|

By 55blacktie - 4 Months Ago

|

|

I intend to use non-posted G heads on my build. The heads have been milled .013. The block will be zero-decked. My calculated static compression ratio is 9.4:1; static is 8.04:1. Best composite gaskets will be used. Although I don't consider this high compression, will it be a problem with non-posted heads?

|

|

By Ted - 4 Months Ago

|

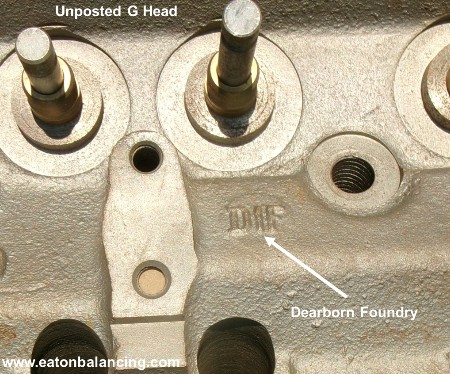

Great question but answers will be somewhat vague or ambiguous simply due to the number of variables involved. The unposted ‘G’ cylinder heads have unsupported decks within them where the head gasket sealing ring resides. This increases the chances for a head gasket failure should there be any flex in those head decks. From the Ford shop manual, it was recommended to hold any milling of the 1957 heads to a maximum of 0.010”. In doing that to a 312 with the ’57 camshaft, that makes the static compression ratio ~9.25:1 and the dynamic compression ratio ~7.85:1. You can consider those your factory safe limits.

It must be remembered that FYB cylinder heads prior to the ‘G’ heads also had non-posted heads but those heads are not as susceptible to excessive deck cutting as the ‘G’ heads are. The reason for that is the earlier heads, take the ECZ-C as an example, had lower intake ports that were cast as part of the decks thus adding a significant amount of support to the deck portion of the head. The ‘G’ heads had lower intake ports that were raised and subsequently had a gap in the casting between the lower port and the deck internally.

All the heads cast at the Dearborn facility are of the unposted variety. Late in the 1957 production run, the Cleveland facility started casting the G heads with the posts cast within them. Earlier Cleveland heads are also unposted. May 15th, 1957 comes to mind as the date that change at the Cleveland foundry took place but feel free to correct that if you have better information. As a general rule, all small letter G heads are unposted but when dealing with the large letter G heads, you will need to verify if the heads are posted or not.

But here’s where those other variables start coming into play. Increase the intake duration of the camshaft or make the intake closing event later, then the DCR actually gets lower thus permitting some latitude in milling the heads more and still keep the combustion pressures the same as with the aforementioned factory ratio.

The heads bolts and head gaskets are yet another consideration. The factory grade six bolts were noted for not holding their torque or said another way, stretching over time. Grade eight bolts do help with this. The factory steel shim gaskets were also not very forgiving when dealing with cylinder head deck flex. The newer crop of composition gaskets do help in this area but some piston to deck adjustments must be made due to those gaskets being thicker in regards to bringing the compression ratio back up. Block deck milling and/or different wrist pin locations are a couple of ways to address this.

Then there’s fuel quality. Any detonation will shake or rattle the head gasket and bring to the forefront a head gasket failure. The amount of head mill in this case is logarithmic in that the propensity for a head gasket failure increases with the square root of the amount of mill. My personal experience with unposted ‘G’ heads is to limit the total amount of mill to 0.025”.

Any other comments always welcome.

|

|

By 55blacktie - 4 Months Ago

|

|

As I've already mentioned, I intend to use Best composite gaskets. I will also use ARP fasteners, but I'm debating on whether to use bolts or studs. Will studs be the better choice in my particular situation? I could also select a bigger cam that will lower the dynamic compression ratio, but it won't change the static compression ratio. With a zero deck and compressed thickness of the Best gaskets, my quench will be .046. I would prefer not to go upwards to .060 on the quench.

|

|

By Blind Willie - 4 Months Ago

|

|

For what it's worth, I saw somewhere that Joe C had stated the small letter G heads were better for porting. Now if I could find the reminder I sent to myself or the link I saved......

|

|

By KULTULZ - 4 Months Ago

|

Wasn't there a TECH ARTICLE written sometime back describing posting a cylinder head with a SS threaded rod or is just another one of my CRS hallucinations?

It seems to me on a factory posted head, that the post itself would be subject to corrosion and failure after so many years.

Are the MUMMERT ALUM HEADS posted?

|

|

By Ted - 4 Months Ago

|

|

KULTULZ (8/12/2025)

Wasn't there a TECH ARTICLE written sometime back describing posting a cylinder head with a SS threaded rod or is just another one of my CRS hallucinations?

It seems to me on a factory posted head, that the post itself would be subject to corrosion and failure after so many years.

Are the MUMMERT ALUM HEADS posted?

Those posts added to the 'G' and newer iron heads are very substantial. The amount of corrosion required to break down the posts is much more than what’s needed to break through elsewhere. The castings are relatively thin at the intake and exhaust runners so that’s the area corrosion would be more of an issue.

No idea on how the Mummert aluminum heads get around the posts but suspect that thicker decks alone would fix that problem. I donated my cut up aluminum heads to the local racing museum but will take a look at them the next time I am there. Zero head gasket issues in regards to sealing with the aluminum heads so however John fixed the problem, it is fixed.

This link will take you to several posts on the subject.

posting heads

|

|

By 1946international - 4 Months Ago

|

Speaking of G heads, does anyone want a pair of unposted G heads? I have a set from a '57 bird that I don't really need so they could go to a good home. I have all the valves and springs but they have been removed. Of course they will need a rebuild. I don't want to get into shipping and I'm in Maryland.

Sorry, I guess I should have just posted in the classified section.

|

|

By Litshoot - 4 Months Ago

|

|

So is there a limit if kept under .025 milling for street or is 9.25 static, dynamic up to 7.85 with .013 the top limit to be certain. would lower dynamic compensate for high static, or thinner deck? (within the 0.25 max)

|

|

By 55blacktie - 4 Months Ago

|

|

Your camshaft selection, particularly the intake closing at advertised duration, will determine what your dynamic compression ratio will be. If you know bore, stroke, cylinder-head volume, piston-head volume, gasket thickness, volume/compressed thickness (Ted has a chart on his website), deck clearance, rod length, and advertised intake closing degrees, you can ask Ted to calculate your static and dynamic compression ratios.

|

|

By Litshoot - 4 Months Ago

|

I seem to have good luck with 396maro.coms dynamic compression calculator, and abdc from advertised duration in summit cam calculator. it checks out with close to teds numbers from a few pages, ive had issue with certain calculators online before. trying 3 different strokes i get static compression to between 8.2-10.1, putting dynamic between 6.4-8.4. I want to make sure I won't create more problems for myself if static reaches near 10 to get dynamic around 7.5. I guess im wondering in general if static compression matters while engine is running or if its just an easy number to calculate to give an idea until dynamic compression can be found. Im looking to get dynamic around 7-7.5 even thought it may end up between 6.5-6.9, cam i like is oregon 34. its similar dcr to mummert 284 with a little more overlap

Seth

|

|

By Ted - 4 Months Ago

|

|

Litshoot (8/26/2025)

I seem to have good luck with 396maro.coms dynamic compression calculator, and abdc from advertised duration in summit cam calculator. It checks out with close to teds numbers from a few pages, I've had issue with certain calculators online. Before trying 3 different strokes, I get static compression to between 8.2-10.1, putting dynamic between 6.4-8.4. I want to make sure I won't create more problems for myself if static reaches near 10 to get dynamic around 7.5. I guess im wondering in general if static compression matters while engine is running or if its just an easy number to calculate to give an idea until dynamic compression can be found. Im looking to get dynamic around 7-7.5 even though it may end up between 6.5-6.9, cam I like is Oregon 34. Its similar DCR to Mummert 284 with a little more overlap.

Seth

It's important that the intake closing event for the dynamic compression ratio be based on the ‘advertised’ or actual intake closing event and not the 0.050” number. The DCR calculation relies on the ABDC degree value where the intake valve actually closes. Using the 0.050” number gives an artificially higher DCR number as the valve is not yet closed.

|

|

By 55blacktie - 4 Months Ago

|

|

A DCR of 6.5-6.9, in my opinion, is pretty low, lower than stock. I would either select a different cam or work on boosting the DCR by raising the SCR.

|

|

By Litshoot - 4 Months Ago

|

|

i agree. Thats the biggest cam I'm considering at 4 degrees advance 30 over 292, felpro gasket, estimated 69cc for the g heads. ill cc them when i finish porting, along with checking if they need to be skimmed. it has the same abdc as a mummert 284 cam. with small tweaks, thinner head gasket and bigger pistons gets it to 9 static and 7 dcr, the plan is more stroke, but thats gets upward of 9.7 static and 7.6 dynamic where the g heads can be suspect.

|

|

By 55blacktie - 4 Months Ago

|

|

Based on my numbers, Ted calculated my static at 9.4 Y dynamic at 8.04, and that's with non-posted heads. I will attempt to compensate by using the Best composite gasket, studs, rather than bolts, install the cam 2 degrees advanced, rather than 4, and run a bit tighter lash.

|

|

By Ted - 4 Months Ago

|

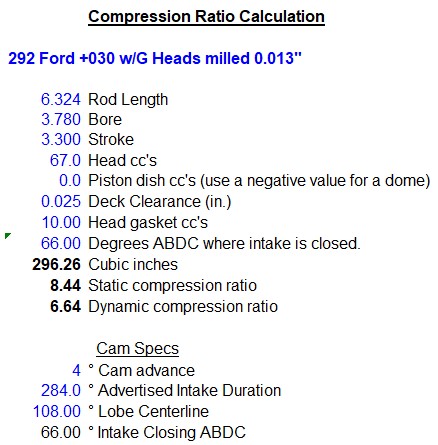

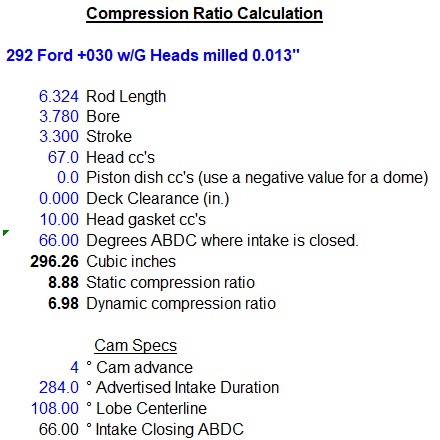

Assuming your heads are 69cc before milling, then the following calculations are performed taking into consideration the 0.013” mill you mentioned earlier. Here are the SCR and DCR numbers for your combination with and without deck milling.

|

|

By 55blacktie - 4 Months Ago

|

|

The simplest, cheapest way to increase your DCR will be by tightening up the IVC. Doing so will make it easier to live with on the street; of course, that means selecting a different cam.

|

|

By Ted - 4 Months Ago

|

The main point in knowing the Dynamic Compression Ratio is to be able to maximize the compression ratio for a given grade of fuel. If the DCR is too high, detonation comes to the forefront. The DCR being lower than optimum simply has the engine not running at 100% for the given grade. The lower DCR values do give a margin of safety when it comes to not knowing exactly what the quality of fuel is. Compensating for a DCR that’s too high once the engine is running typically involves retarding the ignition timing or in some cases, running the fuel mixture on the rich side.

For most engines, I use 8.2:1 DCR as the upper limit for 91-93 octane fuel. If building the engine where it can tolerate 89 octane fuel in an emergency, then I will target for 8.0:1 DCR. I have experimented with as high as 8.6:1 DCR and that tends to bring on detonation issues where both the engine and ambient temperatures are on the high side. A 4° reduction in ignition timing fixed that particular instance but at the expense of some fuel economy and performance. Running a higher octane racing fuel was also an option but not feasible cost wise if it’s an everyday driver. If planning on running 87-89 octane fuel on a regular basis, then the DCR would need to be decreased in which to compensate. But with all that being said, I will run pump premium in any carbureted engine even when the DCR is low simply due to the reduced ethanol content and the extended shelf life (age) properties that’s found in pump premium.

Here's the basic DCR calculation if wanting to use it within an Excel Spreadsheet.

DCR=((B6*B6*(B7-((((SQRT((B5*B5)-((0.5*B7*SIN(RADIANS(B12)))*(0.5*B7*SIN(RADIANS(B12))))))-(0.5*B7*COS(RADIANS(B12))))+(0.5*B7))-B5))*0.7854*16.387)+B8+B9+(B6*B6*B10*0.7854*16.387)+B11)/(B8+B9+(B6*B6*B10*0.7854*16.387)+B11)

B5 - Connecting rod length

B6 - Bore

B7 - Stroke

B8 - Combustion chamber cc’s

B9 - Piston dish cc’s (use negative value for domes)

B10 - Deck clearance

B11 - Head gasket cc’s

B12 - Intake valve closing event in degrees after BDC

Special notes:

The 0.7854 value is pie divided by four. (simply a short cut rather than use the pie r squared calculation).

The 16.387 value is 2.54 cubed which represents the number of cubic centimeters in a cubic inch.

|

|

By Litshoot - 4 Months Ago

|

I had deck clearance at .010 accidentally and cometic 6.9cc .035 gasket which probably isnt a bad setup to give a little quench clearance. Thank you. its a daily driver that doesnt get driven. i try to run rec fuel its a little cheaper than premium and supposed to be ethanol free but varies between 87-90 octane depending where. figure 7.5 is probably top before i need to ensure 90 switch to premium.

|

|

By 55blacktie - 4 Months Ago

|

|

.045 (.010 + .035) should be good. Ted has said that up to .060 quench, he hasn't seen a difference in performance. He has even suggested having pistons .005 below deck and using .046 Best gaskets that would equal a .051 quench.

|