|

By 58F600 - 2 Years Ago

|

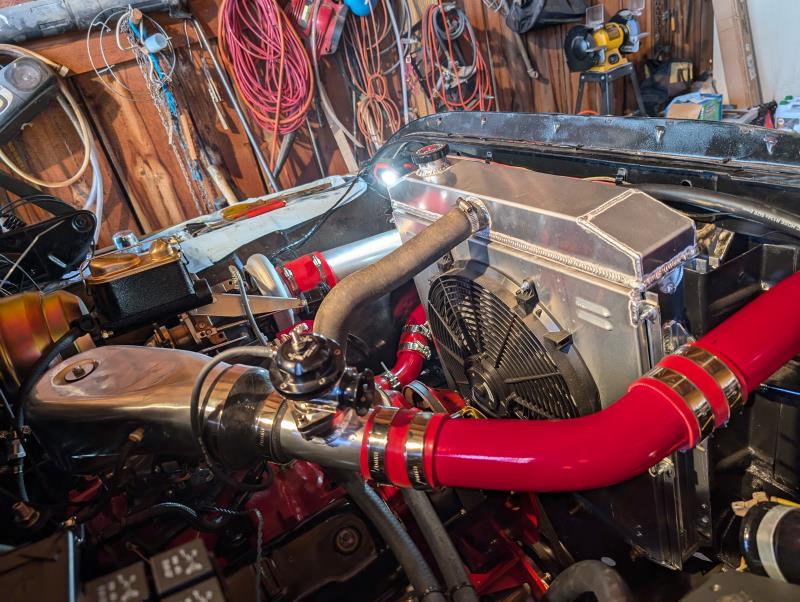

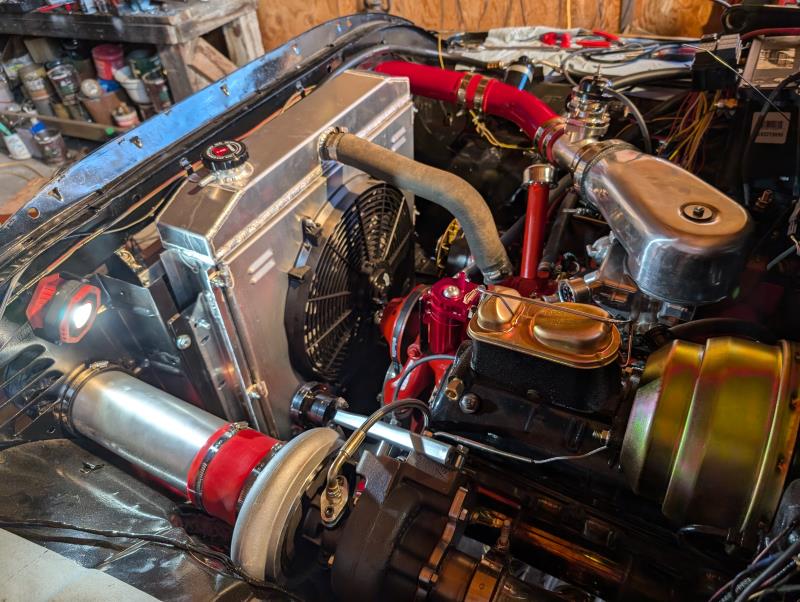

Been building this for my wife. It's her grandpa's old farm truck. We wanted to make it reliable and fun. Dont copy this as it was just for fun. It'll probably make 215hp. But it'll make fun turbo noises. We have to tidy up the wiring but it's getting close.

Details as follows

Stock rebuilt 62 292. C1TE heads

Sniper 2bbl EFI

Holley Hyperspark distributor modified for YBF.

Holley HyperSpark Coil and CDI box

Walbro 255lph pump in tank.

Ebay radiator, intercooler and BOV

Vintage Air compressor and alternator bracket

Powermaster 160amp 12si. 2.125" pulley, runs aux off the A/c Compressor to increase idle amperage stability. So far 14.6v with all systems on 650rpm

Turbo kit we built from a SBC kit off eBay. Stainless 3/8" Header flanges. All back purged and Tig welded and passavated.

Turbo kit, Turbo and EFI went into our luggage and flown out here with us to Eastern Oregon to install at Grandpa's farm.

My dad drove down and helped a ton, replacing the entire brake system while I worked the engine side of things. Her brother did some welding in the cab and cousins helped on other parts.

The LB on the valve covers is Grandpas brand.

First show is this weekend, then driving the 2500ish miles back to Tennessee.

|

|

By KULTULZ - 2 Years Ago

|

There is an awful lot of talent/skill going on there ...

If I may -

How is the exhaust done, especially the turbo mounting?

|

|

By 58F600 - 2 Years Ago

|

That's beautiful!!

I thought the core support needed some extra braces from the firewall, I'll have to find those for her truck.

Turbo kit pictures. These were during the build up in Tennessee a couple weeks ago. We did change the turbo adapter mount to a shorter one, had to bring the cross over closer to the pan and drop the horizontal "tail pipe" portion of the down pipe down a little. Out mock up engine was close, but just a little different. Thanks to those on this site that helped with some measurements!

|

|

By KULTULZ - 2 Years Ago

|

!!! ABSOLUTELY BEAUTIFUL !!!

|

|

By Deyomatic - 2 Years Ago

|

|

Very cool. Have you taken it for a spin, yet? Curious how well it works. When you get safely back to TN are you going to increase boost?

|

|

By miker - 2 Years Ago

|

Nicely done. That should haul enough mash over the mountains and back to the still to pay for the trip.

Seems to me you’re going over a high pass. Highest I’ve had the motorhome was 9300+ at red mountain mt. Would have been nice to have the turbo up there. Enjoy the trip.

|

|

By 58F600 - 2 Years Ago

|

Deyomatic (8/22/2024)

Very cool. Have you taken it for a spin, yet? Curious how well it works. When you get safely back to TN are you going to increase boost?

Just backed it out of the shop tonight. Need to get the gas pedal hooked up and we seem to have a brake dragging. Should be driving it Friday. The engine work was part of a mini make over that included an entire new brake system and interior refresh.

No plans to increase boost ever. 5psi would be perfect. We do plan to use it as a dump truck.

|

|

By 58F600 - 2 Years Ago

|

miker (8/22/2024)

Nicely done. That should haul enough mash over the mountains and back to the still to pay for the trip. Seems to me you’re going over a high pass. Highest I’ve had the motorhome was 9300+ at red mountain mt. Would have been nice to have the turbo up there. Enjoy the trip.

I'm hoping we get to do the passes in Southern Colorado on the way home. They have been getting hit hard with flooding along that route and many are washed out. 3 we are looking to cross are 12k+ so the turbo will certainly be a nice upgrade even crawling in 1st gear.

|

|

By 58F600 - 2 Years Ago

|

KULTULZ (8/22/2024)

!!! ABSOLUTELY BEAUTIFUL !!!

Thank you sir!

|

|

By 58F600 - 2 Years Ago

|

Deyomatic (8/22/2024)

Very cool. Have you taken it for a spin, yet? Curious how well it works. When you get safely back to TN are you going to increase boost?

First drive was a mixed bag. We have an EMI issue to track down. When it run correctly, it runs really good!

|

|

By KULTULZ - 2 Years Ago

|

"I thought the core support needed some extra braces from the firewall, I'll have to find those for her truck."

Listen, I think I gave you the wrong idea on the upper radiator hose design. It is meant to allow the upper hose to flex with engine torque. It was the OEM design.

Your present upper hose looks stressed to me and may fail on the road.

|

|

By 58F600 - 2 Years Ago

|

KULTULZ (8/25/2024)

"I thought the core support needed some extra braces from the firewall, I'll have to find those for her truck." Listen, I think I gave you the wrong idea on the upper radiator hose design. It is meant to allow the upper hose to flex with engine torque. It was the OEM design. Your present upper hose looks stressed to me and may fail on the road.

I think its just the picture. I really hope it doesn't fail!

First drive went pretty decent, we had an issue with Sniper that we finally got figured out. We took it to a local shop and they pressure washed the chassis really good, unfortunately this washed all the old grease that was making the king pins tight! So we are doing King Pins and a Clutch before we go

|

|

By HT32BSX115 - 2 Years Ago

|

Nice Job!

This is really cool with the EFI and the turbocharging!

I will probably want to pick your brain on the EFI!

I have an MSD "Y" distributor and MSD Atomic TBI going on my 272. I don't think I would try turbocharging though!

Cheers,

Rick

in Western Wa.

|

|

By HT32BSX115 - 2 Years Ago

|

Ok,

I have to ask.....

Are you using a double-reservoir (split) master cyl? (looks like it)

And how did you do the brake system with the dual? wheel cylinder brakes you have on the back and the single cyl on the front?

(understanding that yours might be different with mine which does have upper and lower cylinders)

With my split hydraulically assisted master cyl, I will have to use a proportioning valve so as not to apply too much pressure to the back during braking.

(no power steering, but I have a power steering pump just to provide fluid for the master cyl)

Regards,

Rick

|

|

By Deyomatic - 2 Years Ago

|

Rick,

Are you referring to the hydraulic clutch master cylinder next to the brake master in the first photo?

|

|

By HT32BSX115 - 2 Years Ago

|

Howdy,

No.

I am referring to what appears to be a split-system vacuum master cylinder.

All these medium duty trucks had single system brakes, meaning that a leak anywhere in the system (front or back) would result in complete loss of brakes.

It wasn't until somewhere in the 60's (67 or 68 maybe?) they went to a split system like all cars and trucks are nowadays.

The medium duty trucks used a manual split master with 2 separate vacuum boosters where the earlier trucks (including my 55) had a single manual master with an inline vacuum booster. They worked ok ....but if one wheel cylinder started leaking enough to put the pedal on the floor, there was no brakes at !

I for one, do not like the idea of driving a 7000lb (empty) truck around that could lose brakes due to 1 leak.

So I am using a split master from a circa 2000+ Ford Super Duty truck that has 1.5" pistons. (I think my original had a 1.25" piston) It requires a hydraulic pressure source so I am using a PS pump.

I suppose I could have just used a firewall-mounted vacuum master but I wanted to keep the master cyl under under the floor in it's original position and use the original pedal instead of hanging a pedal in the cab.

Here's what mine looks like: (that's a 272-Y there with a Bentsen transmission adapter and a Ford E4OD out of a 94 F450 diesel)

The only "downside" is that I need a hydraulic pressure source instead of a vacuum source.....hence the PS pump....... And I'll probably need a hole in the floor to get to the reservoir unless I relocate it.

SO I would love to know how it's being done in the 58F600 I'm assuming that I will need to do something with brake pressure proportioning!

|

|

By 58F600 - 2 Years Ago

|

HT32BSX115 (9/13/2024)

Howdy, No. I am referring to what appears to be a split-system vacuum master cylinder. All these medium duty trucks had single system brakes, meaning that a leak anywhere in the system (front or back) would result in complete loss of brakes. It wasn't until somewhere in the 60's (67 or 68 maybe?) they went to a split system like all cars and trucks are nowadays. The medium duty trucks used a manual split master with 2 separate vacuum boosters where the earlier trucks (including my 55) had a single manual master with an inline vacuum booster. They worked ok ....but if one wheel cylinder started leaking enough to put the pedal on the floor, there was no brakes at ! I for one, do not like the idea of driving a 7000lb (empty) truck around that could lose brakes due to 1 leak. So I am using a split master from a circa 2000+ Ford Super Duty truck that has 1.5" pistons. (I think my original had a 1.25" piston) It requires a hydraulic pressure source so I am using a PS pump. I suppose I could have just used a firewall-mounted vacuum master but I wanted to keep the master cyl under under the floor in it's original position and use the original pedal instead of hanging a pedal in the cab. Here's what mine looks like: (that's a 272-Y there with a Bentsen transmission adapter and a Ford E4OD out of a 94 F450 diesel)  The only "downside" is that I need a hydraulic pressure source instead of a vacuum source.....hence the PS pump....... And I'll probably need a hole in the floor to get to the reservoir unless I relocate it. SO I would love to know how it's being done in the 58F600 I'm assuming that I will need to do something with brake pressure proportioning!

Yes. It's a split system. The truck already had an issue on the rear axle with the single pot system. We knew we were going to hit some serious mountains on the way home and a single point of failure brake system wasn't going to be a good thing.

We bought a "kit" for a '58 F100 that came with a cantilever linkage that step one of the instructions said to throw away and use the generic $35 booster brackets and DIY a booster rod....

There were kits available with a master cylinder, but the biggest was only a 1.125" bore. We used an All Star 1.25" bore master cylinder pn ALL41064.

With 4 corner drum brakes you don't need a prop valve. But installing one won't hurt anything and could be useful for simply adjusting the brakes for drivers preference. We didn't use one, the brakes work fine.

The biggest issue on our truck was the lack of brake parts to get it right to start with. We had to clean the rear shoes and reuse them. They were soaked with brake fluid and grease/oil from a seal failure. They needed relined, but we simply didn't have two weeks to wait for them to get relined. They got steam cleaned, brake cleaned, baked and reinstalled. Every now and then you get a whiff of burnt gear oil, but they worked!

Brake adjustment was a little problematic as well. We played with it adjusting to get just a light drag, the brakes still got better with a pump or two with the pedal.

With the hydraulic clutch, we used a smaller booster (dual 8) instead of the normal 14" style. We've tested this on cars and the larger booster is much more effective. Our brakes are, and feel like, they are under boosted. A hydro boost ran off a power steering pump would be much better and clear the clutch master. But then you need a P/S pump. We've actually removed and avoid hydro boost on cars as they over assist and terrible to drive. There is a reason they are OEM in larger pickups and no used on cars.

|

|

By HT32BSX115 - 2 Years Ago

|

Thanks for that info!

I think I will probably have some "over" assist as you say but I think a hydraulic regulator might temper that. I was worried about having enough fluid volume with any of the master cylinders that had small pistons to actuate the front and back.

The front brakes on my 55 have single cylinder, SINGLE-Piston actuators. Only the top of the front shoe is actually "pushed" forward. (sort of like a boat trailer drum brake system)

The bottom of the front shoes are hinged together so they all contact the drum when the top of the front shoe is pushed.

I suspect they changed that in the mid fifties I just don't know when. Are your front wheel cylinders single-piston too?

I think I couldn't find replacement shoes either but a local Brake place in Tacoma (Cascade Friction Materials) was able to reline both front and back shoes nicely and they also turned my drums.

I am very lucky, none of the drums had ever been turned and all they had to do is take off a few thousandths to clean them up. The guy told me I would probably never have to find drums for it. (I don't think they exist anyway!!)

By then, I'll either be unable to drive at all or I'll put a DANA 80 on the back and a much more modern front axle on it with disc all the way around!

I think you said you're using a T98 transmission with a 2-speed axle. (5.83/8.11?)

Mine is a 6.80:1 axle but I also have an Eaton 1350 5.83/8.11 too. I am not sure I'll be using it with the E4OD.

The E4OD has a 0.71:1 over-drive ratio. With the 9.00-20's I have on the truck, (roughly 40" rolling radius) I figured I would see around 504 rear wheel RPM @ 60MPH. 504 x 6.8 would then be 3428 RPM in direct drive.

With the 0.71 OD in the E4OD (& torque convertor locked) the 60mph RPM should be around 2400 RPM (2434) maybe that's about right for my 272?

What size tires do you have and what RPM do you see @60 MPH with the 5.83 rear axle?

Using the 5.83 axle, I calculated with 40" tires I would see 2938RPM in 3rd gear (TC locked) and 2086 in OD.

That might be too "tall" in the gearing for my 272 except maybe on a level highway, empty with a tailwind!!

The 8.25-20 tires are of smaller diameter but Les Schwab told me they couldn't get them anymore. My only choice was the 9.00-20's

Now if I were to go to 22.5's or 19.5's I suppose it would be better but when I got my current set of 20" 5--lug lock-ring wheels no one was offering 19.5 or 22.5 wheels.

I think you have more choices in 6-lug wheels.

|

|

By 58F600 - 2 Years Ago

|

HT32BSX115 (9/17/2024)

Thanks for that info! I think I will probably have some "over" assist as you say but I think a hydraulic regulator might temper that. I was worried about having enough fluid volume with any of the master cylinders that had small pistons to actuate the front and back. The front brakes on my 55 have single cylinder, SINGLE-Piston actuators. Only the top of the front shoe is actually "pushed" forward. (sort of like a boat trailer drum brake system) The bottom of the front shoes are hinged together so they all contact the drum when the top of the front shoe is pushed. I suspect they changed that in the mid fifties I just don't know when. Are your front wheel cylinders single-piston too? I think I couldn't find replacement shoes either but a local Brake place in Tacoma (Cascade Friction Materials) was able to reline both front and back shoes nicely and they also turned my drums. I am very lucky, none of the drums had ever been turned and all they had to do is take off a few thousandths to clean them up. The guy told me I would probably never have to find drums for it. (I don't think they exist anyway!!) By then, I'll either be unable to drive at all or I'll put a DANA 80 on the back and a much more modern front axle on it with disc all the way around! I think you said you're using a T98 transmission with a 2-speed axle. (5.83/8.11?) Mine is a 6.80:1 axle but I also have an Eaton 1350 5.83/8.11 too. I am not sure I'll be using it with the E4OD. The E4OD has a 0.71:1 over-drive ratio. With the 9.00-20's I have on the truck, (roughly 40" rolling radius) I figured I would see around 504 rear wheel RPM @ 60MPH. 504 x 6.8 would then be 3428 RPM in direct drive. With the 0.71 OD in the E4OD (& torque convertor locked) the 60mph RPM should be around 2400 RPM (2434) maybe that's about right for my 272? What size tires do you have and what RPM do you see @60 MPH with the 5.83 rear axle? Using the 5.83 axle, I calculated with 40" tires I would see 2938RPM in 3rd gear (TC locked) and 2086 in OD. That might be too "tall" in the gearing for my 272 except maybe on a level highway, empty with a tailwind!! The 8.25-20 tires are of smaller diameter but Les Schwab told me they couldn't get them anymore. My only choice was the 9.00-20's Now if I were to go to 22.5's or 19.5's I suppose it would be better but when I got my current set of 20" 5--lug lock-ring wheels no one was offering 19.5 or 22.5 wheels. I think you have more choices in 6-lug wheels.

Brakes sound the same design as our truck. Primary and secondary shoe up front running off a "single servo" wheel cylinder. Hot tip, they don't work in reverse!

Our rears have dual, "single servo" style wheel cylinders that are very similar to the fronts.

I'd fight to the death to keep the 2 speed rear lol. Especially in the mountains, starting in 1st/hi, then having the ability to simply lift to downshift was a huge help when really pulling. Also helpful rolling over a crest to simply lift/stab down shift for engine braking.

All of your gearing math looks reasonable to what we saw. 2500ish is 48-49mph in 4th/hi. 3100ish was 58-60mph.

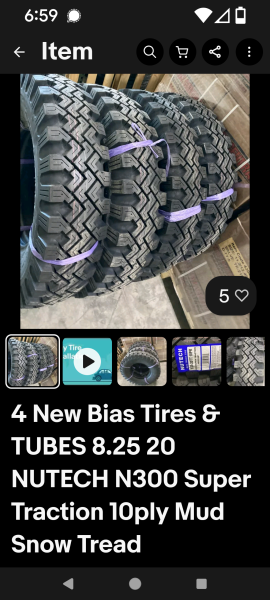

Les Schwab told me the same thing but I found a set of NuTec Super Traction rears and had them shipped right to Les Schwab. I'm glad I did, we really used them on the way home. They offered a different NuTec tie but it was the cheesy zig zag military cheapo pattern.

They also tried to tell me they couldn't balance lock ring wheels and bias ply tube tires, so I convinced them to try and prove they were right lol. They were very rough before balance and reasonably smooth after wards, which they assured me wouldn't last. 3,000 miles later including over 1,000 miles on dirt gravel, they are the same. Very acceptable.

I don't see a stock NA 272 pulling overdrive with a locked converter at 60mph. I guess it would depend on the local terrain. Tacoma isn't too far from flat, but there is hills in every direction!

We're from Moses Lake originally! Great place to be "from" haha.

|

|

By 58F600 - 2 Years Ago

|

Here's the exact tires we got. I love them. They run smooth as well. They are the old FireStone Super Traction molds that were sold to Power King, then NuTec and now sold as NuTec N300. Les Schwab could only get the N200 even though they carry NuTec.

https://www.ebay.com/itm/335497545134?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=5czKIfszRZW&sssrc=4429486&ssuid=G9JJtUK_RLe&var=&widget_ver=artemis&media=COPY

|

|

By HT32BSX115 - 2 Years Ago

|

It was several years ago I got those tires!

The fronts are TOYO 9.00-20 tube-type radials And the backs are recapped radials.

I would have gotten the 8.25-20's if I could have.

Yeah, I think the 5.83 will be pretty tall with the OD. I still have to get the axle spindles redone. one side is damaged from a spun bearing.

I would still like to try it though. I got the 2-speed rear axle from a guy in Seattle for $100. The entire pumpkin was a rusty mess and pretty much unusable. I had a local truck parts outfit find me an excellent condition 2-speed pumpkin for $750 so I bought it.

And I swapped out the vacuum shift unit for the electric-motor shift and was able to find all the parts to rebuild it.

Drivelines Northwest did all the drive line shortening etc.

That transmission in my picture came out of a 94 F450 diesel Superduty.

I knew a guy that worked at a transmission shop in Tacoma and he found a complete transhousing/bell for a 300 I-6. Bentsen makes an adapter for that bell housing (300-6 and SB Ford V-8) so I could adapt from the Y-block to the trans.

The transmission internals (and ratios) are from the Diesel E4OD. The trans guy also found the tail-shaft mounted Parking brake too. Those things are very hard to find and usually cost a fortune. The entire thing was about $1500 for the case swap, parking brake and complete trans rebuild.

I also have a Baumann Engr trans control unit but I may go to the MSD trans control box since it integrates well with the MSD Atomic EFI

I expect that 272 to run well with the MSD TBI system.

I don't even want to think about how much I have tied up in this thing ....but it's all therapy, right?

|

|

By 58F600 - 2 Years Ago

|

HT32BSX115 (9/17/2024)

It was several years ago I got those tires! The fronts are TOYO 9.00-20 tube-type radials And the backs are recapped radials. I would have gotten the 8.25-20's if I could have. Yeah, I think the 5.83 will be pretty tall with the OD. I still have to get the axle spindles redone. one side is damaged from a spun bearing. I would still like to try it though. I got the 2-speed rear axle from a guy in Seattle for $100. The entire pumpkin was a rusty mess and pretty much unusable. I had a local truck parts outfit find me an excellent condition 2-speed pumpkin for $750 so I bought it. And I swapped out the vacuum shift unit for the electric-motor shift and was able to find all the parts to rebuild it. Drivelines Northwest did all the drive line shortening etc. That transmission in my picture came out of a 94 F450 diesel Superduty. I knew a guy that worked at a transmission shop in Tacoma and he found a complete transhousing/bell for a 300 I-6. Bentsen makes an adapter for that bell housing (300-6 and SB Ford V-8) so I could adapt from the Y-block to the trans. The transmission internals (and ratios) are from the Diesel E4OD. The trans guy also found the tail-shaft mounted Parking brake too. Those things are very hard to find and usually cost a fortune. The entire thing was about $1500 for the case swap, parking brake and complete trans rebuild. I also have a Baumann Engr trans control unit but I may go to the MSD trans control box since it integrates well with the MSD Atomic EFI I expect that 272 to run well with the MSD TBI system. I don't even want to think about how much I have tied up in this thing ....but it's all therapy, right?

You and I both don't want to add up what we have into getting ours into one piece and across the country lol.

That rear transmission parking brake is a must. Our brakes simply don't work in reverse. That band brake was used extensively in the Rocky's to keep us from rolling backwards down the mountain.

We weren't able to find the right band to replace ours, but found the military trucks of the same era used one that's almost identical and close enough to work. After weeks of searching the overnight shipping made this about a $300 part....

|