|

By Florida_Phil - 7 Years Ago

|

Here's some text from John Mummert's Y Block Assembly errors.

Cam thrust. It appears that Ford used 2 different thickness thrust washers and plates on the cam. With the wrong combination there will be no end play in the cam. Ensure .004" movement during assembly.

I am concerned that I do not have enough cam end play. Can anyone give me some advice on this subject?

|

|

By charliemccraney - 7 Years Ago

|

Why do you think that you don't have enough? If the engine turns easily, then you at least have some. The only way to check is to pull the timing cover and measure with a dial indicator.

A cam plug which is installed too deep can take up the play as well.

|

|

By 57RancheroJim - 7 Years Ago

|

I think the .004 clearance is need to allow for heat expansion and room for oil to get between the retainer and gear, but I could be wrong and someone will correct me.

|

|

By NoShortcuts - 7 Years Ago

|

Florida_Phil. While you're at it, consider modifying the camshaft retainer. Give thought to where you put the grooves. Consider 10, 4, 2, and 8 o'clock as locations. Grooves do not need to be deep . . .

Notching the cam bearing plate allows oil to better lube the end of the cam. Look closely and you can see the ring where the cam scored the plate due to lack of adequate oil lubrication.

Hope this helps!

Hmmmm. The picture did not make the posting.

|

|

By Ted - 7 Years Ago

|

|

I target for 0.005” +/- 0.001” for camshaft end play. This is easily measured before installing the camshaft by measuring the difference in the cam thrust plate and cam thrust washer thicknesses. The cam thrust washer obviously must be thicker than the thrust plate and not the other way around. When installing the camshaft, be sure it falls at least 0.015" behind the front face of the block. If it doesn't, then the cam plug is likely driven in too deeply. It’s also important that the cam thrust washer be installed with the chamfer facing the cam shaft or there will be too much end play.

|

|

By Florida_Phil - 7 Years Ago

|

I have the engine nearly together on the engine stand. When I degreed the cam it turned freely. However, I did not measure the cam end play with a dial indicator. The cam was not tight when turned by hand, but the end play was not noticeable. I assumed if it turned freely the end play was acceptable. It is possible the cam freeze plug is taking up some of the play. My machinist installed it. I did not groove the cam thrust plate in this engine. I have built Y Blocks in the past, but I have never heard about two different thickness cam thrust plates. What will happen if I don't have enough cam free play? Would you pull the front cover off and check it again or leave it as it is?

|

|

By 57RancheroJim - 7 Years Ago

|

JMHO but for the price of a gasket you will sleep better.

|

|

By NoShortcuts - 7 Years Ago

|

Murphy's Law in my opinion. IF you don't do it and have a problem because of it, you'll never forgive yourself. Remember, beginner's luck only applies to us when we're young! Too, you'll only regret checking it if you don't!

Old saying . . . Why is it that there is never enough time to do something right, but always enough time to do it over!

Now I've shared with you that I'm old and got my handle at the school of hard knocks when I was young and in a rush putting my first 322 y-block together in the early Spring of 1966!

|

|

By Florida_Phil - 7 Years Ago

|

I'm old too. Hopefully, I've learned from my mistakes. I'll take it apart again and see what's going on. Good advice.

|

|

By Florida_Phil - 7 Years Ago

|

I started to take the front cover off my engine so I can recheck the cam end play. Of course I had already installed the balancer, so I had to pull it off. My home made Thunderbird balancer pull tool broke, so I had to order one from Casco. In the mean time, I am contemplating how this cam end play thing works. The engine is on my engine stand and I can see the rear freeze plug. It looks like it was installed flush and the machine shop who did the work is a well known Ford specific shop. I have no doubt it has been installed right.

There are a few things that are bothering me about this cam issue. The first thing is when I had everything buttoned up I couldn't feel any cam end play by hand. The cam turned freely, so I assumed it was OK. I should have used a dial indicator, but I was too lazy. My fault totally. Second, I did not grove the cam thrust plate. Many years ago when I last worked on a YBlock, I always did this. My fault again. Finally, there is a funny feeling to this roller timing chain. As I reported earlier, it made a tiny clicking noise when I first installed it. Kind of like it wasn't aligned correctly. I checked visually and all seemed fine. I degreed the cam and it matched the cam specs perfectly.

Finally, I'm not sure about the cam washers and thrust plate. I have two engines and my engine may be a mixture from both. Having worked on mostly FEs, the Yblock arrangement seems a bit strange. The first washer next to the cam fits into the thrust plate itself. I assume it's suppose to fit tight and not rotate inside the thrust plate? I looked for a beveled edge and I couldn't see one, so it may be installed backwards. This engine does not have the counterweight spacer in front of the cam, it has another spacer. There is a third spacer between the cam bolt washer and the fuel pump eccentric. With this arrangement, is the cam end play determined by the thickness of the thrust plate and washers? Are there different thickness plates or washers? I should have the balancer off on Monday and will be able to take a better look. Everything could be just fine and I am worrying about nothing. At least I'll know. Thanks for your help!

|

|

By Ted - 7 Years Ago

|

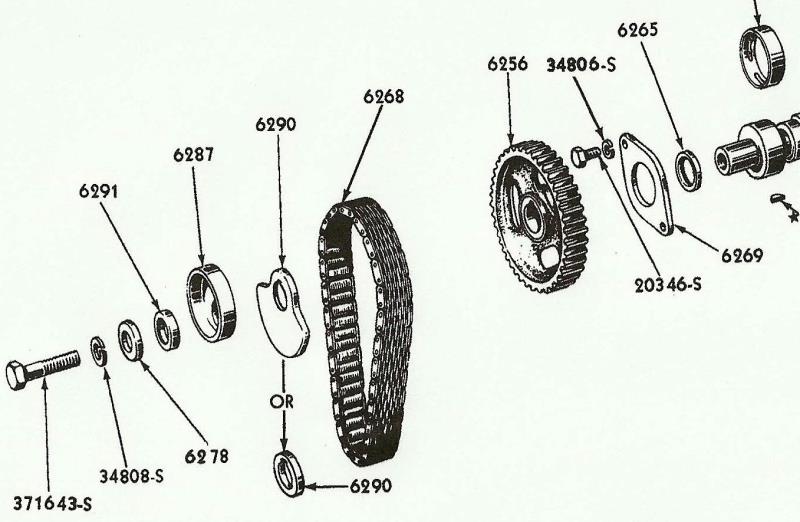

On the camshaft attaching parts picture, its parts #6265 (cam thrust washer) and #6269 (cam thrust plate) that dictate the correct amount of camshaft end play. The difference in measurements on these two parts will determine the exact amount of cam end play. Be aware that the cam thrust washer is not keyed and has a chamfer on one side only. The chamfer goes towards the rear or faces the camshaft. The cam thrust washer is placed on the camshaft before installing the woodruff key in the camshaft snout.

|

|

By Florida_Phil - 7 Years Ago

|

Thank you. If washer #6265 is installed backwards, wouldn't it make the cam end play less? Could be my problem?

|

|

By Ted - 7 Years Ago

|

|

Florida_Phil (10/13/2018)

Thank you. If washer #6265 is installed backwards, wouldn't it make the cam end play less? Could be my problem?

Installing the thrust washer with the chamfer facing forward can increase the camshaft end play assuming there is a radius at the base of the camshaft snout, not reduce it. The reason for the chamfer on the thrust washer is so that the radius at the snout to cam front face can be compensated for. Having no radius on the camshaft snout makes it more prone to breaking or snapping off. Some aftermarket camshafts may not have that radius at the snout at which point it would technically not make a difference which way the thrust washer was installed.

|

|

By Florida_Phil - 7 Years Ago

|

I definitely have a problem here and I'm not sure what it is. I removed the balancer, front cover, gears, timing chain and thrust plate with it's round washer. The washer that fits into the thrust plate was installed correctly with the beveled edge toward to cam. I slotted the thrust plate, reinstalled it and torqued the bolts that hold it to the block. The rear freeze plug is installed correctly. I installed the timing gears and chain as in the shop manual. I then installed the washers and fuel pump eccentric as in the picture. Everything rotates freely until I torque down the cam bolt. This puts a bind on the rotating assembly that I can feel and I have no detectable cam end play. I'm think I may have the following issue. This is from an Internet assembly article.

It appears that Ford used two different thrust washer thicknesses and cam plates. With the wrong combination there will be no camshaft endplay and failure is certain. Ensure at least 0.004-inch camplay endplay during assembly.

Where can I get these parts? Any ideas?

|

|

By Ted - 7 Years Ago

|

Your lower picture does not show the thrust washer so I’ll assume it’s still sitting on the camshaft. You will need to mic both the thrust washer and the thrust plate. The thrust washer should be approximately 0.005” thicker than the thrust plate. This will be your camshaft end play. If your measurements do not get this, then the appropriate part can be machined so you have the correct difference in thicknesses. A belt sander and a light touch or feel can do this.

Check also that the camshaft is sitting at least 0.015” behind the front face of the block when pushed all the way back before installing the thrust plate. If the camshaft is not sitting behind the front face of the block, you have an issue with the rear cam plug being too far forward or in.

|

|

By Florida_Phil - 7 Years Ago

|

Will do. My motor is made up of parts from two different engines. My original engine is a 1955 292. The other engine is a 1957 272. As these engines get older and parts become scarce, this is going to be a problem. I suspect the thrust washer and thrust plate that is in engine now is from the 1955 engine and is thicker. The cam and timing chain are made to work with the later parts. I'll figure this out and post what I find. It's a good thing I addressed it on the engine stand. I'm sure I would have destroyed the engine if I had run it that way. That's a lesson I don't want to learn.

|

|

By charliemccraney - 7 Years Ago

|

|

If the spacer and plate both came from the '55 and neither is worn or damaged then clearance should be good as the two pieces would match. The cam and timing chain should work with either set of parts.

|

|

By Florida_Phil - 7 Years Ago

|

This issue has been resolved. The engine that came with my car when I bought it had a lot of questionable issues. The thrust washer next to the cam fit very tightly into the thrust plate. So tight that I had to force it in. When the cam bolt was torqued down the cam assembly bound up. You could turn the engine over, but it didn't feel right. The cam freeze plug was installed correctly.

I removed the washer and plate from my bone stock 1957 272 and installed them in my engine. The last person to touch that engine was the factory 61 years ago. I could clearly see the beveled inside edge on the thrust washer and there was clearance between the washer and the plate. That is the way I remembered it was suppose to be. I notched the thrust plate and put everything together without the timing chain and the cam end play was perfect. I reinstalled the timing chain and torqued everything down. It is nearly impossible to check the cam end play with the roller timing chain installed as it is very tight. I am confident it is adequate.

There is a lesson to learn here. These engine are very old. Who knows who's been working on them or what has been done to them along the way? Shade tree mechanics are plentiful. Don't assume because you took it apart that way, it is right. Thanks for all the help!!

|

|

By charliemccraney - 7 Years Ago

|

|

You should be able to check the end play with the chain installed. Use a screw driver or small pry bar to gently move it. If you measured the thickness of the washer and plate and they were in spec, then it should be good. You can also check with only the sprocket, without the chain installed, before final assembly.

|

|

By Florida_Phil - 7 Years Ago

|

I installed all the components without the timing chain, tightened the cam bolt and the end play was perfect. The roller timing chain and gears are new with zero slack. I hate prying on things. When I adjusted the valves the engine turns freely by hand with no binds.

|

|

By charliemccraney - 7 Years Ago

|

|

You only pry gently, same as you would for checking crank thrust. It should not require much effort at all. If you checked with the gear, before installing the chain, then it is definitely good.

|

|

By Florida_Phil - 7 Years Ago

|

The cam end play was perfect without the chain installed. I could move it forward and back with my hands. The roller timing chain seemed like a fairly delicate piece of hardware, especially around the edges. I guess I could have forced it, but I didn't want to chance it. I put a lot of assembly lube on the parts as well. It could have taken up some of the play.

|

|

By Joe-JDC - 7 Years Ago

|

Make sure if you have to pry the gears and chain off, that you do not pry against the pins in the chain. That will destroy the chain integrity, and a link will fall off. Ask me how I found out?

This was in my oil pan after the tear down from EMC. Luckily it was found to be missing when the cam was retarded back to 101*, and a new chain was installed. The link was MIA, but all is good now, since I found it. Joe-JDC

|

|

By Florida_Phil - 7 Years Ago

|

Yikes!

The Rollmaster gears are tough to get behind with something to pry with. I'm happy with the test fit I made before installing the chain. All turns freely now and the chain does not make any unwanted noises.

|

|

By MoonShadow - 7 Years Ago

|

|

Is it possible to install the Rollmaster cam bear backwards? Just wondering if that is what is hitting to lock it up?

|

|

By Florida_Phil - 7 Years Ago

|

Anything is possible. It's pretty obvious which way the Roll Master timing gear goes on the cam. The front and back are different and I don't think the timing chain wouldn't go on straight. There are definitely two styles of Y Block cam thrust plates and washers. The parts in my 1955 292 motor are different than in the 1957 272. As soon as I replaced the 292 parts with the 272 parts, the cam end play was perfect. I prechecked the end play without any oil and the timing chain off. The cam end play is about .005", I used Red Line assembly lube in this motor. It's pretty thick stuff. Anyway, I am confident in what I have now. My blast cabinet gave up the ghost for some reason. As soon as I fix it I'll finish the motor and put it back in the car. This whole project started out as a light cleanup of the engine compartment. It's ending with a complete mechanical rebuild from fan to drive shaft.

|