|

By FORD DEARBORN - Last Month

|

Most here probably know I installed a 312 crank in my '64 F100, milled the deck about .023", milled G heads .010, the cam is a copy of the 1957 stock cam by Oregon Cam installed 4* advanced and the pistons are cast Silvolite 312 bore .010" in the hole. I assembled everything about 12 years ago with no issues at all except for an annoying very slight antifreeze leak staining the sides of the block coming from the head gaskets. The gaskets are Fel-Pro composition that I later learned from this site are prone to this condition. Salt is now on Michigan roads so my winter project may? be to finally replace the present head gaskets with "Best" head gaskets. However, my build is not high performance. So, what are the chances of successfully using steel-shim head gaskets just to up the compression, performance and efficiency a notch? There appears to be no shortage of steel gaskets out there. Or have these gaskets outlived their shelf life? I recall back in the day (1960's) assembling at least two Y-blocks using steel head gaskets with no issues, one pair of heads I milled while in high school machine shop - was really cool we could do those things back then. Thanks in advance for any input regarding steel head gaskets....

|

|

By DANIEL TINDER - Last Month

|

|

With the block & heads milled flat, and the pistons down in the hole, I would assume copper-coated steel gaskets would work ok (OEM after all for many years), especially if a 60-70% concentration of propylene coolant was utilized, though re-torquing would likely be necessary

|

|

By Ted - Last Month

|

As long as the pistons are at least 0.010” in the hole, the quench values are adequate enough to prevent the pistons from contacting the heads. With many of the steel shim head gaskets being around 5.24cc, you can expect about a ½ point compression ratio increase versus using the 10cc composition head gaskets.

Daniel brings up the main point on why not to use the steel shim head gaskets and that’s due to the need for a retorque being required after the engine has been initially run. A secondary reason has to do with the coolant leakage that can still occur with those gaskets and that leakage can be to the inside of the engine where it’s not quickly seen. While silver paint and/or various sealers can help prevent leakage issues, persistent coolant leakage problems still exist when using the steel shim head gaskets. Over time, the steel shim head gaskets do erode and/or rust and that also causes issues including potential heating issues when those front coolant holes that are normally blocked do become open. Added to this is the finish and straightness on the heads and decks being much more critical when using steel shim head gaskets versus using the composition style gaskets.

Other comments always welcome so let’s hear them.

|

|

By FORD DEARBORN - Last Month

|

|

Thanks Ted and Daniel for your input. Retorquing would not be a deal breaker but it sounds like there will be a greater potential for leakage with steel gaskets and that's the kind of information I was looking for.

|

|

By 55blacktie - Last Month

|

|

Although I like to see the quench close to .040, Ted has said that he's seen no difference in engine performance up to .060 quench. If your pistons are .010 below deck, and you use Best head gaskets that have a compressed thickness of .046, your quench will be .056.

|

|

By DANIEL TINDER - Last Month

|

Ted (11/21/2025)

As long as the pistons are at least 0.010” in the hole, the quench values are adequate enough to prevent the pistons from contacting the heads. With many of the steel shim head gaskets being around 5.24cc, you can expect about a ½ point compression ratio increase versus using the 10cc composition head gaskets. Daniel brings up the main point on why not to use the steel shim head gaskets and that’s due to the need for a retorque being required after the engine has been initially run. A secondary reason has to do with the coolant leakage that can still occur with those gaskets and that leakage can be to the inside of the engine where it’s not quickly seen. While silver paint and/or various sealers can help prevent leakage issues, persistent coolant leakage problems still exist when using the steel shim head gaskets. Over time, the steel shim head gaskets do erode and/or rust and that also causes issues including potential heating issues when those front coolant holes that are normally blocked do become open. Added to this is the finish and straightness on the heads and decks being much more critical when using steel shim head gaskets versus using the composition style gaskets. Other comments always welcome so let’s hear them.

Ted,

I apologize if this has come up previously (memory failing), but this thread has me thinking:

Stroked/honed 292, non-posted G heads (chambers matched, cleaned up .005), Best gaskets, milled deck with pistons level, Isky E4 cam timed zero.

Aside from ignition advance & 93 pump fuel considerations, what issues might emerge in a street/driver car? Would an alum. flywheel be thus more problematic?

|

|

By 55blacktie - Last Month

|

|

"[C]am timed zero"? Do you mean installed straight up, not advanced or retarded? I'm sure you don't mean zero lash.

|

|

By FORD DEARBORN - Last Month

|

I questioned the use of steel gaskets to find out if there might be a modern sealer or installation method that would put steel gaskets on par with composition gaskets but no such luck. Quench as mentioned above, is one of the items that would be improved by about -.020" but this engine runs and performs close to perfect. It would have been mice to slightly improve all things considered by changing head gaskets though. Thanks everyone for your input....

|

|

By Ted - Last Month

|

DANIEL TINDER (11/22/2025)

Ted, I apologize if this has come up previously (memory failing), but this thread has me thinking:

Stroked/honed 292, non-posted G heads (chambers matched, cleaned up .005), Best gaskets, milled deck with pistons level, Isky E4 cam timed zero.

Aside from ignition advance & 93 pump fuel considerations, what issues might emerge in a street/driver car? Would an alum. flywheel be thus more problematic?

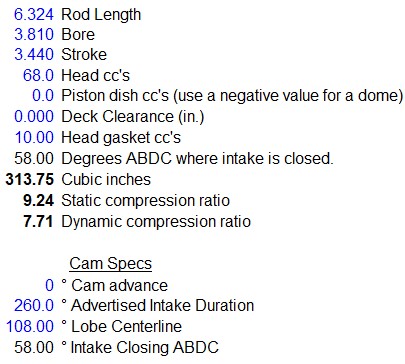

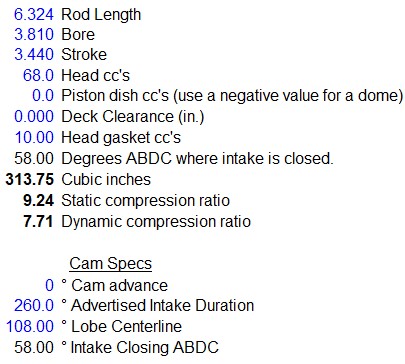

Daniel. While you do not give the particulars on how much bore and stroke increase you have, it’s difficult to get in trouble with the compression ratio on the Ford Y when using iron heads. For the math, I used a 0.060” over bore, a 312 crankshaft with the pistons at zero deck, and the E4 camshaft installed straight up (zero advance or retard). You said a 0.005” mill on the heads, so I used 68cc for the combustion chamber value without any other information to go by.

With these values, I do not see any issues at all with your basic combination. The engine may see a slight hesitation right off of idle with the camshaft at 108° intake lobe centerline depending upon the carburetor. Loosening up the lash some more can help with that. Carb adjustments would include a richer idle circuit and potentially more pump shot from the accelerator pump.

Aluminum or lighter than stock flywheels can make the car difficult to drive in stop and go situations. Aluminum flywheels work well for something like a circle tracker but not so much for a daily driver and/or a drag car where getting the car moving from a dead stop is more important. As a general rule, the flywheel weight for a street driven car needs to be at least 1% of the cars weight. Trucks will use even heavier flywheels to keep the engine from pulling down excessively when engaging the clutch from a complete stop.

|

|

By 55blacktie - Last Month

|

|

Hesitation off idle more/less likely with narrower/wider LSA, generally speaking?

|

|

By Ted - Last Month

|

|

55blacktie (11/23/2025)

Hesitation off idle more/less likely with narrower/wider LSA, generally speaking?

That’s a ‘Yes’ in that narrowing the lobe centerline angle on the camshaft can create some lean and hesitation issues. That’s simply due to the overlap between the intake and exhaust valves increasing as the lobe centerline decreases and that will have a negative effect on the manifold vacuum at idle. Intake manifold design becomes a significant player in all of this. The use of a true dual plane intake is worth as much as a 1½” Hg increase in manifold vacuum versus what you would see with a dual plane intake with a notch in the plenum divider or a single plane intake. The carburetor signal at idle relies on the manifold vacuum so anything you can do to increase that manifold vacuum will help low end performance.

|

|

By DANIEL TINDER - 9 days ago

|

Ted (11/22/2025)

DANIEL TINDER (11/22/2025)

Ted, I apologize if this has come up previously (memory failing), but this thread has me thinking:

Stroked/honed 292, non-posted G heads (chambers matched, cleaned up .005), Best gaskets, milled deck with pistons level, Isky E4 cam timed zero.

Aside from ignition advance & 93 pump fuel considerations, what issues might emerge in a street/driver car? Would an alum. flywheel be thus more problematic?

Daniel. While you do not give the particulars on how much bore and stroke increase you have, it’s difficult to get in trouble with the compression ratio on the Ford Y when using iron heads. For the math, I used a 0.060” over bore, a 312 crankshaft with the pistons at zero deck, and the E4 camshaft installed straight up (zero advance or retard). You said a 0.005” mill on the heads, so I used 68cc for the combustion chamber value without any other information to go by.

With these values, I do not see any issues at all with your basic combination. The engine may see a slight hesitation right off of idle with the camshaft at 108° intake lobe centerline depending upon the carburetor. Loosening up the lash some more can help with that. Carb adjustments would include a richer idle circuit and potentially more pump shot from the accelerator pump. Aluminum or lighter than stock flywheels can make the car difficult to drive in stop and go situations. Aluminum flywheels work well for something like a circle tracker but not so much for a daily driver and/or a drag car where getting the car moving from a dead stop is more important. As a general rule, the flywheel weight for a street driven car needs to be at least 1% of the cars weight. Trucks will use even heavier flywheels to keep the engine from pulling down excessively when engaging the clutch from a complete stop. With these values, I do not see any issues at all with your basic combination. The engine may see a slight hesitation right off of idle with the camshaft at 108° intake lobe centerline depending upon the carburetor. Loosening up the lash some more can help with that. Carb adjustments would include a richer idle circuit and potentially more pump shot from the accelerator pump. Aluminum or lighter than stock flywheels can make the car difficult to drive in stop and go situations. Aluminum flywheels work well for something like a circle tracker but not so much for a daily driver and/or a drag car where getting the car moving from a dead stop is more important. As a general rule, the flywheel weight for a street driven car needs to be at least 1% of the cars weight. Trucks will use even heavier flywheels to keep the engine from pulling down excessively when engaging the clutch from a complete stop.

Thanks Ted. Your estimations are likely right on. Was just concerned by the high static comp., but hadn’t realized how much lower the dynamic would be.

Bought the alum. flywheel assuming quicker revs would enhance highway performance, but didn’t consider the overall driveability penalty reality (any circle trackers out there interested?).

|

|

By 55blacktie - 9 days ago

|

|

Even if you can live with an aluminum flywheel on the street, how long will it last?

|