|

By Cliff - 4 Years Ago

|

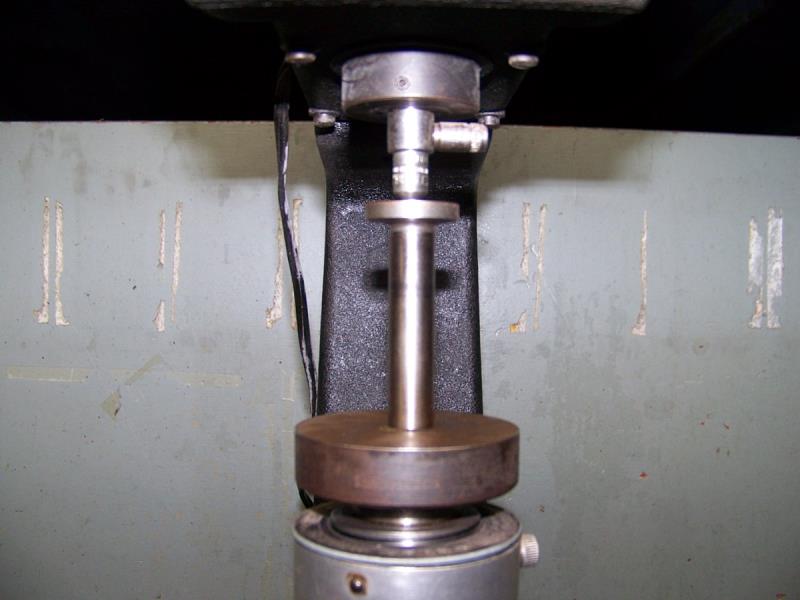

Here are some Rockwell tests I did today

Used FoMoCo = 53C

Used FoMoCo Steel = 57C

Trend = 62.5

Sealed Power HT 892 B = 60C

Erson = 56C

|

|

By Cliff - 4 Years Ago

|

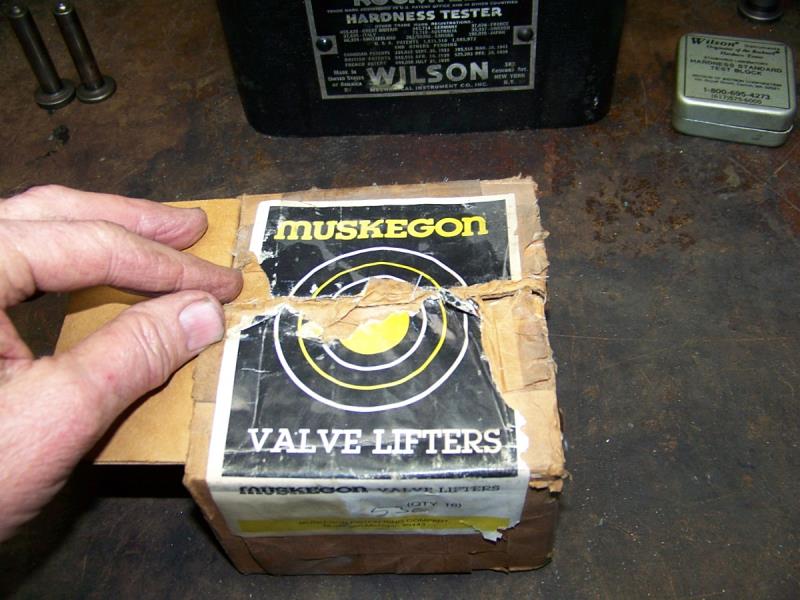

Muskegon = 55C

|

|

By Cliff - 4 Years Ago

|

FoMoCo EAA6500 D =54C

|

|

By Cliff - 4 Years Ago

|

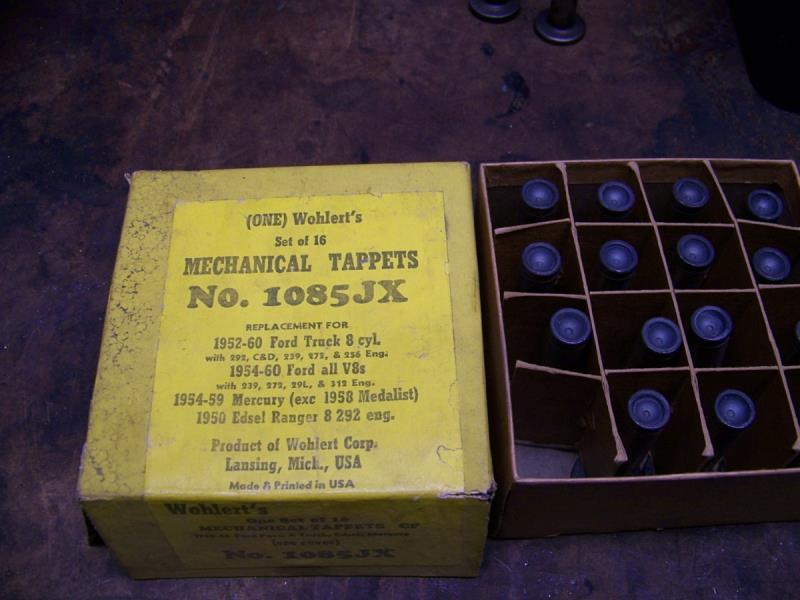

Wohlerts # 1085JX = 56C

|

|

By Cliff - 4 Years Ago

|

Melling Chilled Iron = 59C

|

|

By Cliff - 4 Years Ago

|

EPW I tested 3 of these 52C 53C 56C

|

|

By MoonShadow - 4 Years Ago

|

|

Can you explain for the peanut gallery what the process is?

|

|

By 55blacktie - 4 Years Ago

|

|

According to your test results, the Trend lifters are the hardest. However, is that necessarily a good thing? At what point will lifter hardness cause premature/excessive cam lobe wear? Also, Trend does not list Y-block lifters on their website, only Ford Windsor lifters. I've had confirmation that Comp Cams, Clay Smith, and Isky Y-block lifters are all made by Topline Hylift Johnson. Is Topline Hylift Johnson the only American manufacturer of Y-block lifters?

|

|

By Cliff - 4 Years Ago

|

|

Hi, there has been a lot of talk about soft lifters, so I tested to find out, the Rockwell tester measures the hardness of the metal and it looks like there are good lifters and some not so good, the older FoMoCo were soft, the FoMoCo steel are good, the surprise to me was the Sealed Power there the ones that were supposed to be soft but are the best cast lifter (hardness), I have more to test when I have time and I will be testing camshafts FoMoCo and aftermarket to see what's up, this may not be for everyone but no one wants a flat cam because of a poorly made part.

|

|

By Cliff - 4 Years Ago

|

|

Trend lifters have been proven to be the best lifter you can buy for a Y Block Ford, you can use them over and over switching cams and using them in other engines without refacing (they do not wear), that's what's in my Dragster engine (180 lbs seat pressure), however overkill in a low H/P street car

|

|

By 55blacktie - 4 Years Ago

|

|

Availability?

|

|

By Joe-JDC - 4 Years Ago

|

|

Trend lifters are special order and are not cheap. Don't be surprised at $500.00 plus on a set now. Like Cliff said, they can be used over and over without worry about the lifter going bad. They are polished to a mirror finish, which helps with not wearing the lobes on a new camshaft. Use normal camshaft break in lube on the lobes, and oil on the barrel of the lifter, and you should have a trouble free break-in of a camshaft. Trend will custom build the lifter for you at an extra cost. I ordered two sets with a +.100 length for high lift camshaft so that the lifters would not cock sideways at the max lift. The extra length does add about 10 grams to the lifter's weight. Stock Hylift-Johnson is ~66 grams, and Trends I weighed were ~76 grams. Joe-JDC

|

|

By 55blacktie - 4 Years Ago

|

|

Thanks, Joe. I have Comp Cams Topline Hylift-Johnson lifters, still in the box. Ted uses Hylift and Trend. Unless there is a problem during break-in, I don't expect to replace the cam/lifters as long as my car remains in my possession. I think Florida Phil has the same lifters in his 55 Tbird, and he has no complaints.

|

|

By FORD DEARBORN - 4 Years Ago

|

|

JDC, did you post pictures some time ago of a tappet grinder you bought?

|

|

By Ted - 4 Years Ago

|

That was Cliff that posted about finding the Storm Vulcan tappet grinder. Here’s the link.

Tappet Grinder (y-blocksforever.com)

|

|

By FORD DEARBORN - 4 Years Ago

|

|

Thanks for the link - I remember the thread. Nitriding may be the safe way to go when ever regrinding lifters. In my 64 F100 is a set of OEM steel lifters reground by Oregon Cam. Been 8 years now with no valve train problems but I don't know if those lifters were rehardened. Eight years ago there was a lot of complaints on Y-block cam/lifter issues mostly related to lifter quality. I found a set on epay and sent them to Oregon Cam. That Rockwell hardness tester should solve the hardness mystery. As you test more samples, please post............

|

|

By Cliff - 4 Years Ago

|

|

I will, however after testing many lifters I see a spread of 1 to 3 points even in the same lot, I'm going to grind some lifters (2 or 3 times) until I see the hardness start to go away, at this point I don't have a good idea of what's acceptable and what's not. I was told by a cam grinder that cast lifters are hard all through and forged only about .010 I don't know if this is true but I will soon.

|

|

By 2721955meteor - 4 Years Ago

|

I have refaced 5 sets to dates I use a new lifter for fe engines to rat hardness. sparks and how long it takes to get correct angle.had some checked by acamgrinder .he read ok.tho they Parker so they hold oil. I don't agree. all my sets wher the thin ones for higher lift. it takes a lot of grinding to get them to the right angel. I make this the same as new lifts from the fe. the hardness test I ate familiar with must dent the after,then measure the size. so the tested destroyed that lifter.. have not herd of any failures with mine. the time is not worth what people want to pay .the sets I did I have sent the past to coat the lifter on assembly,as well remove spill tubes ar rocker shafts and at least clean the shafts(remove the core plugs) or replace them

|

|

By Cliff - 4 Years Ago

|

|

With the machine I have after setup (about 3 min) it takes me about 30 seconds a lifter, also it holds the lifter in the same place so all are the same (built in stop), I can park them but don't know if I will, this is still new to me and just a hobby.

|