|

By dennis22 - 8 Years Ago

|

I have put my 272 Y block back together after a rebuild, only to come to break-in and she won't start. Just seems like a timing problem. As I don't know too much I'd thought I'd try the collective knowledge of you y blockers.

Now regards to ignition/timing, I have a new cam, valve springs, timing set, crank dampener and MSD distributor and coil and new leads and plugs.

Bit of insight-

I set #1 piston at TDC compression stroke and counted 12 pins between timing chain marks. The new dampener's timing marks also correspond to #1 TDC. So at this stage I'm looking good. I marked where I wanted #1 lead on my dizzy cap, transferred it down and dropped the dizzy in with the rotor pointing a #1. I then cranked the engine by hand until piston #1 was at compression TDC and checked rotor was still pointing at #1. All good.

After checking a few thinks I tried to start the engine... I threw a tiny bit of fuel in the carby and cranked her over. Nothing- kept cranking until fuel was fully primed in carby. I then left it for 15mim to think and tried again, still nothing but a couple of coughs.

I'm not sure if it has anything to do with the new MSD dizzy and coil or something I have done wrong.

Any help would be appreciated. Thanks, Dan.

|

|

By ponymare - 8 Years Ago

|

|

Were the timing marks on the crank, cam, to your right while standing in front of the engine looking at it? and are the valves set with the proper clearance?

|

|

By 57RancheroJim - 8 Years Ago

|

How did you determine it was on the compression stroke? Could be 180 off. Did you try turning the distributor a few degrees either way?

Nice looking engine, what headers are those? Is that an aftermarket bell housing you have the OD trans bolted to?

|

|

By charliemccraney - 8 Years Ago

|

If you determined that number 1 is on compression while installing the timing chain, then you are 180 out. When you install the chain and have the 12 pins, #6 is on compression and #1 is on exhaust.

Pull a the valve cover, turn the engine untill both of #1's valves are closed. When they are closed, they will wiggle slightly because of the clearance. If they do not wiggle, then they are on overlap of the exhaust stroke (or adjusted incorrectly). That will be the compression stroke of #1. With the damper indicating 0, remove the distributor cap and see if the rotor is pointing to #1.

|

|

By kevink1955 - 8 Years Ago

|

I hope the 12 pins and marks were on the right, the Eckman book is wrong when it says they are on the left.

|

|

By 57RancheroJim - 8 Years Ago

|

It's referring to the left side/bank of the engine not your left hand.

|

|

By 56_Fairlane - 8 Years Ago

|

It's not going to start because you painted it the wrong color.

|

|

By miker - 8 Years Ago

|

|

Don't believe him Dennis, mines that color and it starts just fine.😀

|

|

By BamaBob - 8 Years Ago

|

|

Dennis22, another thing to check is to be sure the plug wires are installed in the correct firing order-the distributor rotates counter-clockwise, therefore the plug wires should be firing around to the left in the distributor cap.

|

|

By dennis22 - 8 Years Ago

|

Ok, so I'll try to answer everyone-

Ponymare- yep the timing marks were on the right when looking at the engine, and the valve lash is correct.

57RancheroJim-

I determined #1 TDC by putting my thumb over the plug hole and cranking the engine by hand until the pressure blew my thumb off.

Not sure about the bell housing- it was like that in the truck when I bought it- see below pic, and the headers are from eBay, advertised as thunder bird headers.?

Charliemccraney-

When I put the heads on I adjusted the valve lash and got #1 TDC Using thumb over the plug hole method. When dizzy was put in I cycled through the strokes with thumb over plug hole method until I got #1 TDC and looked at the dizzy rotor and it was at #1 plug and the dampener wat in marking TDC. I don't think I have installed the dizzy 180 out but you never know, I'll recheck with a fresh mind today.

56fairlane and Miker- the paint is pretty scuffed up now it was way nicer before the rebuild- I cleaned it up and painted it before I had convinced myself it needed to be rebuilt

Before shot-

Bamabob-

I have the shop manual and the y block rebuild book, so I'm sure the firing order is correct and is going in the right direction- I will double check though.

Thanks for all the great feed back! I will go and check everything again. I'm sure it's a timing problem, I'll keep you updated.

|

|

By Joe-JDC - 8 Years Ago

|

|

If you are starting the engine on an engine stand, do you have the engine grounded to the battery and stand? Positive ground vs negative ground? What year engine? You need both battery cables, not just positive if it is on the stand. Joe-JDC

|

|

By dennis22 - 8 Years Ago

|

Joe- The engine is on a stand and the battery is grounded to the engine and stand. Thanks.

The stand is exactly the same as before the rebuild and the engine ran fine with it on the stand.

Could there be a problem with the clutch and pressure plate putting too much force on the flywheel? I had a bit of trouble lining up the shaft when putting the trans back on. Not sure if it's just me but it seem as if the engine cranks slower and is harder turning over, plus the starter is getting red hot. I fully charged my battery last night and gave it a crank this morning, it sounded better- like it might start, but nothing!

I re-checked #1TDC and made sure the rotor was at #1. I ran back through the firing order cranking the engine by hand and checked the valve lash- all good.

I'll do a quick compression test too.

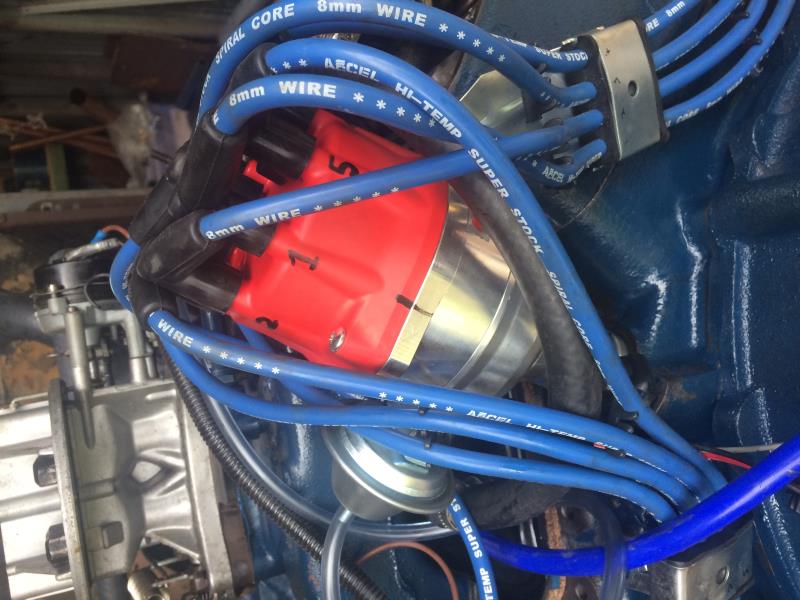

View of dizzy from pass side

|

|

By dennis22 - 8 Years Ago

|

Just checked #1 and #4 for compression and got this reading. This reading was after 3 compressions, I went for 4 but it didn't change.

#1

#4

I'll check the rest.

|

|

By 57RancheroJim - 8 Years Ago

|

Thanks for the picture of the bell housing, it just didn't look like a stock on in the earlier picture, probably my old eyes.

Looks like the firing order is correct. Compression is a little low, but on a new engine I wouldn't worry to much it will take a while for the rings to seat but it should be enough to fire it. Did you have the carb wide open when you took the test?

Have you pulled a plug wire while cranking it to see if its actually getting spark to the plugs?

|

|

By dennis22 - 8 Years Ago

|

57RancheroJim- i didn't have the carb wide open. I did pull #1 plug and tested for a spark, it looked like a good spark. I have ordered an inline spark tester and remote starter, with these i hope to be able to watch the dampener marks and see if the spark is in time with the dampener markings by releasing the remote start when the plug sparks- or at least thats my idea.

Otherwise I'm not sure whats happening, i have been trying to upload a video of the engine kicking over but I'm having trouble, the attachment loading thingy just keeps flashing.

I really worried about damaging my cam and lifters now, although i did throughly lube them up with cam lube, fingers crossed!

The battery dies real quick while trying to crank the engine. Its a brand new Optima 35 (red top) and it cranked the engine ok before the rebuild.

|

|

By miker - 8 Years Ago

|

|

A red hot starter and a dead battery is a sign of very high friction, causing a very high load. Get the mis aligned trans off it and see what happens. With good assembly lube you're probably ok on the cam. But that motor should just spin, even if it doesn't fire. Timing or firing order off, it might hesitate or backfire. Sounds to me like the trans is binding it up. The low cranking speed will reduce the compression test reading. Get the trans off, and if it doesn't spin, pull all the plugs. Even a new motor with the plugs out should just spin on the starter.

|

|

By dennis22 - 8 Years Ago

|

OK Miker, I'll get that trans off and see what happens (hopefully that might be the source of the problem). The bellhousing and trans came off together, when i put it back on it just didn't feel right, but with my inexperience i didn't know any different. So I'll do that, unfortunately i live about 3 hours away from the place where I'm working on the y block, so ill have to wait until next weekend to give it a shot.

If i think of anything else ill give you guys a shout

|

|

By charliemccraney - 8 Years Ago

|

Did you prime the oiling system? No matter what the answer, it will be wise to do it again, given all the cranking with no start, to ensure that the bearings are still lubed well.

|

|

By dennis22 - 8 Years Ago

|

Charliemccraney-

I did prime the oil system using a drill an an old torn down distributor, oil pressure readings were in the range of 65-70. I will keep that in mind for next weekend when I try again.

|

|

By BamaBob - 8 Years Ago

|

Dennis,

From all that I have read here, it seems to me that the problem is in the turning of the engine works. That is, there must be binding somewhere to make the starter overheat and discharge the battery rapidly. Did the engine turn freely with a wrench on the crankshaft before you installed the clutch and transmission? If so, the post about a mis-aligned clutch/transmission assembly sounds like a very probable cause.

|

|

By 57RancheroJim - 8 Years Ago

|

I can't picture how a trans and clutch would go together if it was misaligned,?

|

|

By MoonShadow - 8 Years Ago

|

|

The trans shouldn't have been hard to get in once aligned. Perhaps its too tight in the input shaft bushing? I would at least loosen it up and see if that makes a difference. Sounds like your starter doesn't have the power to turn the engine. Definitely need to find out what is stopping it.

|

|

By YBLOCKEREDH - 8 Years Ago

|

I just finished a 312 engine rebuild start on stand. My starter that cranked the old motor very well barely turned my engine, drained my brand new battery very quickly, made starter hot. Pulled starter and bench tested and spun like crazy. Took it to an old starter generator shop for testing, was told it was good that my ground cable needed to be secured at the starter mount bolt not engine and a suggestion of all new cables was in order. I did all that with charged battery overnight and got a 10% improvement in cranking, would give a little cough and battery die. I was really concerned about my new cam and lifters as well at this point. Although I did not have my tranny attached as you I was going through all the steps you are. I finally said screw it and bought a $100 rebuilt starter from Napa if nothing other than to compare the new/old and put that thought to rest and move on with other remedies. I set my damper on 12 deg. btdc attached my test light to the input wire on side of dizzy and slowly turned the dizzy until the current was broken indicating my points had just started to open on #1. hit the remote starter and the new starter cranked like a maniac and the engine immediately came to life. It was quite shocking and unexpected. Be prepared to grab the throttle , I stood there dumfounded in disbelief that it started so quickly and watched as it died. End result is it runs fantastic, cam and lifters are holding their adjustment so I think all is good. Another on this blog had told me he went through the same experience with his old starter in new motor and a new starter was a game changer. I hope you get this sorted out, it is very frustrating but in most cases sometimes its the obvious especially if you had a free wheeling motor by hand with plugs out . For the sake of spending the extra on starter I would try without tranny attached as suggested first. GOOD LUCK !!!

Gary

|

|

By 2721955meteor - 8 Years Ago

|

glad it all worked out.tho i am sure if you had primed the intake with oil and gas mixture you would not have a need for the new starter,

ENGINE NEW TIMING SLIGHTLY OFF STATER NOT 100% EVEN IF PRE LUBED VAVES HAVE LITLE LUBE,RINGS ARE DRAGING,REAR SEAL TIGKT,BATERY WEAK all is against the starts system,oilwithe gas into carb gives all these issues a boost. have saw this same issue maney times. with older cars we usually pushed started them first start, until a season mechanic came along and showed the light. laugh if you wish.

|

|

By YBLOCKEREDH - 8 Years Ago

|

Still doesn't explain why a new starter would crank 20 times faster, I however do get the idea of oil in the gas just like a 2 stroke for extra lube ...I will use that idea on my next one makes total sense. I did also have oil spread around the bores before and after piston assembly . When I changed my starter I gave the old one one last try on the fresh battery ...same result. Pretty sure the old starter is shot even though I completely disassembled inspected cleaned . The armature looked great the brushed were barely worn. The starter shop also inspected the parts and thought the starter looked and tested fine, but it wasn't.

Gary

|

|

By dennis22 - 8 Years Ago

|

BamaBob (2/14/2017)

Dennis, From all that I have read here, it seems to me that the problem is in the turning of the engine works. That is, there must be binding somewhere to make the starter overheat and discharge the battery rapidly. Did the engine turn freely with a wrench on the crankshaft before you installed the clutch and transmission? If so, the post about a mis-aligned clutch/transmission assembly sounds like a very probable cause.

The engine did turn freely before and after the instillation of the trans.

I just pulled off the trans and it cranked a little easier, but the starter motor started spinning out when it sounded like it was almost starting.

I think maybe it worked just ok when the engine was a bit "tired" and now after the rebuild everything is just that little bit tighter the starter can't handle the load.

|

|

By dennis22 - 8 Years Ago

|

YBLOCKEREDH (2/14/2017)

Hi Gary, I have just ordered a new starter, so I'll see how that goes. Hopefully that's all it was. Now that I think about it... I think that the starter was struggling before, so its due for a replacement anyway, or at least I'll keep telling myself that.

|

|

By BamaBob - 8 Years Ago

|

Hi Dennis,

All things considered, I think you are on the right track with the new starter. That comment about the starter spinning out means the starter drive also needs replacing. That spinning out will only get worse with further use. Good luck and let us know how it works out!

|

|

By YBLOCKEREDH - 8 Years Ago

|

Hello Dennis,

I was looking over your earlier posts you mention grounding your engine to the engine stand, might be worth a try grounding the starter directly from starter mounting bolt to the neg. post on battery.

Gary

|

|

By dennis22 - 8 Years Ago

|

Ok, update time....

So my starter arrived today from Dennis carpenter and I installed it. I cranked the engine over with high hopes but nothing.... not even close. I was deflated to say the least😩.

I checked all the leads for continuity (although they are brand new with new plugs) put I just went into check everything mode. I pulled no1 plug and found TDC, lined up the dizzy to no1 lead and fiddled around with the wires and leads making sure everything was on tight. I tried again. Nothing.

I pulled all the plugs, cleaned them, pulled the dizzy out and re positioned it to get a bit more advance timing movement (a bolt in the cylinder head was stopping it from rotating fully)

Anyway, I found TDC lined up the no1 lead on the cap and screwed it down. Cranked it over and..... nothing!

At this stage I have given up, so I walked inside and had some lunch. After lunch with a fresh head, I thought I'll just go back over and clean up and have a fiddle around. I pulled all the leads off, pushed them back on, checked all the wires again and thought what the hell, one more try won't hurt! And BANG, she fired and roared to life, I shit myself and killed it accidently. I turned it over again and she roared right up again. Turns out I didn't clamp down the dizzy bolt and when I was fiddling with the leads It had rotated the dizzy to the max advance it could rotate.

It was running a little rough so I killed it and re-positioned the dizzy to gain more rotation on the advance and cranked it over again. I rotated the dizzy until it sounded ok and grabbed the timing light. At this stage I will admit I have never used a timing light before. The timing was 30-40 degrees advance when it sounded good. I wound it back to 10 and it started sounding a bit heavy and slow.

So in the end all it needed was more advance timing. But I thought 30-40 seemed a bit extreme. I have a new MSD ready to run distributor, a new dampener and cam from John Mummert.

Does 30-40 sound like too much to you guys?

|

|

By Ted - 8 Years Ago

|

dennis22 (3/4/2017)

.....So in the end all it needed was more advance timing. But I thought 30-40 seemed a bit extreme. I have a new MSD ready to run distributor, a new dampener and cam from John Mummert. Does 30-40 sound like too much to you guys?

Make sure you are using a conventional timing light and not a ‘dial back’ timing light. Your timing at 30-40° at idle sounds excessive. Also keep in mind that you should be checking the timing with the vacuum advance unhooked.

I’ll suggest checking that the damper ring has not slipped on the damper hub. Assuming that checks out okay, then the camshaft timing comes to mind. Did you degree in the camshaft when assembling the engine? A cranking compression test at this point could provide some additional information regarding the camshaft timing. Lower than expected compression readings will point to the camshaft being retarded while advanced will have the compression readings on the higher side.

While not as nearly as accurate as a degree wheel and dial indicator for checking the camshaft timing, you can put either the #1 or #6 cylinders at ‘perfect’ overlap at the intake and exhaust valves and then check where the timing mark falls on the damper. With the exhaust valve closing and intake valve opening, find the point where both rockers are level or depressed the same amount. This is somewhat difficult with the factory iron rockers but very easy with aluminum rockers where a flat straight edge can be placed on top of the rockers. If the damper reads between zero and eight degrees advance, you are in the ball park. If you find it reading 15 or more degrees out in either direction, then this would bear further examination.

|

|

By charliemccraney - 8 Years Ago

|

If that is 30 to 40 degrees at a normal idle speed, then yes, it is too much. Most likely, you are getting a false reading rather than that being the actual timing, because most engines get hard to start at about 20 degrees of advance. With 30 - 40 it just would not be happening.

More likely, you either had vacuum advance connected, providing an false indication of your initial timing. Also, since it is the first start, it should be set up to run much faster than idle for break in, in which case, you are also seeing the effects of the added mechanical timing.

|

|

By dennis22 - 8 Years Ago

|

Thanks Ted,

Yep first mistake- timing was with vacuum on and I forgot I had it running up on the rpm. I guess I was a bit excited and went at it with the timing light too keen.

Also the dampener is brand new from summit.

I didn't degree the cam, I guess I really should have, but I haven't spent enough time to exactly understand the process.

I have a water leak at the timing cover so I won't be starting it until I fix that (see my water leak post if you have any ideas)😊 But I will read up on cam degree, and have a mother res of your post, thanks.

But I'll be sure to get the advance vacuum plugged and engine idling before I whip out the timing light again.

|

|

By dennis22 - 8 Years Ago

|

charliemccraney (3/4/2017)

If that is 30 to 40 degrees at a normal idle speed, then yes, it is too much. Most likely, you are getting a false reading rather than that being the actual timing, because most engines get hard to start at about 20 degrees of advance. With 30 - 40 it just would not be happening. More likely, you either had vacuum advance connected, providing an false indication of your initial timing. Also, since it is the first start, it should be set up to run much faster than idle for break in, in which case, you are also seeing the effects of the added mechanical timing.

|

|

By dennis22 - 8 Years Ago

|

|

Charlie thanks mate, as I said to Ted I was a bit excited and bungled everything up. I will reset and try again and let you know how it goes.

|

|

By dennis22 - 8 Years Ago

|

Ok, so I checked the timing again.

-I pulled the vacuum advance off the dizzy and plugged it up

- set the rpm to 800 and put the timing light on.

The engine was running pretty rough at 800rpm 10btdc but it didn't too bad.

I revved it up to about 2500-3000 and the timing went up to about 35. Then I idled again and was back to 10.

I then hooked up the vac advance and the rpm jumped up to 1100 and the engine sounded smoother but faster.

This is the timing light I'm using. The rpm is on the right and you can set degrees on the left. (Not sure what that's for)

Anyway I'll fix the water leak and have another go at it. Seems like vacuum is in the range of 15.

|

|

By charliemccraney - 8 Years Ago

|

That is probably an electronic version of a dial back timing light Ted mentioned. You set the timing on it for the advance you are looking for. When you check on the engine, 0 degrees, as indicated by the damper will be the number of degrees you entered on the light. It can be useful for stock dampers that don't have marks the whole way around but they are often less accurate.

Idling rough at this point is not necessarily a bad sign, as the engine is not yet tuned and if you have a bigger cam, then it simply will not idle smoothly, but do not ignore things and simply push through the break in. If something seems wrong, shut it down, fix it and then continue with break in.

|

|

By dennis22 - 8 Years Ago

|

Thanks for the info Charlie.

So if I set no1 piston at TDC and TDC on crank dampener I should leave the degrees on the timing light at 0. What happens when I advance the dizzy 10deg, do I change the timing light or leave it at 0.

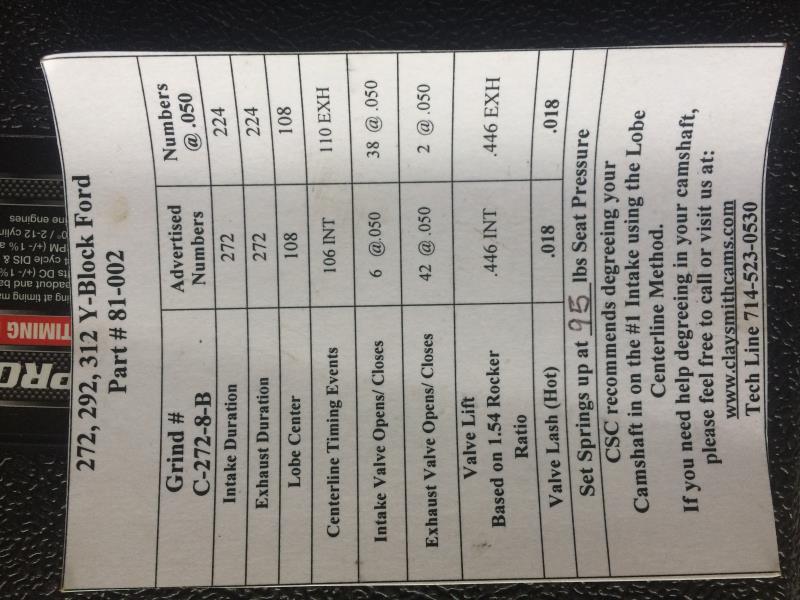

I have a new cam. It I'm not sure what it should sound like at idle, this is the cam card if it's of any help.

This "break in" isn't going as smooth as I had expected but I guess it's all valuable experience and that's what I'm in it for!

Could I have made a critical mistake not degreeing my cam? Is it possible the cam could be that much out? Ps I got the cam from John M.

|

|

By Ted - 8 Years Ago

|

|

dennis22 (3/4/2017)

....Also the dampener is brand new from summit.

I didn't degree the cam, I guess I really should have, but I haven't spent enough time to exactly understand the process.

Assume nothing with new parts. That means double checking that the TDC on the new damper aligns with the timing pointer when the #1 or #6 piston is indeed at TDC. Simply eyeballing the piston for TDC can still have it off 3-4° from actual so extreme care must be taken when determining the actual piston TDC.

Due to manufacturing variances with all the various pieces involved in the cam timing, the camshaft timing itself can be off considerably. I’ve had more than a single instance where the cam timing was off by as much as eighteen degrees and this with the gears properly aligned either by marks or link count. The various places for the cam timing to be off besides the camshaft itself would be the various points that the cam gears attach to the camshaft and crankshaft. What contributes to more error than normal would be stackups and this is where the manufacturing variances are all positive or negative in nature. In these cases, the variances all add up thus compounding the amount of error. All this is easily fixed or compensated for by degreeing in the camshaft and moving either the crank gear or cam gear accordingly.

If you don’t degree in the camshaft, then it’s simply pot luck on where the camshaft is actually installed. If there are tuning problems on a freshly built engine and the camshaft has not been degreed in, then this is an area that may have to be revisited. Only by degreeing in the camshaft can the exact cam timing be determined and corrected if necessary.

Here are some links that cover camshaft degreeing in more detail.

http://www.eatonbalancing.com/blog/2015/09/24/degreeing-in-the-camshaft-part-i-finding-tdc/

http://www.eatonbalancing.com/blog/2015/09/24/degreeing-in-the-camshaft-part-ii-phasing-the-camshaft/

http://www.eatonbalancing.com/blog/2015/09/24/degreeing-in-the-camshaft-part-iii-its-twelve-pins-between-the-marks-for-the-ford-y/

|

|

By charliemccraney - 8 Years Ago

|

Refer to the instructions to understand how to use the timing light. If you leave it at 0, then it should work like a regular light.

I would expect that cam to be a slightly lopey at idle.

|

|

By DryLakesRacer - 8 Years Ago

|

Degreeing a cam was always a "black art" to me. Once I learned by following exact instructions and knowing true TDC everything became easier. It was really difficult when there were very few ways of moving the crank or cam gear other than an offset key and if you were building an engine that didn't have a chain you had to think in reverse. The cam card is a must and is one the most important references you never throw away. Now I do it with the heads off and the largest degree wheel I can find.

Today with crank gears with at least 3 settings all is a little easier with the correct tools. On our current racing V8 we use an adjustable cam gear which we can do by removing the water pump and a plate on the timing chain cover. It is not a Y.

Many, many years ago guys could never figure out why some stock cars just ran better than others right from the factory. Some guys knew about rear gears being a edge but some were just plain lucky with an engine that had a 2-3* advance cam. Good Luck

|

|

By Sandbird - 8 Years Ago

|

|

What heads are on this engine?

|

|

By dennis22 - 8 Years Ago

|

|

The heads are mismatching at the moment. I'm trying to track down another matching head. I have 1 big letter ECZ-G and 1 COAE.

|

|

By Sandbird - 8 Years Ago

|

|

It would be interesting to see what the cranking compression is on the opposite side to see how much, if any, difference there is between the two different heads.

|

|

By charliemccraney - 8 Years Ago

|

|

That is quite a mis-match with the heads. It will be impossible to tune well because you effectively have 2 engines sharing a common crank and carburetor, each with different fuel and timing demands. It could contribute to a rough running condition.

|

|

By dennis22 - 8 Years Ago

|

Charlie, I asked this question a while back, seems that in the short term it probably won't matter too much, but the long term effects would be unknown. It would be interesting to know though.

It's just so hard to find anyone that wants to sell a decent spare ECZ-G head. And seeing that the engine won't be in the car and driving for another year I will just keep searching until one pops up.

|

|

By PF Arcand - 8 Years Ago

|

Dennis: I don't know if you'd want to pay the shipping..but a possible contact for another "G" head might be John Mummert in Calif.. ( see link) Because he has stated that he has run across later posted heads that were cracked, which may have resulted in a good head left over? He has shipped to Australia... Or you could try another guy that has many parts, (Mike) Henaults Enterprises in La Grange Calif. Call 209-852-2476 (calif time) or e mail- henaults@jps.net

|

|

By dennis22 - 8 Years Ago

|

If you caught my earlier post about the water leak- you may already know that I have finished the run-in process and finally have the timing pretty well dialed in.

I am getting a constant 15-16 on the vacuum gauge with the stock air cleaner off. As soon as I put the stock air cleaner (oil bath type) back on, the vacuum dropped down to between 5-10. I'm planning on converting the old air cleaner to a modern filter and cut a few extra breather holes. Anyone have a similar experience? do you think this will help the problem?

|

|

By chris70 - 8 Years Ago

|

Hi Dennis,15/16 hg of vacuum with a non stock cam is ok at idle,but schould not drop to 5 when you put the air filter on.If its bouncing from 5 to 10 it is a vacuum leak.

Check your hoses maybe the filter is hittig somewhere you didn't noticed.Be pacient,i rebuilt my engine from the ground as you did and took me over a year to work all the bugs out and get it running like it schuold!!!!

|