|

By alanfreeman - 3 Years Ago

|

|

Unfortunately, my overdrive problems continue. Before I was able to get the O.D. solenoid installed, I bench tested the replacement with a 6 volt battery and it seemed to work fine. I installed it and road tested the car repeatedly but the overdrive would not engage even at 50-60 MPH when I would back off of the accelerator. I printed the Borg Warner O.D. Manual from the Internet and went through the tests of the electrical components still installed in the car. The relay tested good and the solenoid seemed to be O.K. at first but after repeatedly getting it to click it started making a buzzing or throbbing noise. I got under the car and took the solenoid cover off to check the points. I grounded the governor wire to activate the solenoid with the ignition on so I could watch what was going on inside the solenoid. I saw arcing between the points and the buzzing noise was caused by the plunger trying but failing to fully extend. There was some oil inside the solenoid which I cleaned out and I cleaned the points with some fine sandpaper. I left the cover off and road tested the car again but the O.D. still did not engage. Even worse, the speedometer stopped working on this test drive so the nylon speedo driven gear probably stripped out for reasons unknown. Are the points inside the solenoid supposed to open and close when power is applied and then removed? Watching them with the cover off the points stay closed and the plunger now appears not to be fully extending. Also, I have not tested my governor and I do have two replacements (condition unknown). I see that the governor can be tested with an ohm meter by spinning the gear on the wire wheel of a bench grinder. I have a multi-meter but I don't know how to test ohms. Can someone explain what to set the meter on and what to look for as far as a result on the meter? Any other suggestions would be great. Alan

|

|

By FORD DEARBORN - 3 Years Ago

|

|

Alan, I'll take a stab at this. I think your test of grounding the governor wire is proving the relay is ok because the solenoid is picking up. One contact opens while another contact closes. There is a heavy contact that removes power from the pull-in coil when the solenoid is energized because it otherwise would burn up, thus leaving the holding coil energized which is rated for continuous duty. The other contact closed and remains so thus arming the ignition grounding corcuit. The plunger will not fully extend until conditions are right for the pawl to engage. The armature moves compressing a spring which applies force on the pawl waiting for the driver to momentarily release the throttle. The balk ring moves such that it no longer blolcks the pawl from engagement. I think you may be on the right track with your ohm meter. One scenario is the holding coil could be open thus when the pull-in coil opens by means of the large contact,, the holding coil is not energized and the solenoid drops out and the process repeats, like an old fashion door bell. I don't know what your meter looks like but there should be a selection that looks like an upsidedown horse shoe. Then select a low scale, number wise. When you join the two probes together, the meter should indicate near zero. Working with the two solenoid wirtes, one solenoid wire should show "open circuit" which would then be the ignition grounding circuit. The other wire should indicate some very low reading, like 2, 3, or 4 ohms. That's the coil circuit. Now, open the large/heavy contact and put a piece of heavy paper between them. This will take the pull-in coil out of the circuit and the holding coil should remain. Put your ohm meter on the wire again and it should indicate a much higher ohm reading compared to the first reading taken without the paper between the heavy contacts. This should prove the two sperate coil inside the solenoid. As for the governor, it too should close it's contact indicating near zero ohms when spooled up by a wire wheel. or more elegantly with a drill motor. Also you entioned the speedometer quit. The same drive gear on the trans output shaft also drives the governor - something else to check. Hope this helps, JEFF.......

|

|

By Dobie - 3 Years Ago

|

|

The solenoid contains 2 sets of points, the high amperage pull-in points and the lower amperage hold-in points. When the governor contacts close and ground the relay the pull-in points are energized along with the hold-in points, causing the armature (the plunger) to extend. The instant the armature extends the pull-in points should open leaving only the hold-in points in the circuit. Then, when you lift off the gas, the armature completes its travel allowing the OD to engage. If the pull-in points don't open as described the high amperage will damage the solenoid windings, eventually causing complete failure of the solenoid. Oil inside the solenoid is not a good thing. It indicates the rubber seals in the transmission and the solenoid are leaking. The one in the transmission is easy to replace but the seal in the solenoid requires complete disassembly of the solenoid. If it were me I'd get a new solenoid. Van Pelt Sales and 5ht Avenue Garage both have new ones. There are also places the will rebuild them as long as the windings are in good condition. To test the governor you can just set your ohm meter to read continuity and spin it up with your wire wheel or chuck it up in a drill. I'm betting yours is good, they rarely give trouble.

|

|

By Lord Gaga - 3 Years Ago

|

|

Clean the points on the RELAY. Test with Ohm meter to be sure they are making good contact.

|

|

By Florida_Phil - 3 Years Ago

|

I have been down this road numerous times with my TBird. I test my governor using a long wire with a dash light wired in series running from the battery to the governor wire. If you put the rear of the car on jack stands, you can run the car through the gears. When the governor grounds, the light should go on. Use strong jack stands and take care or you won't like the result.

|

|

By DANIEL TINDER - 3 Years Ago

|

|

A sidenote: I discovered that when bench testing a solenoid, some that appear to operate normally will actually not, under force-load. So, I built a plywood testing jig (easier than installing on the trans) to weed out the defective NOS units offered online (likely returned to the dealer’s jobber back in 50s, and then resold).

|

|

By alanfreeman - 3 Years Ago

|

|

I was successful in getting my original solenoid to work properly (at least when bench tested) and also mounted on the transmission when I energize the blue wire I can hear the strong click of it engaging. Turns out that the problem was that the points on the side of the unit were misaligned so they were not making good contact. I manipulated them with a needle nose pliers which did the trick. I took the car out for another test drive bur the O.D. still would not engage when I backed off the gas at 50-60 MPH. I can think of only two more options before I give up and seek professional help. When I removed this O.D from the car that it was originally in, about 1 inch of the end of the cable broke off. When I installed it in this car I connected the cable as far to the end as possible with the slightly shorter cable. It may be that the shift lever is always slightly cocked forward because of the shorter cable thus manually disabling the O.D. I am going to disconnect the cable, pull the shift lever all of the way back and then see if the O.D. engages on a test drive. The second possibility is a bad governor. I have another one to swap in but I will have to make a special thin 1 3/8 end wrench like the one in the Shop Manual to remove and reinstall the replacement.

|

|

By miker - 3 Years Ago

|

|

It’s been years, but IIRC that lever has to be all the way back. I usually set them so the handle had 1/4” or so travel before it bottomed out, just to be sure. Good luck.

|

|

By Florida_Phil - 3 Years Ago

|

Most O/D problems turn out to be wiring issues. Go back and check all your connections and grounds. Especially check the kick down switch as it's a source of some problems. I disabled my switch due to the circuit messing with my Pertronix unit. The O/D circuit works backward from what you might think. If you have verified both your governor and solenoid are working, you most likely have a wiring issue.

|

|

By peeeot - 3 Years Ago

|

|

Do you have engine braking when you let off the gas? If the shift lever is far enough back to allow an overdrive shift, you should freewheel with no engine braking. If you have engine braking but no overdrive ratio, the overdrive is mechanically locked out. Additionally, you should only be able to move the overdrive shift lever toward the front of the car (locked out position) about 1/4” before meeting a good amount of spring tension. If the lever easily flops freely in either direction, there is a problem with the shift rail binding or else with the return spring.

|

|

By alanfreeman - 3 Years Ago

|

|

Well, it looks like I am running out of options on this non-working overdrtive. I decided to test the governor on a test drive with a test lamp inside the car. I hooked one lead of the test lamp to a hot wire inside of the car and I ran another lead under the car and connected it to the governor wire. With the governor that was in the transmission the test lamp burned "on" all of the time which clearly was not right as the lamp should have come only after 27 MPH when the points in the governor completed the circuit by making a ground. I removed that governor and replaced it with another used one that I had which had tested O.K. on my Ohmmeter. Test drove the car again and the test lamp came on only if the car was moving at 27 MPH or more which is correct. I was convinced that the O.D. would now work so I reconnected the governor to the wiring harness but still no working O.D. In summary, my relay tests good, I got my solenoid working properly and the governor tested good on my test drive. The wiring harness is brand new as is the kickdown switch. When I depress the kickdown switch, the engine momentarily cuts out which I think it is supposed to do, right? I also loosened the cable and pushed the lever as far back as it would go before tightening the anchor but this made no difference. Unless you guys can think of anything else I am wondering if the only possibility left is some mechanical problem inside of the overdrive. Just wondering.....is there some way that I can run a wire from the inside of the car to the solenoid to bypass all of the other electrical stuff and the wiring harness? This would allow me to directly activate the solenoid plunger from inside the car while driving so I can see if the overdrive will activate under any circumstance. If this is possible, can someone tell me which wire or wires of the two on the solenoid to connect and how to run the wires to a hot wire inside the car. I don't want to burn up the coils in the solenoid for this experiment.

|

|

By Dobie - 3 Years Ago

|

|

The 2 terminals on the solenoid should be marked "4" and "6". The #4 terminal normally is connected to the solenoid terminal on the relay. You can run a wire directly from your battery to the solenoid through a toggle switch mounted under the dash for your experiment, bypassing the OD wiring harness. To confirm that you have it wired correctly flip the toggle switch on and listen for the click. When doing your test turn the switch off and drive normally until you reach about 30 mph, then flip the switch on and lift off the gas as you normally would. Be sure to turn the solenoid off before shifting into reverse. A lot of guys wired the OD up this way and just drove it like that all the time.

|

|

By alanfreeman - 3 Years Ago

|

|

My solenoid doesn't have terminals, instead it has two wires exiting the cover, a blue one and an orange one. I assume that the blue one is the #4 as the blue wire goes to the relay. So I only need to run one wire from the battery to the blue wire of the solenoid with a switch on that wire? The ground will be supplied by the metal solenoid housing being attached to the transmission? I think that if I can get the O.D. to engage in this fashion then my problem is electrical. If still no engagement then the problem must be mechanical within the O.D. (assuming that the solenoid is working correctly which seems to be the case). Is that a correct assumption? Thanks

|

|

By Dobie - 3 Years Ago

|

alanfreeman (6/15/2022)

My solenoid doesn't have terminals, instead it has two wires exiting the cover, a blue one and an orange one. I assume that the blue one is the #4 as the blue wire goes to the relay. So I only need to run one wire from the battery to the blue wire of the solenoid with a switch on that wire? Correct.The ground will be supplied by the metal solenoid housing being attached to the transmission? Correct.I think that if I can get the O.D. to engage in this fashion then my problem is electrical. If still no engagement then the problem must be mechanical within the O.D. (assuming that the solenoid is working correctly which seems to be the case). Is that a correct assumption? Thanks It is a correct assumption.

|

|

By alanfreeman - 3 Years Ago

|

|

Thanks Dobie. I will try the "experiment" and post the result.

|

|

By FORD DEARBORN - 3 Years Ago

|

|

Alan, I'm assuming you are running a 6 volt system. Are you sure your solenoid isn't a 12 volt solenoid? That could explain a couple issues. Just a thought............

|

|

By alanfreeman - 3 Years Ago

|

|

Yes, it is a 6 volt solenoid.

|

|

By alanfreeman - 3 Years Ago

|

|

Still no overdrive. I connected a hot wire directly from the battery to a switch inside the car and then down to the blue wire on the solenoid. I Took the car on a test drive up to 60 MPH, backed off of the gas and turned on the switch and still no overdrive. I know that the solenoid is working as I could hear an audible click when I threw the switch. Also, I know that the pawl is being engaged as I accidentally left the switch in the on position when I put the car in reverse to park it after the test drive and the car move only about two feet and came to a dead stop which means that the reverse lockout feature is working which means that the solenoid is indeed engaging the pawl.....correct? I am at the end of what I can do so there must be something wrong inside the overdrive itself. Any suggestions?

|

|

By Dobie - 3 Years Ago

|

|

The only easy thing I can think of is to check the adjustment of the OD control cable at the transmission. If the OD shift lever is not against the rear stop when the control handle is pushed IN tne shift rail may block the pawl from moving into engagement when the solenoid is actuated. If the shift lever is not against the stop loosen the wire at the clamp. move the lever firmly against the stop, then tighten the clamp. The shift handle must be pushed all the way IN during this procedure. I doubt this is your problem since the car would not move in reverse until you turned the solenoid off. I would contact Mac Van Pelt at Van Pelt Sales and pick his brain. He's the Ford transmission guru and an all around good guy. He also rebuilds transmissions if it comes to that.

|

|

By peeeot - 3 Years Ago

|

|

I didn’t see where there was confirmation that the car is freewheeling. If there is engine braking below 25-ish mph then overdrive is locked out mechanically.

|

|

By alanfreeman - 3 Years Ago

|

|

Dobie....yes the shift lever is back as far as it will go against the stop. Peeeot.....there is engine braking and no freewheeling under 27 MPH. If you have a copy of the Borg Warner O.D. Pamphlet, section 23b. regarding transmission to overdrive misalignment is interesting. The pamphlet states that there is only supposed to be 1/4" of forward motion of the shift lever. I am going to check this tomorrow but I think that there is much more than 1/4" of forward motion of the lever on my overdrive. Also, I have an oil leak which seems to be coming from somewhere around the transmission to overdrive housing which could mean that there is the misalignment described in section 23b. Has anyone ever experienced this problem? Is there really supposed to be no more than 1/4" of forward motion of the shift lever as this seems to be very little motion of the lever.

|

|

By miker - 3 Years Ago

|

|

I read 23b, and it doesn’t add up to me. That would be about the same as cable travel, and the cable travel seems like it was more like 1”. Maybe it means the internal rod needs to travel 1/4”, but that doesn’t seem right either. But I can see where if the case to case was slightly out of line it would bind the rod. Without the rod moving correctly, no mechanical engagement even if the electrical is right.

|

|

By peeeot - 3 Years Ago

|

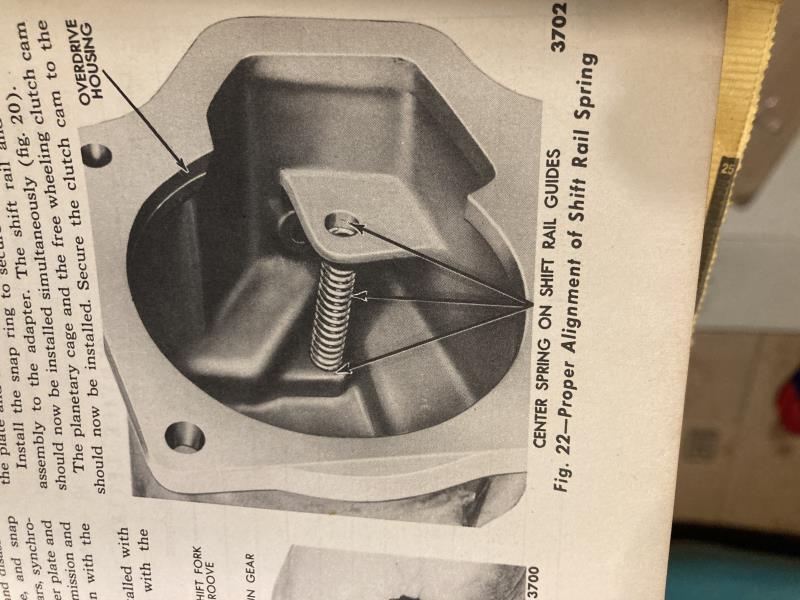

I just went through this a couple of days ago. If you find that, with the control cable disconnected, you can easily move the shift lever from back to front with little or no resistance, then the shift rail internally is stuck in the rearward position. Like the manual said, it could be caused by misalignment of the overdrive parts with the trans case. For me, what had happened was that somehow the shift rail return spring had been dislodged from its place when I was putting the extension housing back on after replacing the output bushing. When I took the extension housing off again, the spring was loose inside.

I was careful to follow the instructions regarding this spring when I assembled it the first time, but I clearly got something wrong. When I assembled it the second time, there was strong spring action after the first 1/4” of shift lever movement—and I got my overdrive back.

Here’s the spring:

|

|

By alanfreeman - 3 Years Ago

|

|

Peeeot....I removed the cable from the shift lever to check for free play. There is free play with no resistance for the first 1/2" and then there is resistance by way of the spring for another 1" or 1 1/2" of travel. Sounds normal? Do you agree? Another question for you or Dobie..... I want to try one last test of the electrical stuff before I give up. If I hook up a test lamp from the terminal on the relay where the blue solenoid wire attaches and run it into the car for a test drive, at what point during the test drive should the lamp light up? In other words, at what point in the electrical process is the blue solenoid wire energized if all of the electrical stuff is working correctly?

|

|

By Dobie - 3 Years Ago

|

|

The solenoid should energize at about 27 mph and de-energize at about 21 mph.

|

|

By peeeot - 3 Years Ago

|

Alan, that sounds about right. The spring should push the lever most of the way back to the overdrive position when released. The spring effort should be moderate. To further evaluate whether the shift rail is functioning properly, if you shift the trans into reverse the overdrive shift lever should then move through its full range of motion with little to no resistance. This is because the transmission linkage pushes the overdrive shift rail into the locked-out position.

If you are in fact getting engine braking at all times after the shift rail is verified to move as it should, then it would seem something is broken or misassembled inside the transmission. You only get engine braking when the sun gear physically slides back into the planetary set and locks it up. If the shift fork was not indexed with the sun gear groove properly, it may have pushed the sun gear into the locked position without being able to pull it back out.

|

|

By alanfreeman - 3 Years Ago

|

|

Peeeot....when I rigged up a switch to the solenoid in the car for the test drive and then forgot to turn it off before shifting into reverse and the car immediately locked up and would not move backward, doesn't that also mean that the shift lever is working properly? I bought this transmission as a used but supposedly rebuilt at some time in the past transmission. It was obvious that someone had been in it as it was clean and I could see blue silicone in the joints so it had been apart. I think that your hunch that something inside was assembled wrong is looking correct. I have another complete O.D. transmission that is filthy and has obviously not been tampered with. Am I correct in assuming that just the O.D. could not be swapped out with the transmission still in the car but instead the whole transmission would have to be pulled in order to do the swap?

|

|

By 57RancheroJim - 3 Years Ago

|

I only use a manual switch and if I forget to switch it off it locks up in reverse, so that sounds normal

|

|

By peeeot - 3 Years Ago

|

Alan, I believe what you and Ranchero Jim describe would happen any time the solenoid is fully engaged and the sun gear is in the locked position (toward rear of car). This would never happen organically because the solenoid would never activate in reverse. I do not believe it confirms anything about the shift rail specifically, but only that (as already suspected) the sun gear is in the locked position, either along with the shift rail or somehow independent of it.

Unfortunately it is not possible to swap overdrives without removing the whole transmission.

If no matter what you do at any time you never have freewheeling, it seems removing and tearing down the overdrive is inevitable.

|

|

By miker - 3 Years Ago

|

|

This is just a question as I try to keep up. I now understand the part about the shift rail and the spring thanks to the above post. Does the rail stop you from engaging reverse (if something fails and you’re in o/d and stopped) or is it supposed to mechanically disengage the o/d as the transmission itself goes into reverse. It been some time since I pulled my last o/d unit, and the only problem I had was a failed solenoid. Just trying to learn a bit and refresh my memory.

|

|

By peeeot - 3 Years Ago

|

Miker, when the rear transmission shift fork is moved into reverse position it physically pushes the overdrive shift rail (and sun gear) rearward into the lockout position. This is why the overdrive shift lever loses all resistance to movement (cable disconnected) when the trans is in reverse—it doesn’t “feel” the return spring pressure anymore.

Here is a link to the manual for any who haven’t seen it. http://www.oldwillysforum.com/forum/TechData/BWOverdriveManual.pdf

|

|

By miker - 3 Years Ago

|

|

peeet, I get that. But If the rail is properly in place and working (solenoid not engaged while parked). Shouldn’t the shift to reverse either 1) force the o/d to disengage or 2) stop the main transmission from engaging reverse? Maybe I’m confusing the remarks “locked up” with both being engaged. I owned a car with a bit of a Mickey Mouse factory 4 speed that would do that. If you pulled it from reverse and weren’t careful you could stick it in first (not always, just when it lined up right), with reverse still partially engaged. Letting the clutch out then really locked things up. Like call a roll back and put dolly’s under the rear wheels to load it. (It was a scrubby by the way).

|

|

By alanfreeman - 3 Years Ago

|

|

Peeeot....as you suggested, I disconnected the O.D. cable to test the tension of the shift lever with the transmission in reverse. Just as you predicted, there was no resistance to moving the lever from one stop to the other and no spring tension. I then shifted the transmission into first gear and the free play of the lever was about 1/2" and the spring tension returned for the rest of the travel. I assume that this means that the shift lever is working correctly???? Now what????

|

|

By peeeot - 3 Years Ago

|

Miker, when I am using the term “locked up” I am referring to the planetary gear set being locked, causing the transmission to operate like a conventional 3-speed. As for your question, it looks like there is a groove in the O/D pawl that corresponds to a larger diameter section of the shift rail. I am not positive but it looks like the idea is that when the rail is moved rearward (overdrive lockout) the pawl is prevented from moving at all because the large diameter section of the shift rail fits in the pawl groove. Conversely, if you were trying to shift into reverse while the solenoid is engaged, with pawl extended, you would be blocked from doing so because the large diameter section of the shift rail wouldn’t match up with the groove in the pawl.

Alan, based on what you described it sounds like the shift rail is indeed moving forward and backward like it should. I’m going to have to reread the thread to see if I can come up with anything else to try short of pulling the transmission out.

|

|

By alanfreeman - 3 Years Ago

|

|

Peeeot....I have a feeling that my problem is going to come down to one of the causes described in sections 27-29 in the Borg Warner Manual.

|

|

By alanfreeman - 3 Years Ago

|

|

It is looking more and more like my transmission is going to have to come out and someone who knows what they are doing will need to tear down the overdrive to figure out what is wrong inside of it. I could pull the transmission myself but working on the internal parts of the overdrive is "way above my pay grade". Does anyone know someone in the Southern California area who knows these transmissions?

|

|

By peeeot - 3 Years Ago

|

Alan, after reviewing the information again, I continue to believe that the root problem is mechanical and evidenced by the lack of freewheeling. I can see only two causes of no freewheeling: sun gear stuck engaged in locked position with planetary set, and locked up freewheel clutch. I can’t think of any way of dealing with either potential problem without overdrive disassembly.

I hope you can find a pro to sort it out for you. Good luck! I’m curious to know what the ultimate solution is.

|

|

By miker - 3 Years Ago

|

|

peeeot, thanks. I knew the lock out was there, but never really understand how it worked. Got it now.

|

|

By peeeot - 3 Years Ago

|

|

Miker, I’m not 100% on that explanation. The thing I’m not clear about is how it is possible for folks with a switch-activated overdrive to lock their drivetrain as described earlier in the thread. If the sun gear engages the planet carrier locking teeth and the pawl engages the sun gear control plate, that would lock the whole drivetrain just like shifting into park—but in order for it to happen, the shift rail would have to be able to move rearward with the pawl extended, contrary to my earlier explanation. Maybe someone else knows for sure.

|

|

By miker - 3 Years Ago

|

|

The passage of a lot of years makes things a bit fuzzy. But when I was 17 I disassembled a T-85 R-11 unit to put a new first gear in, the original was chipped pretty good. I took the overdrive apart, checked everything, and managed to get it back together just following a (probably Motors) manual. The only trick I remember was from an old mechanic to “use a rubber band to hold the neddle bearings in, when you drive it it will break and not hurt anything”. I drove it for years with the only problem being a burned out solenoid years later. I’d tear one apart again. But mine was all working right when I started. Makes it easier than diagnosing a problem.

|

|

By pintoplumber - 3 Years Ago

|

|

Here’s a possibility, if your sun and planetary gears are chewed up, your overdrive won’t work. It will be just a 3 speed transmission. No freewheeling.My overdrive section ran low or out of oil and chewed up the gears. Had to get a new gear section off eBay.

|

|

By alanfreeman - 3 Years Ago

|

|

Pintoplumber....you may be right but anyway you look at my problem this transmission is going to have to come out.

|

|

By alanfreeman - 3 Years Ago

|

|

Peeeot....I did one final test to confirm that all of the electrical components i.e. relay, governor and solenoid are working correctly. I hooked up a wire from the solenoid terminal on the relay into the car with a test lamp on the end of the wire. I grounded the bulb socket and took the car for a test drive and the light came on right at 27 MPH. I also heard the solenoid click when the light came on. Do you agree that this pretty much proves that my problem is not electrical but instead mechanical inside the overdrive?

|

|

By peeeot - 3 Years Ago

|

Alan, it definitely sounds like the controls are working like they should.

Do you have a tachometer installed? Regarding freewheeling, I just want to clarify that if you are looking at a tach, when you are freewheeling the tach will drop to idle rpms as soon as you let off the accelerator. If this does not occur (as you have otherwise stated) when the overdrive shift lever is all the way back then there is a mechanical problem. Similarly, if you park the car in any gear other than reverse, without setting the parking brake, and the car holds its position as you would expect with a normal manual transmission, then there is a mechanical problem.

|

|

By alanfreeman - 3 Years Ago

|

|

Peeeot....No tachometer, but I parked the car on a slight downward incline with the engine off, put it in first gear, released the emergency brake and the car rolled forward. Same result in second and third gears. Only in reverse did the car not roll. Now I am totally confused! Thanks again for all of your help. Alan

|

|

By peeeot - 3 Years Ago

|

|

Very interesting! So, previously you indicated that you had engine braking below 21MPH. How confident are you that that is the case? Similarly, what tells you that your overdrive is not engaging on the road? Are you able to execute clutchless upshifts? At what speed do you typically shift from 2nd to 3rd? Just trying to get a clearer picture of what you are experiencing.

|

|

By alanfreeman - 3 Years Ago

|

|

Peeeot......I will take the car out tomorrow to verify that there is engine braking under 20 MPH as opposed to freewheeling (which I assume I should have if the OD was working correctly). As to clutchless upshifting, I did not know that this was possible with a working OD so I never tried it. I would be reluctant to try it as couldn't I end up damaging a gear if it didn't work? Right now, at least the 1-3 gears work flawlessly and I don't want to mess that up. This '54 Ford police car that I am currently working on is not my only car equipped with an OD. I also have a '54 Mercury convertible with the 3 speed OD that I restored and the OD in that car has always worked flawlessly. When I get up to about 55-60 MPH and back off of the gas, I can feel the Mercury shift into OD and the engine RPM's are reduced. The police car has never done this. I get it up to 60 MPH on a straight away and the engine is really revving. I back off momentarily, and then hit the gas again but the engine is still revving just the same as before I backed off so it feels like the OD did not engage. Needless to say, I am getting real frustrated with this problem.

|

|

By Dobie - 3 Years Ago

|

|

Clutchless shifting is possible when the OD is enabled but not engaged. In other words the OD cable is pushed IN but your speed is below the governor cut-in speed. When you let off the gas below the cut-in speed the freewheeling clutch acts as the clutch, allowing you to shift gears. When I do it the stick feels a little stiff compared to a normal shift.

|

|

By peeeot - 3 Years Ago

|

My experience with clutchless shifting matches Dobie’s. 1-2 is easier than 2-3. I usually just use the clutch pedal.

Sounds like you are familiar with normal overdrive behavior from your Mercury, so that definitely helps!

Let us know what you find regarding freewheeling. I think that is critical information in the diagnostic process.

|

|

By alanfreeman - 3 Years Ago

|

|

Don't ask me how or why but the OD is now working (sort of). First, there is now freewheeling in first gear under 27 MPH. Also, I can do easy clutchless shifting to second and third gears while driving. Here is how I got it to engage the OD: I took the car up to 55-60 MPH, let off but no shift into OD. However, when I hit the kickdown switch and then let off the gas it does shift into OD! I tried this several times and it worked each time. Although the trans is not exactly working as it should, I will leave well enough alone as I can at least get the OD to engage. My only problem now with the trans is an oil leak. It is not leaking at the solenoid, the speedometer cable or the governor. It is hard to see where the oil is coming from but the leak looks to be in the area where the OD section bolts to the rest of the transmission. I tightened the four bolts which attach the OD to the transmission but the leak persists. Does anyone have a solution short of pulling the transmission and resealing it? Thanks

|

|

By DANIEL TINDER - 3 Years Ago

|

Try swapping solenoids with the convertible. Oil, low current, etc. can effect operation of the sometimes finicky devices. If the police car issue continues, you can at least rule that out.

‘BTW: If the seal leaks at all, installing solenoid upside-down can inhibit draining.

|

|

By peeeot - 3 Years Ago

|

|

Alan, I’m glad to hear you have been able to get overdrive! Questions: how high is your idle speed set? Does your throttle linkage readily snap back to idle setting every time? And, when you engage your kickdown switch, does it interrupt the ignition briefly like it’s supposed to?

|

|

By alanfreeman - 3 Years Ago

|

|

Peeeot....I don't have a tachometer but I would estimate the idle speed at maybe 500-600 RPM. I was having trouble with the accelerator linkage sticking and not quickly returning to slow idle. I solved that problem last week when I fabricated a new longer adjustable rod which attaches to the carb. The rod that was on the car was a little too short so the linkage would hang up without returning to slow idle. Yes, when I engage the kickdown switch the engine momentarily cuts out.

|

|

By peeeot - 3 Years Ago

|

Alan, I asked about the idle speed because for a while my car was hanging up slightly when I would back off the gas due to a minor linkage issue. When it did this, the engine would only slow to something like 800-1000 rpm, and I would not get an overdrive shift until I hooked my toe under the pedal and pulled it back to drop the rpms down to 650 or less. There has to be a certain amount of “drag” from the engine on the input side of the overdrive to get the blocker ring to move out of the pawl’s way. In your case, if the shift only happens when you mash the kickdown switch followed by pedal release, perhaps the momentary loss of ignition paired with throttle release is causing the engine to drop rpms very quickly and thus generate the needed “drag” to shift the blocker ring.

I need to look at the manual again but I think there was a comment about the amount of friction between the blocker ring and the sun gear plate.

What are you using for gearbox oil?

|

|

By alanfreeman - 3 Years Ago

|

|

I am using STP 80-90 weight gear oil.

|

|

By Dobie - 3 Years Ago

|

|

Hmmm, probably the wrong stuff. STP says it's for axles and non-synchro transmissions. It likely contains hypoid additives for axles. Hypoid additives aren't good for our transmissions because they attack the brass synchronizers. These transmissions want a straight mineral oil without hypoid additives. Tractor Supply has it under the brand name Traveller Ford Tractor Transmission Oil. NAPA Auto Parts also has it but may need to order it from their warehouse.

|

|

By peeeot - 3 Years Ago

|

I agree with Dobie, GL-5 hypoid gear oil is not recommended for the trans or overdrive. I use Redline MT-85 which is a GL-4 intended for manual transmissions with brass synchros. Viscosity is comparable to the factory recommendation as well.

I can’t say whether the use of hypoid gear oil could be affecting overdrive engagement.

|

|

By 57RancheroJim - 3 Years Ago

|

Sometime in the past I read not to use synthetic oils, which GL5 are in OD trans. It was said they are too sticky and can effect the pawl engagement some how?. I've always used GL4 in my two OD trans.

|

|

By charliemccraney - 3 Years Ago

|

|

Gl-5 does not indicate synthetic and most modern GL-5 is safe with yellow metals. If in doubt, refer to the manufacturer of the particular oil you want to use.

|

|

By alanfreeman - 3 Years Ago

|

|

Dobie.....I checked the Tractor Supply Website but I don't see any transmission oil, only motor and hydraulic oil????

|

|

By Dobie - 3 Years Ago

|

Wrong nomenclature. It's Ford Tractor Transmission Fluid:

https://www.tractorsupply.com/tsc/product/traveller-ford-tractor-hydraulic-oil-3-2-gallon

API Service GL-1. For use in final drives, hydraulic systems, and manual transmissions of Ford Tractors manufactured between 1939 and 1952

|

|

By alanfreeman - 3 Years Ago

|

|

THANKS!!

|

|

By 57RancheroJim - 3 Years Ago

|

charliemccraney (7/1/2022)

Gl-5 does not indicate synthetic and most modern GL-5 is safe with yellow metals. If in doubt, refer to the manufacturer of the particular oil you want to use. What GL5 isn't synthetic? I haven't found one..

|

|

By charliemccraney - 3 Years Ago

|

Here are a couple examples. There are many more. Check out manufacturer websites, look on the shelves at parts stores.

https://maximausa.com/series-283-premium-gear-oil.html

https://sharena21.springcm.com/Public/Document/18452/b05f7475-4d54-eb11-b800-48df3793b338/510adab1-8a54-eb11-b800-48df3793b338

|

|

By alanfreeman - 3 Years Ago

|

|

When I first installed this OD transmission it leaked real badly. The same was true of the rear axle pinion seal which dripped continuously. Both the transmission and the rear axle had sat uninstalled for many, many years. Gradually, the leaks slowed down and then stopped completely. Sounds crazy but the only explanation that I can think of is that the seals in the transmission and the rear end had dried up after having been drained and then left sitting for years. Once refilled with oil, the seals expanded and plugged the leaks. Anyway, I am a "happy camper" now as the OD is working and no oil leaks. Thanks to everyone who gave advise.

|

|

By 57RancheroJim - 3 Years Ago

|

charliemccraney (7/2/2022)

Thank you. All the local big box parts stores by me only have synthetic

|

|

By alanfreeman - 3 Years Ago

|

|

The STP 80-90 weight that I was using is GL5 but is not synthetic.

|