|

By Brent - 8 Years Ago

|

I am in search of a set of ECL-B heads.

I have a single 471 and lots of C1TE heads to trade with, if interested. Add to that C1TE and EBU rods, 292 cranks and cams, timing and valley covers, 2 and 4 manifolds and carbs.

|

|

By carl - 8 Years Ago

|

|

what is your location. Carl

|

|

By Brent - 8 Years Ago

|

Hello Carl,

I'm in Brookings, OR 97415

|

|

By NoShortcuts - 8 Years Ago

|

Brent. Unless you are seeking to make your car as original as possible, I'd recommend using a set of ECZ-G or 5752-113 cylinder heads. That said, the ECZ-C heads you have are decent in terms of combustion chamber size (compression ratio) and street performance (drive-ability). Just sayin' . . .

This stuff is getting sooo old, that most people looking at your engine won't even know what it is, let alone whether the heads are the 'correct year' or 'original application'. The fact that you've got the correct species of engine makes the car noteworthy. Unless you go to a C.T.C.I. meet, so many 'Birds have had other engines stuffed in them whether they be Ford small blocks, FEs, or other makes.

Compression ratio makes a lot of difference in stop-and-go driving and engine torque in accelerating to pass or speed-up on a highway entrance ramp. In rebuilding these engines, most of us are using the newer composite gaskets which seal better and stay sealed, but their thickness reduces compression ratio by increasing the effective combustion chamber volume. Remember, too, that the manufacturers' ADVERTISED compression ratios AND horsepower figures from back-in the-day were theoretical calculations not measured or verified by anyone.

IF you haven't seen it, click the link below to view John Mummert's info on y-block head specs.

http://www.ford-y-block.com/cylinderheadchart.htm

Food for thought . . .

|

|

By Brent - 8 Years Ago

|

Thanks for the input!

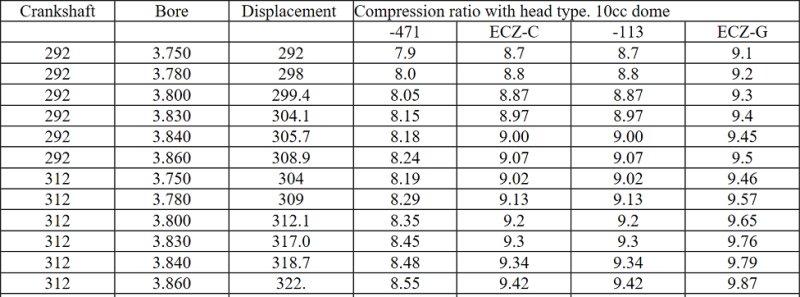

RE: CR - John's chart confuses me. the 113 and ECZ-C show identical CR with 10cc domed pistons.

http://www.ford-y-block.com/forgpiststk.htm

the head chart @ ford-y-block.com/cylinderheadchart.htm shows 8.4 vs 8.8 CR

There is a lot to consider when concocting a recipe for hp.

|

|

By Brent - 8 Years Ago

|

Charlie,

What happened to the valuable info you had posted? I had planned to study after the game is over.

|

|

By NoShortcuts - 8 Years Ago

|

Brent. Apologies for pulling that down. I totally missed what you had posted regarding the chart from John Mummert and had gone off in the weeds thinking you were misunderstanding some information on the Mummert chart I had previously posted.

Let's go at this a bit differently.

What are you looking to put together to power your '55 'Bird? Are you trying to go with a rebuilt stock engine or something warmed over? Are you going to go with the Merc automatic transmission or standard transmission? What did your 'Bird have originally?

Charlie

|

|

By Brent - 8 Years Ago

|

Thanks for sharing your knowledge Charlie!

I am keeping together the parts for a concourse '55 bird, that's where the ECK will end up, if that happens. I drove this bird 32 years ago and decided I was going to do a body off resto after I dinged it up. Well here I am planning to build an engine for the street first. I just got word that that the B9AE I hoped to build will not clean up where we want it. I will haul a virgin C1TE to the shop next week for sonic test. I am learning from every bit of information that you guys share. The part where you mentioned the aftermarket skirted pistons was valuable info. All of the information that you had posted is relevant and informative.

THANKS!

|

|

By NoShortcuts - 8 Years Ago

|

Are you thinking just boring a 292 OR are you considering putting a 312 crank in to the 292 also?

Charlie

|

|

By Brent - 8 Years Ago

|

John's 331 stroker kit is on the menu, thinking 3.81" - 3.83" bore, 312 - 317 ci. 350 hp, pump gas. I have to run.

Thanks again!

|

|

By NoShortcuts - 8 Years Ago

|

I THINK I can locate a set of the '55 heads you asked for originally, but I'm not sure I can accomplish it before Winter.

The thing with used heads this old can be pitting on the deck surface IF they've been in a vehicle sitting outdoors with normal temperature changes. Condensation on the heads machined metal surfaces seems to cause the forming of what I term pock marks. These pock marks or mini pits form on the head flat deck surfaces over the pistons and in the combustion chambers. The 'pits' can be a source for pre-ignition in the combustion chamber. I don't like to use heads afflicted with those 'pits' in engine rebuilds.

|

|

By Brent - 8 Years Ago

|

Charlie,

Again, very valuable info...I will pay attention to that when looking at the 113's I want to use.

Thanks for looking for the heads!

|

|

By Brent - 8 Years Ago

|

http://www.ford-y-block.com/stroker%20kits.htm

THANKS!

|

|

By Brent - 8 Years Ago

|

Charlie,

Do you have an ECK-C head? A single is all I would need.

|

|

By NoShortcuts - 8 Years Ago

|

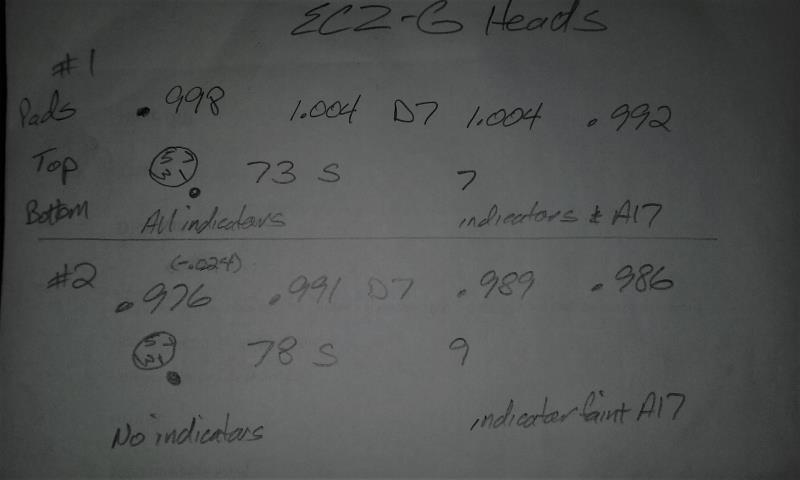

Brent. The two pads Ted mentioned on the exhaust port side of the cylinder heads, common to the deck face of the cylinder head, are what you want to check with a micrometer to help understand the shop history of anything you're considering purchasing. Checking the thickness of the 'pads' indicates if the deck surfaces have been resurfaced by milling to make them true (flat). When originally manufactured, the pads were 1.000 thick plus or minus next to nothing [.001 / .002?] Ted could tell you what the tolerance may be that he has seen. IF resurfaced, the heads should be the same thickness on both heads. Some shops may have not been concerned about their being milled identically. They may have been focused on just 'cleaning them up' adequately. The difference in pad thickness between the two heads can result in a combustion chamber volume difference between the two heads.

Heads excessively milled can be problematic. On the un-posted ECZ-G heads, both John Mummert and Ted speak of limiting surface milling to .025 inch. ECZ-G posted heads, the recommendation is that they will handle up to .045 inch material removal. These figures speak to a concern pertaining to having the cylinder head deck thickness great enough to prevent flexing and head gasket failure.

I previously mentioned the condition of the deck surface being eroded by moisture forming from the heating and cooling of the cast iron heads causing condensation in the porous surfaces of the iron and the temperature change outside (freezing) causing expansion of the frozen moisture and forming mini pits or 'pock' marks in the head deck surfaces above the pistons and potentially in the surfaces of the combustion chambers as well. Milling the heads may not remove the 'pock' pits. Smoothing the 'pock' pits in the combustion chambers or deck surfaces above the pistons to eliminate potential sources of pre-ignition could be a headache, too, depending upon the severity of the pitting damage.

Another 'tell' regarding the history of the heads you're looking at would be looking at the intake and exhaust valves to indicate if they are 'original' or replacements per a possible previous valve job. Ford produced replacement service valves for the intake have had the O/S number amount raised on the exposed valve top surfaces near the FoMoCo raised label. Example 30 indicates .030 oversize stem. Ford produced replacement service valves have had the O/S number raised on the underside of the valve head away from the stem and near the valve face. Can't speak to TRW or other make valves. The O/S number refers to the oversize of the valve stem.

Hope this helps!

|

|

By Brent - 8 Years Ago

|

Charlie,

Thank you for sharing such valuable insights!!! I'm going to look at heads that I have so that I can further educate myself...

Thanks again

|

|

By NoShortcuts - 8 Years Ago

|

Brent. Below is a link to the index of articles written by Ted Eaton principally covering topics related to Ford y-blocks. These articles are all available for viewing on Ted's Eaton Balancing web site. Suggesting this resource list of topics is triggered by your interest in building a modified y-block for the street.

Ted gives fantastic written run-downs on any topic he undertakes. I think you'll find his various engine builds extremely informative depicting what was done and why. Much food for thought as you move forward on the engines for your '55.

Not just y-block related is his series of articles on engine balancing, too.

Click the link below

http://www.eatonbalancing.com/2000/03/24/quick-index-for-eaton-balancing-articles/

Charlie

|

|

By NoShortcuts - 8 Years Ago

|

Brent. I received your email message pertaining to the Forum Search function. I wrote and sent you a reply, but I'm doubting that you received it.

The Forum email and PM (personal message) system seems to work for some accounts and not for others in my experience. Example, I sent Jim with his '56 'Bird parts Technical Section source info inquiry an email and PM (personal message) yesterday. He reported not getting either!

IF you did not get my email to you that I sent today, please consider sending me your email address at my home address and I'll resend the info directly to you.

Send your Internet address to me at cncbrown2@gmail.com

Thanks,

Charlie

|

|

By Brent - 8 Years Ago

|

Charlie,

Just checked and I got your msg. I will try to search soon when I get a free moment. Please have another look at the decoding topic. I will post new info in a few.

THANKS as always.

|

|

By NoShortcuts - 8 Years Ago

|

Brent. Haven't forgotten you on the decoding topic. Still reading in the Forum Archive.

Different topic dealing with '55 heads. Ran into this in the Forum Archive. Click the link below started by Ted.

http://forums.y-blocksforever.com/FindPost129359.aspx

|

|

By Brent - 8 Years Ago

|

Charlie,

The ECK-B engine that I purchased has two different heads.[ http://forums.y-blocksforever.com/Topic140773.aspx ] I'm concerned that if I buy an ECK-C to match the weird ECK-C that I have it may cause an unbalance.

Got these ECZ-G heads back today. I think this is a good example of milled heads. One pad measures .976" and what appears to be milling indicators are gone in that area. Looking at the coding, they appear to be matching heads

|

|

By NoShortcuts - 8 Years Ago

|

Brent. There is an amazing amount of discussion about ECZ-G cylinder heads in the Forum Archives. From early times, ECZ-G heads were sought after for improved y-block engine performance. The big intake valves and the small combustion chambers with the advertised compression ratio of 9.7:1 on the D code 1957 Fords and Merc 312 engine applications made them sought after.

As you get into this stuff, you learn that there are three (3) species of ECZ-G cylinder heads. In short, there are 'posted' and 'un-posted' ECZ-G heads with larger casting letters and 'un-posted' ECZ-G heads that have smaller casting letters. The differences in the three species are significant.

The four links below provide pretty complete coverage of information you might be interested in. There is some overlap in the info, but by reading all of the entries, you'll get a good handle on the nuances.

http://www.yblockguy.com/techtips/postedheads.html

http://forums.y-blocksforever.com/Topic113734-1.aspx

http://forums.y-blocksforever.com/Topic128650-1.aspx

http://forums.y-blocksforever.com/Topic125750.aspx?Keywords=G+heads#bm125752

|

|

By Brent - 8 Years Ago

|

One more head oddity. This is a picture of a 113 head CC. Notice the dimple between the valves (all 4 CCs have it). Do you suppose this is forged that way or someone's experiment, definitely goes against the smooth chamber theory.

|

|

By NoShortcuts - 8 Years Ago

|

Brent. I have no info on the dimples in the 5752 / 113 combustion chambers. All the 113s I've seen have the dimples. Notice how there seems to be less shrouding of the intake and exhaust valves in the 113 chambers than what you see in the ECZ-G chambers. In my last entry I mentioned how historically y-blockers', including myself, thought the G heads used on '57 Fords and '58 Mercs were THE thing to have on their build. Today, I'd rather have a set of 113s!

Yes! The G heads have smaller combustion chambers offering a higher static compression ratio, BUT the 113s, as cast, have less valve shrouding and ALL 113s are posted! Need a smaller combustion chamber to accomplish a higher static compression ratio? Have the machine shop mill the heads!

The link below details a very street-able build that Ted Eaton did on a 292 block for Karol Miller. Ted used a .070 overbore (yielding a 3.820 bore) on a 292 block, a stock 3.3 stroke, 113 heads, '56 Ford 1.54:1 rocker arms, flat top pistons, and a custom Isky grind camshaft with a dual pattern grind using a 110 degree lobe center angle. End result? 303 cubic inches producing a peak of 315 horsepower, and 335 ft. lbs. of torque @ 3,300 rpm! This shakes out to just over 1 horsepower per cubic inch of engine displacement! Substitute a 312 crank and connecting rods and the hp and torque numbers will go up with the ~317 cubic inches of displacement.

http://www.eatonbalancing.com/2015/05/01/unported-iron-heads-can-still-make-over-a-hp-to-the-cubic-inch/

|

|

By Brent - 8 Years Ago

|

Ted's recipe for hp is inspiring. Waiting to hear the CITE will be the block. I have the 312 crankshaft wet tested and ready to go. Regarding the 113s all having dimples. I guess the oddity is the three I have without dimples. We will use 113s and a 218 @ 50 111 cam, some head work and hopefully a 350hp, 317ci - C4 w/2000 stall - 3.31 Dana 44 gears and my bird is back on the road in style after a long 32 year hiatus.

THANKS to everyone for sharing your knowledge!...

|

|

By NoShortcuts - 8 Years Ago

|

Brent. You may have read in the Archive or on JM's web site that 113 heads were supplied as replacement heads over-the-counter by Ford after the G heads went out of production. I've seen several sets of 113s that came off of marine engine applications. I think I recall Ted indicating that y-blocks were used by some boat manufacturers longer than they were used in production cars and trucks. I'm not positive of that, but we're talking into the early '60s anyway. The dimples in the 113 combustion chambers may indicate a production change to the later castings. My 113 heads have the large S in the rocker arm area that John speaks to in the insert below.

From John's web site page on cylinder head applications

Heads with large "S" in between center exhaust valves are service replacement heads as date codes are after production run. 5752-113 was sold as replacement head for ECZ-G

Going back to installing a 312 crank in your 292 engine build. Somewhere in the Forum Archive is info detailing the 312 crank modifications required to accomplish the swap into the 292. The short of that is

- the 312 crankshaft main bearing surfaces, rear slinger dimension, and rear seal dimension need to be reduced to 292 dimensions by a competent auto machine shop. Crank main journal radius-es are critical to maintaining crank integrity and strength.

The link below is to John Mummert's web site and shows the machining dimensions required

http://www.ford-y-block.com/crankshaftid.htm

Hope this helps!

|

|

By cos - 8 Years Ago

|

|

Hello Brent Sent you a E-mail. Bill Oregon

|

|

By Brent - 8 Years Ago

|

Bill,

I did not get your email. Please try again, I updated info.

|

|

By cos - 8 Years Ago

|

|

Hello Resent E-mail. Bill Oregon

|

|

By Brent - 8 Years Ago

|

Hello Bill,

No emails. I tried to sent an email to myself and it did not work either. Try PM msg. it seems to be working.

|

|

By Ted - 8 Years Ago

|

|

Brent (10/26/2018)

I am in search of a set of ECL-B heads.

I have a single 471 and lots of C1TE heads to trade with, if interested. Add to that C1TE and EBU rods, 292 cranks and cams, timing and valley covers, 2 and 4 manifolds and carbs.

Be aware that there are two versions of the ECL-B heads. Per the Service Bulletin #973, the 1955 182HP Special 272 CID engines had the version that was milled 0.035” versus the non-milled version supplied on the 1955 Thunderbird 292 engines. The two different heads can be distinguished only by measuring the two center machine locating pads located under the exhaust ports. They both have the same casting numbers.

That said, I have a pair of ECL-B heads off of a 182HP Special but shipping costs are a real cost killer in moving those heavy parts around the country. Just contact me via email or phone if interested but be aware that my two heads are the factory milled versions. My contact information can be found at www.eatonbalancing.com .

|