|

By charliemccraney - 18 Years Ago

|

A Ford Racing Super-Duty T-5: 330ft/lbs capacity. Mustangs run 400hp through the stock 300ft/lb transmissions with no issues. This one should be enough for me... for a while.

I have to make a trip to Summit - Hopefully the last before Columbus - to pick up seat belts, a coolant catch can, and a shifter boot. I'll finish up the trans cross member this week and fill the hole for the other shifter. The cross member probably is not needed but the mount is there so I may as well use it. I may get a different shift handle - I'll see how this one fits with the bucket seats. I was thinking about getting an aftermarket shifter but the throw is so much shorter and the feel much more positive than that universal 3 speed deal I had - I'll put that off for a while. The drive shaft should be back by the end of next week.

There is still much more work to do. The floor pan still isn't finished. But I am one step closer to finished enough for the trip to columbus. I really hate working on the floor pan. Completing these smaller projects in between prevents me from burning out.

Does anyone know if there is a break in procedure? It had no instructions. I know it needs ATF for lubrication. I have not yet tried to contact Ford Racing.

|

|

By speedpro56 - 18 Years Ago

|

I sure wish we had the same clearence in a car as you have in your truck transmisson tunnel.

|

|

By 63 Red Stake Bed - 18 Years Ago

|

|

Looks great! By the way, can you post some pics when the seat is in to show how much clearance? Also, let us know what your cruising rpm ends up on the Highway, & how the cam & other combos tolerate pulling in OD.

|

|

By pintoplumber - 18 Years Ago

|

|

Atta boy, Charlie.

|

|

By charliemccraney - 18 Years Ago

|

63 Red Stake Bed (8/5/2008)

Looks great! By the way, can you post some pics when the seat is in to show how much clearance? Also, let us know what your cruising rpm ends up on the Highway, & how the cam & other combos tolerate pulling in OD. Will do! I'll be using bucket seats but I'll throw the bench seat back in for some pics. It should work out to something like 2250rpm at 70mph. That should have it in the power band. We'll see how it is in reality. I like that the 1st gear will make it like putting a 4.11 in!

|

|

By Unibodyguy - 18 Years Ago

|

|

Charlie, sure wish I could afford to put one in my truck. Any used ones I find out here in Vegas are like $500.00 with no garrentee's. I'd just buy a new one if I'd do that anyway and then I know what I have. Thats a big step on your truck though, getting that put in. I'm sure they'll be quite a difference when you get done. Michael

|

|

By Tom Compton - 18 Years Ago

|

|

bought my World Class T5 completely rebuilt w/ 90 day warranty for $600 a few years ago. Think he is retired or slowing to retirement. 3.73 gears a djust over 2000 RPM @ 70. TC

|

|

By charliemccraney - 18 Years Ago

|

I guess I'll talk some about the technical aspects of the install.

John Mummerts modifications to the truck bell housing worked flawlessly. I actually had more trouble getting the bell housing onto the engine than getting the transmission onto the bell housing.

I measured the length of the 3spd input shaft and found that the T5 needed to be shortened by about 3/32". I taped up the spline to prevent the grit from getting in there and cut the shaft a dremel. If you have a compressor and a real die grinder, even better.

I also ordered one of his throwout bearing reducer sleeves and an 11" clutch disc. The sleeve is just slightly smaller than the inner diameter of the bearing through most of its length. It steps about 1/4" larger at one end. The sleeve slides into the bearing from the front (engine side) and gets tack welded on the back side. The tacks need to be ground smooth so that the bearing can sit flush against the transmission. Unfortunately, I forgot to take pictures or measurements of this.

I marked the hole for the shifter while dry fitting the transmission. To do this I used a scribe and held it at one end so that it behaves like a plum-bob. When it was just touching the corner of the shifter mounting pad I made a mark on the floor pan. If you use this method you will probably have to find an additional way to mark the point; it's such an awkward position that it is difficult to make a mark that is easy to see. I also scribed a circle around the point so that I would not loose it once the transmission was back down. Once the transmission was back down I center punched the 4 marks and drilled a small hole. I think 9/64 is the smalles bit I had that my drill would hold. These holes can now be used as reference points from the top of the floor pan.

I then made a template of the shifter base with some poster board - for light duty work, poster board is excellent template material - and centered the template in the 4 holes, making sure to take note of the top and front of the template, then scribed the line and cut it out. Templates can be time consuming but I've learned that they are often less time consuming than the trial and error approach. So make templates whenever you can.

On a truck, a transmission cross member probably is not required. The transmission felt lighter than the 3 speed. But I am putting one on. Maybe it will add more stability. Maybe it will do nothing. But it will be there. I'm using 1 x 2 tubing with a .065 wall for the cross member and 12 gauge steel for the frame mounting brackets. I will add a little more about this when it is done.

So far it's been a very easy install. The transmission comes with a back up light switch and a neutral safety switch. I'll put both to use eventually.

One important thing to remember: The clutch fork goes in first! There does not seem to be enough room to get it in there once the clutch has been installed. That goes for the 3spd and T5. I've made that mistake twice now. Maybe I'll remember next time. It does not have to be on the pivot ball but it does need to be through the hole in the side of the bell housing before installing the clutch.

|

|

By y-block don - 18 Years Ago

|

looks good keep the pics coming

|

|

By unibodyboy - 18 Years Ago

|

Charlie,

While you're at it, do a one piece driveshaft. It is worth your while. I ended up going with a short throw also, B and M. Smoothed everything up quite a bit.

|

|

By charliemccraney - 18 Years Ago

|

Should it have had a 2 piece shaft? Hasn't since I've owned it. It's a short wheel base. The new shaft is one piece. It will be on its way back to me tomorrow.

Edit 02/24/2011

In my case, the 3speed slip yoke is the same spline size as the T5. If, for whatever reason, your yoke does not match, the driviline shop who shorten the shaft can provide one that will fit.

|

|

By unibodyboy - 18 Years Ago

|

|

No my goof, I thought you had LWB like me. You're going to love this setup....

|

|

By charliemccraney - 18 Years Ago

|

|

I saw on the UPS tracking that it will be 5lbs lighter! Not that I would be able to tell the difference. I think they cut about 10" off - the transmission is about 10" longer. They said that the old shaft, at about 68" long, had a maximum safe RPM of about 4500. This one should be well into the mid 6k's. That will be good because 4500rpm is right at about 90mph in 3rd - or now 4th.

|

|

By unibodyboy - 18 Years Ago

|

|

Yeah, the length adds quite a bit of weight. I had a really nice one piece 4 inch aluminum shaft made because of that reason. Are you going to eventually make a crossmember for the tranny? They say it's not necessary, but I would venture in high performance applications some kind of floating member would be beneficial.

|

|

By bird55 - 18 Years Ago

|

|

looks nice, charlie. you're doing a good job.

|

|

By charliemccraney - 18 Years Ago

|

|

Here are a few pics of the crossmember.

It's not the most elegant. I have to do a little bit of grinding to get it to fit a little easier between the brackets. I can't offer much tech on the crossmember because, frankly, I don't know what I'm doing. This is my first crossmember so it is a learning experience. I am glad to say that my welds are getting better! Still not really nice to look at, though. One other thing I did before torquing the rear motor mounts is centered the transmission between the frame rails. There is some casting flash that runs down the center of the transmission. I used that flash, at the output shaft to get it all centered.

|

|

By Unibodyguy - 18 Years Ago

|

|

Charlie, make sure and save the patterns/templates that you made up. I think there would defiently be a "market" for those down the road for other people doing the same thing. I for one would be interested once I get a little more $$$ saved up. That is an excellent job your doing on it, very very professional work. Michael

|

|

By BFOOTER03 - 18 Years Ago

|

|

Great post Charlie! Really interested in the bench seat picture and how the shifter fits. I've been considering a T5 but have reversations about the shifter location. Thanks

|

|

By charliemccraney - 18 Years Ago

|

|

This weekend I completed the Crossmember install.

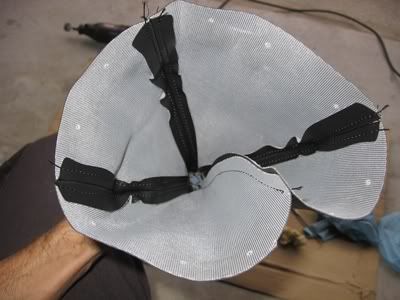

And started work on the shifter boot. I got a Lokar unit that should look quite nice once installed. A friend helped with this one. I had him mark the holes, trying to keep the pattern square with the bead in the floor pan. Note that there is not enough room for the front two holes. With this particular shift boot, it cannot be avoided. The hole in the floor is barely large enough to get the shifter bolted to the transmission.

To overcome this I had him make an adapter of sorts out of 16 gauge steel. This will be held to the floor with all but the front 2 bolts. This will allow me to completely fasten the bezel to the floor. I'll make a rubber gasket to seal this to the floor.

I decided to cut out the circle rather than making it exactly like the bezel for two reasons. It should add a significant amount of rigidity to the front and hopefully make a good seal with the gasket. It will also keep more road crud out. It's starting to look Good! I should have the shift boot completed this week.

Here are a few pics with the bench seat in place.

It will require a shifter with an immediate bend forward. It is not as far back as I had expected. I think I'll need something that bends a little toward the driverside. I try to CAD model anything I can get the appropriate measurements for. So if anyone needs patterns I may be able to help. Many of these are one off sorts of things that may not apply to every truck.

|

|

By Greg D - 18 Years Ago

|

|

Looks great, can't wait til I do mine!

|

|

By charliemccraney - 18 Years Ago

|

|

Holes have to be marked on the shifter boot for the bezel screws. The only way I could find to hold it in place in order to mark the holes is to use some masking tape. It worked like a charm. I marked the centers with a scribe. The screws do the rest. Once the boot is installed, the excess that you see on the sides is trimmed with a razor.

I then made a rubber gasket for the adapter plate. For this I just placed the bezel on a sheet of rubber and carefully cut out the shape with a razor. I marked the centers with the scribe and cut out the holes with a hollow punch. A leather punch will probably be easier but I don't have one. Hopefully this will be enough to seal the plate to the floor. I used 1/32" thick High-Strength Multipurpose Neoprene Rubber. It is oil resistant, abrasion resistant, impact resistant, weather resistant, and flame resistant. All sound great for use in a car!

And here it is all together!

I forgot to take a picture of the finished adapter plate. I'm sure you can guess by now that I painted it black. Note the completed floor pan! The old speedo cable and drive gear seem to bolt right in and seems to be real close to it's original location. I'll see how that works once I am able to drive it. Now I just have to figure out what's going on with the clutch. I'm sure I'll have more to post about that. But this should pretty well cover the installation of a T5 in a 61 F100 and is probably mostly the same for the other years.

|

|

By BFOOTER03 - 18 Years Ago

|

|

Charlie Great thread!! Very detailed and I'm sure many will find it helpful in the future. I know I will when I start my install this winter. Thanks again

|

|

By charliemccraney - 18 Years Ago

|

|

I pulled the transmission today. As I suspected, the throwout bearing reducer sleeve is the problem. It hits the fingers of the pressure plate after some point of the travel. Fortunately no damage has been done. You can see where the conatact has been made on the upper 3/4 of the flange.

I'm not sure if this would have been an issue with an original style plate. I'm calling original the ones which have a screw in each of the 3 fingers which is adjusted and welded. The plate I'm using has no screws. I'm not sure, but I also suspect that the wear pattern of the 3 fingers will be closer to center on the bearing surface with an original pressure plate. I have both plate styles and I'll try to remember to take a picture. I also have my old bearing somewhere. That will help confirm my theory. I'm going to try to have my friend remove the flange on his lathe and tig weld the sleeve into the bearing hub tomorrow. I've also cad modelled the hub for the stock 1 3/8 input transmission with stock bearing, and T5 using the stock bearing. I will also design one for the T5 and and Mustang bearing ,which will work with the truck clutch fork, when I get a hold of a Mustang bearing. This way sleeves won't have to be dealt with and Mustang clutches will be easy to use.

|

|

By charliemccraney - 18 Years Ago

|

|

You will need a shift handle bent in such a way that it misses the seat. I have a feeling it is something that will have to be made but shouldn't be too difficult. A straight shift handle will not allow 2nd, 4th, and reverse with the bench seat.

|

|

By Ted - 18 Years Ago

|

|

Charley. Did you see the shifter handle on the five speed in Bill Patridge’s ’60 truck? Was homemade and definitely kept to the external appearance theme of the truck.

|

|

By charliemccraney - 18 Years Ago

|

|

I did not see that. I didn't know it had a 5 speed. Too busy looking at the turbo! Did anyone take a picture?

|

|

By Greg D - 18 Years Ago

|

|

Another way around the shifter issue is to change the tailshaft housing to one from a S-10. It's stock shifter isn't a bad in one of our trucks either. I will use an after market short throw with the S-10 tailshaft housing and modify my stock shifter handle to bolt to the shifter.

|

|

By unibodyboy - 18 Years Ago

|

I made my own shifter out of stainless, bent it and polished it. It was a pain, but well worth it. I've got pictures of the finished product/T5 junk, but I don't even want to try to upload them here. If you want them, email me at drummerboy57@hotmail.com, and I will send them. Charlie, sent you back an email. Sorry for the delay.

Greg

|

|

By Ted - 18 Years Ago

|

|

charliemccraney (9/8/2008)

I did not see that. I didn't know it had a 5 speed. Too busy looking at the turbo! Did anyone take a picture?You gotta love Bill and Reed’s sense of humor. Shifter is made out of piece of rebar with a bicycle handlebar grip which definitely keeps with the ‘hillbilly’ theme of the truck. For those of you that haven’t seen it, the turbo charger and associated piping under the hood is a work of art and runs good too. Here’s pics of both.

|

|

By pegleg - 18 Years Ago

|

Like anybody in this group is Normal?  The truck is really neat, the tubo setup is going to be awesome when they get it dialed

|

|

By charliemccraney - 18 Years Ago

|

|

I went to my friends shop and had the reducer sleeve modified. Now the fingers clear the sleeve and there is no more noise!

However, I've discovered another problem. The throwout bearing hub is too wide and has no play between the fingers of the pressure plate and the transmission. So the clutch slips. I don't know if this is the case with every T5 or just the Ford Racing T5. I had noticed that getting the transmission the last 1/16" was difficult. I just did not notice why until today. Anyhow, after seeing this I figured it would slip but I had to take it for a drive around the block. Even with the clutch slipping it felt awesome! I think, once I have it all figured out, it will be about the same magnitude as the new engine last year! So the next step is to find out how much shorter the bearing hub has to be and, probably, to have a hub made. I don't think the stock hub could be reliably made shorter. Is there a minimum or maximum freeplay I should aim for. I think 1/8" shorter will do the trick. I did get a good video for youtube. http://www.youtube.com/watch?v=_-N1uP7m3b4 And I'm working on the Y-block Shootout videos. I have 4 up so far.

|

|

By pegleg - 18 Years Ago

|

|

Charlie, Is it possible another throwout bearing or pressure plate would be shorter?

|

|

By charliemccraney - 18 Years Ago

|

That's an idea. Sticking with the truck pressure plate, there aren't many options but a thinner bearing may be possible. Timken has catalogs online. I'll browse those to see if a thinner bearing for some other clutch application will work.

Does anyone have access to a T5 mustang clutch and can get some measurements, possibly as installed? I think diaphragm plates are thinner than the long plates but I'll still have to deal with fitting a smaller diameter throwout bearing. The throwout bearing used in mustangs looks similar to the truck bearing - just shorter. Does anyone have one and can measure the clutch fork groove diameter and width? Maybe it will work with my fork.

Edit: Well, I've looked through the catalog. The bearings that have a bore diameter that will work vary in thickness by a few 100ths which I do not think will be enough. What grade steel do you all think is suitable for the bearing hub? I can pick up 1018, 1117, 12L14, 1215, 1045, and 1144 locally. Chrome-moly is also available but I don't think it is necessary. I'm thinking about going with 1144.

|

|

By pegleg - 18 Years Ago

|

|

or 1045, either.

|

|

By charliemccraney - 18 Years Ago

|

|

thanks, Frank. It just occured to me that I'm assuming the 86 - 93 Mustang Pressure plate will just bolt up to my flywheel. Anyone know if this is the case? They use the 10.4" diaphragm clutch. I'm using an 11" long clutch.

|

|

By pegleg - 18 Years Ago

|

|

Charlie, I dunno! Maybe a parts store would let you match one up to your Long PP.

|

|

By Ted - 18 Years Ago

|

|

charliemccraney (9/10/2008)

It just occured to me that I'm assuming the 86 - 93 Mustang Pressure plate will just bolt up to my flywheel. Anyone know if this is the case? They use the 10.4" diaphragm clutch. I'm using an 11" long clutch.The Mustang pressure plates typically use metric bolts of the non-shouldered variety and use three dowel pins equally spaced to maintain pressure plate alignment on the flywheel. If the pressure plate bolt holes can be made to match up with the existing threaded holes in the Y flywheel, then the holes in the pressure plate may have to be made slightly larger in which to accommodate the shouldered bolts. If only three of the holes align up, then it's easy enough to drill and tap the remaining three holes using the original three as a centering reference. I’m an old hand at redrilling flywheels for completely new pressure plate bolt patterns when the bolt holes do not line up so that’s a possibility also.

|

|

By charliemccraney - 18 Years Ago

|

|

Thanks, Ted. I remember that now. Is that the case with all diaphragm plates? My flywheel is one of the billet ones sold by Mummert and it has 2 bolt patterns. I think the other is for a diaphragm but I can't remember. I need to give him a call.

|

|

By pegleg - 18 Years Ago

|

|

Charlie, You reminded me of something, I've got one of Mummert's wheels also. I'm using a diaphragm pressure plate with a Kevlar disc behind it. I know the diaphragm isn't supposed to be strong enough for anything serious, but it works, breaks u-joints! Anyhow you can get a diaphragm from a local driveline dealer or if that fails I'll get one fom South Bend Clutch or Fort Wayne and ship it......or try RAM, they're in NC. The real question is, is it shorter? John Mummert might have that answer too.

|

|

By charliemccraney - 18 Years Ago

|

|

I spoke with John. The second pattern is for the mustang 10.5" clutch. So that will make things easy. He also has an adapter for using the truck clutch fork with the mustang bearing but I'll still see what I can come up with.

|

|

By charliemccraney - 18 Years Ago

|

|

I picked up a Centerforce Dual Friction. I've heard a lot of good about them. And it should be strong enough for future plans. What is the torque for the 8mm bolts that hold the Mustang PP?

|

|

By Greg D - 18 Years Ago

|

|

My Mustang manual states 12 - 24 ft lbs PP to Flywheel, all years - Fox body.

|

|

By charliemccraney - 18 Years Ago

|

|

Thanks Greg! I went with 20ft/lbs. The throwout bearing should be here Thursday. Hopefully It'll be the last time I have to put the transmission up!

|

|

By suede57ford - 18 Years Ago

|

|

You will like the Dual Friction Centerforce after it gets broke in. I used the 10.5" 5.0 mustang application on one of Mummert's steel flywheels. I cannot believe how tough that clutch is! I have really abused it and have a ton of street miles as well as dragstrip launches and it does not miss a beat. The clutch worked so well I was able to break a bunch of T5's until I went to the Tremec TKO. Powershifting into 3rd is where the T5's let go, so be gentle on the 2-3rd shift with a T5 and it should last awhile. It was knocking the teeth right of the gears. You will love 5th gear on the highway. Mine cruizes at 2150 at exactly 70 mph with 4:11's and 30" tall rear tires. The low first gear is a major plus driving around town as well.

|

|

By yehaabill - 18 Years Ago

|

|

Pat: Changing the subject, How difficult was the change over to the Tremec transmission from the t-5? My F-100 has the hyd. clutch and I am using Mummert's adapter. Thx Bill

|

|

By charliemccraney - 18 Years Ago

|

Well, that's just one more to add to the positive things said about the Dual Friction. It's a wild looking clutch disc - for me, anyway. The only thing I don't like is they want 450 to 500 miles of in town driving for break in before full power is applied. It will be tough holding out that long!

Mines primarily a street driver so I don't think I'll break the transmission. The T5 has a pretty good aftermarket, though. If I do break it I'll probably have it upgraded by G-force or some similar company. Plus the T5 is lighter and, I hear, requires less power to drive than a TKO in stock form. I don't know how the modified versions compare. Then I won't have to go through all this fitment and installation stuff again.

I can't wait to get it on the highway to see how it does.

|

|

By charliemccraney - 18 Years Ago

|

|

Well, I got it together and took it for a spin. It's great! 1, 2, and 3 pull harder because of the torque multiplication. 4th is the same as the 3 spds 3rd. I got out on the highway for a few miles and I was only doing 2000 RPM while keeping up with everyone. I'm not sure how fast I was going. The speedo said 70 but it seems to be reading fast. However, 70 is about the right speed on the highway around here. In 3rd with the old transmission 2000rpm was about 40 mph. Now in 4th, at 2000rpm it says about 50. So I probably need to get a different driven gear. So, if you do this conversion get some clutch kit with a diaphragm plate. If you can afford it, have your flywheel drilled for the 1986 - 1993 mustang or, even better, get one of Mummert's billet flywheels which are already drilled, so you open the door to a seemingly limitless number of aftermarket options. Also get one of Mummerts throwout bearing assemblies. It is a hub which uses a mustang bearing and allows the use of the trucks fork. And always make sure the flywheel is flat - even if it is bran new - and get it balanced - It will be worth the extra money. I'll add some pictures and try for a more fluid and clear post later. I'm tired and I'm going to bed.

|

|

By charliemccraney - 18 Years Ago

|

|

Here are a few more pics illustrating the difference between the height of the diaphragm plate and the long plate.

And here are some showing Mummerts truck T5 bearing compared to the stock with the reducer sleeve installed.

The bearings hubs are about the same height but the diaphragm plate comes out about 1/2" shorter at the fingers so there is plenty of room. All of the linkage seems to work fine. I have about 50 miles on it now - been driving it every day - and it is great. I can tell the engine really likes it. So now, those of you contemplating a T5 swap should have a very good idea what will be involved. It's not as difficult as you might think and it's definitely worth the time, sweat, and money.

|

|

By charliemccraney - 18 Years Ago

|

At the minimum:

Modified Bellhousing

New clutch disk

Throwout bearing reducer

T5 transmission

Change drive shaft length - probably shorten.

cut a hole in the floor for the shifter

Shifter boot

May need:

Diaphragm clutch

Truck/mustang hybrid throwout bearing.

Shifter and handle.

crossmember

I think that's it.

Update 05/28/09:

Depending on the application from which the transmission was taken, a different pilot bearing may be required. See the following thread.

http://forums.y-blocksforever.com/Topic27151.aspx

12/23/09:

A more DIY approach.

http://forums.y-blocksforever.com/Topic36580.aspx

Update 07/24/10:

More people have done this conversion now, and it looks like the problem I was having with using the stock throwout bearing has to do with T5s equipped with a steel bearing retainer for the input shaft. The forging (or casting?) protrudes a fair bit further than the aluminum retainer and does not allow any clearance for the length of the stock bearing. If your input bearing retainer looks like this you will not be able to use the stock bearing and pressure plate:

This requires the use of a special throwout bearing and a completely different clutch than stock.

03/16/2014:

Installation in a 1955 F100.

www.ford-trucks.com/forums/1287451-getting-ready-for-t5-swap.html

10/29/2014

Another DIY, and some S10 tailhousing info

http://www.slick60s.com/viewtopic.php?f=1&t=12055

6/17/2016

Installing a hydraulic clutch for '61-'64 F series.

http://www.slick60s.com/viewtopic.php?f=32&t=30263

1/10/2017

Installation into a 1955 TBird

http://forums.y-blocksforever.com/Topic119969.aspx

|

|

By Indianbullet - 2 Years Ago

|

|

Following.

|