|

By PF Arcand - 16 Years Ago

|

|

With respect to the "corner" in the factory exhaust port outlets. I asked a similar question a short time ago. ( I was referencing off the new heads) Tim has explained what he actually did there, and Hurricane John pointed out to me that heavy grinding of the hump will hit water!

|

|

By Doug T - 16 Years Ago

|

|

Re Exhaust porting, I don't think there is much disagreement to the idea that the exhaust port is undersized in the G heads. I.60"dia exhaust valves are definitely a help. For porting my preference is to do it like the old heads that Ted has pictured so well: that is with an arched or curved roof. Flow testing on a bench will show that a flat roof will flow more but in all instances there needs to be a square to round transition for the header tube some place between the flange of such a port and the tube that will speed up the flow causing an increase pressure. I like very smooooth flow paths with a flow reversion as the only change in cross section until well beyond the exhaust flange. Therefore I make the transition as part of the port itself. In any case be sure to use the proper safety goggles when you start to port the intake side!

|

|

By Y block Billy - 16 Years Ago

|

|

Good stuff in Docs article, I think Johns expertise speaks for itself and it shows in his new heads.

|

|

By aussiebill - 16 Years Ago

|

grovedawg (7/1/2010)

Ted (7/1/2010)I’ve put them back together just to run a short stint on the dyno to see how they stack up against conventionally ported heads. What was the result of your dyno testing? Just curious....  Ted, probably in the early 70,s i ported heads with the round port theory and cant remember the results but looked good, but there are few heads made with round ports, the D theory port has proven itself in most applications, but those ones with the angled mill job should perform well for constant high RPM range. On another part of these theorys, i have heads with the intake port runners removed as far as can be done, again for constant high rpm use. Thankfully we have the benefit of your time and interest to dyno these varying modifications and form a baseline list of improvements to aim straight off with. We all sit watching these results and are thankfull for your enthusiam. regards bill.

|

|

By aussiebill - 16 Years Ago

|

57FordPU (7/1/2010)

I realize this is an exhaust port thread, but I have an interest in what Aussie Bill mentioned. I read in a previous Yestertech article by Jerry C in Y-Block Magazine that removing the runner separation in the head did just what you said, it worked better at the top end, but at the expense of low end torque. Of course that peaked my interest because that is mostly what I am interested in. Bill, do you remember any performance details when removing the runner separation? I have recently talked to Jerry and he suggests that I start with no runner separation in the intake adaptors, but leave the head runner separation with a good radius on the leading edge. Then later, try removing the separation in the heads for a comparison. Any thoughts? (Sometimes Tim just shakes his head at me  ) If the forum moderators feel like this should be moved to a sperate thread please feel free to do so. Hi charlie, it was so long ago i cant remember, actually yesterday is a chore also, but those heads were run on speed boat along with Cain open runner intake and basically pedal to floor all the way, in those days everything was a "lets try this and see what happens" . I agree with jerry on trying a bit at a time with that idea and note the improvements, nowadays things can be measured and comparisons drawn, i,m sure ted might relate to possible results from this type of head mod. best regards bill.

|

|

By 57FordPU - 16 Years Ago

|

I realize this is an exhaust port thread, but I have an interest in what Aussie Bill mentioned. I read in a previous Yestertech article by Jerry C in Y-Block Magazine that removing the runner separation in the head did just what you said, it worked better at the top end, but at the expense of low end torque. Of course that peaked my interest because that is mostly what I am interested in. Bill, do you remember any performance details when removing the runner separation? I have recently talked to Jerry and he suggests that I start with no runner separation in the intake adaptors, but leave the head runner separation with a good radius on the leading edge. Then later, try removing the separation in the heads for a comparison. Any thoughts? (Sometimes Tim just shakes his head at me ) If the forum moderators feel like this should be moved to a sperate thread please feel free to do so. ) If the forum moderators feel like this should be moved to a sperate thread please feel free to do so.

|

|

By mctim64 - 16 Years Ago

|

|

Yes I have removed the corner area to match the gasket, but I leave the hump in and just clean up the pocket. I don't have a flow bench but I do have a great low end in my '58, the "Brick" and "Elwood" are mostly top end but pull pretty good on the low. I also try to make the header/manifold slightly bigger than the exhaust port, 'sposed to discourage back flow. I'm sure Ted and John will chime in soon.

|

|

By mctim64 - 16 Years Ago

|

I am running 1 5/8" primaries on the FED but only 1 1/2" on the '58 Effie and the "Brick", I have a kit for a set of tuned headers with 1 5/8" but just haven't assembled them yet. As Charlie Mc said there should be some good info on headers coming up soon. I am always learning too.

|

|

By mctim64 - 16 Years Ago

|

Charlie, I always listen to your ideas.

|

|

By mctim64 - 16 Years Ago

|

LOL! Nice Doug!

|

|

By mctim64 - 16 Years Ago

|

|

"D" port has the flat on the bottom and curved on top, the gasses natually flow to the top.

|

|

By YellowWing - 16 Years Ago

|

|

Good job. It will be interesting to hear how they perform when you get it back together. Mike

|

|

By Talkwrench - 16 Years Ago

|

Im no expert but I would say better to leave it as taking too much out will lower velocity. taking more out might be ok for forced induction applications... rememeber you can't go back once its gone, just tidy up around the edges.

|

|

By grovedawg - 16 Years Ago

|

Doc Frohmader wrote an article about porting Y-Block heads, and it's online at Egge's website HERE

Towards the end of the article he talks about port matching the intake side to the intake gasket- not much work was needed there. But he also references the exhaust side, and talks about that corner that is blocked off. It's visible in this picture HERE

Doc says not to take that corner out as it's a low flow area, and removing it will drop exhaust velocity. But, I recently watched a YouTube video where Tim removes that corner to match the entire port to the exhaust gasket. That video is HERE

At 3:06 mins into the video you can see that he has nicely matched the ports to the gasket, and has removed a large bit of metal that makes up that corner.

Any ideas as to what I should do? Right now, I've only matched the port to the gaskets on the outside edges of the port, and have completely left that blocked off corner alone.

|

|

By grovedawg - 16 Years Ago

|

|

I keep wondering about the loss of velocity if I did remove them. I just need to trust what people have found out through flow benches. Thanks duders

|

|

By grovedawg - 16 Years Ago

|

|

Thanks Tim! So you just relieve from the manifold surface back to the hump. In essence it's like a radius from the peak of the hump in the center of the port that meets the edge of the exhaust manifold. Thanks again!

|

|

By grovedawg - 16 Years Ago

|

This is also a side question for you Tim (or anyone for that matter). But I've heard conflicting reports on exhaust size and velocity theories. What exhaust primary would you recommend for a 1.6 valve exhaust?

I was planning on a 1 5/8 exhaust primary, but an engine builder that I respect said stay with the 1 1/2 to maintain velocity. What do y'all recommend? Obviously I'll follow your advice Tim, and enlarge the manifold flange to cancel reverb into the ports etc. But, give me some advice cause I'm still a newb!

|

|

By grovedawg - 16 Years Ago

|

Thanks Charlie and Tim! The nice thing is I'm still probably about 3 weeks out form building my exhaust headers. So, hopefully the dyno testing will be done by then!

|

|

By grovedawg - 16 Years Ago

|

|

Ted (7/1/2010)I’ve put them back together just to run a short stint on the dyno to see how they stack up against conventionally ported heads.

What was the result of your dyno testing? Just curious....

|

|

By grovedawg - 16 Years Ago

|

Is Doug a Cyclops??? I wonder if we can measure the difference in efficiency/performance of cycloptic head porting, verses the more traditional two-eyed approach!

If one eye works better I'll need to fashion an eye-patch of sorts to block out vision in one eye. I'm sure there's a pirate forum somewhere that I can ask about building an eye-patch in my garage... I just need to make sure it's a "TRADITIONAL PIRATES ONLY FORUM." I can't have any of this non-traditional crap....

|

|

By grovedawg - 16 Years Ago

|

|

Those heads are currently sitting on the dyno engine awaiting a break in shop activities so the engine can be put back on the dyno. Probabaly in a couple of weeks the way things look right now.Two sets of ported heads will be tested back to back on the same day when it does happen.The second set of ported heads (more conventional porting) will be used for the exhaust and header tests.

Thanks Ted. I can patiently wait for the results. I do appreciate all of the knowledge you share!

|

|

By grovedawg - 16 Years Ago

|

One more quickie post on the same thread...

Doug T (7/2/2010)

Flow testing on a bench will show that a flat roof will flow more but in all instances there needs to be a square to round transition for the header tube some place between the flange of such a port and the tube that will speed up the flow causing an increase pressure. I like very smooooth flow paths with a flow reversion as the only change in cross section until well beyond the exhaust flange. Therefore I make the transition as part of the port itself.

So, you're saying two things that are news to me. The first: That a flat roof flows better. Of a D port, with the flat side of the D on the top of the port, or bottom of the port?

Second: That you like to radius the port side into a circular shape to match the circular shape of the exhaust tubing coming out of the flange? (Did I catch that right?)

My intuition about the second point is that might lead to more reversion without having some disparity between the square exhaust ports and the circular exhaust tubing. But, I'm still a total newb!

|

|

By grovedawg - 16 Years Ago

|

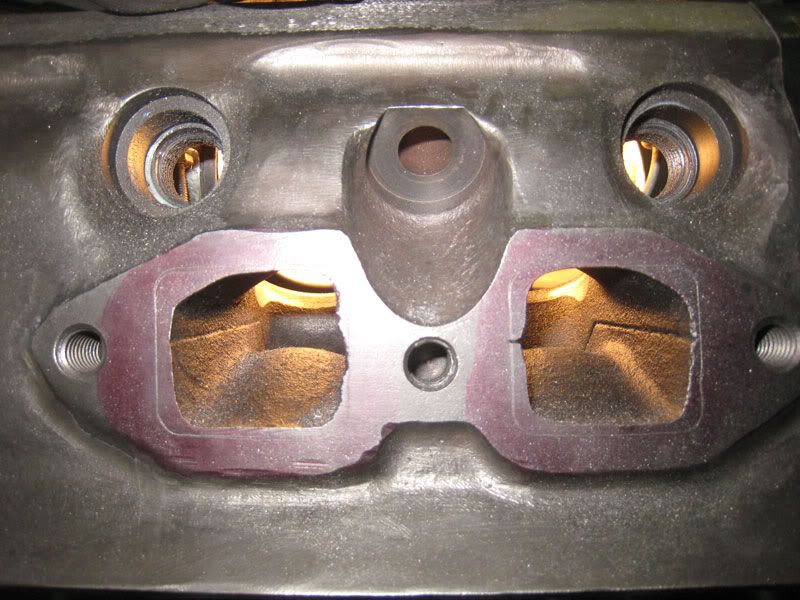

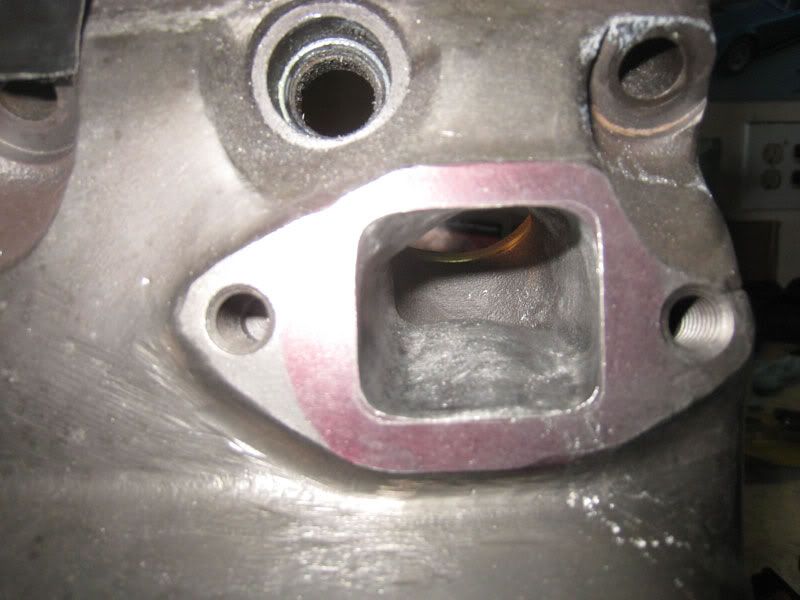

So, I finished all of the porting. I'm going to finish cc-ing the chambers and modifying them until they are all the exact same. At that time I'll go through the ports one last time to clean out any final burs, and rough out the intakes one last time. But otherwise I appreciate all your guys help. Here are some pics.

|

|

By grovedawg - 16 Years Ago

|

Yellow Wing: Thanks. I've had them on a flow bench and they tested to 159-160CFM per port. So, I'm really excited as well. Not to bad for my first crack at porting eh?

I can't wait to put a header and an exhaust and see how they RUMBLE!

|

|

By charliemccraney - 16 Years Ago

|

|

I think you'd want at least 1 5/8 primaries. Hold out for a little while longer and we'll know lot more about it. A very comprehensive exhaust dyno test will be taking place some time soon.

|

|

By Ted - 16 Years Ago

|

|

My preference is to leave the hump in the exhaust that’s above the spark plug when porting the Y heads but that’s more for insuring that the casting does not get too thin in that area as a result of grinding. As John originally makes reference to, there’s water under that hump so you’ve got to be cognizant of that when grinding in that area. The FE heads are designed similarly in that it’s easy to hit water in the hump area in the exhaust if trying to remove the hump entirely. For both the Y and the FE, the exhaust flow itself is more highly concentrated at the roof of the port so that’s where the emphasis for exhaust porting work will need to be concentrated. It goes without saying that the headers ports themselves should not be any smaller than the exhaust ports in the heads or have any restrictions present. Here are some pics of various ported exhaust ports.

And here are pictures of the exhaust ports on a set of heads that were run in the late Sixties on a circle track engine and won the series that year. I’ve put them back together just to run a short stint on the dyno to see how they stack up against conventionally ported heads. These particular heads are small letter G heads that had already been angle milled 0.175” and fitted with homemade ‘posts’. CC’ing the heads indicate a 1½ point compression ratio increase in just bolting them on in place of a set of G heads that were flat milled 0.025”.

|

|

By Ted - 16 Years Ago

|

grovedawg (7/1/2010)

Ted (7/1/2010)I’ve put them back together just to run a short stint on the dyno to see how they stack up against conventionally ported heads. What was the result of your dyno testing? Just curious....  Those heads are currently sitting on the dyno engine awaiting a break in shop activities so the engine can be put back on the dyno. Probably in a couple of weeks the way things look right now. Two sets of ported heads will be tested back to back on the same day when it does happen. The second set of ported heads (more conventional porting) will be used for the exhaust and header tests.

|

|

By Ted - 16 Years Ago

|

57FordPU (7/1/2010)

...I read in a previous Yestertech article by Jerry C in Y-Block Magazine that removing the runner separation in the head did just what you said, it worked better at the top end, but at the expense of low end torque. Of course that peaked my interest because that is mostly what I am interested in. Bill, do you remember any performance details when removing the runner separation? I have recently talked to Jerry and he suggests that I start with no runner separation in the intake adaptors, but leave the head runner separation with a good radius on the leading edge. Then later, try removing the separation in the heads for a comparison. Any thoughts? (Sometimes Tim just shakes his head at me ) ) The Cain intake manifold is completely runnerless; both at the carb flange and the ports. Testing on two different engines has this particular intake design down on both torque and horsepower as compared to modern dual plane intake manifolds (Mummert and Blue Thunder). This testing gives an idea of what the horsepower and torque does if removing the dividers from an intake that originally had divided ports. Removing the dividers in the heads should have similar results as removing the dividers from the intakes. I have heard the stories of the dividers being removed in the heads and lowend performance always suffered but performance above 5000 rpms tries to come back. Based on what I saw with the Cain intake testing, topend performance is still going to be weaker with the runners being removed than with a good modified stock intake or an aftermarket manifold. Here are a couple of past threads showing dyno results on two different engines with the runnerless design Cain intake manifold. http://forums.y-blocksforever.com/Topic29068.aspx http://forums.y-blocksforever.com/Topic46008.aspx

|