|

By Brent - 2 Years Ago

|

This engine is running very strong. I have a 600cfm mech 4150 carb. The fuel pump seems to be adequate the floats may be just a bit towards the rich side.

last run I noticed a hesitation when I hard braked from brief WOT. I wonder if it gets too rich from the float bowls sloshing forward or if it causes a lean condition?

|

|

By Ted - 2 Years Ago

|

Try lowering the rear float level so it is ~1/8” below the rear fuel level sight hole assuming the carb has the removable screw to check the level. If it’s a sight glass, then set the float level to the bottom edge of the rear sight glass.

|

|

By Brent - 2 Years Ago

|

"For the Brawler carburetor to operate correctly, the float levels must be in the middle of the sight glass."

I adjusted the secondary float 1/8" below the marks in the middle of the sight glass, after full throttle the engine returned to idle then hesitated and almost died, I pumped the gas and the engine reponded and began to run normally. the secondary float was 1/4" then returned to 1/8". The fuel pressure is around 7 psi at first idle, then after I run it and the psi reads around 3.5. This excersize leads me to beleive that I overlooked the need for an adequate fuel pump. After reading this post "Any FE fuel pump from 1958 thru 1976 will bolt up" I finally understand the need for a high volume pump, it seems an FE pump is a solution. THANKS!

|

|

By charliemccraney - 2 Years Ago

|

If the pressure gauge is on the hot engine, it is not reliable once it becomes hot. I've had multiple different regulator mounted gauges and they all drop to an indication of 0 psi when they get warm, yet the engine continues to run fine, indicating that pressure is not, in fact, 0.

|

|

By Brent - 2 Years Ago

|

Thanks for the heads up!

I have installed a guage with a bleeder and with the nipple on the bottom for mounting vertical : These new gauges feature a special sealing plug, fitted with a stainless steel pin-valve that can be pulled up slightly to equalize internal pressure and then pressed back down to re-seal. The gauge remains sealed but able to be equalized at any time, regardless of gauge temperature, immediately restoring accuracy and eliminating heat related inconsistency. Fuel Pressure Gauges: Liquid Filled vs. Dry (verociousmotorsports.com)

It seems apparent that the AC 4212 is not up to the task. I have an AC 4918 which is an antique high volume pump, however, I have my eye on a six valve Nascar sytle FE pump. Thanks again...

|

|

By Brent - 2 Years Ago

|

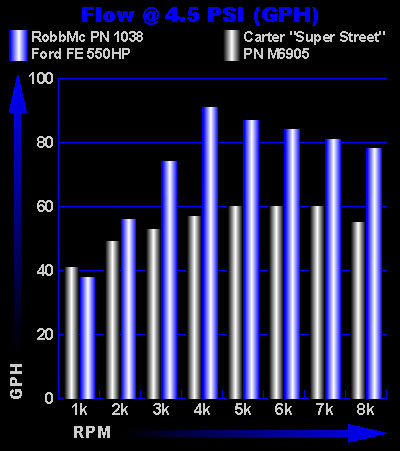

I installed the Carter M6905 only because it was here in 2-days, the RobbMc looks awesome. In the Thunderbird you have to rotate the valve body counter clockwise to get 45 nipples to clear the crossmember.

The issue of hesitation after WOT let off is gone, I am guessing that when fuel is sloshed in the bowls and the fuel pump is not supplying enough volume there is a lean moment. The engine is running strong. Next is carb fine tuning.

Fuel gauge read 7 psi cold and 6.5 after the run.

|