|

By charliemccraney - 9 Years Ago

|

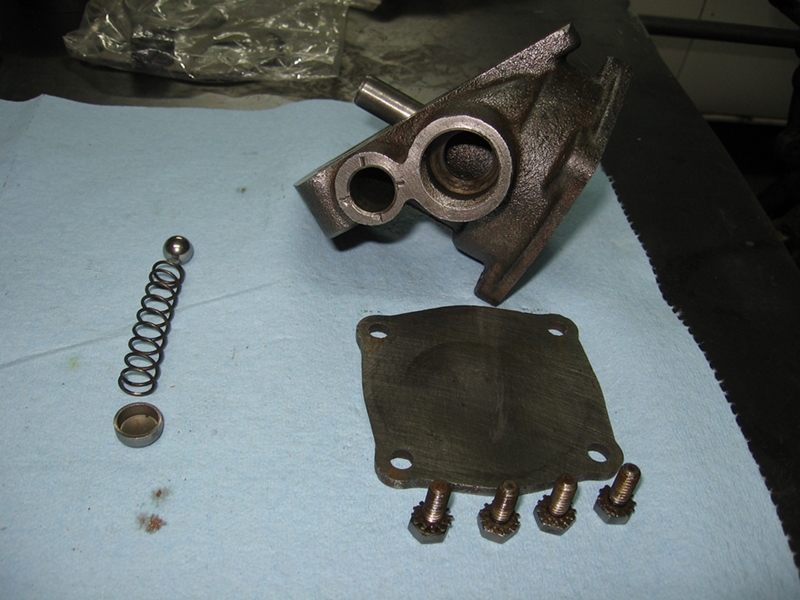

I got a hold of one of these. The most significant difference, aside from the material, seems to be the bypass valve. It is a ball, rather than a piston and uses a press in plug, rather than screw in. I think that might be a better design. The ball seats in a taper at the end of the bore and is quite a bit smaller than the bore so it will not stick like a piston might. It should also make it easier to dial in the desired pressure. If you shim the oem spring too much, it can come out of the bore in the plug and cause the piston to bind. No chance of that happening here. I'd be more comfortable with a screw in plug so I'll see how easy it will be to modify that.

The only thing I see cast onto it is W 5779 A and 3 dots. It looks like it might be based on the ECG pump because of the cover orientation, which is different on the C1 pump. I'll take a closer look and compare to some Ford pumps later.

|

|

By 57RancheroJim - 9 Years Ago

|

Interesting find. I've never been able to locate an aftermarket one.

|

|

By charliemccraney - 9 Years Ago

|

|

This one was on eBay. I've hoped to come across one for several years, since I heard Ted say they exist.

|

|

By Lord Gaga - 9 Years Ago

|

Not so easy to remove plug to change spring/shims on that pump...seems to be a cheaper to manufacture reproduction.

I'd rather have a threaded plug. If that one should pop out, you're screwed! Just my opinion.

|

|

By Ted - 9 Years Ago

|

|

Good find Charlie. I’ve come across several of the aftermarket iron gerotor pumps but all were similar to the FoMoCo aluminum gerotor pumps in design including the spring loaded piston and the threaded screw in cap holding it all in place. Yours having the spring loaded check ball and having a press fit plug rather than one that screws in is definitely different; I’ve never come across a pump like that one. I did a Buick 401 Nailhead recently and it had a ball check valve in the oil pump but it kept the oil pressure at a constant 35-40 psi regardless of the rpms. I’m in the same camp as Lord Gaga on the press fit plug but I suspect that the housing you have could be threaded for a conventional screw in plug of some sort. If you’re interested, I could run that pump on the dyno mule just to see how the oil pressure with a ball check valve compares to the piston design. I’m thinking that the oil could be stepped up to a 20W-50 just to force the oil bypass to work sooner for a dyno test.

|

|

By 57RancheroJim - 9 Years Ago

|

It would be nice to find out who the manufacturer was. More then likely some extinct small company. I wonder what pumps were used on the South American Y's?

|

|

By charliemccraney - 9 Years Ago

|

I compared it to a couple original pumps. It does look like it is based on the ECG pump but it is not an exact copy. So whoever produced it must have used the ECG as a reference for the design.

The rotors are the same and the cover plate o-ring recess is the same so a Melling kit will work to rebuild, if necessary.

The bypass bore measures .558" with my caliper, so that's 9/16" bore, which is just about right to tap for a 5/8" plug, like the originals.

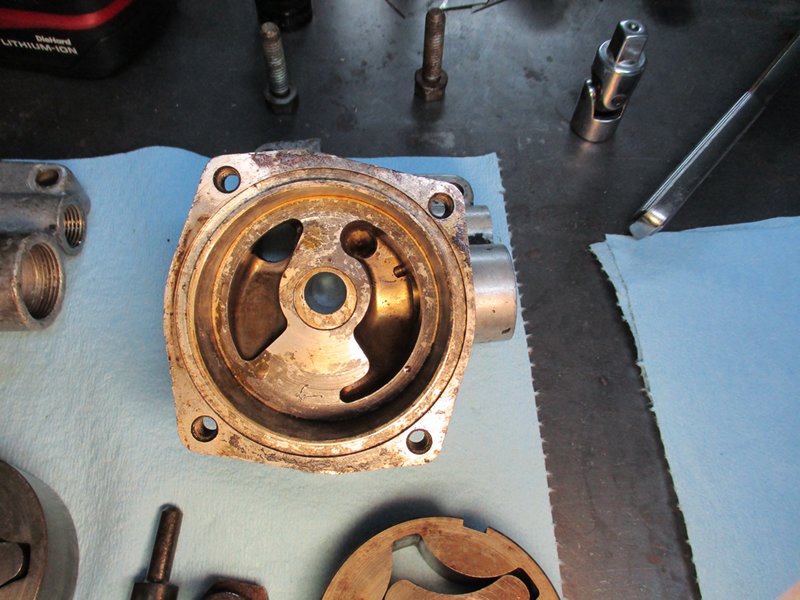

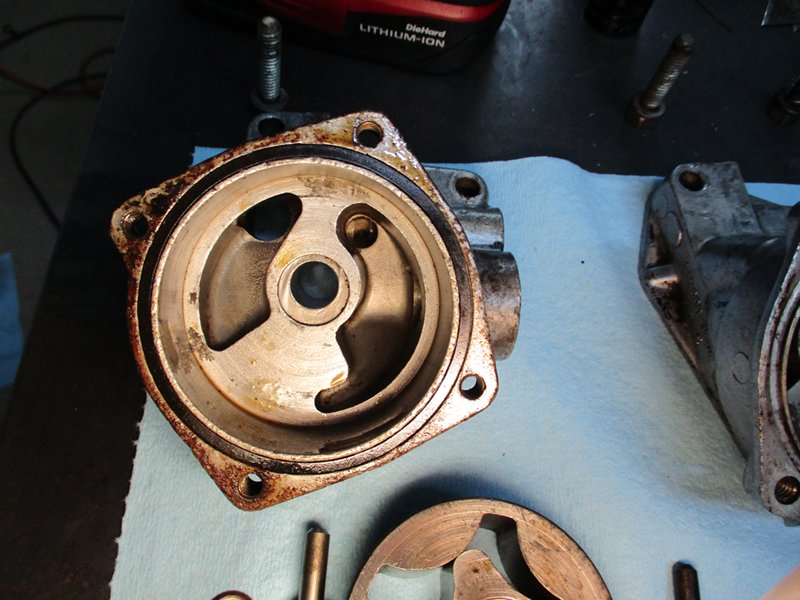

My observations are made with caution because the pump had already been disassembled when I got it. Two differences stand out, not including the bypass valve. One is that one of the cover plate holes is counter bored. It does not look like it has been stripped. Another is the threaded boss for the one of the three bolts that hold it to the block. There is a recess in the casting of originals, limiting thread engagement to only about 1/4". On this one, the recess is not present, allowing for more threads, which is good to prevent careless installers from stripping them, which I have seen in many aluminum pumps.

Counter bored hole, upper right hole:

Mounting bolt thread boss recess, toward the right side of the pump:

To show what I stated earlier in the thread regarding the cover plate orientation. Iron top, ECG left, C1AE right:

This helps to see the bypass valve piston stop extension of the original pumps. With the ball, that will never be in the path of the oil flow. The pistons can only move by about 23/32" because of interference with the piston and plug, which would pull it all the way out of the flow but that would only occur at the highest pressure if it happens at all.

|

|

By 57RancheroJim - 9 Years Ago

|

Good comparisons, wish we could solve the mystery as to the manufacturer.

|

|

By charliemccraney - 9 Years Ago

|

A picture with a stock bypass valve and components, to see how different they are. The spur gear pump has a slightly different piston and spring but looks about the same as the original gerotor parts.

|

|

By 57RancheroJim - 9 Years Ago

|

The difference in design looks like a simple case of how can we make it cheaper.

|

|

By Lord Gaga - 9 Years Ago

|

57RancheroJim (10/14/2017)

Good comparisons, wish we could solve the mystery as to the manufacturer.

It was probably made somewhere in India!

|

|

By charliemccraney - 9 Years Ago

|

I will be sending it to Ted for testing so as long as he is comfortable using it, we will have some real world functionality info about it.

It could be that the bean counters wanted it cheaper. It could also be that the factory design is overly complex.

|

|

By 57RancheroJim - 9 Years Ago

|

Did you modify it for the screw in plug or are going to test it with the press in?

|

|

By charliemccraney - 9 Years Ago

|

|

I haven't made any modifications, yet.

|

|

By Ted - 6 Years Ago

|

I did find out some of the back story for the iron gerotor oil pumps that use the check ball for the bypass rather than a piston. Those pumps were made specifically for the military as there was an issue with the oil relief valve pistons ‘sticking’ when the engines set up for extended periods of time. The use of a ball fixed that particular problem.

Charlie. I am getting closer to performing a full blown oil pump test on the dyno mule which will include your ‘ball relief valve’ oil pump. Driving this upcoming dyno test is the development of a new oil pump for the Y.

There is a new oil pump for the Y being designed as we speak that will incorporate what is called ‘paddle wheel’ technology. That new pump is also incorporating a spring loaded ball instead of a spring loaded piston for the relief valve. The 'paddle wheel' technology is already being used on some specialty oil pumps for other applications and that new technology has solved some of the issues with the normally slow exit speed of the oil when using spur gear oil pumps.

|

|

By Dave C - 6 Years Ago

|

Along the lines of this subject I have a question. Ted has an article where he fabricated a hi volume oil pump for a Y. My question is since finding a Gerotor pump is damn near impossible can you use a Melling Gerotor rebuild kit and use it in the spur gear housing?

Dave

|

|

By Hoosier Hurricane - 6 Years Ago

|

|

No, gerotor and spur gear parts are not interchangeable at all.

|

|

By Dave C - 6 Years Ago

|

Dang. Thought I had something there..

Dave

|

|

By charliemccraney - 6 Years Ago

|

|

Where can I find info about "paddle wheel" tech?

|

|

By Ted - 6 Years Ago

|

Try this link for some more detail.

https://www.aa1car.com/library/oil_pumps_high_flow.htm

|

|

By charliemccraney - 5 Years Ago

|

I've acquired another with a standard piston style bypass. It was listed as a Melling HV HP oil pump. It didn't come in any box but it looks brand new.

The tag has HM42 and 91282. The bottom plate looks cast with HP cast into it. The main casting itself has 542 on one side and on another side, 5201 with a larger 2 to the right, with a diamond shaped logo which looks like it has the letters BCI in it. I like the shape of the cover. It provides a way to tell how to orient the cover. On the stock ones, it's not so obvious. Minor detail but nice if you take it apart. The rotors are the same depth as stock so it's not a HV (High volume) pump. None of the cover plate bolt holes are counterbored in this unit. Come to think of it, that counter bored hole in the other may be for easier orientation of the cover to that unit.

The pump housing is most similar to an original ECG pump. The cover plate end is clocked differently on a C1AE pump.

ECG left, Iron right.

The most apparent difference that may have any effect on performance (HP?) is the size and shape of the cavities in the housing, the passage to the engine is more open and about .050" larger in diameter and the bypass passage into the rotor cavity is larger. That bypass passage looks to be as cast in the iron unit and drilled in the originals.

I don't know if my other is similar in these areas. I don't have pictures with the rotors removed and it is at Ted's at the moment. That one wasn't advertised as anything special so I didn't think to take a closer look.

Iron:

C1AE:

ECG:

The bypass piston is different from the stock gerotor pumps I've taken apart but looks to be the same as at least one piston I have removed from a spur gear pump.

Center and left, original gerotor. Right Iron:

Differences on the block side.

C1AE left, Iron Right:

ECG left, Iron right:

|

|

By famdoc3 - 5 Years Ago

|

|

I’m just putting together my new y and was lucky enough to have to gerotator pumps. I found the number for the rebuild kit on a T’bird site from Gill Baumgartner. Melting kit came, went together and feels smooth as pie.

|

|

By DryLakesRacer - 5 Years Ago

|

The photo of the plungers shows 2 machined rings from georotor pumps, mine had none. Are they normal. Thanks

|