|

By slumlord444 - 7 Years Ago

|

|

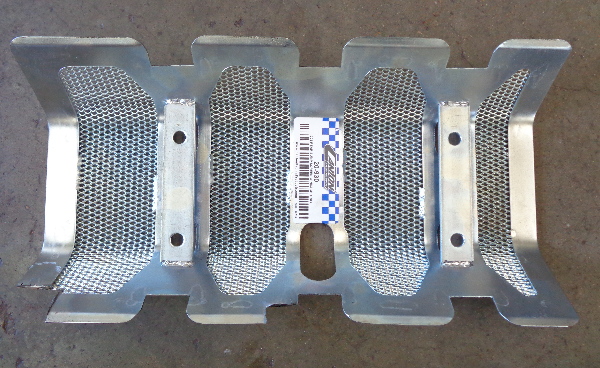

The new Y Block Magazine came today and an article on a 303 Y Block by Ted featured a Canton small block Ford windage tray adapted to the Y Block. The artice stated it was easily adaptable to the Y Block. I would like to see details on this. I have a Ford factory windage tray on a small block Ford and didn't see any easy way to adapt that to my Y Block. The Ford bolts to the main bearing bolts using special main bolts with studs manufactured on the heads of the bolts. The Canton looks like it belongs there and I want one on my Y Block.

|

|

By Ted - 7 Years Ago

|

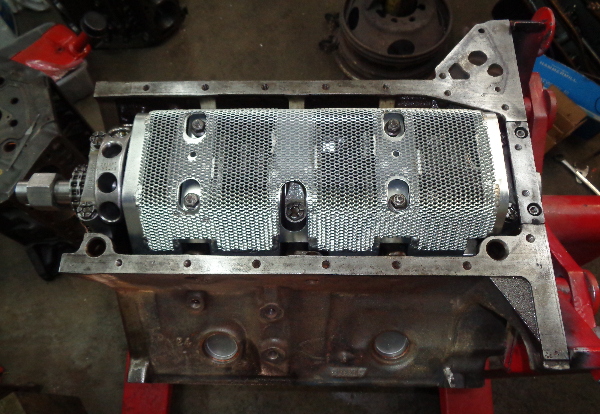

To adapt the Canton SBF windage tray to the Y, I used four main cap bolts originally from the rear sump 351W or Ford M engines that had studs on them for the oil pickup tube. If you don’t have them sitting loose then those particular bolts are available either from Ford or Canton. With those bolts installed with spacers sandwiched between the bolt heads and the #2 and #4 Y-Block main caps, the holes on one side of the windage tray are slightly elongated to allow the tray to fit cleanly over the main cap studs. Here are some pics.

|

|

By charliemccraney - 7 Years Ago

|

|

I used Mopar main studs with windage tray standoffs incorporated. They are just barely short enough to work in later blocks. Earlier block may need the holes tapped deeper but if you're fitting a windage tray, that has likely been done.

|

|

By Joe-JDC - 7 Years Ago

|

|

Canton offers the four studs for the 289-302, and 351W-C mains. The 292 crankshafts were used as stroker cranks for the 289-302 SBFs before aftermarket stroker cranks became available. The bore spacing is same as SBF, and the mains spacing makes it nearly a bolt in for the Canton windage tray/screen. There is a front sump and rear sump screen for the 289 and 351W. Joe-JDC

|

|

By slumlord444 - 7 Years Ago

|

Thanks for the clarification. I will be ordering the parts. Sure wish I had known this several years back when I was putting my engine together. Getting the oil pan off on my T Bird with the engine in the car will not be fun. I have had the block drilled and tapped for the longer ARP bolts. Any issures with replacing the ARP bolts with the Ford bolts? What did you use for the spacers?

|

|

By Ted - 7 Years Ago

|

|

slumlord444 (11/26/2019)

... What did you use for the spacers?

The material for the spacers is 7/8” diameter cold roll with a lathe drilled 33/64” hole down its middle. There’s nothing set in stone on the material or numbers as options could include using 1” cold roll while the drilled hole itself could also be slightly larger at 17/32”. The spacers are cut to length in the lathe with the exact thickness of each spacer being maintained by spot facing each end to insure that they fit square on the main caps. The length of the spacer was determined by the difference in ‘under head’ length between the original Ford Y main bolts and the replacement studded bolts. The holes in the spacers were chamfered to prevent any burrs at the drilled hole edges.

|

|

By slumlord444 - 7 Years Ago

|

|

I'm assuming that you can't just shorten the bolts to the same length as the Y Block bolts is that the windage tray wouldn't clear the crank? Would a mild steel spacer or a stack of hardened steel washers also be satisfactory? I don't have a lathe or a friend with one.

|

|

By Joe-JDC - 7 Years Ago

|

|

I bought the Canton 20-942 351W stud bolt kit, and if you use two washers under the main cap nut, then it can be torqued down properly, and leaves quite a bit of room for you to move the tray up or down. You will need 4 extra 1/2" grade 8 washers, and 4 extra 1/2"-20 nuts if you don't have access to Ted's type of spacer and bolts he used. The Canton studs cost more than the windage tray. You will have to trim the screen some, and elongate or oversize the four holes. Joe-JDC

|

|

By Ted - 7 Years Ago

|

slumlord444 (11/29/2019)

I'm assuming that you can't just shorten the bolts to the same length as the Y Block bolts is that the windage tray wouldn't clear the crank? Would a mild steel spacer or a stack of hardened steel washers also be satisfactory? I don't have a lathe or a friend with one.

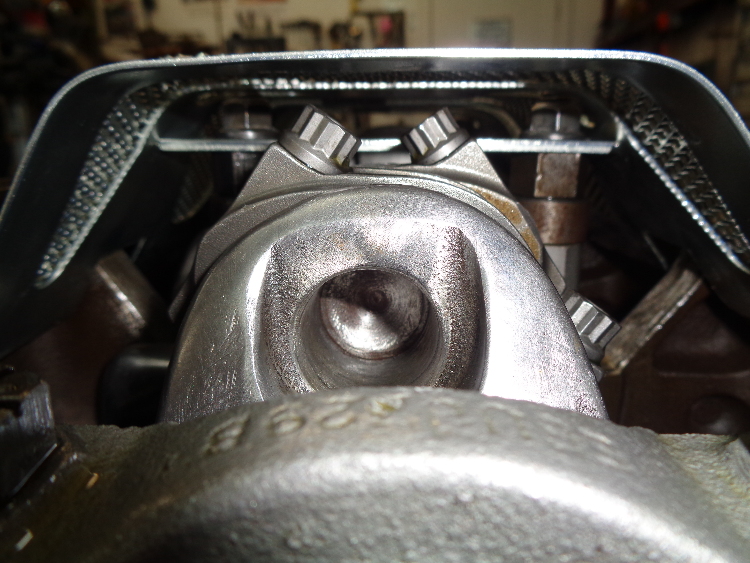

Joe’s suggestion of using a stud kit is a good alternative to what I did. It also makes adjustment of the windage tray height for the proper clearance to the swinging connecting rods much more flexible.

Shortening the 351W bolts will not get you where you need to be. First the thread length just gets too short but more importantly, the windage tray will sit too low and create clearance issues with the rotating assembly. Shortening the bolts will also force more modifications to the windage tray itself as it will now be sitting lower in the block and doesn’t fit as well as a result.

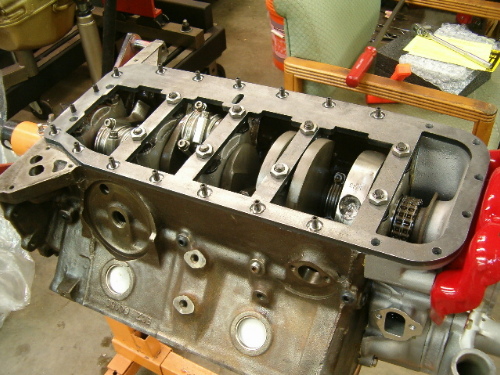

The spacers do two things. First: they allow the underhead lengths of the 351W main bolts to be the same installed length as the original Ford Y-Block main bolts. That’s important as it allows for the proper thread penetration into the block. Look at that first picture in my post above as it shows the 351W bolt with spacer laid next to the original main bolt. Second: the spacers raise the bolt mounting surface for the windage tray so that the windage tray is sitting high enough to clear the connecting rods as they swing past the windage tray. Keep in mind that the EMC engine is using a stock 3.3” stroke crankshaft and using a 312 or stroker crankshaft will decrease any clearance to the windage tray so the installed height is important. Also lowering the windage tray will force more modifications to the tray itself to get it to fit within the confines of the block.

You asked about using washers. Stacking washers under the main bolt head to get the same height effect as a single spacer is not recommended. Maintaining the correct torque on the main bolts with a stack of washers will be difficult to achieve as there’s too much going on when those washers are all heat cycling individually. If it was just two washers, I’d say go for it but in this case you are looking at using potentially at least 5-6 washers depending upon their thickness. And then the diameter of the washers is another issue. You don’t want the washers any thicker than the caps themselves which means the maximum diameter for those would be 0.975”. I used 7/8” cold roll so there was no need to machine the O.D. of the material any smaller to fit within the thickness of the main caps. If the washers exceed the thickness of the main cap, then they are potentially in an area that will hit a crankshaft counterweight. Looking through the MSC, McMaster-Carr, or Granger catalogs may find some extra thick ½” hole washers being already available.

|

|

By Ted - 7 Years Ago

|

Here are a couple of more pictures showing the clearance both with the connecting rods and the crankshaft counterweight.

|

|

By slumlord444 - 7 Years Ago

|

|

That helps a lot. I'm thinking it should clear in my 312 but I'll want to carefully check for crankshaft clearance. I'v got ARP main bolts with the block drilled and tapped for the extra length. Since the Windsor bolts are much longer anyway the big thing is to shim the new bolts so the length going in the block stays the same. I'll be looking for a thick washer of spacer that comes close enough to hand fit or if worse comes to worse the local machine shop that did my other machine work can do it. From what I can see there may be enough length on the studs that the windage tray bolts on to shim slightly between the windage tray and the head bolts for more clearance if needed. Great info as always. Going to be interesting pulling the pan with the engine in the car. It can be done but messy and no fun.

|

|

By slumlord444 - 7 Years Ago

|

|

Parts came in today. Amazon is quick and good prices with free shipping. I ended up with the Canton 20-942 stud kit. When I compare these with the factory bolts and the studs are prety close in length. One washer may work. Two at the most. Since I have had the block drilled and tapped for the longer ARP bolts I may only need the one washer. When I get it apart I will run the stud all the way down and see where I end up. Since I may have some latitude as to where I finally place the windage tray, would I be better off with it as close as I can get it to the crank while clearing it or as far away from the crank as I can get it? Thanks again for all the great info. I love it when you can switch and swap parts and make them work in different applications. Its what hot rodding is all about.

|

|

By Joe-JDC - 7 Years Ago

|

|

Yes, the ARP stud kit is nearly identical in length, and if you have one thread deeper than stock it may work just fine. I am thinking of doing that same thing of drilling and tapping deeper, plus maybe taking one thread off the end of the stud for insurance. Good luck. Joe-JDC

|

|

By Carefree Charlie - 6 Years Ago

|

Did any of you follow up with what bolts, etc worked best for this situation if you did not do the install as Ted explained?

|

|

By Dave C - 6 Years Ago

|

Ted,

Have you done any kind of back to back testing using a crank scraper versus a windage tray?

This thread got me wondering..

Dave

|

|

By Ted - 6 Years Ago

|

|

Dave C (3/31/2020)

Ted,

Have you done any kind of back to back testing using a crank scraper versus a windage tray?

This thread got me wondering..

Dave

While there has been some testing with windage trays and oil level depths, there has been no testing on my end regarding windage trays versus crankshaft scrapers. With all the different designs out there, that could take awhile to get a definitive answer. The main girdle I make for the Y does incorporate a degree of oil scraping in it but because of the universal nature of it fitting a variety of strokes, it’s not exact either.

|

|

By Dave C - 6 Years Ago

|

Thanks Ted..

Yeah I understand testing would take forever if trying to do all of them. Was just wondering if you had tested what you had on hand.

I have a scraper for my 572 which is set up to only have .050 clearance on rods and crank throw was the reason for my question.

Dave

|

|

By charliemccraney - 6 Years Ago

|

|

I understand that windage trays and scrapers perform different functions, but for a similar goal, oil control so I'm not sure that a versus would be beneficial. Different designs of each could be but like Ted says, there are lot's of different ideas and designs out there. Scraper testing would be a huge undertaking since no one produces one for the Y so all configurations to be tested would have to be custom made.

|

|

By Dave C - 6 Years Ago

|

charliemccraney (4/3/2020)

I understand that windage trays and scrapers perform different functions, but for a similar goal, oil control so I'm not sure that a versus would be beneficial. Different designs of each could be but like Ted says, there are lot's of different ideas and designs out there. Scraper testing would be a huge undertaking since no one produces one for the Y so all configurations to be tested would have to be custom made.

I agree.

The windage tray that came on the original Boss 302 looks nothing like the canton discussed in this post. For those who have never seen it the Boss tray was a metal one with louvers in it.

As to the scraper, as Ted said each one would have to be for a specific stroke.

I bought one for my 572 Mopar 4.5 stroke from a Super Stock racer out of FL he builds a lot of engines. He had a cad/cam file and just lazer cut it. Nice piece, not cheap for a piece of metal. Each area around the rod and crank throw was knife edged. Once I got it fitted perfectly I drilled and installed pins so it would go on in the same place every time.

I'm sure if someone was to make one for the Y it could be digitized and converted to cad/cam and then be manipulated for different stroke combinations. May not be worth it as to numbers to produce though.

I get to reading in here and then I get the "what ifs" or "I wonder" so I have to ask if anyone has done or heard of something.

Thanks

Dave

|

|

By charliemccraney - 6 Years Ago

|

I have a cad file for a scraper that is in my engine. I could help with that aspect but I'm sure Ted has it mostly worked out because of the girdles. Even so, it's still a lot of expense and work.

It's not just the stroke that you are concerned with. Also rod shape / size and bolt positioning and crank counterweight shape. These won't be much of a concern for most Ys but for performance oriented ones with more specialized parts, it can be.

For instance, my 3.47 stroke with 2" journals extends about the same amount below the pan rail as a stock 292. I don't remember the exact figures now, but if the scraper had been tailored only to a longer stroke, it would have been off quite a bit. But, a scraper intended for a stock 292 would have also been incorrect for the combo.

|

|

By Dave C - 6 Years Ago

|

charliemccraney (4/4/2020)

I have a cad file for a scraper that is in my engine. I could help with that aspect but I'm sure Ted has it mostly worked out because of the girdles. Even so, it's still a lot of expense and work. It's not just the stroke that you are concerned with. Also rod shape / size and bolt positioning and crank counterweight shape. These won't be much of a concern for most Ys but for performance oriented ones with more specialized parts, it can be. For instance, my 3.47 stroke with 2" journals extends about the same amount below the pan rail as a stock 292. I don't remember the exact figures now, but if the scraper had been tailored only to a longer stroke, it would have been off quite a bit. But, a scraper intended for a stock 292 would have also been incorrect for the combo.

Point taken.. I realize this, just didn't go far enough in my comments.. It would be like taking a set of stock, oliver, or aluminum rods and trying to make a one size fits all.. lol

But I would think if you were to take yours and allow more or less material for whatever rod/stroke you could then fit it for what you were doing. Maybe looking at it as universal with fitting required..

Dave

|