|

By B-rad - 7 Months Ago

|

I finally was able to get my 317 primed with oil up to the rockers. I had to turn the crank to line up something, I guess.

I'm trying to get the engine set up to drop the dizzy in. I know the #1 piston is at the top and the timing mark is lined up. Does that mean it's ready for the dizzy to go in? Don't want to have to redo once the engine is in. I attempted to put the dizzy in but it didn't want to go down the last 1/4". Maybe it's not lining up with the intermediate shaft? I am using the hex dizzy and oil pump.

Any help timing and installing dizzy is appreciated, along with any engine installation issue remedies. I took the engine and tranny out about 3 years ago and my memory is slowly fading.

|

|

By Joe-JDC - 7 Months Ago

|

|

If you had compression in the #1 cylinder as it came up on TDC, then you are at the correct position. You can have #1 up but not on the compression stroke. Pull #1 plug and rotate the engine over and hold your finger in the sparkplug hole as you rotate the engine over. It will spit your finger out as it comes up on compression. Set the timing mark at ~25*btdc and install the distributor. Check that the rotor is pointing to #1 plug terminal and not #6 or what number is in the firing order. Installing the distributor at ~25* will allow it to start and run fast while you are closing things up, checking water level, and then you can concentrate on setting initial timing. I would set it at 12-14* and try it there. Joe-JDC

|

|

By B-rad - 7 Months Ago

|

|

Thx Joe. So the timing mark will be on the pointer both times the piston is at the top? Trying to do this alone, so it's difficult to turn the crank and check for compression at the same time by myself. Does it matter if I turn motor cw or ccw to move the piston?

|

|

By Joe-JDC - 7 Months Ago

|

|

Always try to move the engine in clockwise direction so that the bearings will be properly oiled. Yes the rotor can be pointing at the #1 and not be on compression stroke on one of those times. I use a remote starter button to turn the engine over quickly enough to check for compression on this test when I am by myself. Remember the crankshaft gear is half the size of the camshaft gear and that compensates for the four stroke/two revolutions per firing of each cylinder. Joe-JDC

|

|

By paul2748 - 7 Months Ago

|

I never heard of the minus 25 degrees for initial setup. Could you explain that to me. I always put it on top dead center to start and it always worked (not a lincoln engine)

Joe-JDC (5/25/2025)

If you had compression in the #1 cylinder as it came up on TDC, then you are at the correct position. You can have #1 up but not on the compression stroke. Pull #1 plug and rotate the engine over and hold your finger in the sparkplug hole as you rotate the engine over. It will spit your finger out as it comes up on compression. Set the timing mark at ~25*btdc and install the distributor. Check that the rotor is pointing to #1 plug terminal and not #6 or what number is in the firing order. Installing the distributor at ~25* will allow it to start and run fast while you are closing things up, checking water level, and then you can concentrate on setting initial timing. I would set it at 12-14* and try it there. Joe-JDC

|

|

By Ted - 7 Months Ago

|

Even dead stock engines are typically factory timed to some degree value that is BTDC. By the same token, a first start for any engine should always have a liberal amount of ignition advance before TDC to ensure an easy start. I have found that 25° BTDC for the first fire up will guarantee an easy start. As a general rule, that extra bit of ignition advance does not need much correction once the engine is fired up and the actual timing is set. Having some extra ignition advance on the startup will not hurt the engine and in most instances will have the engine running cooler for that initial camshaft break in period.

With all that being said, he’s a link to a past thread on the subject.

http://forums.y-blocksforever.com/FindPost138330.aspx

|

|

By B-rad - 7 Months Ago

|

I was talking about the timing mark and pointer on the crank. Will that pointer and tdc mark line up even if its not on compression? Not rotor, since the distributor isnt even in yet. And the crank should turn ccw ?

As far as the distributor not going all the way down....

Is there a trick for lining up the intermediate shaft and distributor? If the shaft is against the wall how should i center it and keep it there?

|

|

By Ted - 7 Months Ago

|

|

B-rad (5/26/2025)

I was talking about the timing mark and pointer on the crank. Will that pointer and TDC mark line up even if it's not on compression? Not rotor, since the distributor isn't even in yet. And the crank should turn ccw ?

As far as the distributor not going all the way down....

Is there a trick for lining up the intermediate shaft and distributor? If the shaft is against the wall how should i center it and keep it there?

The damper TDC mark and the pointer will line up twice during the four cycles that it takes to make an engine run. The four cycles take two complete revolutions of the engine to complete. Looking at the front of the engine, the crankshaft turns clockwise.

On one of those line ups, the piston will be at TDC but the exhaust valve is closing and the intake valve is opening. This would be the overlap cycle which is simply that period of time that both the intake and exhaust valves on the same cylinder are open. The overlap cycle is not to be confused with the other four cycles required to actually make an engine run.

On the other line up, the piston will be at TDC with both valves closed. It’s this second event that you want the rotor in the distributor pointing to #1 spark plug wire in the cap.

Another useful piece of information is that when #1 is at compression TDC, the #6 cylinder is at TDC but at the overlap cycle. Likewise, when #6 cylinder is at compression TDC, the #1 cylinder will be at the overlap cycle.

As far as centering up the oil drive shaft, that should not be necessary. Once you get the distributor part way down but it does sit squarely on the block yet due to the oil pump shaft not being in the correct orientation, you will need to bump or turn the engine over slowly until the distributor completely drops in place. You may need to put a light downward pressure on the distributor housing to make this happen as gravity alone may not do it for you. Once it has done this, then you can double check that rotor is indeed still pointing to #1 in the cap with the damper at 20-25° BTDC.

|

|

By pintoplumber - 7 Months Ago

|

paul2748 (5/25/2025)

I never heard of the minus 25 degrees for initial setup. Could you explain that to me. I always put it on top dead center to start and it always worked (not a lincoln engine) Joe-JDC (5/25/2025)

If you had compression in the #1 cylinder as it came up on TDC, then you are at the correct position. You can have #1 up but not on the compression stroke. Pull #1 plug and rotate the engine over and hold your finger in the sparkplug hole as you rotate the engine over. It will spit your finger out as it comes up on compression. Set the timing mark at ~25*btdc and install the distributor. Check that the rotor is pointing to #1 plug terminal and not #6 or what number is in the firing order. Installing the distributor at ~25* will allow it to start and run fast while you are closing things up, checking water level, and then you can concentrate on setting initial timing. I would set it at 12-14* and try it there. Joe-JDC

That’s not a minus sign in Joe’s post, it’s got curly ques at each end.

|

|

By DANIEL TINDER - 7 Months Ago

|

Ted (5/25/2025)

Even dead stock engines are typically factory timed to some degree value that is BTDC. By the same token, a first start for any engine should always have a liberal amount of ignition advance before TDC to ensure an easy start. I have found that 25° BTDC for the first fire up will guarantee an easy start. As a general rule, that extra bit of ignition advance does not need much correction once the engine is fired up and the actual timing is set. Having some extra ignition advance on the startup will not hurt the engine and in most instances will have the engine running cooler for that initial camshaft break in period.

With all that being said, he’s a link to a past thread on the subject. http://forums.y-blocksforever.com/FindPost138330.aspx

Ted,

Re-reading your 2018 reply, concerning startup advance ‘leeway’, and ‘low’ compression’:

Would you likely consider your 20 degree BTDC recommendation a maximum with 10:1 static in a fresh rebuild (Isky E-4/centered)?

|

|

By paul2748 - 7 Months Ago

|

Yes - I misread it.

pintoplumber (5/26/2025)

paul2748 (5/25/2025)

I never heard of the minus 25 degrees for initial setup. Could you explain that to me. I always put it on top dead center to start and it always worked (not a lincoln engine) Joe-JDC (5/25/2025)

If you had compression in the #1 cylinder as it came up on TDC, then you are at the correct position. You can have #1 up but not on the compression stroke. Pull #1 plug and rotate the engine over and hold your finger in the sparkplug hole as you rotate the engine over. It will spit your finger out as it comes up on compression. Set the timing mark at ~25*btdc and install the distributor. Check that the rotor is pointing to #1 plug terminal and not #6 or what number is in the firing order. Installing the distributor at ~25* will allow it to start and run fast while you are closing things up, checking water level, and then you can concentrate on setting initial timing. I would set it at 12-14* and try it there. Joe-JDC That’s not a minus sign in Joe’s post, it’s got curly ques at each end.

|

|

By Ted - 7 Months Ago

|

DANIEL TINDER (5/26/2025)

Ted (5/25/2025)

Even dead stock engines are typically factory timed to some degree value that is BTDC. By the same token, a first start for any engine should always have a liberal amount of ignition advance before TDC to ensure an easy start. I have found that 25° BTDC for the first fire up will guarantee an easy start. As a general rule, that extra bit of ignition advance does not need much correction once the engine is fired up and the actual timing is set. Having some extra ignition advance on the startup will not hurt the engine and in most instances will have the engine running cooler for that initial camshaft break in period.

With all that being said, he’s a link to a past thread on the subject.http://forums.y-blocksforever.com/FindPost138330.aspx

Ted,

Re-reading your 2018 reply, concerning startup advance ‘leeway’, and ‘low’ compression’:

Would you likely consider your 20 degree BTDC recommendation a maximum with 10:1 static in a fresh rebuild (Isky E-4/centered)?

That would be a No.

25° BTDC for an initial start is not a problem for most engines. The 13.0:1 compression in my Y powered roadster starts just fine at 26° BTDC even when heat soaked. You must keep in mind that when both the mechanical and vacuum portions of the distributor are maxed out in certain driving conditions, you are potentially looking at well over 50° BTDC on many of your stock engines.

|

|

By B-rad - 7 Months Ago

|

|

Im putting my finger over the no 1 plug hole and I turn the crank clockwise around the tdc mark and instead of feeling my finger being pushed out i feel a slight sucking. I'm using a breaker bar so I can't move it a whole lot at a time. Is there another way to verify the no 1 piston is in the correct position besides this method?

|

|

By Hoosier Hurricane - 7 Months Ago

|

|

Take the left rocker cover off. Turn the crank and watch the #6 exhaust valve. When the valve begins to close, as it nears almost closed the intake valve will just begin to open. At this point the timing mark should be at or near zero. Number one piston is now at the top of the compression stroke. You can now proceed with the distributor installation with the rotor pointing to the #1 plug wire.

|

|

By B-rad - 7 Months Ago

|

|

Which one is the exhaust valve

|

|

By Ted - 7 Months Ago

|

Not having a LYB engine here to look at, I’m going to say that the #6 exhaust valve is the 4th valve from the front. The #6 intake valve will be the 3rd valve from the front. Verification of this is the exhaust valve will be in line with the exhaust port. When the valves are moving as the engine is rotated clockwise as looking from the front, the exhaust valve will be the first to move and then followed by the intake valve.

As John mentions, as the #6 exhaust valve is just closing (coming up) and the #6 intake valve just starts opening (going down), the damper should be close to reading TDC. That will be #1 compression and where you want to drop the distributor in for #1 cylinder timing purposes.

|

|

By KULTULZ - 7 Months Ago

|

I think it is important to use a piston stop to determine correct #1 TDC on fire. It will also ensure the damper is indexed correctly and cam/ign timing is correct.

If you know for certain (no doubt in your military mind) that all of this is correct, then you would use the shortcuts (IMO).

This is a fresh build.

|

|

By Hoosier Hurricane - 7 Months Ago

|

|

Kultulz, how do you know with a piston stop whether the piston is on compression or overlap mode?

|

|

By KULTULZ - 7 Months Ago

|

Well, I would turn the engine over by hand until I heard compression being released and then back it off before inserting the piston stop.

I know what you are thinking and I realize you are much more experienced than I am but I would be concerned about the quality of the assembly work of the shop he had it in. I would just simply verify the timing(s) are correct before hitting it with the starter motor (and then watch the oil pressure gauge very closely).

I am not dogging anyone, just here to learn and I have learned a lot on this forum.

BTW - I am OCD (CDO in correct alphabetical order) ...

|

|

By B-rad - 6 Months Ago

|

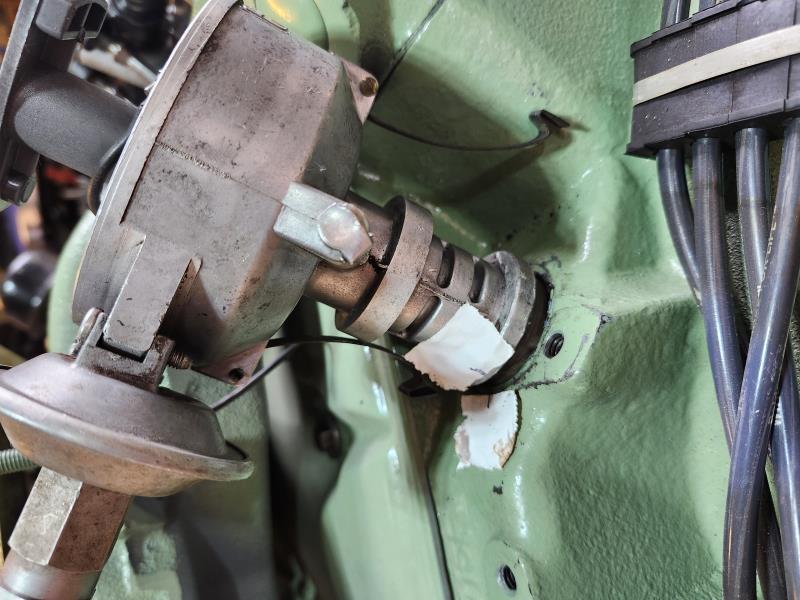

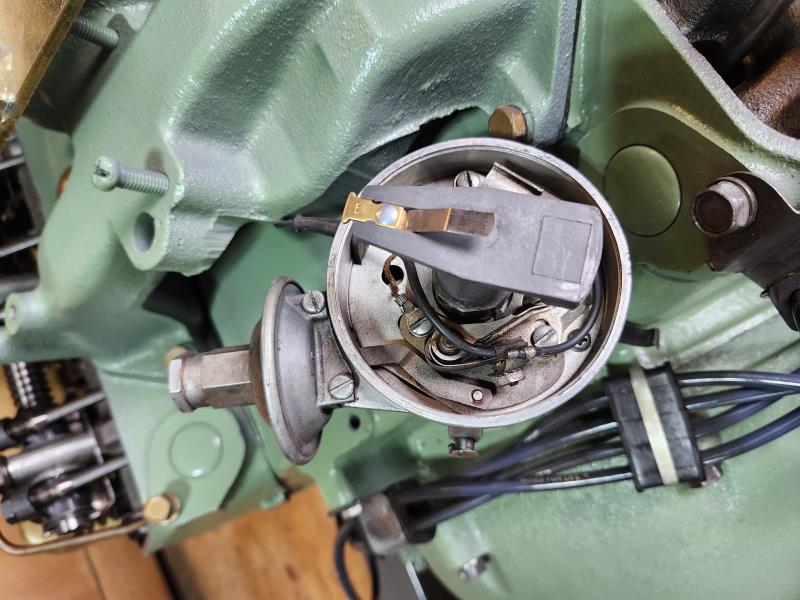

This is as far as it wants to drop in. What do I need to do to get it down all the way?

|

|

By Ted - 6 Months Ago

|

|

B-rad (6/1/2025)

This is as far as it wants to drop in. What do I need to do to get it down all the way?

Once you get the distributor in place but it does sit squarely on the block yet due to the oil pump shaft not being in the correct orientation, you will need to bump or turn the engine over slowly until the distributor completely drops in place. You may need to put a light downward pressure on the distributor housing while rotating the engine to make this happen as gravity alone may not do it for you. Once the distributor has dropped all the way down, then you can double check that rotor is indeed still pointing to #1 in the cap with the damper at 20-25° BTDC.

|