|

By fiskmus - 7 Years Ago

|

Hi i got an ford fairlane 500 -57 with an 312 engine that runs great when driving but i have a problem, when the engine gets warm and im standing still with the engine at idle speed it stalls after maybe 5-10 minutes. when its about to stall i can rev the engine but as soon as i get of the throttle it will die, but if i put it in D and drives for maybe 1 min the idle will work again for another 5-10minutes.If the engine dies it not funny to get started again. i can add that when im driving my engine temp is normal but when im standing still it will go up to maybe 200 degrees F. I have tried several things to solve this and dont realy know what to do. I have change sparkplugs and cables, ignition coil, and installed a pertronix ignitor gen 1 and set the ignition timing to 6°. i have changed all gaskets in my edelbrock 600 and adjusted float level. changed fuel filter, adjusted valve lash. i have also mounted a thick "plate" between carb and intake. nothing has helped. anyone got a clue on what to do next ? and one more thing, if i set idle speed to 600rpm it can be 500rpm a few stops later and can also be 7-800rpm maybe its normal ? and sorry for my bad english im form sweden.

Best regards Joel

|

|

By Tedster - 7 Years Ago

|

Joel I have found that a mechanic's vacuum gauge is invaluable for engine and carburetor tuning and diagnostics. At Sea level a stock engine in good condition should pull 18" to 20" steady needle on the dial gauge. Be sure to check for this. Usually 10° to 12° BTDC is optimum static or initial base ignition timing.

Carburetors have several different circuits that work together but also operate independently of each other. The idle circuit particularly is dependent on a strong manifold vacuum signal, as very little outside air moves through the carburetor at idle. So carburetors utilize engine vacuum for precise metering and atomization of the fuel. As the ignition is advanced at idle the manifold vacuum signal is increased. Study the setup and adjustment carefully and take care that the throttle plates are not excessively open at idle. The idle mixture plays a role in off idle and transition carburetor circuits, where a lot of driving takes place.

|

|

By oldcarmark - 7 Years Ago

|

|

The reason the Temp goes up when You are stationary is because there is no Coolant circulation.If You take off the Cap (let it cool off first) and watch the coolant at Idle there is no circulation.When You increase Engine RPM you should see the Coolant moving. One way to improve this is to install a smaller Water Pump Pulley. Also a Fan with more Blades such as a 6 Blade or an Electric Fan helps. I have installed Aluminum Rads in both my 56's and the improvement at all Speeds is very apparent..The Idle Speed should remain Constant once set. If its changing as U indicated something is not quite right. Is the Throttle Linkage free to return so that the Idle Speed Screw is in contact with the Carb Throttle Stop?

|

|

By charliemccraney - 7 Years Ago

|

A 200f temperature is nothing to worry about IF it stabilizes there. Does it continue to climb after 200 or does it stay at 200? Your engine is not overheating until coolant is boiling out. If that is not happening, then it doesn't matter what temperature it is as long as it is stable.

If the stall only occurs at idle, my guess is that your idle mixture is far too rich. It fowls the plugs at idle but when it is above idle, the mixture is better and cleans the plugs. If you don't already have the manual for your carburetor, download it from Edelbrock's site. Read and understand everything about the carb theory and function so you know how to tune it.

As far as your eratic idle speed, make sure all throttle return springs are in good condition and not broken or worn out. Make sure your throttle linkage is lubricated and operating smoothly. Make sure that the throttle plates were not binding on the smaller holes in the manifold manifold and that they are not binding on your spacer. Also make sure that your mechanical and vacuum advance are operating correctly. Everything else the same, rpm will increase with more timing and decrease with less so if advance weights are sticking or the vacuum advance is sticking, it can cause your idle to change.

|

|

By fiskmus - 7 Years Ago

|

Hi, i have checked the vacuum on idle 600rpm av its about 16 when i measure it on the big middle connection on the front of the carb, i have my distributor connected on the left side on the carb and there is no vacuum there on idle is correct? this is the number on my distributor C3AF-12127-U i have checked so it moves and returns good with vacuum. about the temp i have an electrical fan that starts at about 200f so it wont go much higher than that. i had the carb taken apart a few weeks ago and cleaned and new gaskets, i have tried to set up idle screws but they currently sits at 2 turns out at both sides. When setting the ignition the vacuum should be plugged to the distributor, right ? i will check the linkage one more time to make sure its not getting stuck.

I read somewhere that a 600cfm carb is to big for an 312? dont go over 500cfm with stock engine they said, some of them had problem tuning the 600cfm carb but solved the problem with the smaller carb. is this true?

update i have now tried to adjust the idle screws to maximum vacuum bat cant get it higher then 16 and it goes up and down between 15-16 all the time

|

|

By Ted - 7 Years Ago

|

|

fiskmus (7/25/2018)

...I read somewhere that a 600cfm carb is to big for an 312? Don't go over 500cfm with stock engine they said, Some of them had problems tuning the 600cfm carb but solved the problem with the smaller carb. is this true?

The 600cfm Edelbrock carb is definitely not too big for your engine. The primary throttle bores are considerably smaller than the secondary bores so air velocity at idle and cruise within the carb is expected to be the equivalent of stock or better in that department. Vacuum leaks on the ECZ-B manifolds are common so make sure the carb and associated spacers are sealing well to the manifold.

You don’t say anything about the overall condition of the engine. If its high mileage and/or the heads were never configured to run on unleaded fuel, then there is the possibility that the valves are not sealing consistently to their seats. Valve guide wear is also a consideration as well as the valve lash being set on the tight side. Don't rule out worn rocker arms. Performing both a cranking compression test and a leak down test is suggested to get a feel for the condition of the rings and cylinder heads. By ruling out some of the basic mechanicals that could be the root of the problem, you can then concentrate on the carburetor and ignition systems.

|

|

By 62bigwindow - 7 Years Ago

|

|

I'm no expert by any means but could it be either a heat soak issue or vapor lock?

|

|

By Florida_Phil - 7 Years Ago

|

I chased a similar problem on a friend's Galaxie late last year. It was very intermittent and drove me nuts. It finally turned out to be a bad coil wire. The wires were carbon in the center and burnt on the end that goes into the coil. The coil was arching just enough to run the car. The car would stall, run fine for a few miles then stall again. I was pretty embarrassed when it turned out to be something so simple. Sometimes the simple things can be the hardest to find.

|

|

By fiskmus - 7 Years Ago

|

i dont know the condition of the engine the rocker arms looked okay i think. but about the carb is it possible that the engine gets to much fuel and gets flooded with gasoline and therefor dies? because if i let the engine stall its realy hard to get started again. and if i drive away when its about to stall the sparkplugs dry up and works properly again? just a thought i have. and this might be caused from a to big carb. but i will try to get the cranking compression test done tomorrow. and i have no idea on the milage

|

|

By charliemccraney - 7 Years Ago

|

The results of a compression test and leak down test will give you a good idea of the condition.

Re the idle screws, one test you can do while it is idling well is to screw one all the way in. The engine should stop running when you do that. If it does not, then fuel is getting into the engine some other way, resulting in a richer than necessary idle mixture. Another thing to check for a rich idle mixture is to let it idle until it stops and then pull a couple spark plugs to see if they are gas fouled..

Re your cooling setup, since it doesn't get hotter than 200 degrees, it is ok; there is no problem. If you will be more comfortable with a cooler temp, then have the fan turn on sooner.

|

|

By fiskmus - 7 Years Ago

|

I have tried the test with idle screws and engine dies if i screw all the way in.

I was just out driving the car now and it runs good i think its got the power and goes smooth, left it on idle for just a min and there is no missfireing or stuff like that witch make me think its not an internal engine problem. but i think the exhausts smells quiet strong so i guess its running abit rich? is that something i can tune on my 600 cfm carb without changing meteringrods?

|

|

By charliemccraney - 7 Years Ago

|

Again, Download the manual from Edelbrock's website and read it so that you understand how the carb works.

It's been a while since I have used an Edelbrock but I'm pretty sure that the metering rods affect the main circuit and not the idle circuit so if the problem is only at idle, those will have no affect on the problem.

|

|

By fiskmus - 7 Years Ago

|

If i understand the manual correctly primary jet and metering rod can affect the amount of fuel the car gets at idle ?

This text is taken from manual

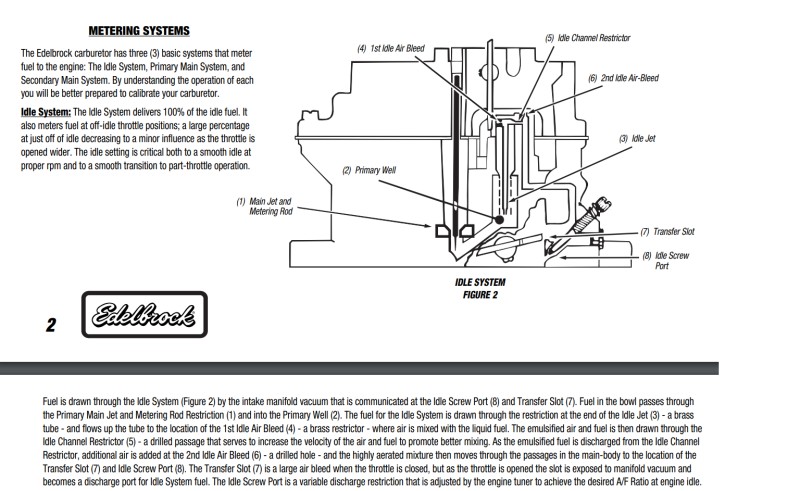

"Fuel is drawn through the Idle System (Figure 2) by the intake manifold vacuum that is communicated at the Idle Screw Port (8) and Transfer Slot (7). Fuel in the bowl passes throughthe Primary Main Jet and Metering Rod Restriction (1) and into the Primary Well (2)."

|

|

By charliemccraney - 7 Years Ago

|

|

Not exactly. While the fuel does travel through the main jet to the primary well, the idle jet is so much smaller that the main jet will not really affect the idle circuit.

|

|

By DryLakesRacer - 7 Years Ago

|

|

If you've got compress air take out the idle screws and blow thru them. Same for any other passages. That canned air for your computer works too. If you need to change metering rods, it's the easiest thing on those to do. I check for vacuum leaks with starter fluid and a nozzle from a WD 40 can..... carefully. Good luck.

|

|

By miker - 7 Years Ago

|

Kind of a long shot, but pull the metering rods and springs. It’s just two screws with the air cleaner off. The manual will show the vacuum range of the spring based on color. If you’ve got a vacuum leak, or any problem causing a little bit low vacuum, you could be running with the enrichment open (power valve on other carbs). That will run you rich, especially if the throttle hangs open a bit. I think a vacuum leak or other mis adjustment is more likely, but it’s easy and free to check.

I like those Edelbrocks, I’ve used them on Yblocks and other motors. Takes a while to understand the tuning chart, but for me it finally made sense. Your language skills seem fine to me.

|

|

By Tedster - 7 Years Ago

|

The language barrier complicates things but there are translation abilities online today that make things a lot easier than it used to be.

What you want is the Ford Shop Manual for your car. It will have all the specifications and setup adjustments to optomize the tuning. MoToRs Repair manuals also have a very good tuneup section at the beginning.

Today I always suggest that any "new" car someone takes ownership of first have the true TDC "0" mark on the vibration damper checked or verified with an 18mm piston stop. Comp Cams part #4792; or, you can make one from an old spark plug and threaded rod. Pull all the spark plugs, install the tool in the #1 cylinder, turn the engine over by hand in both directions till the #1 piston hits the stop. The true #1 TDC lays exactly halfway between these two points. It is important to verify this, because all subsequent ignition timing events are predicated on this start point being true and correct. It is very common for the outer steel inertia weight to slip off its "clock" or axis, making the timing marks on the damper inaccurate. If the damper on your engine is original it should be replaced regardless.

A cylinder compression test will also prove if there are other engine derangements. Make sure all the spark plugs are removed and throttle & choke blocked open wide, and battery is charged completely. Gauge Needle should move quickly and powerfully to a high level relatively quickly, and ideally all cylinders within 10%

16" of idle manifold vacuum isn't necessarily too bad, but this is dependent on the type of camshaft installed, (and your local altitude) a stock motor in good condition should pull about 20" at Sea level. If you have a stock motor, then it sounds like retarded ignition timing, or tight valve lash, or both.

If you take a deliberate, methodical approach to troubleshooting, setup, and adjustment for every component and system you will be rewarded with a fine running machine, you'll get there.

|

|

By johnnydidd - 7 Years Ago

|

|

My 56 Merc had the same problem, put an insulating block carburetor, I am using compressed wood one, solved p;roblem

|

|

By newbill - 7 Years Ago

|

I had the same problem with my 56 Victoria dying after it had been idling for a while. It would start right back up and it would run fine out on the road. Some months later it started cutting out and dying if I tried going over 60 MPH. It was starving for fuel. So I did a fuel pump test to check its pressure and flow rate. Pressure was fine (5 psi), but flow rate was way under what the manual calls for (way under 1 pint in 30 seconds at normal cranking RPM). The old original fuel pump had finally given up. I would recommend you do a fuel pump test. Disconnect the fuel line running from the fuel pump to the carburetor at the carburetor. Connect a hose to the end of the fuel line long enough to reach a container (not glass, for safety reasons). You are messing with gasoline here, so be careful. Make sure the hose fits the line tightly so it won't leak. Crank the engine for 30 seconds and check the amount of fuel in the container. Should be at least 1 pint. You can connect a low pressure gauge (or vacuum gauge that has a pressure scale) to check for 4 - 5 psi.

|