken cluster and I did both runs in high gear only. I was 59. The engine is a 321 in 1952 GMC with a Skinner 12 port cylinder head. Skinner injectors with a Hiborn pump and Enderle nozzles. A Howard roller cam, A Joe Hunt 5 Amp magneto and 78% nitro in the tank. I have since gone back to my gas GMC stock and made a pass at 171 setting the record for that class at 168. I'm on the Y-Block site because I recently aquired a 56 Victoria. I'm rekindling my high school daze when I got to use my moms black 56 Vic on dates in '60 and '61. This one is not black and is totally restored. Can't keep my hands off anything so I've already replaced the Holley teapot with a 53 Caddy WCFB and the Loadmatic laid waste to a 57-62 Dizzy. Had to cut up an E-Bay bought stock air cleaner to hid the WCFB. I'll try to post pics of both...I still inspect but normally now on the QT. Steve Davies likes to keep me involved and in the loop since I did it for 30 years. Once again good luck

|

|

By mctim64 - 14 Years Ago

|

Great story! Thanks for sharing.  bla bla

|

|

By 57FordPU - 14 Years Ago

|

|

Thanks for the story, very interesting stuff. The 56 looks great too! I have been keeping (Kiwi) Steve Davies in the loop with this build and he has given me great feedback. Hope to see you at El Mo and Bonneville this year.

|

|

By 57FordPU - 14 Years Ago

|

|

Bill, I need to stir up some emotions from time to time in order to keep me motivated. Nothing like a blower on top of anything to get the juices flowing. Initial shake down runs at El Mirage will be naturally aspirated just to make sure the wheels don't fall off and to get my category "D" (125 to 149 mph) driver's license. If all goes well there will be a turbo (or turbo's) later at Bonneville. Headers have been fabed for some time, but finally finished welding all seams.

Exhaust will exit ahead of the front wheels.

|

|

By Hollow Head - 14 Years Ago

|

Charlie, if you are going to use big enough turbos with those headers, you may end up to break a hole to your hood. Looks as high installation as in our dragster  ... ...

|

|

By Y block Billy - 14 Years Ago

|

Exhaust in front of the front tires? Very clever, i see what you are doing. If you exhaust them so they

Are blowing down on the front of the tire and drill dimples in the

Tire back wards to rotation so they cup the exhaust, once you are rolling you could take it out of gear and run by front wheel drive turbine power!

Every little bit counts!

|

|

By 57FordPU - 14 Years Ago

|

|

Now that makes me smile. Convenience is only one reason to exit in front of the tires (it is nice to not have to deal with crossmembers, starters and steering). Also there is a low pressure area that builds just behind the front bumper. By running the exhaust into that area, it reduces the low pressure and therefore creates less drag.

|

|

By 57FordPU - 14 Years Ago

|

|

Exhaust is finished and has room due to engine set back.

|

|

By Hollow Head - 14 Years Ago

|

Looks weird enough  . Fresh ideas are always welcome but have you had any thoughts about heat build up that is generated under the hood with that system? Ofcourse you will take intake air from a ducting placed behind the grille? Usually, the hottest spot in exhaust is the place where the x-pipe is. . Fresh ideas are always welcome but have you had any thoughts about heat build up that is generated under the hood with that system? Ofcourse you will take intake air from a ducting placed behind the grille? Usually, the hottest spot in exhaust is the place where the x-pipe is.

|

|

By 57FordPU - 14 Years Ago

|

|

Engine compartment heat buildup would certainly be a problem if left as is. I have purchased 100' of heat wrap for the headers and I will check to see if more attention is needed. Heat shields would be the next step. Intake air will come from a hood scoop.

|

|

By Hollow Head - 14 Years Ago

|

|

Charlie, here is one idea about intake air. If you use a hood scoop, that itself creates an aerodynamic obstacle over the hood and the airflow has to do 90 degree travel down the carb. You have good openings at the front bumber to take air from there by ducting. Hood would be smooth and would not harm the airflow over the car. Gross sectional area at the front stays the same and you get the same pressurized airflow to carbs although it has to travel that same 90 degree down to carb under the hood. Don't know if that has any effect to speed but...

|

|

By pegleg - 14 Years Ago

|

|

Charlie, that or the base of the windshield. we talked about this before I invited myself for dinner!

|

|

By glrbird - 14 Years Ago

|

|

Charlie, Not only do you think outside the box, you seem to make it round. I love it!

|

|

By 57FordPU - 14 Years Ago

|

|

Thanks for the comment Gary. I am not hampered by experience! Frank, you are correct with my intentions of getting the air from the base of the windshield. It will be another outside of the box solution, thanks to you and another friend Cliff Williamson. I'll post it as soon as it's fabed. By the way, when are you coming back for dinner?

|

|

By Y block Billy - 14 Years Ago

|

|

Hmmm! thats not going to create lift under the tires is it? because I am sure its hard enough steering anyway at those speeds. I was thinking more of blowing the exhaust down on the front of the tire,Like 3:o'clock position, give more downforce and help the final outcome of speed by helping drive the front wheels.

|

|

By 57FordPU - 14 Years Ago

|

|

Side tracked with a front suspension change. Air bags and 2" drop spindles.

Lower air bag mounting bracket.

Upper spring pocket enlarged to accept larger diameter air bags.

Finished edges and welded seams.

Air bags installed.

2" drop spindles.

Highest position.

Lowest position.

|

|

By MoonShadow - 14 Years Ago

|

|

Now Charlie thats what a call attitude! Chuck

|

|

By pegleg - 14 Years Ago

|

Good grief is that YELLOW! you'll be able to sell it to a Low rider when you get tired of it.

|

|

By 57FordPU - 14 Years Ago

|

|

Hi, Chuck, yeah, it is low and surprisingly nothing rubs or drags the ground. Hi, Frank. It is the same yellow as the 57 F-100. No one will want this "through away" after the salt gets through with it.

|

|

By MoonShadow - 14 Years Ago

|

|

I figured speed and salt would sand blast the paint but does it rust them out too? Chuck

|

|

By pegleg - 14 Years Ago

|

Charlie, knowing how you came by the body, seems like nobody wanted it to start with! It's a H--- of alot more desireable now than before you got it. when you're done with it, send it to the midwest, it'll look like all the rest of them up here.

|

|

By 57FordPU - 14 Years Ago

|

|

Yeah, Chuck, some racers only get about 6 or 7 trips to the salt before they need to do major repairs, especially the frame. Some pockets in a boxed frame just seem impossible to remove all of the salt. I've talked about using pressure washers, rainbird sprinklers (for hours) and still had clumps of salt fall out months later. You got that right Frank, easy come, easy go. 1-1/8" front sway bar. (need to fab one for the rear)

Proportioning valve and brake lines ran to bulkheads on the firewall.

|

|

By Hollow Head - 14 Years Ago

|

Charlie, will it be ready for this season or do we have to wait until next year. Looking really good and fast. I'am "yeallows"  . .

|

|

By pegleg - 14 Years Ago

|

Hollow Head (6/10/2012)

'am "yeallows"  . Winston Churchill said,"Puns are the lowest form of Jokes!!"

|

|

By 57FordPU - 14 Years Ago

|

|

Seppo, I keep moving the expected date back as each month rolls by. I have told Tim that I will not make it to Bonneville for Speedweek, but I sure hope to make it in October for World Finals. I will take it to El Mirage in September if finished by then and if not then in November after Bonneville.

|

|

By Hollow Head - 14 Years Ago

|

Frank, Puns are used to create humor and sometimes require a large vocabulary to understand.  Ok, ok yeallows was a bad one.... Ok, ok yeallows was a bad one....

|

|

By pegleg - 14 Years Ago

|

Winston said puns are the lowest form............, but then he never heard my humor. Ask Hoosier Hurricane, I get looks from him from time to time.

|

|

By Hollow Head - 14 Years Ago

|

Frank, is it like "if looks could kill" looks  . .

|

|

By pegleg - 14 Years Ago

|

More like "why do I put up with you?"

|

|

By 57FordPU - 14 Years Ago

|

|

Throttle in cab.

Throttle under hood.

Fun to finally work on something related to the engine.

|

|

By Hollow Head - 14 Years Ago

|

|

Hmmm... looks to work ok at the moment but how about decent Teleflex Morse cable? http://secure.chassisshop.com/partlist/6195/

|

|

By 57FordPU - 14 Years Ago

|

Sounds like good stuff..........but this is all I had around here on the farm.

|

|

By 57FordPU - 14 Years Ago

|

|

Roll cage extension under hood. Now it is an 8 point cage.

|

|

By 57FordPU - 14 Years Ago

|

|

It is finally looking like a race car. The roll cage door bars and body doors will stay off until most of the interior work is done.

|

|

By bird55 - 14 Years Ago

|

Hey Charlie, It's lookin fast already. I bet it will be.

|

|

By pegleg - 14 Years Ago

|

|

Truck Charlie, it's a truck. Well it's a chevy but still a truck. Looks better than it did when i was there. Nice build, very nice.

|

|

By 57FordPU - 14 Years Ago

|

|

Aluminum covers for the instrument panel, glove box, and speakers. The new framework is for a switch panel on the right side of the steering wheel which will also contain the fire bottle push pins. Frank, where should I put the radio?

|

|

By Hollow Head - 14 Years Ago

|

Charlie, nobody uses radio anymore! Put an iPod in the dashboard and play some funky music from internet radios  . .

|

|

By pegleg - 14 Years Ago

|

Hollow Head (7/2/2012)

Charlie, nobody uses radio anymore! Put an iPod in the dashboard and play some funky music from internet radios  . `Probably weighs less too!

|

|

By 57FordPU - 14 Years Ago

|

|

Gotta lose the drag race thinking with this truck. I will probably end up with over 400 lbs of ballast before it's over. The "Brick" had only 200 lbs of tractor weights under the bed, but at those lower speeds more wasn't necessary.

|

|

By pegleg - 14 Years Ago

|

|

Charlie, i know you said something along those lines before. Just doesn't compute in my (drag oriented) brain. The weight is to add traction or to correct handling issues from the trucks aerodynamic issues?

|

|

By GREENBIRD56 - 14 Years Ago

|

|

Hollow Head - I think the radios in these rigs are a "Citizen's Band" (CB for short) used to listen to race control (SCTA) at the dry lakes and salt flats. It would be very cool if a guy could tune in over the internet though! They (used to) maybe still -call out the time and speed at the mile markers........great to listen in on. You have to know your friend's car numbers because the line-up is helter skelter.

|

|

By landspeedy - 14 Years Ago

|

|

Your truck looks great Charlie!!!!!!!!!!!!!!!!!! I think I read on hear it wont be ready for speedweek,but are you going to be there? Hope to see you there. Keith Cornell

|

|

By 57FordPU - 14 Years Ago

|

|

I would really like to be there. I haven't missed Speed Week for a number of years. It would be great to see you and Tim pound out new personal bests, but I need to work on the race truck every chance I get in order to make it to the October meet.

|

|

By 57FordPU - 14 Years Ago

|

|

The side switch panel is necessary in this truck because of the seat set back. With arm restraints, it would be impossible to reach the dash area. It will house all toggle switches, starter button, both firebottle push cables and the master 12 volt switch. Front

|

|

By 57FordPU - 14 Years Ago

|

|

The pressure management system will allow me to set the air bags to different heights. It will help me in loading/unloading from the trailer, get a floor jack under the front crossmember, and set race ride height.

|

|

By 57FordPU - 14 Years Ago

|

|

The long road from the battery to the starter. Power starts at the safety switch in the bed and is sent into the cab through a bulkhead.

The end of the first cable terminates at the master power switch next to the side switch panel.

Then the power is sent to the starter solenoid and passed through the firewall with a cable bulkhead.

Finally, the cable is sent from the firewall side of the bulkhead to the starter.

By using (0) or (1) size cable, very little power is lost over the long system.

|

|

By landspeedy - 14 Years Ago

|

|

Looks good Charlie,very clean. Good luck in October. Keith

|

|

By 57FordPU - 14 Years Ago

|

Thanks Keith, my questions on your link was an attempt to make sure I haven't overlooked anything.

The tach and shift light are inline with the track and the supporting gauges are all in an array and visible over the steering wheel.

Now all the interior parts are fabed up and can be removed to finish welding the entire cage including door bars. Interior paint will follow and then reassymble it all again to wire it up.

|

|

By 57FordPU - 14 Years Ago

|

|

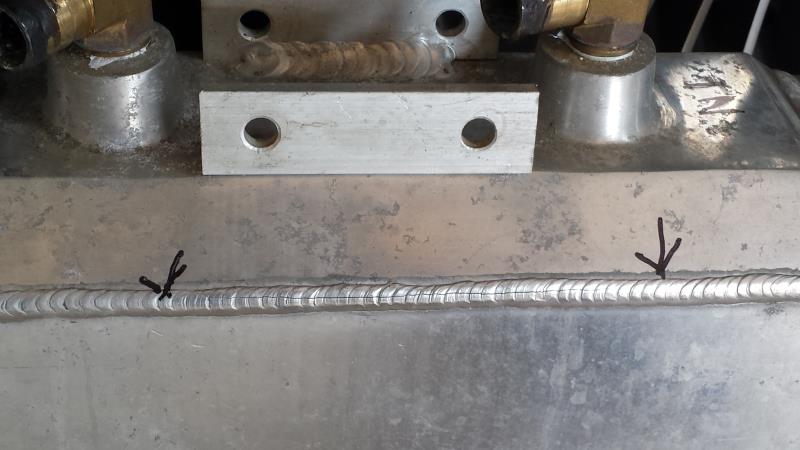

Major step forward yesterday. All interior parts were removed to finish welding the entire roll cage. Young friend, former student of mine, and professional race car chassis welder Rick Bray volunteered to well up the roll cage for me and what a treat it was. Door and shoulder bars were added.

Sample of finish welds.

More samples.

Rick needed to be a contortionist all day to get the job done.

Many thanks Rick....

|

|

By MoonShadow - 14 Years Ago

|

|

The "Kid" is good. Nice welds. When are you going to the salt? Chuck

|

|

By mctim64 - 14 Years Ago

|

|

Looking good Charlie! Wish you could be going with us next week.

|

|

By 57FordPU - 14 Years Ago

|

Tim, I wished I could be there too. However, I need to do everything I can to get this project finished this racing season. Good luck to you and Keith, go fast, be safe, and call me after every round.

Chuck, I have a small chance (read that very small) to finish by the Bonneville World of Speed that starts Sept 8th. I have a good chance to make the World finals starting Oct 3rd. Speed Week is the Big Go, but September or October would suite me just fine.

El Mirage Dry Lakes is another possibility Sept 16, Oct 21, and Nov 10 & 11.

|

|

By 57FordPU - 14 Years Ago

|

|

All interior fabrication done and paint applied.

|

|

By mctim64 - 14 Years Ago

|

Looking good Charlie! You're gonna make it.

|

|

By 57FordPU - 14 Years Ago

|

|

Had to cover the moon roof hole. Friend Rick who welded the cage also fabed up the cover. Thanks Rick.

|

|

By glrbird - 14 Years Ago

|

|

Charlie, I think for your type of racing that is a SUN roof.

|

|

By 57FordPU - 14 Years Ago

|

|

You're right Gary. I often think it would be great to drive a roadster at Bonneville (perhaps a no top 57 T-Bird). Having the bright, hot sun beating down on you would be one thing, but the rush of air buffeting your helmet would be quite the experience.

|

|

By MoonShadow - 14 Years Ago

|

|

Something like Jerry C's SR57 would be pretty slick. Maybe he will make a LSR assualt someday. Chuck

|

|

By glrbird - 14 Years Ago

|

|

Charlie I own a 57 bird and back in 69 or 70 I was on I-45 outside Houston Headed toward Dallas, there is a long straight section. needless to say top off and flat out wasn't the smartest thing to do, but it sure was exzilirating !!

|

|

By 57FordPU - 14 Years Ago

|

Arm and leg restraints.

"> ">

|

|

By charliemccraney - 14 Years Ago

|

|

kinky.

|

|

By 57FordPU - 14 Years Ago

|

|

No 50 Shades remarks.

|

|

By pintoplumber - 14 Years Ago

|

|

Hey guys, what kind of tires do you use to run those speeds?

|

|

By 57FordPU - 14 Years Ago

|

Hey, Dennis. We use Goodyear Front Runners on both front and back and they are easily available from Jegs and Summit. I use 29" dia. in the rear and 25" dia. in the front. I have seen cars capable of 225 mph pass tech with these tires. They are very light and have very little tread.

The largest group of users are the drag race cars. Obviously they use slicks in the rear and hence the term Front Runners.

|

|

By DryLakesRacer - 14 Years Ago

|

|

Moroso, Firestone, and M & H frontrunner tires have been used succesfully in LSR as well a Dunlop Vintage Racing tyres which are up to 32" in diameter. M & H diameters are as little as 22" and have run near 300. ZR "street tires" are good to 200 and I've run Michilen HR "Highway patrol" tires in the past to 170 when it was allowed. Under 200 today tires are not too much of a problem but 350 to 400 they are a big one..............JD

|

|

By pintoplumber - 14 Years Ago

|

|

Charlie, with leaving for Columbus, I forgot to wish you a happy birthday. If I'd have seen you in person I would have remembered. No point in coming with rain like that though. Happy belated birthday anyway.

|

|

By 57FordPU - 14 Years Ago

|

|

Thanks Dennis, I see the Pinto won again and against Harry. Did you dazzle 'em for a few rounds with a consistent ET and a great RT?

|

|

By pintoplumber - 14 Years Ago

|

Charlie, this was not my year. In the 1st round of y blocks, I missed 2nd gear. Was a full second slower. 1st round of bracket 3 I had a terrible reaction time and lost.

We reset the points friday afternoon and Wally retimed the motor. Saturday morning it ran a 17.949 @ 76 mph my personal best.

|

|

By mctim64 - 14 Years Ago

|

Dennis, a personal best is always a good thing. I'm still quite a few MPH from a record in my truck but I go faster each time. Personal best is the only award I get.

|

|

By pintoplumber - 14 Years Ago

|

|

Tim, I was tickled to run that. I hope the photographers caught the scoreboard. 17 seconds is a big deal for me.

|

|

By RB - 14 Years Ago

|

|

Charlie, Does it look like you will make it to the salt or to the lakes yet this yr?

|

|

By 57FordPU - 14 Years Ago

|

Dennis, congrats on your personal best, that had to be very exciting. You are very consistent and usually have great RTs, they can't keep you down forever.

Royce, it is looking dim for the October 3rd salt run. The deadline for the $425 entry fee is 9/22 with no refund except in person at Windover. The fee is $625 at the gate. I am close, but I just cannot afford to gamble at this time. However, I have every intention to run in either the October 21 or the November 10 & 11 El Mirage events. If the stars line up just right, I will be at the September 15 El Mirage race for a pre inspection even though the truck will not be ready to run that day.

|

|

By charliemccraney - 14 Years Ago

|

Bla

|

|

By pintoplumber - 14 Years Ago

|

|

Thanks Charlie.

|

|

By 57FordPU - 14 Years Ago

|

Interior finished.

"> ">

"> ">

|

|

By landspeedy - 14 Years Ago

|

|

Looks pretty serious Charlie. So your plans are for World Final's in October? Best of luck to you. Keith

|

|

By 57FordPU - 14 Years Ago

|

Keith, how I wish, but it looks like El Mirage is the only race I will be able to make this year. I know however that I will be at Bonneville next August. You coming back?

Bed cover finished.

"> ">

|

|

By landspeedy - 14 Years Ago

|

57FordPU (9/13/2012)

Keith, how I wish, but it looks like El Mirage is the only race I will be able to make this year. I know however that I will be at Bonneville next August. You coming back? Bed cover finished.   "> Good luck @ El Mirage.Yes I will be back. We have a few more tricks for some speed................

|

|

By yehaabill - 14 Years Ago

|

|

Charlie: I know you're itching to fire it up.....engine pictures next??? Bill

|

|

By Y block Billy - 14 Years Ago

|

|

Are you going to have another piece of bed cover ahead of that and cut around the roll cage pipes? just wondering if any air getting under that would create it to act like a pocket/parachute and slow you down?

|

|

By 57FordPU - 14 Years Ago

|

Hi, Billy

No, what you see is all there is. It is intentional and it would be hard for me to abandon the design as it came from a reputable source.

In 2009, while at the SEMA show in Las Vegas, I met Gale Banks in the lobby of our hotel. I struck up a conversation with him and asked about his GMC pickup Sonoma pickup that had previously gone over 200 mph. I specifically asked about the bed cover and why it was only partially covered. He told me that he had used wind tunnel testing to calculate coefficient of drag using different bed cover lengths. His best cd came from only covering the last 2/3 of the bed. He said the deeper and wider area for the circular low pressure area allowed the air stream to make a gradual downward slope to the end of the truck. I didn't understand half of it, but the 2/3 bed cover stuck pretty good. At the time I was running the "brick" and we talked about having a bed cover of perhaps 1/2 the length of the bed due to the taller cab.

|

|

By Y block Billy - 14 Years Ago

|

|

Thanks for the sectret Charlie, I guess that answers my question.

|

|

By pegleg - 14 Years Ago

|

|

Does everyone know who Gale Banks is? If not try looking him up on Google, the Guy's a Legend and he earned it the old fashioned way, brains and hard work.

|

|

By mctim64 - 14 Years Ago

|

|

Charlie's right! I had a full cover on Jake although we had talked about this. It's not that I didn't believe Charlie but I just liked the way it looked with a full cover. At El Mirage in May I was just over the 130 mph mark and though I'd give it a try so we took the front part of the cover off for the next run and went 132. No other changes.

|

|

By 57FordPU - 14 Years Ago

|

Doors, side windows and windshield installed. Aluminum covers for the mirror cavities.

"> ">

Rear roll cage braces painted.

"> ">

|

|

By pegleg - 14 Years Ago

|

|

Really top notch work Charlie. Wish I was thjat good, or even close!

|

|

By 57FordPU - 14 Years Ago

|

Thanks Frank, that is a nice compliment.

Due to the front air bag suspension, outboard shocks are now fabed.

"> ">

|

|

By DryLakesRacer - 14 Years Ago

|

|

I don't know how you are pressurizing the driver compartment but my friends Firebird at El Mirage was really dusty inside. He used the mirror blanks for a 1" tube facing forward and the dust is now a non issue. El Mirage dust has a way to get into everything. As a total side note I just returned from World Finals @ Bonneville and we were very happy to pushup the XO/Gas Roadster record to 169.2 mph with a qualifying run of 169.9 mph. For you non LSR rules guys this a 1952 stock 7 port head 310" GMC 6 on gasoline pushing a 32 Ford grille shell. My Y-block is in my 56 Victoria. Hope to see you at El Mirage by the end of the year....Keep us posted..................JD

|

|

By pegleg - 14 Years Ago

|

|

How about some photos of the Jimmy. I really liked them. Had a buddy with a 50's Sprint car that ran one. When he gave up on it and went to a SBC we bought the motor and stuck it in a 52 Chev Convert. THAT was a fun ride. I learned a lot about replacing bearings with that motor. Probably trying to rev it too high. 302 with a 270 head and a McGurk 5 carb intake!

|

|

By DryLakesRacer - 14 Years Ago

|

|

I hope these come out. An older picture before it went in the roadster, one in the car and my 2 car garage. The '56 Vic is now in there too.

|

|

By mctim64 - 14 Years Ago

|

Neat stuff! liked all the pix! any at speed?

|

|

By pegleg - 14 Years Ago

|

|

That's cool, didn't realize Clifford makes parts for them. Do you have to use the original head or would a 12 port (Wayne) be legal?

|

|

By DryLakesRacer - 14 Years Ago

|

|

Funny you should say that...Clifford never did offer a manifold for a 302, and if you look very closly that isn't one either. Many hours on a 194-292 to make fit. They make one now because of what I did. They recieved too many calls and were showed pictures and now cast one up but it doesn't flow like mine. I'm starting a 12 port crossflow head engine for my next one. It's a Skinner. Originally 5 were built in New Jersey. 15 were recast and I have #14. It's the best of all the heads. You can still get a Wayne, Horning/Fisher, or Howard/Arias all the patterns a own by a close friend in So Cal who currently is casting the "new Ardun" overheads for Flathead Ford/ Merc. and building show and racing engines. I'm sure he will own the Skinner castings some day too. Another friend in No Cal owns the molds and has cast some Wayne Chevrolets. My son and I both got into the Bonneville 200 MPH club with a Skinner on 75-80% nitro in my roadster and the owner of the engine raisied the compression ran in on gasoline in a streamliner at 255 mph to get in the club. He was 82. Working with any of the old engines is great fun..............Thanks for inquiry

|

|

By DryLakesRacer - 14 Years Ago

|

|

Opps sorry to miss part of the question. The engine in the picture is a 7 port stock head and a crossflow puts you in another SCTA class.

|

|

By 57FordPU - 14 Years Ago

|

JD, my idea of a cabin pressure/fresh air vent was a snorkel in the roof and aimed at the driver. It is just under an inch in id. Originally I thought it would be plenty as it should displace the volume of air in the cab at least once in the three mile run at 150 mph. Over the last few months, I have been wrestling with the thought it should be bigger. When I was covering the mirror cavities I was wondering how much drag some scoops would be in that position.

"> ">

The rear window is now covered.

"> ">

|

|

By mctim64 - 14 Years Ago

|

Who needs a rear window? Always going forward!

|

|

By pegleg - 14 Years Ago

|

mctim64 (10/12/2012)

Who needs a rear window? Always going forward!  Well, We HOPE so anyhow!

|

|

By DryLakesRacer - 14 Years Ago

|

|

Charlie I'd go with the single one on the top and see what happens. Jim Loving's Firebird needed 2. My first suggestion was 1" emt tubing under the hood following the roll cage up thru the firewall from front of the car; but going to the plates covering the mirrors were an easier fix. Before he put them on he could hardly drive the car from the dust. I had the same problem years ago with my 40 Chevrolet Coupe. One may be enough for your driver compartment. If not you can go from your side covers with reverse louvers. I actually used those clear circular air intakes from small private airplanes. Drilled a hole (about 1-1/2") and popped them in. I remember finding them at Ventura Municipal at a supply store. I'm sure Aircaraft Spruce has them and would work great now because of the need for Lexan windows......Good Luck

|

|

By 57FordPU - 13 Years Ago

|

Speed Week 2013 at Bonneville will not happen this year. I am so close, but just not ready. Plan B is to attend either September World of Speed or October World Finals. Speed Week gets all the hype, but the other two meets are just as important.

I thought I'd give a quick update on the build, so I will post most every day. The Y-Block will be very interesting.

Additional cabin air intake

Drawer pull from Lowe's

Parachute, emergency power disconnect and push bar (roller)

|

|

By 57FordPU - 13 Years Ago

|

This is the last of the truck build, the Y-Block is next.

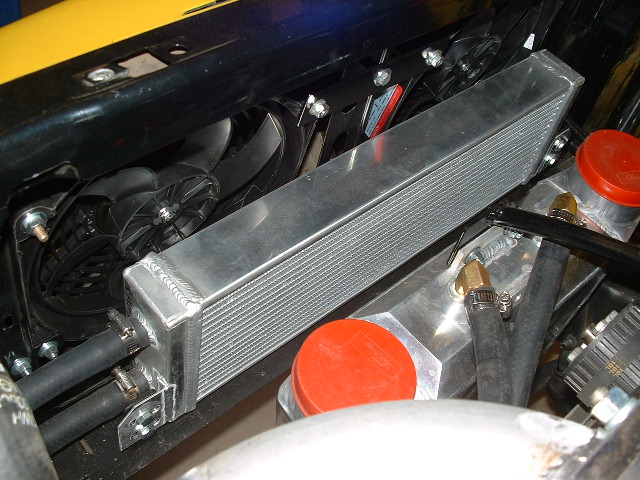

Battery, fuel cell, pre filter, fuel pump and intercooler ice tank.

Fans and post intercooler heat exchanger (hard to see, bottom half of fans)

Exhaust bezel

|

|

By pegleg - 13 Years Ago

|

|

Beautiful Work Charlie, Looks a whole lot better than when I was there.

|

|

By 57FordPU - 13 Years Ago

|

Thanks Frank, when are you delivering to our area again?

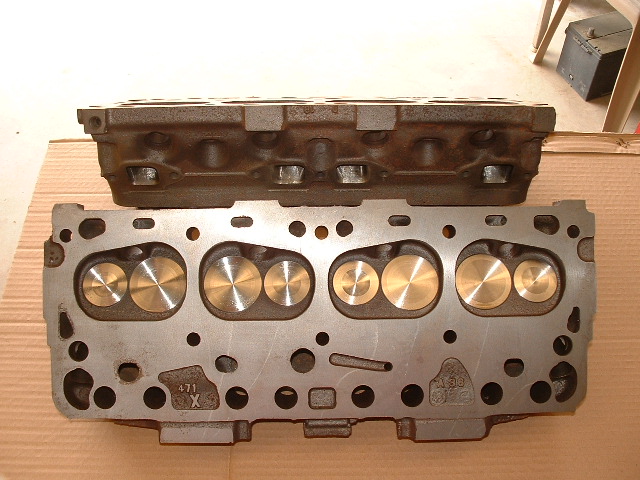

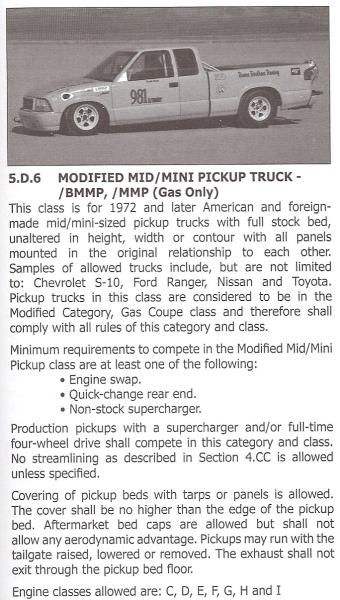

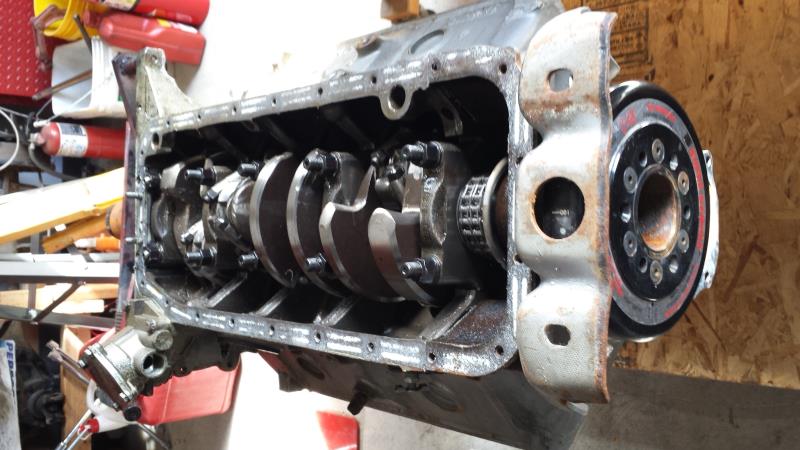

Finally we get to the engine. The first class to enter is E/BMMP. E is for the engine size and it has to be between 183 and 260 cu. in. B is for blown (in this case turbocharged). The first M is for Modified which means it is running an engine that wasn't available from the factory for this truck. The second M and the P are for mini-pickup. (E/blown modified mini pickup) The next Y-Block is already off the drawing board and will be a stroker 339 cu. in. turbocharged C motor (306 to 373 cu. in.). That will be a C/BMMP. I was hoping to run that engine this year as well, but time is running short. All the engine machining, porting, and short block assembly is of course by Tim McMaster...........Thanks Tim.

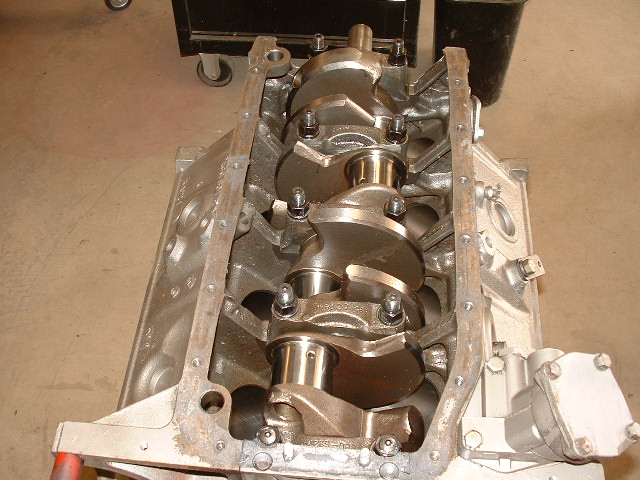

258 cu. in. block and knife edged crank.

Pistons and rods ready to install.

471 heads machined and ported.

|

|

By landspeedy - 13 Years Ago

|

Looks really good Charlie.

Looking forward to seeing you soon.

Keith Cornell

|

|

By 57FordPU - 13 Years Ago

|

Thanks Keith, I plan to be at Speed Week (without the truck). Looking forward to seeing the coupe.

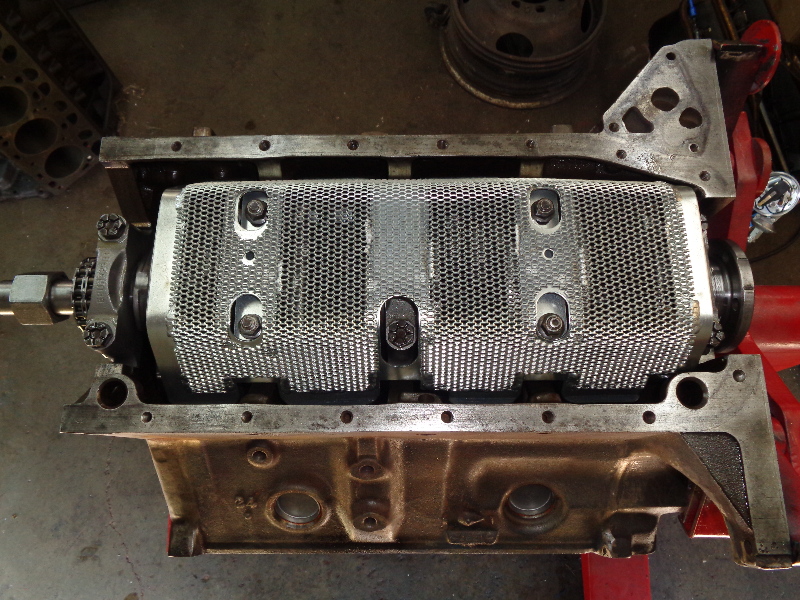

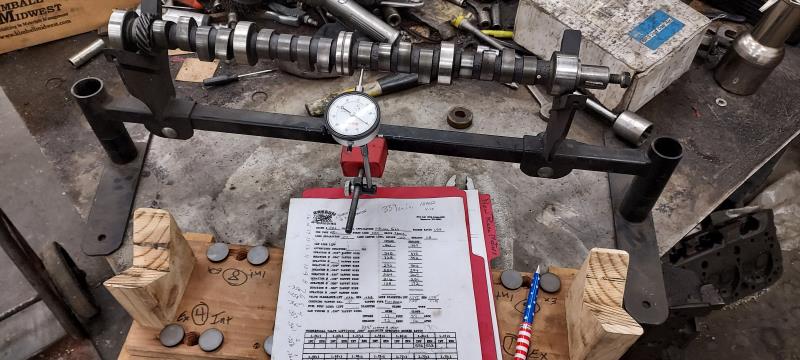

The cam is relatively mild with 220* duration at .050 lift. The total lift is .550 and the lobe separation is 114*.

The headers send the exhaust upwards and forward.

Long block assembled

258 in the run-in stand

|

|

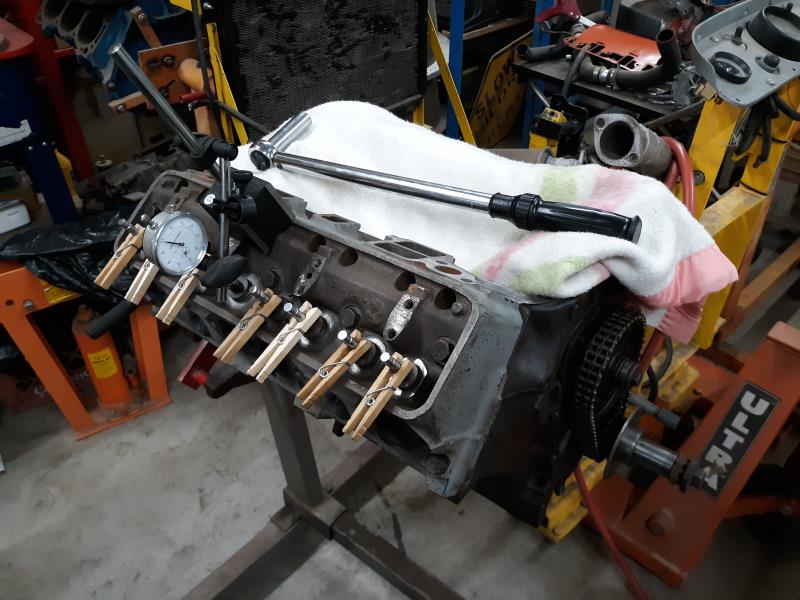

By 57FordPU - 13 Years Ago

|

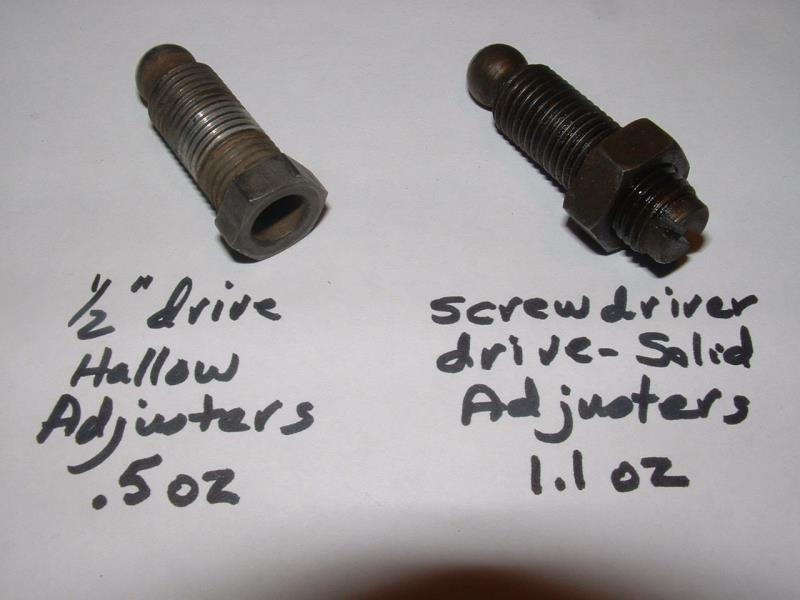

Cylinders relieved. New TRW lifters from Ted Eaton. Blue Thunder intake, head and main studs, tubular push rods along with a new true roller timing chain from John Mummert. Rockers are 1.54 ratio that have been lightened together with a restricted oil passage and a pressurized rocker shaft.

lightened 1.54 ratio rockers

lighter adjusters

258 now in place

|

|

By 57FordPU - 13 Years Ago

|

The 258 cu. in. comes from a destroked 239 crank, Ch***y 6 cyl rods, and Ford Taurus 4 cyl .030 over pistons. The new bore and stroke is 3.71 x 2.99.

Running normally aspirated was such a piece of cake compared to turbocharging. I have read the books, followed forums including Finlands finest Hollow Heads and Hutz 292 , talked to experts like Reed Patridge, and discussed cam profiles with cam grinders. Man, can I talk the language. However, I have ZERO experience. We will see how it goes.

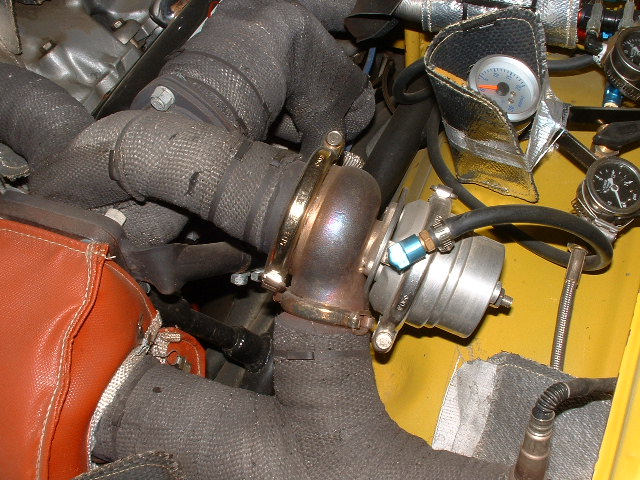

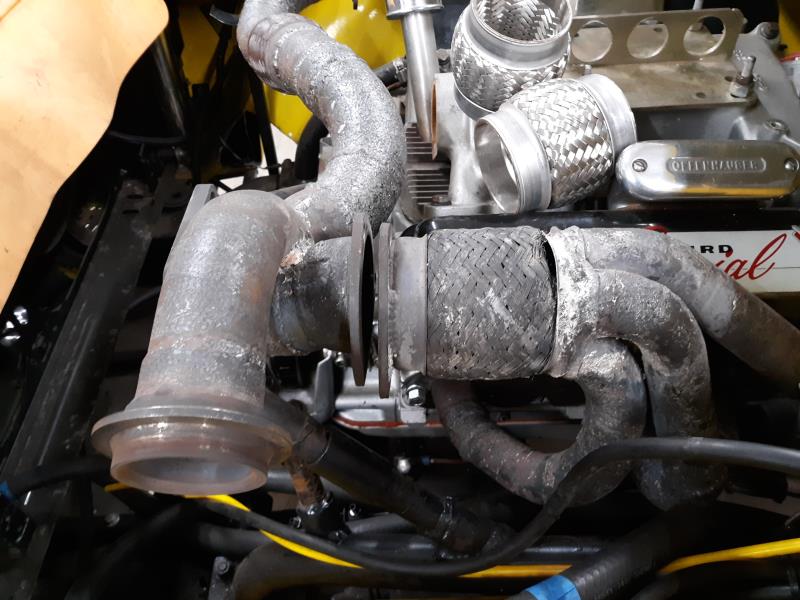

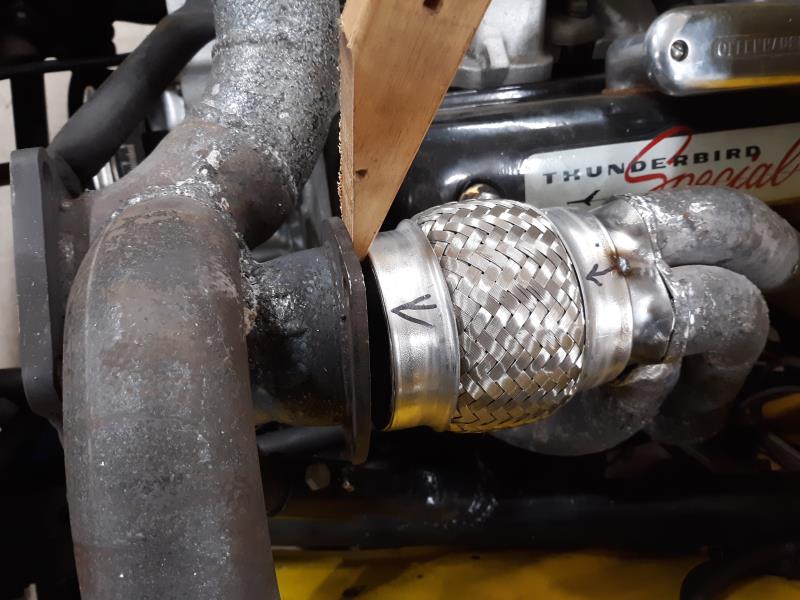

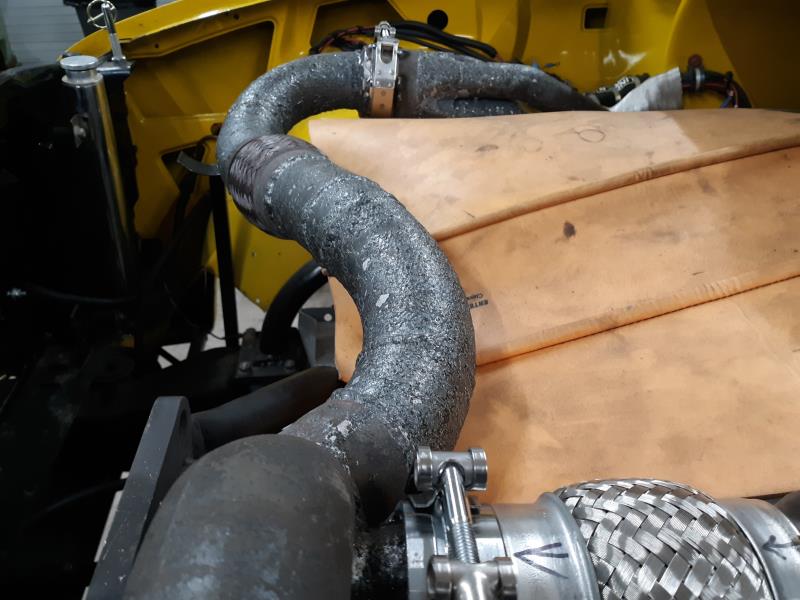

Positioning intercoolers and piping is such a challenge while trying to keep everything under the hood of a small engine compartment (without a scoop). Locating the turbo gives you another challenge in order for intake air, exhaust, and compressor discharge to be aimed in the right directions.

The radiator seperates the intercooler and the post intercooler heat exchanger.

Placement of the T-4 mounting flange gave me direct discharge of the turbo into the intercooler.

Better view

|

|

By LordMrFord - 13 Years Ago

|