|

By peeeot - 4 Years Ago

|

As long as I’ve owned my Crestline, there has been a knocking noise evident at idle. It is relatively minor, but consistent. As soon as engine speed increases a bit it is drowned out by fan noise, etc, so it doesn’t get any louder and the only time I can ever perceive it is below about 1000 rpm. It seems to be most audible near the timing cover. It does not sound like any kind of valve train noise. It has not changed at all over the 2-3000 miles I have driven since purchase. Changing oil viscosity from 10w-30 to 15w-40 has made no difference.

What does this sound like to you?

|

|

By darrell - 4 Years Ago

|

|

could be the fuel pump you need to get a hose if you dont have anything else put it to your ear and search for the noise.

|

|

By 2721955meteor - 4 Years Ago

|

|

remove the oil filter cut it open if it is a spin on put the metal end in the vice, take a good carpenter chisel and cut around so you can remove the paper element.no cuttings in the paper your isue is not fatal. then get your hose and listen to the fuel pump, then check valve clearance

|

|

By peeeot - 4 Years Ago

|

I used a long screwdriver as a stethoscope and probed around. I do not believe it’s the fuel pump. The sound is strong on timing cover, block, head, exhaust manifold all local to cylinder #1. Holding the screwdriver near the head gasket surface on the head, I believe I could actually feel the knock slightly in the handle of the screwdriver. The further from cylinder #1 I get, the less I hear it.

I’m pretty sure I cut open my last oil filter a few months ago and saw no shavings or cause for alarm. I can revisit valve adjustment soon but I feel like this is something else; I’ve heard loose y-block valves before.

|

|

By darrell - 4 Years Ago

|

|

a lot of knock ive heard on y blocks is from worn or spun rod bushings.that is wrist pin bushings.ive seen them go for years like that.

|

|

By paul2748 - 4 Years Ago

|

Is it a Fordomatic ? The ears on the flex plate have known to loosen up and make a knocking sound

|

|

By peeeot - 4 Years Ago

|

It's a 3-speed/overdrive.

Is there any way to determine whether it's wrist pin knock, short of dropping the oil pan and wiggling things?

|

|

By 30 coupe - 4 Years Ago

|

|

With the engine running at idle, pull the plug wire off the cylinder you suspect the noise is coming from. If the noise goes away, or is greatly reduced, it is likley a wrist pin, or piston slap. does the noise get any quieter as the eng. warms up to operating temp? pull the plug wires off one at a time to find the offending cylinder.

|

|

By Florida_Phil - 4 Years Ago

|

Don't panic. I built my current TBird engine about three years ago and have driven it about 4,000 miles. My engine was a total rebuilt with new pistons, valve train and a standard crank from a 40,000 mile 1957 Ford station wagon. Since then, I have had a plethora of knocking sounds, some of them quite troubling. They all turned out to be minor issues from a bad fuel pump, a corroded intake manifold exhaust crossover, PCV issues, exhaust leaks and even a bad fan belt. It all comes with owning an old car.

|

|

By peeeot - 4 Years Ago

|

I tried pulling the #1 plug wire with no effect on the knocking. I will try checking the others later today.

It’s been colder today and I noticed that the knock was less significant than usual when the engine was cold. It seems warming up to operating temperature makes the knock louder rather than quieter.

As soon as I can pull plug wires and check valve lash I’ll post back with any findings.

Oh, one other observation: I drove to work today with a vacuum gauge hooked up. Readings were very good, but there was some minor needle flutter pretty often, especially while accelerating through the 1500-2000 rpm range. Hopefully my valves haven’t already tightened up too much, it’s only been a few thousand miles and I use lead substitute.

|

|

By peeeot - 4 Years Ago

|

I pulled each plug wire while idling, and in each case the knock did not change and a miss was evident.

I also ran through the valves this morning (cold) and was pleased to find that most of them were right at 0.019”. None were loose, but a few were a few thousands too tight. I plan to run the engine with the valve covers off later, then check clearances one more time.

|

|

By 30 coupe - 4 Years Ago

|

|

since the noise did not change when pulling off the plug wires, you could try pulling the fuel pump off and running the eng. there should be enough fuel in the carb. to run the eng. long enough so that you can see if the noise is still present. If it is not, it is probably the fuel pump. If the noise is still there you will have to go deeper, or wait for something to break. Not a good thing. do you have an automatic trans? If you do does the noise change when shifter into drive or reverse, is it louder one way or the other? there is the possibility of loose torque converter bolts, or cracked flex plate/ flywheel if the noise changes

|

|

By Deyomatic - 4 Years Ago

|

|

Looks like he has a 3 speed with OD.

|

|

By Ted - 4 Years Ago

|

Any idea if the last time the engine was freshened up if it was a complete rebuild with new pistons and ground crankshaft or was it a re-ring and re-bearing rebuild. If the old pistons were reused, then a cracked skirt is a possibility.

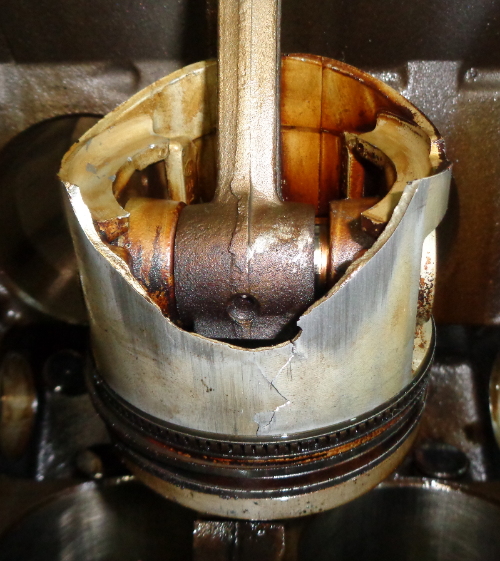

Here’s a picture of a cracked piston from a 272 that just had a light knock.

|

|

By peeeot - 4 Years Ago

|

Running the engine with the valve covers off, the knocking sounds exactly the same; only the valve train clatter is more audible. With the covers on, valve train noise is not noticeable—it’s a pretty darned quiet engine. I do not know anything about its history but nothing about it looks fresh.

As for the fuel pump, I haven’t tried removing it, but my “stethoscope” suggests the source is elsewhere.

I’m inclined to just let it be for the foreseeable future; it’s very minor and not at all evident behind the wheel above idle.

The only concern I have at this point is the vibrations at 1600-2000 rpm and the vibration of the vacuum gauge. I was thinking these might be related to the audible knock, but I’m not sure whether it merits dropping the oil pan and surveying things. Maybe if a piston (probably #1) has a broken skirt, it is causing a balance issue in the bottom end—but if that were so, wouldn’t it get worse at higher engine speeds?

|

|

By 30 coupe - 4 Years Ago

|

|

I don't know how hard you drive your car, but if you baby it, there is the possibility that there could be some carbon build up on the top of a piston. I had this happen on the GM 454. I would have sworn that it had a bad rod , until I used some "top engine cleaner", a product made by gm. and de carboned the eng. this can be done also by using straight water, or some have used a mix of water and brake fluid with good results. A carbon build up though is usually heard even from inside the car when driving, not just at idle. As Ted suggested it could be a cracked or broken piston skirt, it could possibly cause a balance problem with a vibration depending on if a piece has broken off, and how big of a piece. if just cracked, there is a possibility that it can go a long time before complete failure. another possibility would be a piston that is slightly under size in the skirt area, or one that has a "collapsed ", with out being able to hear your eng. running in person, at this point I am not sure what the noise could be. maybe Ted, or someone with more experience with Y-blocks may have more suggestions. sorry I was not more help--- Jim

|

|

By peeeot - 4 Years Ago

|

I appreciate all the help, even if it hasn’t led to resolution yet.

I did remove the fuel pump tonight and ran the engine without it. The knock was still evident, but not any louder. Looking in the fuel pump hole, everything looked normal, if not particularly clean.

The next step is probably to drop the oil pan and look near the front of the block for anything irregular. Will the pan clear the steady rest on a ‘54 Crestline? Motor mounts are new.

|

|

By DryLakesRacer - 4 Years Ago

|

|

The pan will miss the steady rest on my 56 but I need to remove the sway bar. #5 needs to be near TDC to it slide off. I also installed 2 set screws at the rear of the pan for ease of reinstalling it when it was off. Good luck.

|

|

By peeeot - 4 Years Ago

|

I love that I was able to remove the oil pan without even jacking the car up. I can’t imagine that’s possible on very many cars!

I believe I have spotted the source of the knock. In

The end of the wrist pin bushing was visible outside the rod end. I was able to easily push it back into place with a screwdriver—basically no resistance.

Additionally, I found about 3-4 tablespoons of metal paste in the bottom of the otherwise-clean oil pan. There was also two pieces of a small spring I don’t recognize.

I checked the #1 rod bearing as well. She’s done.

I didn’t see any chips or cracks in any pistons or the crank, nor anything else I would expect to create a 1600-2000 rpm vibration. Could bearing slop account for it?

|

|

By Ted - 4 Years Ago

|

That wrist pin bushing is a strong candidate for the noise you are hearing. A set of bearings would not hurt at this point either. No idea on the spring.

|

|

By Hoosier Hurricane - 4 Years Ago

|

|

Loose wrist pin bushings happen when the bushings are replaced without the proper equipment. Sunnen makes a set of tooling for the job. The bores in the rod are not smooth, they are rough bored. Then Ford swedged the bushings in place, and the OD of the bushing was forced into the rough bore in the rod. If replacement bushings are simply pressed into the rod, the bushing OD is sheared, and the fit in the rod is only temporary. With the pounding of the wrist pin, the OD of the bushing starts to conform to the rough bore, losing its press fit. Then it is loose and makes noise. Sunnen tooling (I'm sure other companies have similar tooling) swedges the bushing in place, then you can hone it fit. If peeot's engine has one bushing loose, I would suggest that the other 7 are in the same shape.

|

|

By peeeot - 4 Years Ago

|

Hoosier, that explanation makes sense. Not knowing the engine’s history, I can’t say for sure whether the piston pin bushings have been replaced.

I dropped the front main bearing cap and found this:

Looks to me like original 1956 bearings suggesting that this engine was never overhauled. No more babbitt but bearing surface feels perfectly smooth. Just worn out I guess. I have about 30-35 psi hot oil pressure from about 2000 rpm but it’s very low at hot idle—less than 10 psi.

It appears the engine is due for a rebuild, but that won’t be in the cards for me any time soon.

Would it be worth the money to put a set of standard size bearings in at this point? I don’t push this engine hard and mostly just cruise around. If I’m not doing/risking lasting damage by continuing to do so, I might prefer to just button it back up and keep motoring until a good opportunity to rebuild.

|