|

By Tealy64 - 3 Years Ago

|

This bolt broke off in my head while taking the manifolds off. Tried cooking for days in deep creep, tried heat, welding a nut on it, drilling, etc. It just keeps destroying my tools. 😩

If I'm taking them off and over to a machine shop, what else should I have them do?

Looking for advice and suggestions.

|

|

By Joe-JDC - 3 Years Ago

|

|

Drill it larger and larger to get enough area for an "easy out". If you need to remove the threads, then re-tap it for a heli-coil. Should be something you can do at home if you have the room to get at it with a hand drill. Joe-JDC

|

|

By 55blacktie - 3 Years Ago

|

I had good luck extracting a broken bolt with a Rescue Bit (rescuebit.com). I was able to remove the broken bolt, and the threads were still intact. I was able to replace the broken bolt with the same size bolt & thread pitch. The bits aren't cheap; however, being double-ended, they have a longer lifespan. You might want to try it before removing the head and taking it to a machine shop. Be sure to follow directions, and let the bit do the work.

|

|

By 55 GLASS TOP - 3 Years Ago

|

|

Tell you what I have done with broken bolts that just would not come out . Take a hacksaw blade grind the back away about one inch long grind it to the width of the hole you have drilled . Put the hacksaw in the hole saw through the bolt once you have a cut in the bolt it will collapse in the hole and come out . Sounds crazy but it works for me

|

|

By 55blacktie - 3 Years Ago

|

|

If I understand you correctly, wouldn't it be easier to start with a coping saw blade?

|

|

By 55 GLASS TOP - 3 Years Ago

|

|

Coping saw is made for wood , the hack saw blade is rigid and you have the rest of the blade to hold on to just grind the back of the blade until you fit into the hole you drilled

|

|

By KULTULZ - 3 Years Ago

|

|

Take a hacksaw blade grind the back away about one inch long grind it to the width of the hole you have drilled . Put the hacksaw in the hole saw through the bolt once you have a cut in the bolt it will collapse in the hole and come out . Sounds crazy but it works for me.

... hmmpf ...

I'm an old fart and still learn something everyday.

THANX!

|

|

By Tealy64 - 3 Years Ago

|

|

wow...I never would have thought of that! I'll give it a shot before I start taking it apart. Thanks!!

|

|

By Tealy64 - 3 Years Ago

|

Well, unfortunately the hacksaw truck didn't work (I could get a hole drilled all the way through due to a previous bit being broken off in the bolt) so I dropped it off at the machine shop. He's doing a cleanup, valve job and removing that broken bolt.

Having removed the heads, I discovered another broken bolt in the block.

hopefully I can get this one out on my own.

|

|

By 55 GLASS TOP - 3 Years Ago

|

Sorry to hear that but it will all be good in the end

|

|

By Tealy64 - 3 Years Ago

|

That's what I keep telling myself (and the wife). What started out as a clean-up for painting has turned into a "soft" rebuild.

That's how it goes, right?

|

|

By 55blacktie - 3 Years Ago

|

|

The more you dig, the more you'll find that needs to be done.

|

|

By Tealy64 - 3 Years Ago

|

So true!

I have to make myself stop, otherwise I'll dig too deep. Wake up a Balrog or something...(for any Lord of the Rings fans on here).

I'm thinking that while the heads are off at the shop, I can focus on getting that bolt out of the block (hopefully it's not in a water jacket and will come out easy) and then get everything cleaned up and painted before they get back. I'm also thinking of ordering some new head gaskets and head bolts from Mummert.

Question: do you guys typically treat the block or heads with anything before you install them? I'm seen mention of a copper spray or something?

|

|

By 55 GLASS TOP - 3 Years Ago

|

|

i have always used a good quality gasket on two clean dry surfaces. I am sure others have used the copper spray. I have not had any issues in the 60 years I am working on cars. As for your broken stud, to which I am no stranger and a self proclaimed expert .Buy your self a good set of left handed drill bits ,some time if the gods are in a good mood just drilling with the reverse drill will back out the stud.

|

|

By 55blacktie - 3 Years Ago

|

|

Is any manufacturer making "quality" drill bits? Aren't they all being made in China? Consider buying multiple cheap bits that won't last and hope you won't break one off in the stud while you're trying to remove it.

|

|

By 55 GLASS TOP - 3 Years Ago

|

There are still a few excellent companies in America making drill bit. Quality stuff.

1 American Made Drill Bits Saint Paul Minn

2Drill Hog

3 KnKut

4 Melim

5 Montana Brand Tools

6 Norseman Drill and Toll

7 Rocky Mountain Twist

8 Triumph

9 Vick Tool Company

10 WL Fuller

I would not use a drill ,tap or die from harbor freight that is the stuff that gets you in trouble

|

|

By 55blacktie - 3 Years Ago

|

I'll keep this list handy.

I have found that the drill bits sold at local hardware/chain stores aren't any better than what's sold by Harbor Freight.

It seems that the majority of the above sell on Amazon and use "domestic and globally sourced materials."

Some years ago, I purchased a pair of "American Made" leather hiking boots. When they arrived, the box said, "Made in America with Imported Materials." I had to ask myself, "Why is it necessary to import materials? Don't we have cows in America?" Rubber soles?

|

|

By 55 GLASS TOP - 3 Years Ago

|

|

"When I look back at all the crap I learned in high school" I think of my shop teacher Mr. Bay who made it a point (no pun ) too make sure every kid could sharpen a dull drill bit. He would take a good bit mess it up on the grinding wheel hand to you and say "make it like new" so most of my bits I have for many years drill bits that were 5 inches are now 3 from being sharpened over and over. That is the diffrence between quality and junk . Just an old man rambling

|

|

By Tealy64 - 3 Years Ago

|

i'd love to just have a bit that's actually worth sharpening. I made the mistake a few weeks ago of buying a "high" dollar bit from ACE, thinking "ok, this has to be better than the HF ones that I have right? Wrong...it broke just drilling a pilot hole in a metal stud just to hang some shelf brackets. I don't mind paying for quality, but it better actually be good! Thanks for that great list. I'll check 'em out and give that left turning bit idea a try.

Merry Christmas, fellas.

|

|

By Richard - 3 Years Ago

|

|

I bought set of cobalt twist drills at Harbor Freight. Expensive but man cut steel nice

|

|

By Tealy64 - 3 Years Ago

|

Machine shop called this morning, herbs telling me that someone has been in those heads before and they're in pretty rough shape. He can rebuild them, put new seats, guides and valves or..I can try and track down reconditioned heads...Or, buy a set of used if I can find them from someone I trust.

Thoughts? Anyone been through this before or have some suggestions?

|

|

By miker - 3 Years Ago

|

I might have missed it, but I didn’t see what casting numbers your heads are. Lots of heads, different port sizes, chamber sizes, etc. some posted, most at this point milled to some degree.

If your not familiar with it, here’s a link to the head casting chart on John Mummert’s site.

http://www.ford-y-block.com/cylinderheadchart.htm

|

|

By Tealy64 - 2 Years Ago

|

After doing much digging and searching, it looks like my best bet is just having our Machine Shop / Engine guy rebuild the heads that came off the motor. At least that way, I know they're fresh AND they belong to that engine. It'll do until I decide to hop it up and get some of those fancy aluminum ones.

That being said, anyone know where I can get some new head bolts? Seems like there's a bit of shortage out there on those.

Thanks in advance, my friends!

|

|

By DryLakesRacer - 2 Years Ago

|

I believe I purchased mine from head bolt.com. They were just over $100.

When I had my cylinder heads off for another reason I bought the tool set and installed positive seals. You can ask your machinist concerning them. Every engine I have built I’ve used them. This is the first time I did them myself along with cleaning and lapping the valves. The engine had 10k miles.

|

|

By Tealy64 - 2 Years Ago

|

I got super excited when I found that site last night, and of course, they're out of stock. I called Mummerts yesterday and he's also out of stock. I see a trend here...

John did say that they can be purchased individually, you just have to know the exact sizing, threads, etc. which I do not trust myself with. LoL

Don't suppose anyone in here already has that info?

|

|

By Ted - 2 Years Ago

|

You might try custom ordering from ARP if having difficulty in getting grade eight head bolts elsewhere. Here’s the link to a prior thread giving the individual ARP numbers for the Y head bolts.

http://forums.y-blocksforever.com/FindPost162034.aspx

|

|

By 2721955meteor - 2 Years Ago

|

|

go to the closest cat dealer. they have grad 8 bolts that will work. you may have to trim the longer 1s. run a bottom tap down all the threads in the block. use the old bolts for length. I have used ther bolts on several engines. the original bolts ford used some ok ,most garbage when you assemble small dab of grease on each bolt thread

|

|

By Tealy64 - 2 Years Ago

|

Called ARP yesterday and got all these bolts ordered. They told me that they're all on back-order until late Feb / March. The lady wasn't super friendly, but I guess if I had to spend my day telling people that the parts they want are on backorder, I would be grouchy too.

Guess that gives me time to do all the other necessary bits to the block before the heads go back on.

I still need to get that broken bolt out...

|

|

By Tealy64 - 2 Years Ago

|

Heads are done!

|

|

By Lord Gaga - 2 Years Ago

|

Low compression 471 heads. Is your engine supercharged?

|

|

By Tealy64 - 2 Years Ago

|

Negative, sir. No super-charger over here.

Although...that would be cool. Do they make super-chargers for these engines? I can only imagine what it would cost to deck one out to take advantage of something like that.

|

|

By charliemccraney - 2 Years Ago

|

Some were factory supercharged, F codes.

Cost will vary wildly. To do it like the F codes but without the correct parts would probably be cheapest and easiest. To do it with correct F code parts is probably the most expensive by far and best left to restorations. Aside from that, i don't think anyone makes a kit but just about any supercharger could be used, if you can produce the necessary parts and this price, again will vary wildly depending on your own abilities and skills. And then to build the engine with modern techniques and good practices for supercharging would increase the baseline cost for all of the previously mentioned. So no, it's not cheap but to do most engines correctly with quality parts simply isn't cheap..

|

|

By miker - 2 Years Ago

|

F code clone. 471 heads, ported by J Mummert (when he still did that). Brackets by Pegleg. VR 57 rebuilt by Pat F. Kind of fun, can be done other ways.

|

|

By 55blacktie - 2 Years Ago

|

|

rexhp.com. They have a supercharger kit for y-blocks and other desirable parts, but they aren't cheap.

|

|

By Tealy64 - 2 Years Ago

|

I think I'll just stick to what I have and see if I can get that running first. =)

I am considering taking the block in to the shop and having it inspected. Maybe check the pistons, pins, bearings etc and replace if necessary. My worst nightmare is putting this thing all back together and having it grenade just because I didn't get something checked 'cause I'm a cheapo.

|

|

By DryLakesRacer - 2 Years Ago

|

|

There at least 2 books on the building/assembly of y-blocks which show step by step and what to check. There are members here that believe 300hp is the starting place for a build and that’s fine. For a 62-64 pick up 292 the starting point is 162 hp which is a very very drivable engine which will run on today gasoline and perform well. If your engine has .002-.003 cylinder wall taper is not a deal breaker. Same for a few thousandths wear on the bottom of your pistons. A good set of Hastings rings, rod and main bearings on a polished crank shaft and cleaned parts are what’s needed. In 50 years I have never resized a rod and never lost one. I believe a good oiling system and doing the need changes to make our Y’s better is a good thing but today’s oil and more frequent changes will negate all of it. I like better valve seals when doing servicing the heads and hardened seats. A new timing gear set and chain is a plus as well as block and head surfacing but not always needed after checking with a straight edge with todays gaskets. Don’t ever get discouraged. Take your time as you have. There are many here to help and don’t be afraid to call master rebuilders like Tim McMaster and Ted Eaton. They build stockers more often than race engines and and can recommend change for what you need. My 292 was built 12 years ago by an unknown shop in Phoenix Az and you can barely hear it running. I have only improved the valve seals one year ago. I would be extremely happy if it has the 202 hp it was advertised to have stock. . Good luck.

|

|

By 55blacktie - 2 Years Ago

|

|

DLR, if you rarely see 3000, but can easily keep up with highway traffic, either you have a numerically low axle ratio or overdrive. Which is it?

|

|

By DryLakesRacer - 2 Years Ago

|

|

Removed as not relevant to the original posting

|

|

By 55blacktie - 2 Years Ago

|

|

Quite a coincidence! I put 2.72 gears and limited-slip in my 55's Dana 44, and I'm replacing the Fordomatic with a C5/w C4 torque converter, valve body, Dynamic Racing Transmission's C4 wide-ratio gear set and their C4 governor secondary valve kit for higher WOT upshifts in Drive. My 215/70R15 tires are 26.9". The 292 won't be stock, but the Howard's 292002-10 cam is relatively mild compared to what others are using.

|

|

By Tealy64 - 2 Years Ago

|

We're definitely not discouraged by anything. My wife and I both understand we're working on a old thing that isn't super popular, so there's challenges. I think the most trouble we're having (at least I am) is the "do I spend the time and money to hop it up now or do we put it together and get it running and worry about it later".

I'm going to talk to the machinist on Friday when I pick up the heads and see what he'll charge for a block inspection. I don't have a ton of experience with deep engine work, and zero XP with these Y-blocks. While I'm not opposed to learning, I also don't want to learn "the hard way" and grenade my motor by forgetting/not knowing about something simple. This is definitely one of those times when I wish Grandpa was still around. :-\

|

|

By 55blacktie - 2 Years Ago

|

|

Tealy, you're likely to remain interested in a car that's running and drivable. If you prolong completing it to your satisfaction, you might lose interest. On the other hand, you probably don't want to do it twice, which will be costly in time and money. The cost of parts has gone up significantly since I started a body-on restoration of my 55 Tbird.

|

|

By Tealy64 - 2 Years Ago

|

|

I've noticed that too. Even in the few months of sourcing parts I've noticed an increase. It's not going to get any cheaper or easier to find parts for these engines, that's for sure.

|

|

By Tealy64 - 2 Years Ago

|

A good thing happened this weekend. A little hot wrench and a lot of patience tapping on a punch.

With that worry safely behind us, we're back on track.

|

|

By Tealy64 - 2 Years Ago

|

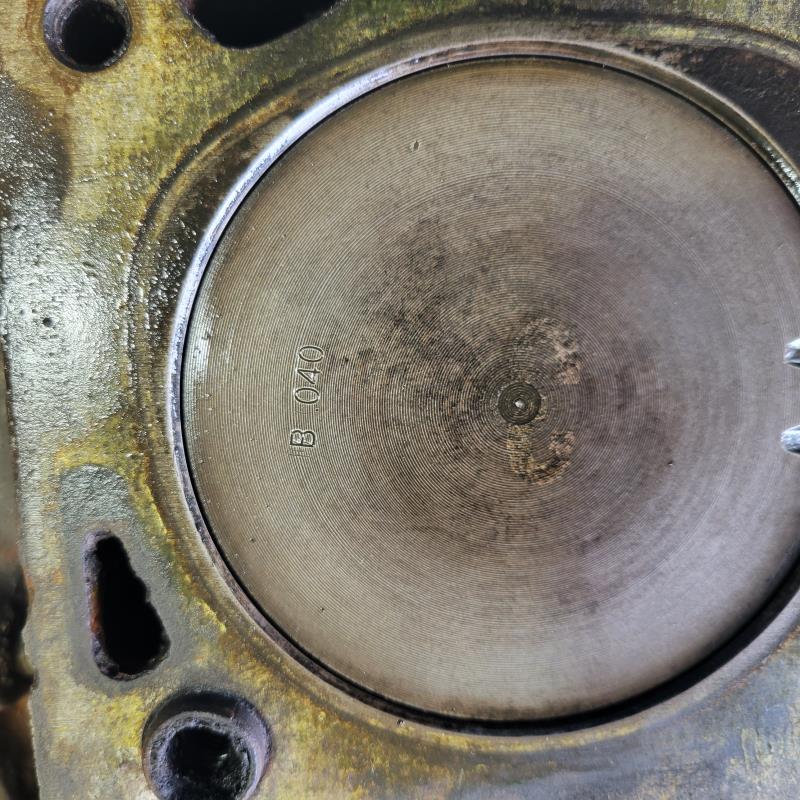

Cleaned up the pistons and cylinders this weekend. Looks like these have been bored .40 if reading that correct.

|

|

By 55blacktie - 2 Years Ago

|

|

Yep, +.040.

|