|

By thundercat - 9 Years Ago

|

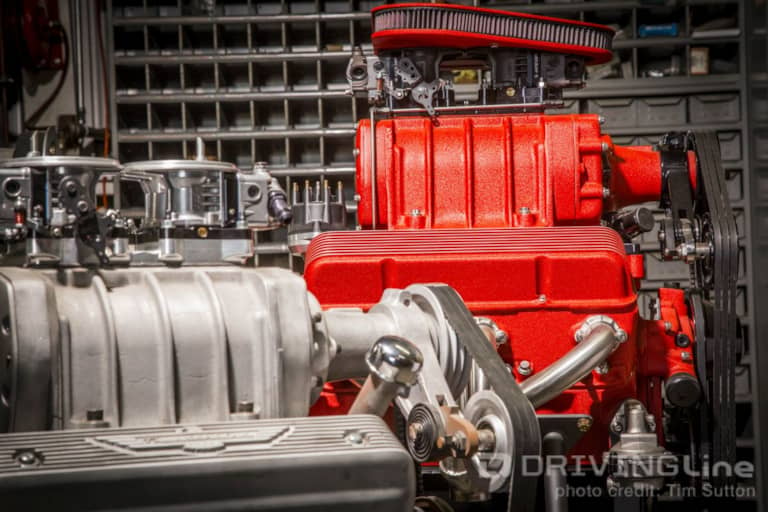

I finally finished my project.. Ive been sneaking out nightly to test & tune . Got my state inspection sticker last Thursday and drove 250 miles to & from Car Show in Northern Pa on Sunday. It still needs to learn fine tune but not bad. Runs pretty good.. Its the same 312 .060 that has about 1000 miles on the short block. It was built with the blower in mind about 3 years ago with dished Racetec pistons . I installed Mummert heads with the chambers opened up a little by John M. I used his short cover and shortened the damper about an inch. Shortened the alt. bracket also. The crank sticks thru the damper & the aluminum blower drive adapter I made so I had to bore it out and use longer crank bolt.. I used MSD EFI as all my other parts are MSD [ dist, coil, wires, boxes] you can control timing and retard timing as boost increases . This was my first attempt at EFI....It was worth the effort & cost to me.. A side note : I had to settle for "HUFD 312" License Plate as Pennsylvan ia will not let you use "BLWN 312" No Way !!... Steve McD THUNDERCAT ia will not let you use "BLWN 312" No Way !!... Steve McD THUNDERCAT

|

|

By thundercat - 9 Years Ago

|

|

|

By thundercat - 9 Years Ago

|

|

Lindsay Shoemaker "Y-Bloke" Intake from Australia They are made well. Only thing I altered was to drill two pipe thread ports near the top where thermostat goes for senders.....Steve McD

|

|

By Talkwrench - 9 Years Ago

|

|

Hell yeah! At least it looks traditional. Nice with the salt flats and some decent rubber, cant stand those that put low profile tyres on their hotrods [street rods] and most of all it doesn't have a scrub motor! well done hats off..

|

|

By speedpro56 - 9 Years Ago

|

As beautiful as it gets!

|

|

By 62bigwindow - 9 Years Ago

|

|

Looks great! Had a chance to stretch it's legs yet?

|

|

By MoonShadow - 9 Years Ago

|

|

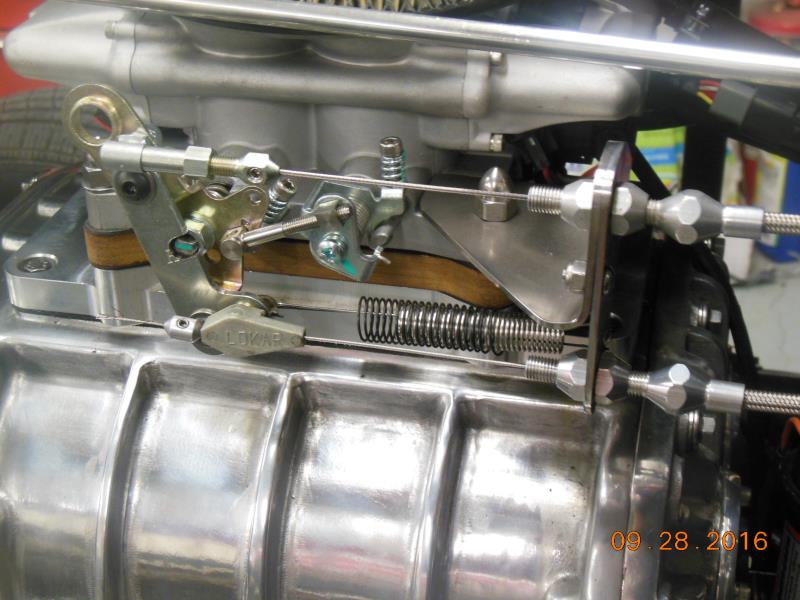

I've posted twice about linkage but it seems to disappear. Do you have close up pictures of your throttle linkage? Did you use a bell crank or cables? I'm going to work on my blower motor this winter as far as rigging up linkage etc. And could use some ideas. Chuck

|

|

By thundercat - 9 Years Ago

|

Thanks for nice comments and THANKS TO ALL for help from this site both directly and from past information "Searches"... I have about 350 miles now has quite a bit more power and throttle response... Throttle linkage I reused the cables from before to see how they would work , just made new brackets...May try a mechanical throttle this winter as throttle doesn't return exactly same each time[ a very small amount] probably from "S" turn in cable...I will post if it works better..  Steve McD Steve McD

|

|

By Lord Gaga - 9 Years Ago

|

|

BEAUTIFUL!!

|

|

By MoonShadow - 9 Years Ago

|

|

Thanks, that's the picture I needed to see. Are you running an AOD? I have the same style cable on mine. Lokar suggested I just get longer cables and move the linkage up like you have. I would think that would work but will watch the cable turns. The manual bell crank seems doable but the AOD kickdown may still need a cable. I would like to have a solution before I put the engine in the car. Chuck

|

|

By thundercat - 9 Years Ago

|

|

Yes I am running an AOD [ Only because I had access to an expensive rebuilt 700R4 did I use it] Works very well had everything with it including Lokar shifter for cheap..Had to make the bracket Lokars in next to junk. theres wont lock in place at carb [look at how this just fits at carb base]. they use a little set screw to hold but doesn't work..loosens up..there spacing vertically is way off also for cables to pull straight.. You will have to buy theres to get all the hardware but easily make a custom bracket to fit your application. I used 1/8" stainless..My throttle cable might work better if it were new. I reused the old one and it could have a worn spot in the Teflon liner and in a different place now..i just wanted to run before winter will work on in off season . Started list..I know you have been working on your system about as long as I have .. You will be pleased when completed.. Worth the work.. Steve McD

|

|

By charliemccraney - 9 Years Ago

|

I don't understand the balance spring concept as described. Do you have pictures?

|

|

By MoonShadow - 9 Years Ago

|

|

Are you talking about a second spring pulling forward on the throttle and hooked to the top of the linkage plate? I've done a lot like that for many years. Even used them as a standard double spring setup.

|

|

By famdoc3 - 9 Years Ago

|

Looks great congratulations! Still working at on mine for my Model A coupe. MIKE.

|

|

By MoonShadow - 9 Years Ago

|

Are you looking a the 2V setup? I have a couple that were made for scrub accessory pullies. One is about 6.25" and the other is about 5.75". I figure if space is a problem I can go to the V belt setup. Since the difference in the diameter are what makes the under or over drive ratio I don't see why this wont work. It would be either 1.08 over drive or 0.92 under. I'm really hoping to keep the 3" pulleys though. Since I'm running a two V accessory pulley I needed 9" snout for the blower. I used a 7" and a 2" spacer. Chuck

|

|

By thundercat - 9 Years Ago

|

|

Your setup looks great.. I had collected Scrub pulleys also and was going that route also until I went with the short cover.. My snout is 8" I cut about 1" from back of damper . crank now sticks out into my adapter. I had to bore adapter to crank size to depth of a little over 1" I'm hoping the crank bolt stays tight. ive been checking it .. Good so far.. I actually liked the looks of the V belts better in 30's car but wasn't sure if it wouldn't slip..Steve McD

|

|

By thundercat - 9 Years Ago

|

|

I cut my drive pulleys down from 3" to 2" for space saving also..Your projects both look Great !! I my as well throw away throw away the radio as the whine overrides it. Cant tell if its even on!!

|

|

By MoonShadow - 9 Years Ago

|

Walden's hot rod shop makes a pulley setup for the Y-Block. It uses the 3V belt pulleys and includes the upper, lower, idler arm and idler pulley. Price was around $800. I thought it was high for the pulleys.

|

|

By Rono - 9 Years Ago

|

Great job on the motor and it looks awesome in your coupe. I can only hope my blower motor turns out half as well for my 37 coupe project.

Rono

|

|

By famdoc3 - 9 Years Ago

|

|

We'll see how mine works. I am using an add AC pulley with the 2 equal sized pulleys to drive the supercharger and the smaller front pulley to drive the alternator. Used a 7.90 snout on the 4/71 on a ybloke manifold with an aluminum scruby crank pulley adapted to the snout. Piece by piece just working it out. MIKE

|

|

By charliemccraney - 9 Years Ago

|

That thing looks great. Does that efi system adjust fuel and timing based on MAP? Or does that not matter if the throttle body is not under pressure?

My next major project will be fuel injection but I need something that works with a blow through setup, for a turbo. It would be great if it was self tuning otherwise it will have quite a learning curve at the start but that doesn't seem to exist, for use with blow through setups, yet.

Auto Specialties make custom pulleys, https://www.autospecialties.com/ I had them make a set of crank, alternator and water pump pulleys for use with the Innovators West harmonic damper. Those three were $375, but that was only one groove. Two more grooves means you start with a larger chunk of aluminum, and more time and wear and tear on the machines and tooling.

That in mind, $800 for the set of 3 groove blower pulleys, which is probably low production, might be about right.

|

|

By thundercat - 9 Years Ago

|

The MSD system is self tuning or you can dial in what you want..

there is a hand held unit in car that you can see what is going on [also a card you can take into house and plug into computer--I haven't done that yet] you can change anything manually you want with hand held like mixtures at any RPM or pump shot % .... control 2 electric fans.. if you use MSD distributor you can lock rotor and control all timing advance also take timing out as boost builds.also enrichen when more boost... it starts instantly every time.. so far ive had no problems and it runs better each time I take it out.. EXCEPT it works better at operating temp [not as smooth until temp up] and occasionally will die when I leave of throttle and I have to touch throttle back down..im sure it will work out.Im still in the learning stages also...im very pleased.. Steve McD

|

|

By thundercat - 9 Years Ago

|

|

The paperwork states it will work with blow -thru boost also..

|

|

By charliemccraney - 9 Years Ago

|

Does it indicate that it will still self tune with blow through boost?

|

|

By thundercat - 9 Years Ago

|

|

Manual doesn't state Here is the # I have called when I have had questions So far I have had good answers .. 915-857-5200 sometimes hard to talk to same person though.. Bret Kugler I have talked to couple times.. hope this helps.. Steve McD

|

|

By thundercat - 9 Years Ago

|

|

Negative is ....there system is pricey compared to some of the others.. from my research it does much more [ especially with power adders] and quite a bit simpler to install. less wiring and more of the components are inside the throttle body instead of remotely mounted... It can be used without return line but they recommend using return as I did BUT if I had to do it over I would have mounted pump in tank [pain in neck] its noisey and ive been told that the pumps last much longer if in tank by being cooled buy fuel..[like OEM setups] ....

|

|

By LordMrFord - 9 Years Ago

|

I hope MSD can be locked after tuning, because self tuning under boost is fatal for engine if Lambda sensor goes bad.

And blow thru is only option when playing with turbos. Internals dont like fuel and you cant use intercooler with air/fuel mixture.

Nice setup Thundercat by the way.

|

|

By mark9088 - 9 Years Ago

|

GREAT WORK!!

couple of questions as I am building a blown y also

how much boost?

using a main girdle?

static compression ratio?

thank you,

Dean Markuson

|

|

By thundercat - 9 Years Ago

|

|

I do not have a main girdle.. I did use ARP stud kit & drilled to longer depth of later engines. The static compression is 8.9 with dished Racetec forged pistons. The heads were opened up a little. The blower is under driver 36teeth on top and 32 teeth on bottom. Probably 6# at most ...likely less... I can't tell you the boost [ guage not installed yet] and i've only been running 3/4 throttle because I'm not happy with the stopping distance of my car.. It has Wilwood Dynalites on front and Ford "Big" station wagon drum brakes on 9" rear end. but doesn't stop as well as I think it should for a 2200# car.. I was a little rushed to test run before winter. I now know some of the items I need to change or alter over winter. Regards Steve McD

|

|

By famdoc3 - 9 Years Ago

|

Getting more done on my blower set-up. Take a look. MIKE

|

|

By thundercat - 9 Years Ago

|

|

Looks good !! . That tensioner should help keep even tension. I'm unsure of how tight the belt should be on mine. It cant slip but I don't want it to break or wear out too soon. Steve McD

|

|

By Rono - 9 Years Ago

|

Chuck;

I went to the Walden's website but couldn't find the pulley set-up for the Y Blocks. Also, I was wondering if they included the crank coupler for the lower blower pulley in that $800.00 price? I did buy one from Y Bloke, but that design requires some machining of the crank pulley.

Rono

|

|

By MoonShadow - 9 Years Ago

|

Rono,

Walden's was a 3 vbelt setup and I don't know if it included an crank adapter. I don't think it did. I believe the lower pulley bolted up like the V belt accessory pulley. Did I send you the info on the adapter I had made. Very simple and not real costly. Made of a block of aluminum to fit into the damper, like the accessory pulley. It bolts up with a longer crank bolt and the two accessory pulley bolts.

|

|

By Rono - 9 Years Ago

|

Chuck;

Thanks for that info. No, you never sent me the specs on the blower pulley to crank adapter. It would be great if you could send me an e-mail or PM with that info. It looks very similar to the one I got with Gord McMillan's blower kit, but I sold it with the VS-57 set-up. I don't have a lathe or milling machine, but I have friends that do.

Thanks, Rono

|

|

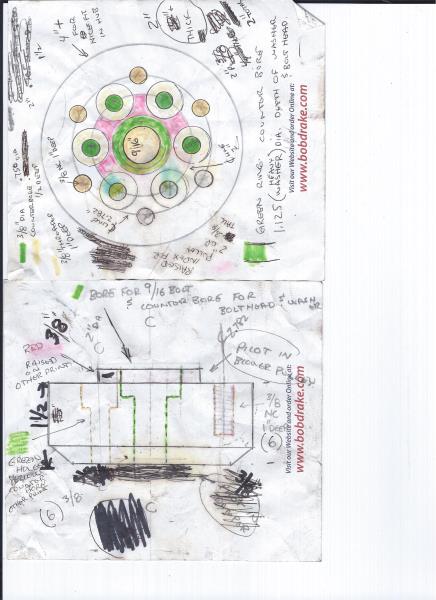

By thundercat - 9 Years Ago

|

I don't know if this will help. this is my sheet from my adapter it fit into the mummert billet damper. .I drilled 4 more holes so it had 6 mounting bolts instead of 2.. The crossouts were changes along the way.. when wife gets home. I don't know how to load from my phone.. Steve McD Thundercat Ill post pics of final piece Ill post pics of final piece

|

|

By MoonShadow - 9 Years Ago

|

This is the machinists drawing of the one he made me.

|

|

By thundercat - 9 Years Ago

|

|

Moonshadow, I see yours indexes 1/8" inside damper. I could not do that as I had to shorten damper 1"....... Mine is a tight fit [4"dia] in the inner part of the damper.. my crank sticks out of damper almost 7/8". Its not shown on drawing but had to bore adapter to crankshaft size 1" deep. I will try to show how much shorter my engine is with the shorter cover. I have a picture of the new Mummert cover on an old block with pan I had altered for tierod in roadster with previous engine. I do not have a picture after I made the new pan I now have lots of room. I cut up the pan in picture. Regards Steve McD

|

|

By thundercat - 9 Years Ago

|

Mummert Short Cover T-Bird Pan

|

|

By thundercat - 9 Years Ago

|

Heres a picture in car I had to notch oil pan to clear tie rod before for clearance.. With short cover have lots of room BUT considerable amount of work everything has to be shortened or moved or both!! Different pulleys and bracketsalso

|

|

By Rono - 9 Years Ago

|

Thanks Steve and Chuck! That helps a lot!

Rono

|