|

By mytoolman - 6 Years Ago

|

Good Saturday Morning All! I hope you are all well.

I am in the middle of dealing with a weird issue I had with a recently replaced head gasket and freshly machined left head that leaked coolant out of the rear corner of the head right above the #8 spark plug. I am still not completely sure why my previous attempt produced that result...I found no head gasket issues or cracks in my new head etc...I did find I had installed the spark plug wire loom at an angle so that one of its two tabs for the bracket that act to keep the spark plug wire organizer block in position was cocked so that one tab was above the deck surface. I put that spark plug wire loom assembly on before I installed that head because I had a clear shot at it since the head was not in the way...Its my contention since the leak was RIGHT THERE that that is what was wrong... My vehicle is named Ethyl. She is a 1955 Ford C600 2 ton COE that I use when she is drivable as a Tool Truck I am a former Matco Dealer and for the Past 3 years have been running Ethyl as an independent.

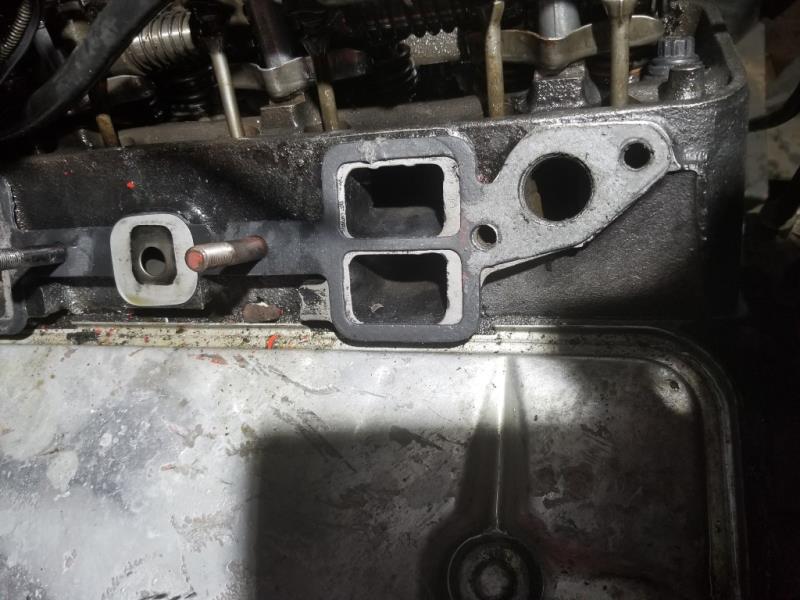

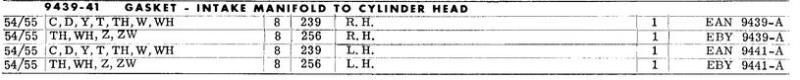

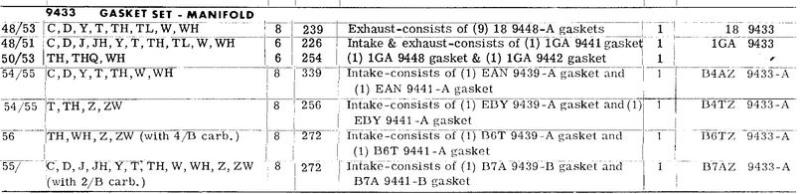

I had everything back together Thursday hoping to see I had fixed my original leak issue from my prior head gasket work. On initial start up...My 272 y block wanted to act like it was Full Throttle....Long and short of it was I had installed intake manifold gaskets that did NOT FIT...I have yet to find some that do....I have what came with the engine set from Best Gaskets that are their part number 14045. I have the felpro ones for a 272 and they fit the same as the Best product. I have a NOS Gasket set for the 272 and both of its intake gasket offerings fit like all the others already mentioned...

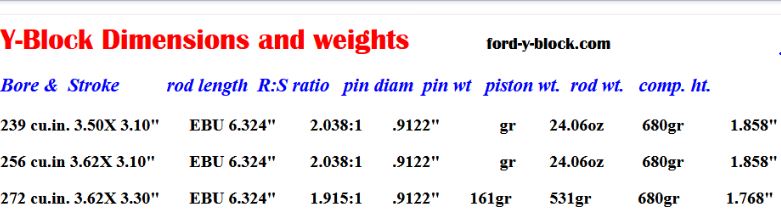

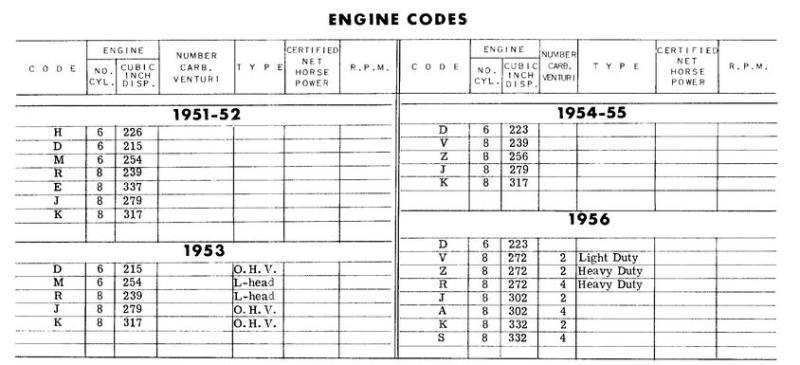

The intake is a cast iron OE type. Its a TWO Barrel that a Teapot sits on. Stamped on it is EBZ-9425-D the block is stamped so that one believes it is a 272. Is this intake from a 256 or a 239? Does anyone have a way to check what is stamped to see what is what? Meanwhile I called BEST GASKET COMPANY and they have Three part numbers for Y Block intakes...I ordered the other Two I havent tried yet...the one for the 239 and the one for the 256....I am not wanting to find out MONDAY if this is going to fix my issue I would rather get the jump start on it today....if anyone can assist here....

WHAT ENDED UP FIXING THIS ISSUE or Summary of solve... 1. iT TURNS OUT I have the 256cid Y Block circa 1954 and then into LATE 1956 SMALL PORT INTAKE MANIFOLD(stamp "EBZ"). There is ALSO a small port intake from prior to what I have for the 239 cid Y Block but that manifold would be stamped with EB"V" and the 239 is clearly different in configuration. The 256 and 272 are similar enough that in my opinion you could make an error and choose the wrong gasket if you dont know any better or dont check well enough. The engine gasket set I used originally that allowed the massive intake leak FROM BEST Gasket Company ONLY CONTAINED the LARGER PORT ones from after LATE 1956(I thought I had a 272 so they gave me the set for a 272. 2. I have learned that the heads I have are for a 256 cid Y Block and NOT the 272 NOTE I am not sure if the HEAD ports for the 256 and 272 are the same or NOT once again my heads are 256. My Block DOES HAVE a CASTING NUMBER THAT shows it to be a 272 that is what threw me here and caused me to order the incorrect gaskets set. The jury is out as to why my block is a 272 with 256 heads and intake. My truck was manufactured in DECEMBER 1955 so because it was late in the year Ford may have used 272 blocks for some reason(maybe they ran out of 256 blocks). One day I might have access to the front of the engine where there are other numbers present. I am told that those numbers likely will shed more information on what is what regarding this 272 block and it being in a truck where that 272 is NOT the absolute norm for the year make and model it is. I can not also know if someone else has changed out the engine here....lots of things can happen over 60 years.

The following posts in this thread contain a ton of information that is valuable...even though I have summarized the fix for this concern, I do still suggest you look at each post following.... there may be a nugget of info that will answer some nuance you may be experiencing...I know I have found one sentence in instructional posts that in the past have reached out and grabbed me luckily that absolutely were the difference between continuing to chase my tail and actually solving what I was trying to solve.

|

|

By Florida_Phil - 6 Years Ago

|

Unless someone knows different, there are only two types of YBlock intake gaskets, small port and large port. Late 56 and up YBlocks had the larger ports. Your heads have the small ports and your gaskets look to be for the big ports. My Felpro gasket sets included both.

|

|

By charliemccraney - 6 Years Ago

|

From the pictures, your intake looks like a small port, 1954 manifold. The number for the intake will be 9425, not 8420. There is an EBV-9425-D, which is 1954 239.

How well do the gaskets match the heads?

|

|

By Cliff - 6 Years Ago

|

|

There are many intake gaskets available, if you buy a complete Felpro head set you will get the right gasket, However It looks to me like you need a gasket for a 1954-1955 239 Ford, get rid of that thick washer and buy the right size bolt for the intake manifold, watch that it's not to long (it will hit the pushrod)

|

|

By KULTULZ - 6 Years Ago

|

The problem here is if the engine is original to the chassis (or has been upgraded to a 1956 272). Cataloging does not show the 272 being used in a truck until the 1956 model run. If it was, the description should be in a PRODUCT SERVICE LETTER.

The HD FYB for 1955 was the EBZ 256CI (CF). The LD FYB was the 239CI - EBV.

Is yours a 2V or 4V?

Are you comfortable posting the VIN here?

Do you see (or see) any CASTING NOS on the cyl head?

|

|

By mytoolman - 6 Years Ago

|

Thank you.... YOU sir are correct...Im prone to make mistakes right now...Im not sure what is going on with me....What I have is the

EBZ 9425-D so this is a 239 manifold... You asked how the mating surface for the head was for the intake gasket. The picture shows the gasket that was included with the engine set. It does NOT allow the gasket to seal against the manifold I have...as you know...

The block on this truck is ECG 6015-A I cant really determine if that is an 8 or a 6 or just casting mess... please... verify it is a 272 Y block

|

|

By charliemccraney - 6 Years Ago

|

I don't know what EBZ 9425-D is but it does look like a small port. EBV is the 239.

The block should be a 272. You are correct that blocks have the number 6015.

|

|

By Tedster - 6 Years Ago

|

|

Just an admin note, are there pictures on this thread?? No seeum anything here.

|

|

By mytoolman - 6 Years Ago

|

First let me say thank you for taking your time here to aid me. Im not afraid to post the VIN...I think its been posted before if anyone with bad intentions wants it they could get it....c60z5e26168.

The driver side cylinder head is stamped EBZ6090L- I cant read the number or design stamped on the underside of the passenger side head. I have Included a photo of what shows there on that passenger side maybe you can determine what those marks are....I did not see any other markings on this passenger side head.

The block is stamped ECG 6015A

The intake is stamped EBZ 9425 D TWO BARREL with teapot

Driver side head stamped EBZ6090L

Passenger side head has $A1 marked on its underside..see the picture I blew it up to 150 percent and could only see A1 or maybe A7 cant determine the mark just ahead of the A

|

|

By miker - 6 Years Ago

|

|

I couldn’t see the pictures either on my iPad, till I “requested desktop site”. Then they came up as attachments. First time I’ve seen that.

|

|

By mytoolman - 6 Years Ago

|

|

thank you...I did get rid of that too long bolt...I did not have a shorter one so for the moment I used that mickey mouse set up...good catch..some of you are VERY observant.....I only used those washers because that long bolt DID want to touch the push rod...

|

|

By mytoolman - 6 Years Ago

|

Yes I have included pictures but like EVERYTHING I am doing right now Im going about things upside down....sorry...guys...I used the insert a file I did not see the icon for an image until I was made aware that you all couldnt see the pictures I have spent all day transfering to my computer from my phone and reducing in size and putting into a file on my computer so I can find them again if I so need...here are all the pictures....I found no way yet to caption them for you yet....

1st picture is showing how the gasket that came in my set fits on the head.

2nd Picture shows the casting number for the Left cylinder head...is it a head from a 272?

3rd picture is there so you can blow it up and see the casting mark there in the right cornerish area and determine whatever you can from that mark its the only mark I found on it

4th picture is the block casting number which I have been told earlier and again today represents a 272 block

5th picture shows how the intake gasket is incorrect for the intake that was on this engine the whole time I have owned this prior running truck now 4 years ...\

6th picture shows the casting number on the intake manifold in question here

|

|

By KULTULZ - 6 Years Ago

|

|

c60z5e26168

C60 - Series Code

5 - Engine Code -256CI

E - ASSY PLANT - Edgewater

The driver side cylinder head is stamped EBZ6090L- I cant read the number or design stamped on the underside of the passenger side head. I have Included a photo of what shows there on that passenger side maybe you can determine what those marks are....I did not see any other markings on this passenger side head.

The block is stamped ECG 6015A

The intake is stamped EBZ 9425 D TWO BARREL with teapot

Driver side head stamped EBZ6090L

Passenger side head has $A1 marked on its underside..see the picture I blew it up to 150 percent and could only see A1 or maybe A7 cant determine the mark just ahead of the A

It should read 5:AI which is the CASTING DATE CODE.

ECL is 272. But the head(s) and intake are earlier 256 although the EBZ intake was also used on the 1956 272.

Either the engine may be a late year assy and they used a next model 272 short (need block DATE CASTING CODE - FOUNDRY MARK - ASSY DATE @ front of engine) to know exactly what happened. The short may also be a later service replacement short assy or was swapped in at some point.or possibly it is a later casting machined to 256 short specs. Regardless, it has EBZ heads and requires an earlier intake set.

I have read several descriptions of engine assembly details, even one or two claiming EBY 256 MERC inclusion.

Hope that helps. Just ask if you need anything else.

|

|

By mytoolman - 6 Years Ago

|

Thank you so much. The one error I made when considering using an antique as the tool truck was not considering that information to keep ETTT running might not be as readily available ....I knew the technology was old but I also knew that it worked back then so it should work today....And it does work today...but things like all of this intake stuff has once again shown me where I stand. Through some pretty rotten luck and three large back to back to back repairs. I have now been "down" for 2 months....which is very bad for my business...as much as my customers tell me they love me, I see the opportunities for a huge leg up my circumstances have provided my competition...I am sure I will get through this and work hard to regain my status...So your help is really important here..and will be with the next thing I will encounter...I AM Driving this truck and am trying to be a good steward to preserve her....so something will pop up or wear out or? I try to have extra parts and things ready but..

.I also now know that I need to pay EXTRA special attention to small details or they WILL bite me in a big way...Its really hard to not know what you dont know.....

On Friday I only reached John Mummerts answer machine...again. trying to get the correct gaskets..He told me he often doesnt have time to answer the phone although..he has been good and has phone me back. When I got the BEST Gasket set from him recently I just took a chance that he would be in the machine shop and drove east 40 minutes one way to go see Mr Mummert. Instead, I spoke to BEST GASKET COMPANY (they are located as it happens a few hours north of me in Santa Fe Springs CA), I asked about all the choices I could have for Y Block intakes....BEST mentioned they had three part numbers. The one I have that clearly does not work for my smaller ports because its shape fits the bigger port intake manifolds(BEST part # 14045). The one for the 239cid (part#14043) and the one for the 256cid(part#14044) I list all of this so someone else who might need intake gaskets can have the part numbers readily. I ordered the remaining two so I could eliminate most of the chances that I would be disappointed on Monday.....I am looking forward to my early morning call from my UPS Depot where I had them shipped telling me I can come get them....

|

|

By Cliff - 6 Years Ago

|

I have the gasket you need, I'm in Long Beach, CA

714 514 7535

|

|

By KULTULZ - 6 Years Ago

|

|

256cid(part#14044)

I believe that is the BEST GASKETS set you need.

Your top end is 1954-55 256CI EBZ Engine Series.

Let the board know and make sure you acquire the correct hardware.

|

|

By Tedster - 6 Years Ago

|

How close are you to Tim McMasters? He's one of the west coast division experts on all things Y. Could pick up a fresh rebuild from him for only 4k to 5k, easy. Give ole Ethyl a little spring in her step, nome sayin'?

Since the heads are off now is a good time to inspect/replace the rocker shafts and rocker bores for excessive wear and/or galling. A new set of valve springs and shim them up to the "installed height", new valve guide seals, maybe lap the valves etc etc. Make sure the oil passageways are free and clear, fresh oil pump &c.

|

|

By mytoolman - 6 Years Ago

|

Soo...In June it became absolutely necessary to do a head gasket job. What went from adding a gallon of coolant every 6 or so weeks went to doing that in three days. It drove me crazy the whole time...Long and short is the P/O had done work to Ethyl. Under the valve covers looked spotless. The temp gauge NEVER moved off of 190 once warm UNTIL I needed to add that coolant and then it only went to 195 hills/grades OR NOT. Even using a gallon in three days did not cause any sort of over heat. I would occasionally smell coolant from what could have been the exhaust but it could have also been from the overflow...like I said it made no sense then..

Upon pulling the head off, it became clear that the driver side head gasket had signs of trouble between cylinders five and six. Another forum I frequent answered well to guide me when I asked if I should replace the head bolts. Through devine intervention or plain luck or? One of the people guiding me had ONE SENTENCE in their instructional post that caught my attention For SOME reason. Luckily I didnt just glance past that sentence. He said "be sure to put the head bolts where they belong there ARE THREE DIFFERENT Lengths".....I had poked all the head bolts through the lid of a box to keep them where they came from on their removal and found that the Two longer bolts were in holes that required the bolts that were just slightly shorter....Ah ha that is why I have always used coolant....that is why the head gasket finally failed...

I brought the heads even though they looked so nice to the machine shop. They did a valve job cleaned up surfaces etc. The seats were ALREADY hardened so they did not have to replace them. The guy doing the work was a 60 year old who was happy to see Y Block heads and we hit it off...Im sure he took every precaution to make sure no stone was left unturned...

That is when I also met John Mummert. The machine shop sent me to him for the ARP head bolts He is in EAST County here in San Diego. 40 minutes from me each way. I tried to phone him then to no success. On our meeting he told me he doesnt answer his phone because he needs to get stuff done. Since the heads were done at a place halfway to him, I choose to pick them up after I went to him. I went without really knowing if I would find a locked John Mummert machine shop door or not. Lucky for me John was there. He sold me the bolts. He sold me the BEST BRAND gasket set. I had a nice meeting with him where he told me he already knew about Ethyl...He is friends with a Truck Salesman at a Dealership I service and his friend had texted John a picture of Ethyl like a year before...It can be a small world. After I left John I picked up my fresh heads and proceeded to put Ethyl back together.

After I put her back together I had her running for a couple of days when I had brake issues and had to have ETTT down again for 3 weeks while I messed with all of those issues. I was NOT Thrilled with how my engine performed now with the recent work I had done but I had brake issues to deal with...

ETTT now had EVANS Waterless coolant in her. I had done Oxylic acid flush and the Evans Pretreatment to the letter etc So I was wanting to limit the back flow of coolant that only a 4psi pressurized cooling system has....NOW ETTT had 195 5 degrees warmer for where the temp gauge used to be Evans says to expect a little higher operating temp...not terrible but NOW on longer inclines The SAME exact uphills etc that I previously also drove with no ill effects, the temp gauge would GO UP TO to 230....and there was pinging at medium acceleration that was never present before all this work. I didnt have a chance to dive in to see what was what because the brakes needed my attention first. And NO I hadnt done anything to check or alter timing so I still dont know about any of that yet either.....I need it running now to see all of that...I figured that heads off, heads back on it would run as well or better than before without touching anything else....maybe...maybe not...too many variables I need to solve this intake thing first before looking further.

After the brakes were fixed, I drove ETTT for a few days and found that I now had a coolant leak out of the driver side head at the corner of that head down the side of the block right at where the spark plug is. Like it was coming out of the spark plug wire loom bracket/holder that is bolted in place on the block just under the head. My NEW Work there was leaking.a small small steam out onto the block and then onto the ground....

I left for a getaway to Reno via Yosemite for 10 days. My youngest son lives in Reno. His boss gave him Labor day off. I had not met my newest grandchild 4 month old Gwen yet so on Aug27th at 2am wifey, our new puppy Ziggy and I left for Yosemite. We had three days in Yosemite before we headed to Truckee CA where we stayed in a guest house AirBNB...Until Sept 6 . Coming home

I pulled off the intake and the left head to see what was what. I saw nothing obvious wrong. Then since I had NOT checked the work the machine shop did on my heads or I had NOT checked the blocks deck on my prior head gasket replacement, I did so NOW. I broke out the machinists straight edge in my tool inventory (I have a 35" one) The deck was good .002 or less. What I did find was that I had improperly installed the spark plug wire loom bracket....I had installed it BEFORE setting the head down because it was EASY TO GET TO WITH THE HEAD OFF. I didnt realize that it needed to be square....it was installed at an angle so that one of its two tabs that are supposed to just touch the bottom of the head was sticking up enough so that the straight edge made contact with it while trying to slide it over the edge there. I am still NOT Sure that was the cause of the leak RIGHT ABOVE THAT SPARK Plug WIRE ISOLATOR LOOM Since I havent got this engine back together yet...Im waiting for the correct intake gaskets.....

Due to my prior complaints to the other forum about running too hot and pinging, Ive been instructed to verify timing and advance. I have found that I have no vacuum advance...the tube at the distributor advance was siliconed into the ford nut there. It was not crimped and its tube just came out of the fitting there when I messed with the vacuum hose...I have a new solid line now that I need to make sure the ford nuts do the crimp on....I dont know what I put down for an intake gasket last time, I thrashed it pulling it apart.and just chucked it on Sept10 or so..Im sure it was incorrect the gasket set John Mummert Sold me was the same one I just got from C&G Ford in Escondido its for a 272...I was probably lucky the last attempted must have just barely sealed...who knows...I did not have the massive vacuum leak I experienced on Thursday that was for sure....but maybe it had SOME vacuum leak that is why I had pinging and the engine ran to 230?

On Monday I hope to have a priest throw some holy water on me and then go to UPS to get the 239 and 256 intake sets I ordered on Friday and put an end to this saga...anyone got a virgin to sacrifice to the engine gods?

|

|

By KULTULZ - 6 Years Ago

|

|

Upon pulling the head off, it became clear that the driver side head gasket had signs of trouble between cylinders five and six. Another forum I frequent answered well to guide me when I asked if I should replace the head bolts. Through devine intervention or plain luck or? One of the people guiding me had ONE SENTENCE in their instructional post that caught my attention For SOME reason. Luckily I didnt just glance past that sentence. He said "be sure to put the head bolts where they belong there ARE THREE DIFFERENT Lengths".....I had poked all the head bolts through the lid of a box to keep them where they came from on their removal and found that the Two longer bolts were in holes that required the bolts that were just slightly shorter....Ah ha that is why I have always used coolant....that is why the head gasket finally failed...

Ain't that something ...

As a matter of fact, the differing length head bolts did not began being used until the 1956 model run. You must have a 272 short with a 256 top end.

He most likely gave you the wrong intake set as a result of your thinking you had a complete 272.

Do you have a 1954-55 FORD TRUCK SHOP MANUAL?

BTW-

When you get all of this sorted out and your duckets all caught up, I expect to see alum wheels on the truck. Who decorated the box? Very tasteful.

|

|

By mytoolman - 6 Years Ago

|

|

Tedster9 I really need Ethyl up and Running NOW....actually by Tuesday Night...I might need to find another Engine to put in Ethyl and then go through the one in her right now....That way can run her with the least amount of down time...I like being on top of things and right now I am not. That is most of my problem right now...not being on top. Thanks for suggesting this forum too....lots of knowledge here also...Between the two I should be ok and maybe stop making critical errors...I have an interesting engine....Really a 256 cid Y Block...Except maybe the block....eventually I will see marks on the front of the engine to see what will tell more of the story with that block...The truck WAS produced late in the year for 1955 so maybe Ford had to do some shifting of gears to make things happen...either way...that block number showing 272 and the rest being 256....I wonder if things like the front timing chain cover and the special high mount water pump can transfer between the 256 and the 272...I hope so...I have a NOS water pump for what I think will replace the one on ETTT right now on the shelf waiting for that day when it shows it doesnt want to play any longer with the bearings it has in it now....That is a hard item to find...once the one in her fails Ill send it out for rebuild.

|

|

By mytoolman - 6 Years Ago

|

Thank you for the compliment on the design of the box....Kultulz...That was a colaberation between myself and the graphic artist whose company has the contract with GEARWRENCH. After my Matco Truck was stolen in 2015 Gearwrench came to me on a fishing expedition asking what my intentions were in coming back...they made it known they wanted me to be a part of their "Street Team" I had to play it cool at that period because I was still a franchisee for Matco...I told them if I ever were to consider what they wanted I would not do so with the two wraps they offer their people...I had something else in mind....they told me they would pay to have what I wanted produced as a custom for me thing..."we are thinking of allowing custom wraps for our folks anyway" It took about 3 months to work with their guy and it ended up costing Gearwrench about twice what they thought it would..Even though they were thrilled with my result....I will be the only custom wrap you see with the Gearwrench logo...

60 percent of what you see in my showroom/mobile tool store is Gearwrench the other 40 percent is whatever you would see in a Snap on or Matco or Mac Truck without those names lazer etched into the tool...Snap on still produces about 5% of what you see in one of their trucks that means that 95% is a private label type of thing...I have gone to those brands and asked them not to change out the handle, to keep their name on the tool and sell it with he who built the tool's name on it...same warranty, same tool, maybe a different color or shape of handle...save 40% due to cutting another distribution system out....I go where I want, sell what I want, drive what I want....my customer tells me what is what...not some franchise flag....Now I just need to get this truck back to the street to actually do that....

I want to do one more piece of art work on ETTT....In that large white box area behind the cab, I want to put the Preamble to the Constitution....as soon as I get back to seeing my clients and get into a routine...I am going to find someone to help me do that.....

|

|

By mytoolman - 6 Years Ago

|

|

Thank you...Last Friday I paid for two sets that Egge Machine in Sante Fe Springs said they sent UPS...with any luck the UPS depot here in San Diego will text me Monday at :30 am with a picture of a package containing the 239 and 256 sets.....from BEST....who is also in Sante fe Springs....I appreciate you though for responding and caring.

|

|

By HT32BSX115 - 6 Years Ago

|

Hey Gary, Hows that thing coming? Did you figure out why it's running hotter than before?

|

|

By Genuinerod - 6 Years Ago

|

|

Love your truck, perfect for your business.

|

|

By mytoolman - 6 Years Ago

|

All it looks like I have had success after receiving all the help you all have provided. My intake manifold is back in place on my engine. I started the engine late last night and it ran well enough without the air intake and the left valve cover on it for a brief see what was what....Im having an small issue getting a miniscule annoying coolant seep from coming out of the bottom of my Radiator hose at the thermostat housing connection above the bypass hose there which I am actually unsure if that bypass hose is also holding tight and not also seeping...I reused the 3 month old silicone hose connectors that attach to the bent pipe connected to the thermostat housing. All of that was doing this same annoying seepage on the very last attempt last Thursday with the incorrect intake gasket so it was not a surprise here that it continues...I replaced the bypass hose last night because I actually damaged the other 3 month old one digging the clamp into it on the last go around... all of this is why I havent put the oil bath and the hose and the special cover air intake fixture back on the teapot to dial everything in yet...all of that gets in the way to fix coolant leaks etc...

I have edited my very first post of this Help finding the correct Intake manifold gasket Post at the end of it with a basic SUMMARY of that fix to make it easy for the next reader to get information if they should somehow run into a similar thing...or for any of you to see what info you provided that bore fruit for me...Once again thank you to all of you.

|

|

By charliemccraney - 6 Years Ago

|

|

The bypass tube or nipple within the thermostat housing and on the water pump tends to rust out. If the leak continues, take a close look at those.

|

|

By KULTULZ - 6 Years Ago

|

|

Im having an small issue getting a miniscule annoying coolant seep from coming out of the bottom of my Radiator hose at the thermostat housing connection above the bypass hose there which I am actually unsure if that bypass hose is also holding tight and not also seeping...I reused the 3 month old silicone hose connectors that attach to the bent pipe connected to the thermostat housing. All of that was doing this same annoying seepage on the very last attempt last Thursday with the incorrect intake gasket so it was not a surprise here that it continues...I replaced the bypass hose last night because I actually damaged the other 3 month old one digging the clamp into it on the last go around... all of this is why I havent put the oil bath and the hose and the special cover air intake fixture back on the teapot to dial everything in yet...all of that gets in the way to fix coolant leaks etc...

Like Charlie mentioned, if there is any doubt as to the integrity of the thermostat housing, replace it.

MUMMERT has nice repros. Make sure where the housing goes to the intake that the intake mounting is not eroded also. Same where the WP fitting goes to the WP (by-pass hose) and the WP mounting boss also.

Do not use worm clamps as they will damage the coolant hoses. Shown below are two styles to use with silicone hose -

GATES Hose Clamp - Green Stripe® Silicone

GATES Hose Clamp - Green Stripe® Constant Tension Clamps

Put a pressure tester on it and make aure it holds pressure.

What Intake Set did you find to fit (Vendor and PN)?

|

|

By blocky - 6 Years Ago

|

|

i just installed BEST intake gaskets and all is well. part number 14043!!!! they did fit 272 y block

|

|

By paul2748 - 6 Years Ago

|

If the nipple on the thermostat housing is bad, there are replacements.

|