|

By 1930artdeco - 4 Years Ago

|

Hi All,

I just put a deposit on a 312 (well hopefully it is, as it has a 4 bbl) and power train, I will pick everything up this week or next. The Rad and Tranny will eventually got to shops to get worked over, the engine I can do up to a point. What I would like to (at least in my mind) is clean it up, lube it up and see if I can fire it up to see what/if any life it has left in it. I still have a feeling that the heads will have to come off and go into the shop, then I can turn it over and look at the bearings, bores, crank etc.

What ideas do you all have for getting this engine cleaned and lubed up and possible fired up? It has not run since the 90's. Although, in the ad, a pic was taken of the oil on the dipstick-and it actually looked good. So I am hoping it is not seized. I am close enough to Hanford to drop the engine off to get reworked.

Update, I just found my first post that is essentially the same thing. So I will follow that info. But, at least I am in the Y block game finally!

Mike

|

|

By 312YBlock - 4 Years Ago

|

|

Hi Mike, I can tell you what I remember about my 55 which happened to have a 312 in it that wasn’t running. After towing it home I drained the oil, and coolant from radiator and block. I flushed coolant as best I could and refilled, it had the old oil filter canister and I replaced it with a spin on adapter. I removed the spark plugs and poured some marvel mystery oil into the cylinders, I was able to turn over the engine easily by rotating the fan, thrilled that it wasn’t seized. I think I also removed the valve covers and poured oil over the rockers just in case. I replaced the plugs, points, condenser plug and coil wires. I installed a new battery, primed the carburetor and It fired up. I drove it to a service station where the motor and trans were steam cleaned as well as could be done with the car on the ground.Good luck 🍀

|

|

By Florida_Phil - 4 Years Ago

|

I'm not a professional, so you may get different answers here. If it were my engine, I wouldn't attempt to fire the engine. I would try to turn it over by hand just to see if it's free. After all this time, you don't know where it's been, what's been done to it and it's current condition. I would disassemble the engine and inspect it carefully before I rebuilt it. 312s are getting hard to find. Virgin 312s are even rarer. Good luck.

|

|

By Tedster - 4 Years Ago

|

What are your plans for the engine, what is your budget, and what kind of storage conditions has the engine in question been subject to? There are a lot of different ways to go depending on the answers.

In questions like this in the past I've seen the keyboard mechanics run the gamut, some insist on nothing less than a complete engine disassembly all the way down to the subatomic granular level with total machine shop overhaul of every part, sparing no expense. (It's easy to spend other people's money) Others apparently just hook up a battery, fuel it from an old boat tank, and see if it will fire.

I tend to take a more middle approach in most things. Find out exactly what it is that you have. Make sure it is reasonably safe to fire before proceeding. If you decide to fire it, removing the oil pan and inspection first might be a good plan if the condition is otherwise suspect, I'd be a little worried first about barn critters or vermin setting up shop inside the engine depending how well or where the engine spent the last 30 years. I might even forego that - flexible inspection cameras are cheap now, they pair with smartphones - I'd take a peek down the intake, maybe the cylinders, and I think the oil pump screen might be visible via the oil pan drain plug area? See where I'm goin' with that?

Generally speaking if the engine turns freely, compression is good, valve rockers, pushrods &c are looking good, oil is flowing, I'd be in no hurry to spend all kinds of money on it (unless that's what you feel you must do for some reason).

If it turns out that the engine is in good shape, runs well, has good compression, has good oil pressure, I wouldn't be in any hurry to tear it apart.

|

|

By Joe-JDC - 4 Years Ago

|

|

On an engine that has been sitting for that long and not in a climate controlled environment, there are several things that need attention as mentioned in a couple of the posts. The biggest problem will be rings rusting to the cylinder walls if ANY moisture got into the engine at any time, and if the rocker arms were not released to shut the valves. The gaskets will have dried out and become brittle even when soaked in oil, the rubber valve stem seals will be brittle and break, possibly ruining the oil pump and starving the engine of any oil, the front timing cover seal will need replaced, the rear main seal/rope will need replaced, intake gasket will need replaced, valve cover gaskets, thermostat and gasket, water pump, and carb freshened as well as normal tune-up electrical items. I recently went through this with a FE that had sat for nearly 30 years, and it needed every gasket/seal replaced as well as water pump and complete tune up. Will it fire up, what is the purpose? If it is a real 312, then take the time to go through it ONE time, and not ruin it. JMO, Joe-JDC

|

|

By 1930artdeco - 4 Years Ago

|

I kind of figure it will happen something like this: Put it on the stand pull the valve covers oil the snot out of it and make sure everything moves. Rotate it and check the bearings. If everything looks good in the bottom end pull the heads and send them in for a rework. Replace all of the gaskets, pump, tune her up and see where that goes. This is the rough plan and I know how plans go and what assume stands for.

It sat in a wrecking yard for 30 years so I am assuming it will probably need a total tear down as everything maybe frozen. But then again I may get lucky-who knows.......

Mike

|

|

By PF Arcand - 4 Years Ago

|

Since you don't know if it's a 312, I hope you didn't pay big money for it? The 4 Bbl is a clue..but could have been installed at any time & some 292 truck engines had 4 bbls. It's difficult to ascertain without going to a bit of trouble. If the trans is off, check the crankshaft flange for the following; There may be a cutout on the flange with one 5/16" dia. very short pin showing. If so, it's a 312.. If not or has more than one pin it's probably a 272-292. If not marked, then the 2nd thing is to pull the pan & check the Rod caps for the "ECZ" markings. If there it's a 312.. You can also link from here to John Mummert's site which lists the various block casting letters, which may be helpful..

|

|

By 1930artdeco - 4 Years Ago

|

I am hoping as well that it is a 312. But right now I have nothing-or less than that in some respects. I am paying for to get everything: rad, engine, tranny and all of the linkages-of which I have none of that. I will find out on Sunday and if it turns out to be 292 then I will see about negotiating a lower price.

Mike

|

|

By 1930artdeco - 4 Years Ago

|

Ok, here are some pics of the engine. Carb-replaced at some point with a Ford something 4 bbl. No sludge in the valves galley, and the block is still full of antifreeze. I am going to be optimistic and hope the engine still has life left in it. Hey-one can hope. I will try and verify the 312 next weekend when I get a chance to pull the tranny off.

.

|

|

By 1930artdeco - 4 Years Ago

|

I just verified the little Aspirin on the crank flange! She also rotates and the starter looks good to go.

Mike

|

|

By RB - 4 Years Ago

|

|

If it turns over and the valves are not stuck it WILL run...

|

|

By 1930artdeco - 4 Years Ago

|

I am hoping that she really only has the 47K the odometer says she does. Looks like she was babied in her life time. So, heads go into the shop, check the bearings (replace the rear main seal) clean her up and stuff her back in. Hey, I am going to play the optimistic card here.

Mike

|

|

By DryLakesRacer - 4 Years Ago

|

With the heads off clean out the oil holes that feed the rockers. a pipe cleaner works great and you can see the the sludge if there is some. Chamfer the oil feed hole on both the head and block side. I put some grease in the hole in the block and used a die grinder with grease on it then cleaned out the hole. I taped off the piston holes. A babied engine that never warmed up properly can cause sludge build up. My mothers 56 292 lead a sheltered life and was dead at 40,000 because it never warmed up. Good Luck

|

|

By 1930artdeco - 4 Years Ago

|

So I did my first compression check on my engine that I got for my wagon. Here are the results-I ended up using an O-Reilly gauge as that is all had at the time. Opinions please (first test/second test):

1-100/110

2-0/0

3-50/50

4-45/35

5-40/15

6-50/0

7-40/0

8-30/0

The valves were adjusted to .020 cold per the book (used Tim McMasters method) and this gauge is the screw in type. I checked #2 with my grandfathers hand held gauge and it registered 30#. #1 it blew my hand off of the head so I could not verify the reading. I suspect the valves my be the cause so I rechecked and adj. a few on the drivers bank and here are the numbers:

5-40/40

6-20/20

7-45/50

8-30/30

It is possible that the valves are good but the guides/seals are bad. Maybe the rings? But all indications are that this engine has about 47K and never opened up. Sneaky suspicion the heads are going in.

Thanks,

Mike

|

|

By Tedster - 4 Years Ago

|

Mike, don't take this the wrong way, but those numbers can't be valid??

Just to be clear - so everyone is on same page - Compression test means all spark plugs removed before test, fresh charged serviceable battery, throttle blades & choke fully open? A fully warmed up engine is specified for compression, but most engines should give an accurate enough indication of their health even when cold. If those compression numbers are valid, it probably won't even fire. It needs a complete overhaul

Expect ~ 150 psi on a factory stock Y Block in good mechanical condition. I suppose stuck rings will bring compression down quite a bit, though that much, I'm not sure. I doubt it. Very often stuck rings (from years of sitting in place, sludge, varnish) will improve compression considerably with some normal heat cycles and driving. But those compression #s are way off the beam.

Guys who routinely resurrect motors from the dead would know better than I. Suspect maybe a faulty test method, or a defective gauge, or "something".

|

|

By miker - 4 Years Ago

|

|

I’m with Tedster here. Somethings wrong. But before you pull it apart, I’d try oil in each cylinder for a cranking test and a leak down test, with and without oil. More knowledge members will chime in, but that would tell you a lot. On a leak down, you can listen for the air at the intake and exhaust. But don’t give up or get too down. If it turns over, that’s a good sign.

|

|

By 1930artdeco - 4 Years Ago

|

There is no carb on her right now as I bent one of the little brass tubes lifting it-so it took it off. The throttles are frozen anyways. But I could hear it suck air and then the sound would go away and come back.

Either way when she goes on the stand I am going to check all of the bearings, probably replace the rear main seal and have the heads redone. If she requires a rering then I would do it the as well. This all assumes the bearings are good. Thanks for the ideas and help.

I poured oil all over the rockers and down the pushrod holes to lube everything. I even shot oil into the cylinders to lube the walls. When I used the hand held compressor on #1 it blew my hand off and the gauge was covered in oil. So I think she is pumping oil to the valves and it is leaking into the cylinder. Or that is left over oil that I put In. Either way I some shop time is in order-hopefully not a lot.

Tedster- no offense taken. There were no plugs in and no carb. The engine hasn’t run in probably 30 years as that was when it was tagged (I got the original plates from the donor car). I would screw in the gauge crank her over about 6-8 times and write the number down. Then I would repeat on the same cylinder before moving on to the next one. It is entirely possible that I am doing something wrong in the test-and wouldn’t be surprised. But she is out of the car so now is the best time to get stuff done.

Mike

|

|

By 1930artdeco - 4 Years Ago

|

I could not find a search button to look for this so I apologize if I missed it. But, the heads are coming off, how do I do that? The bolts all came out easily-they all had either oil or what appears to be some water on two of them. But how do I unstick the heads. Do I need a head puller? Rope trick? What?

Thanks,

Mike

|

|

By Dobie - 4 Years Ago

|

|

No magic to it, just find some good spots to use a pry bar and have at it.

|

|

By charliemccraney - 4 Years Ago

|

I've loosened up stuck heads by reinstalling the rockers pushrods and adjusting the lash. Thread several head bolts to keep the head from falling out of place when it comes loose. The pressure eventually popped them loose.

I figured that trick out by accident, while preparing to do something that was probably stupid.

|

|

By 1930artdeco - 4 Years Ago

|

Well they are off! Used a block of wood and some tire irons and they popped right off easily, after a few good whacks. And this is what I found.

GOOD-Some carbon ridge-albeit not all of the way around and just a very slight wear ridge. No major scoring, although there is one spot that can be seen and just barely felt. Standard bore, clean piston tops-more or less and Ford valves in the heads. Not bad for a sub 50K engine.

BAD-some sludge, not much and it will get cleaned out when on the stand. some scale and goop in the antifreeze in the water jackets. Rust on some valve heads but I think that is from sitting in the yard.

Overall, she is in pretty good shape. Next up is to see what the bearing look like. What do you all think? Passenger head/block and then driver side head/block and finally #6 before scraping and after.

Mike

|

|

By Cliff - 4 Years Ago

|

|

471 cylinder heads (most likely from a truck, 1958 -1959) late model push rods.

|

|

By 1930artdeco - 4 Years Ago

|

Well Crap, now I don't know what to make of this motor. I did look at Y-block guy's website and found my head casting numbers and yep, they are for a 2 bbl truck car low comp engine. So...someone at some point did rebuild this engine for some reason. Time to see about massaging these heads or look for the correct ones. The next step is to look at the bearings this weekend.

Mike

|

|

By 1930artdeco - 4 Years Ago

|

Just looked at Tim's site and they have the same valves but just a larger combustion chamber. I wonder if Steve can just shave the head down to match the ECZ-G head chamber?

Mike

|

|

By Ted - 4 Years Ago

|

The nominal combustion chamber size for the ‘471’ heads is 82cc. That’s 10cc larger than the ‘113’ heads and 13cc larger than the ‘ECZ-G’ heads. The 471 heads would need to have their decks milled at least 0.060” to get them to a 72cc size assuming they are 82cc now. The heads really do need to be cc’ed before doing any cutting just to see what the starting point is as they can be easily larger than 82cc if never been cut on before.

One fix for using the ‘471’ heads so that they do not have to be milled excessively is to use a piston with a 10cc dome. Going even larger on the dome size could even be beneficial if trying to get the compression ratio in a more suitable range. Using the domed pistons would eliminate having to mill the heads excessively which also can cause some intake manifold fitment issues. Keep in mind that for every 0.010” that the heads are milled, the intake sides of the heads need to be milled 0.014”. There’s not a lot of room for milling on the intake side before getting into the valve cover flange at which point the intake side has been milled as far as it can be cut. If needing more, then the intake would need to be cut. There’s some leeway with the intake sides being milled if using composition head gaskets but this gives you an idea of what is going to be involved.

|

|

By miker - 4 Years Ago

|

There’s another fix for the 471 heads. I’ve got a set that Mummert ported, they work nice on my F code clone. Just add a supercharger.

LOL.

|

|

By KULTULZ - 4 Years Ago

|

ECZ-6015-C is a 1957 292-312 block. The dot on the C/S identifies the crank as being 312. You need to verify main caps as someone may have cut a 312 crank into 292 block. A set of correct heads (non-posted) should be readily available.

The CARB is a FORD 4100 4V with an electric choke of all things.

|

|

By 1930artdeco - 4 Years Ago

|

So, since this engine has been opened-at least on the top end so far-it has become a Frankenstein motor. Not that that is bad, but just not what I was hoping for. I checked the numbers on the block, heads, exh and intake manifolds and I get different years. This is what I got:

Block= ECZ 6015C=292/312

Exhaust manifolds R=B9AE, L=EDB (58-59 292 manifolds)

Water outlet=ECE-8/3

Intake=ECZ-9425-B

So my guess is this, the engine is a genuine low mileage 312 (well at least at this point in time) that went to the fairlane I got it out of. But at some point the heads and manifolds got replaced along with the valley pan. The only reason I say this about the pan is that it was designed with a PCV valve in it from the factory. It has a stamped indentation where the valve sits so I don't think it is a later mod.

Mike

|

|

By 1930artdeco - 4 Years Ago

|

Got the valley an oil pans off, not to bad. It has 312 caps🎉🎉. Some sludge but not too bad. So as long as the bearings are good, I will regasket her and button her up.

Mike

|

|

By Cliff - 4 Years Ago

|

1958-1959-1960 Mercurys had a 312 Engine (standard equipment) with 471 cylinder heads and a 2bbl, the blocks were ECZ or B9AE. look for a casting date on the block that will help.

|

|

By 1930artdeco - 4 Years Ago

|

Ok, should I pull a main cap or two to check/plasti gauge the main bearings? On the one hand I can check clearances but on the other hand if the block is cracked due to that 56 misprint then I disturbed the crack. Dad suggested just checking #1/8 those being the furthest and hottest cylinders. Any ideas?

Mike

|

|

By darrell - 4 Years Ago

|

|

you can see numbers stamped on main caps so its a rebuilt.the steam holes in the block were a giveaway at any rate.

|

|

By 1930artdeco - 4 Years Ago

|

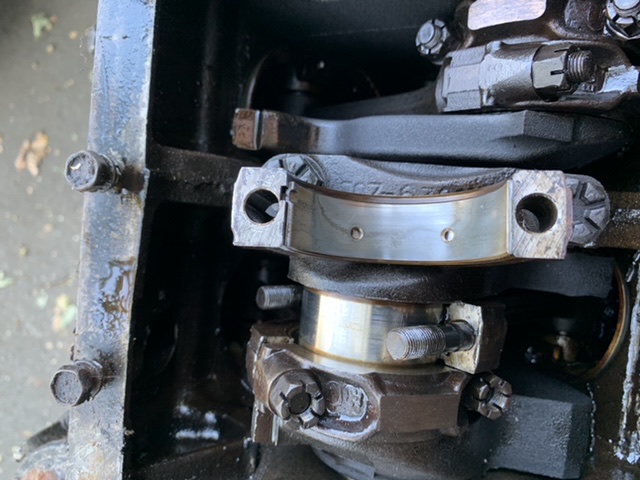

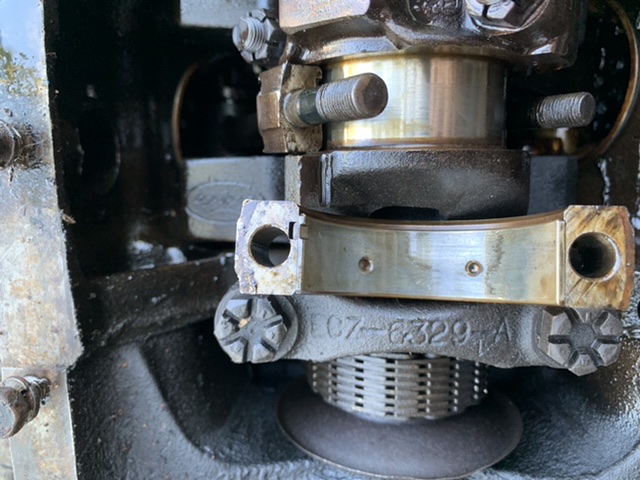

1/5 rod caps. I think they are bad or are they salvageable?

|

|

By Ted - 4 Years Ago

|

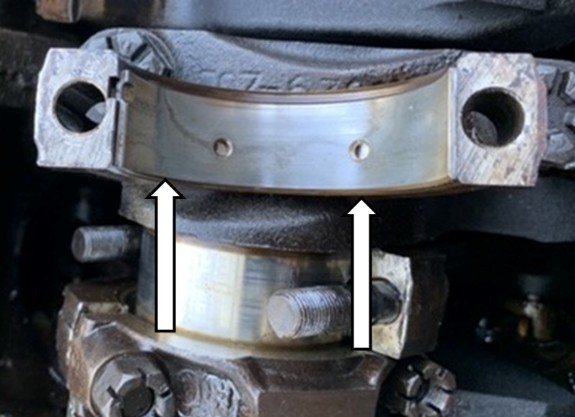

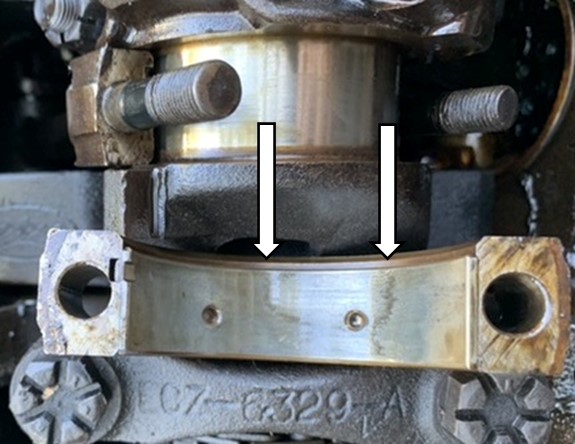

It may be an optical illusion in the pictures you posted but the bearing wear looks to be the result of too much clearance. I have placed arrows on what the pictured wear pattern looks like on my end. It should be wider than what the arrows show. Doing a micrometer check of the crankshaft journal will give you an idea if that particular rod journal is undersize more than it is suppose to be.

|

|

By 1930artdeco - 4 Years Ago

|

Thanks Ted. The wear pattern is on one side only and not even across the bearing surface. Either width or lengthwise. That is why I figured they were toast. I have a digital caliper that should get me close readings. But I am no machinist that is for sure. The next thing up is a main and I am assuming g they will come out similarly. I have the sinking feeling that she is going to make a long trip to see Tim the Y block guy……

Mike

|

|

By 1930artdeco - 4 Years Ago

|

Checked all of the rod bearings and they were all pretty much the same. Found two score marks on the bearings but not on the journal . One of the shells popped out and I found they were made by Clevite and the crank appears to have been ground.010. So off to order new bearings and button up the bottom end. . One of the shells popped out and I found they were made by Clevite and the crank appears to have been ground.010. So off to order new bearings and button up the bottom end.

Mike

|